Stirring disc screen type feeding machine

A feeder and disc screen technology, applied in mixers, dissolution, chemical instruments and methods, etc., can solve the problems of shortened service life of the extrusion arm, insufficient mixing and homogenization, poor material cutting effect, etc., to achieve reduction Number of changes, easy mixing and homogenization, less drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the drawings.

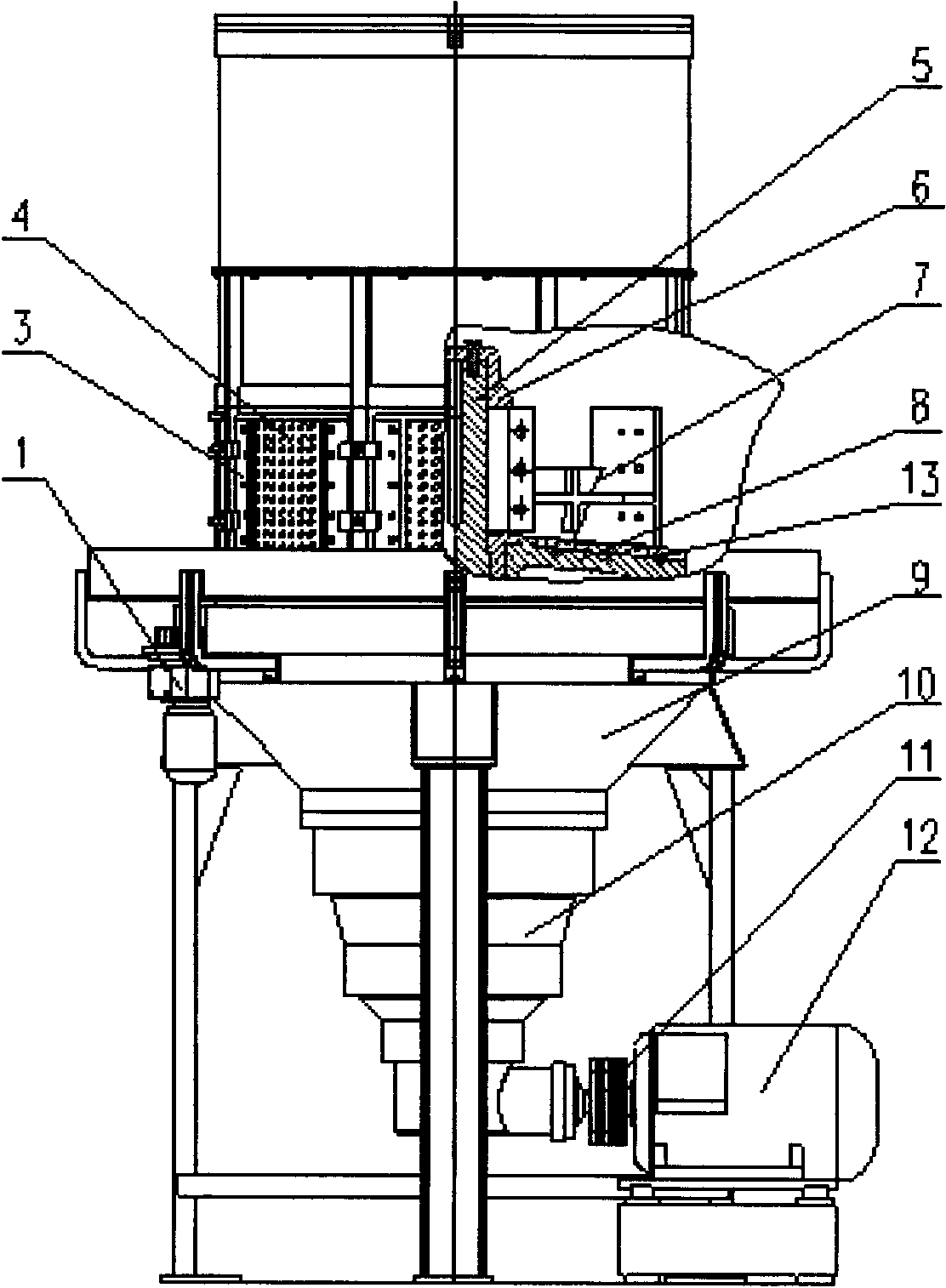

