Lubrication structure of engine

a technology of lubricating structure and engine, which is applied in the direction of auxilaries, machines/engines, mechanical equipment, etc., can solve the problems of increasing the height of the engine, and reducing the lubricating oil supply from the crank chamber. , to achieve the effect of reducing the agitation loss of lubricating oil from the crankshaft and other things

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

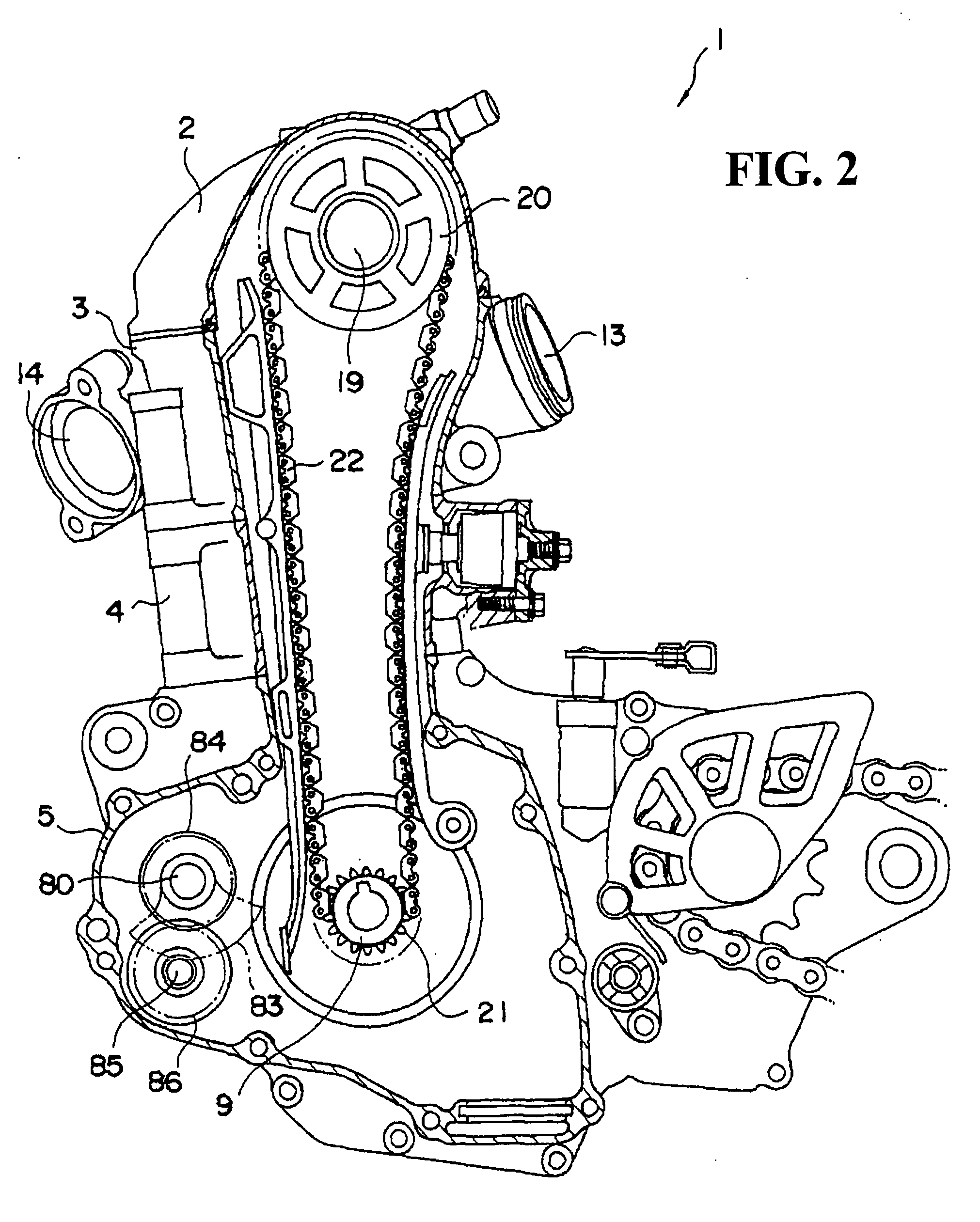

[0020]The present invention will now be described in detail with reference to the accompanying drawings, wherein the same reference numerals will be used to identify the same or similar elements throughout the several views.