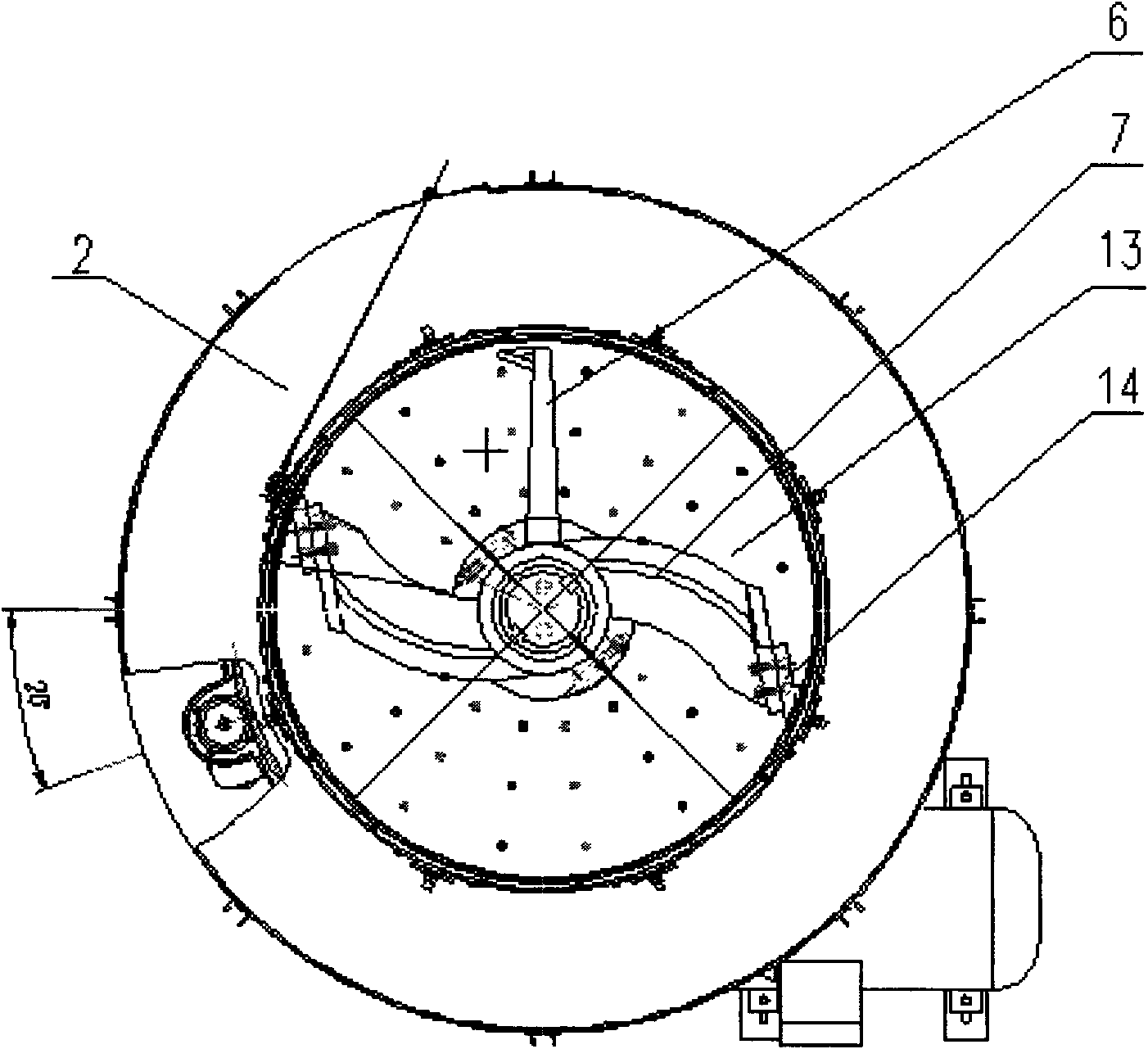

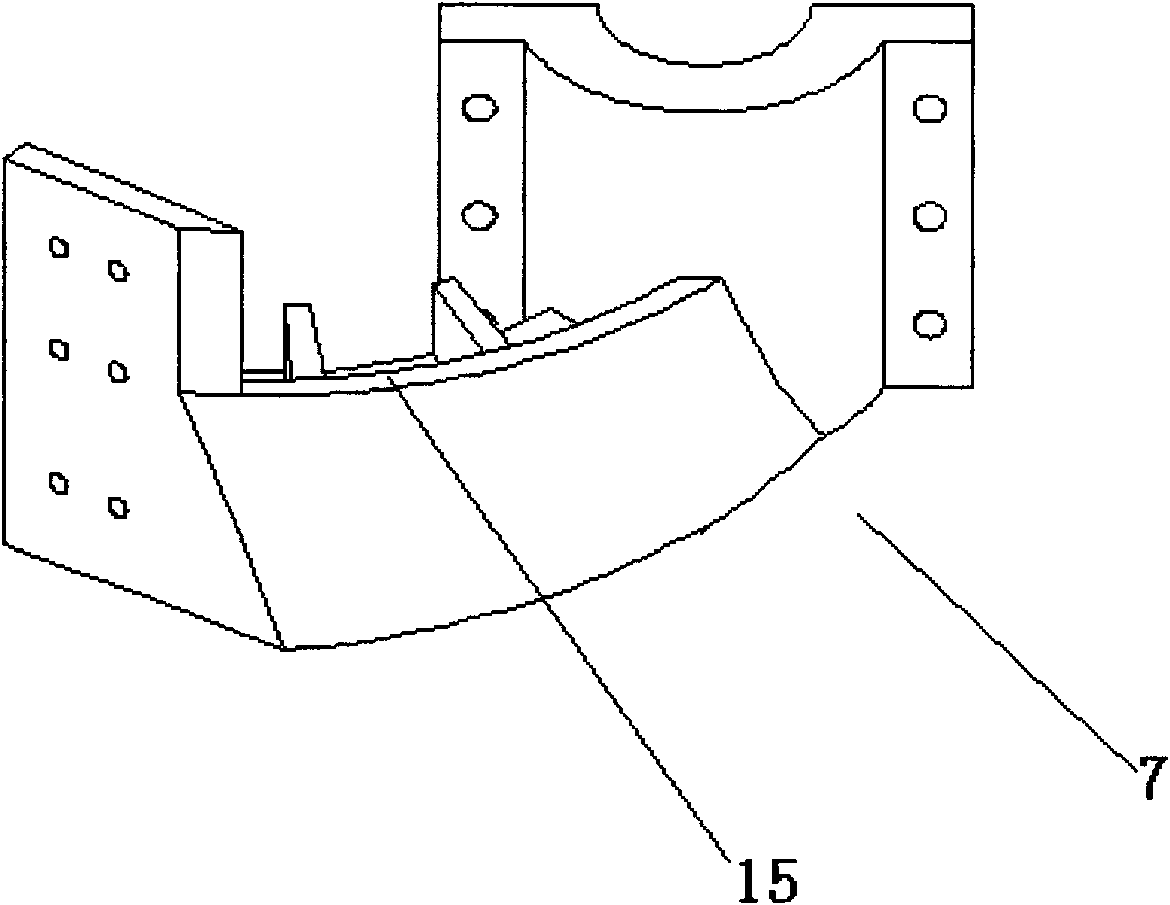

[0014] Reference figure 1 , figure 2 with image 3 , An agitating disc screen feeder, including a main shaft 5 and a scraper arm 6 and an extrusion arm 7 connected to it. The main shaft 5 is connected with the output shaft of the main reducer 10, and the wear plate 14 is bolted Attach it to the extruding arm 7. The wear-resistant plate 14 is processed with a long strip hole structure, and the distance from the inner wall of the barrel 3 can be adjusted. The middle section of the extruding arm 7 is an oblique arc plate. The turning up and stirring can make the materials fully mixed and homogenized, and at the same time make it easier for the materials to gather on the inner wall of the barrel 3, and the materials are quickly extruded. The output flange of the main reducer 10 is fixedly connected with the base 9, and the main reducer 10 is connected with the main motor 12 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com