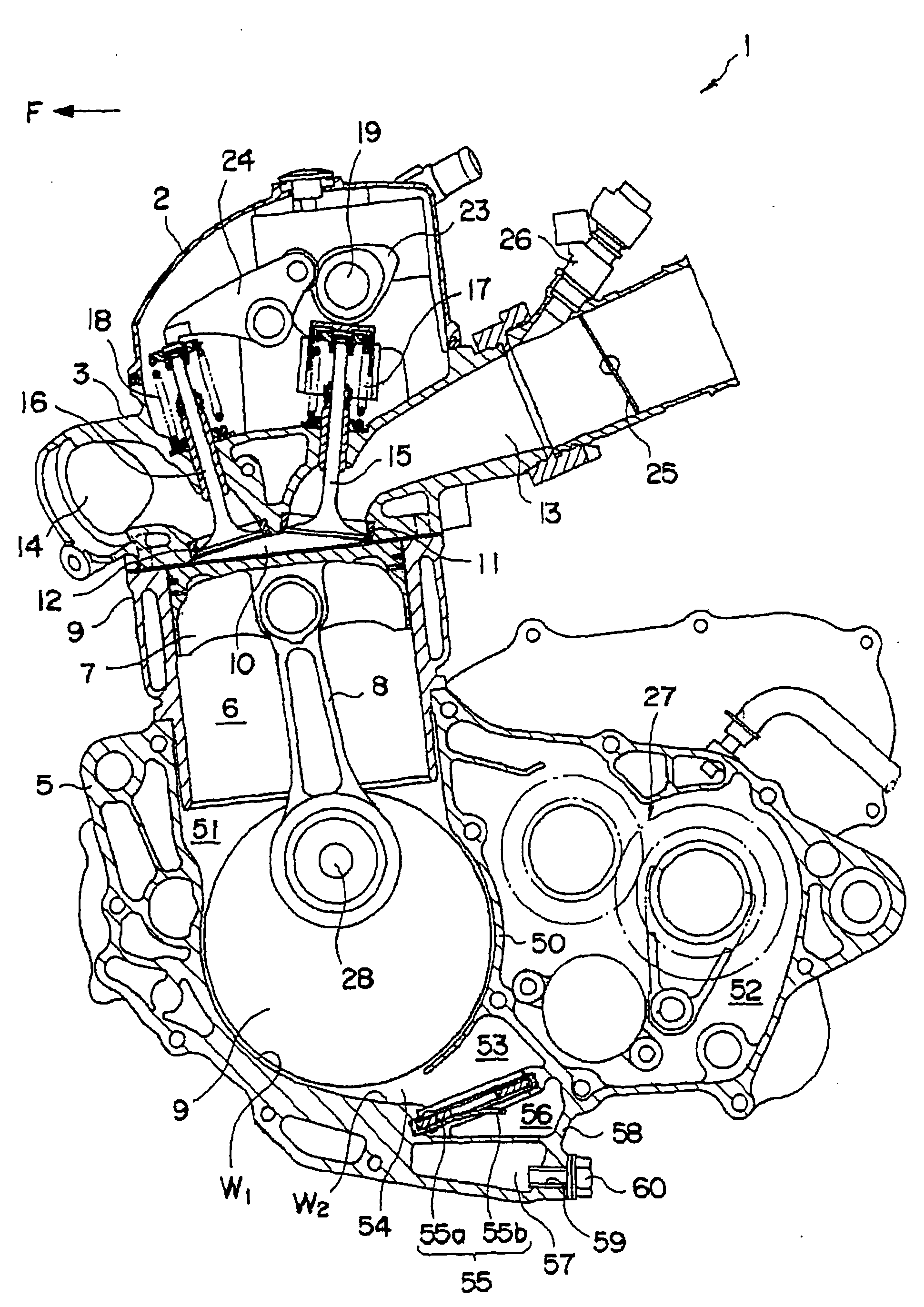

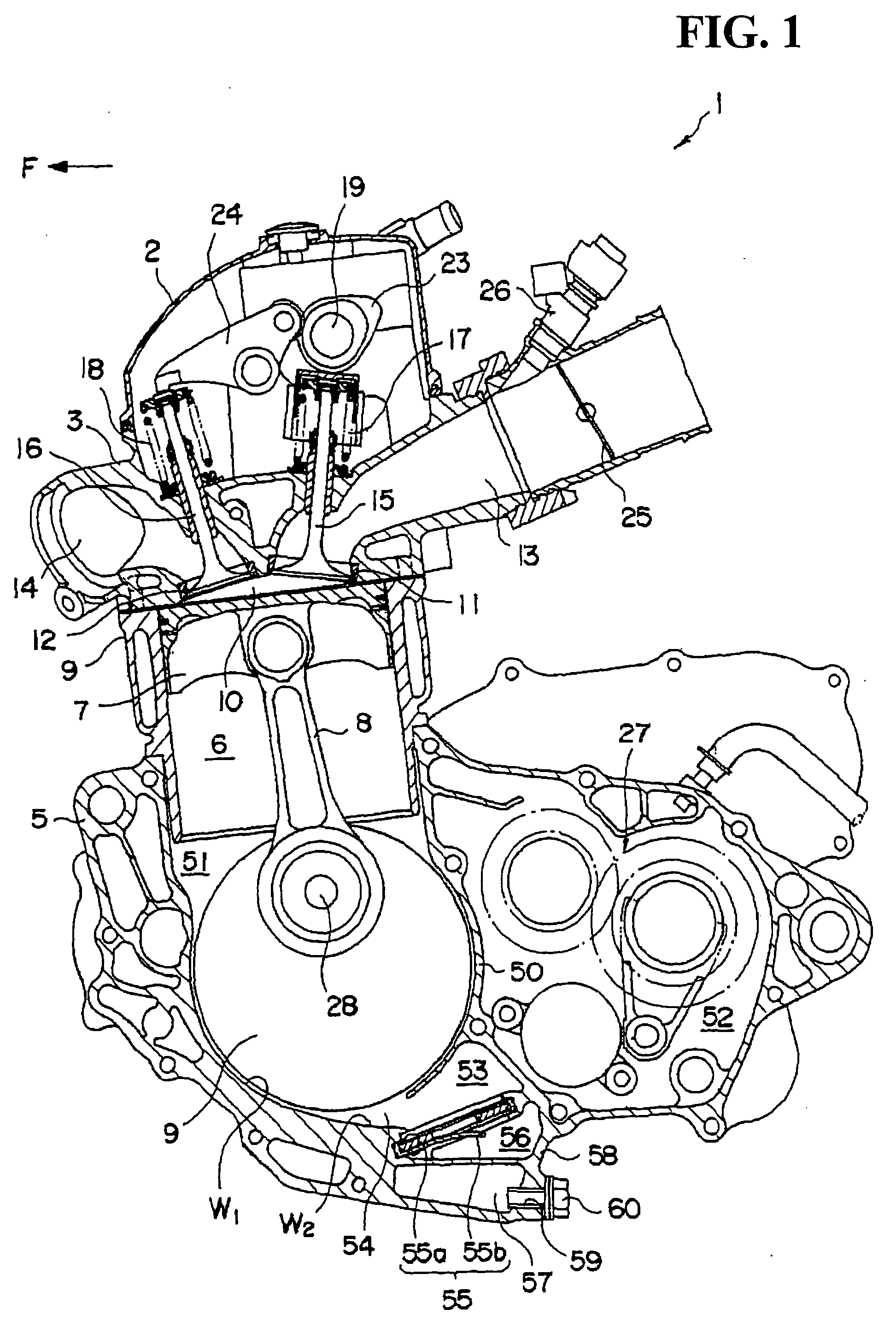

[0021]Referring to the drawings, a preferred embodiment of the invention will be described below. First, referring to FIG. 1, an engine 1 to which lubrication structure according to an embodiment of the present invention is applied will be described. The engine 1 is used for a motorcycle, particularly for a motorcycle for off-road driving sports. In the following description, an arrow F shown in FIG. 1 points to the front of the motorcycle.

[0022]The engine 1 includes a cylinder head cover 2, a cylinder head 3, a cylinder block 4 and a crankcase 5. A cylinder chamber 6 that extends vertically and cylindrically is formed in the cylinder block 4. A piston 7 is arranged in the cylinder chamber 6 so that the piston can be vertically slid and is connected to a cranksha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com