In-gear control method, device and system for synchronizer

A control method and control device technology, which is applied in the direction of mechanical control devices, control/regulation systems, transmission device control, etc., can solve the problems of cumbersome mechanical locking mechanism, increase the risk of system reliability, increase the weight of gearbox, etc., and achieve The effect of reducing the weight of the mechanism, avoiding the risk of wear and deformation, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

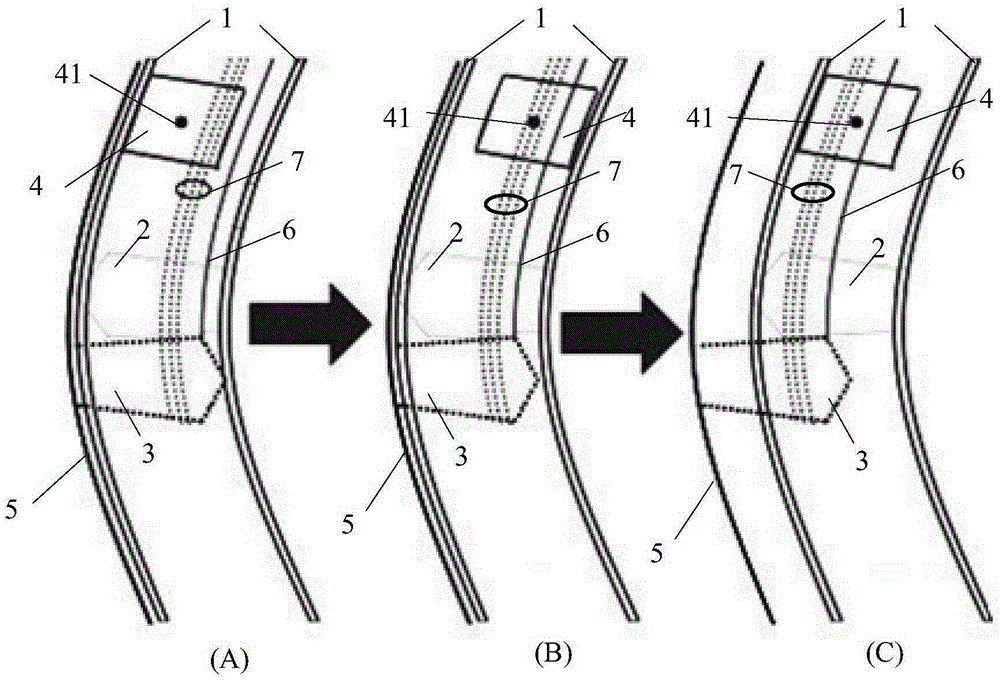

[0023] At present, for a mechanical gearbox that relies on a synchronizer to shift gears, the position of the synchronizer is kept in gear mainly through a mechanical mechanism. The mechanical way of maintaining the gear of the automatic transmission is basically the same as that of the traditional gear box. The gear is locked mainly through two methods. The chamfering of the teeth outside the ring gear prevents the gear from being out of gear; the second is to lock the gear through the mechanical part such as the locking ball that is rigidly connected with the synchronizer sleeve on the shift fork. However, the mechanical locking mechanism in the above-mentioned second method is very cumbersome, which not only increases the weight of the gearbox, but also increases the risk of system reliability.

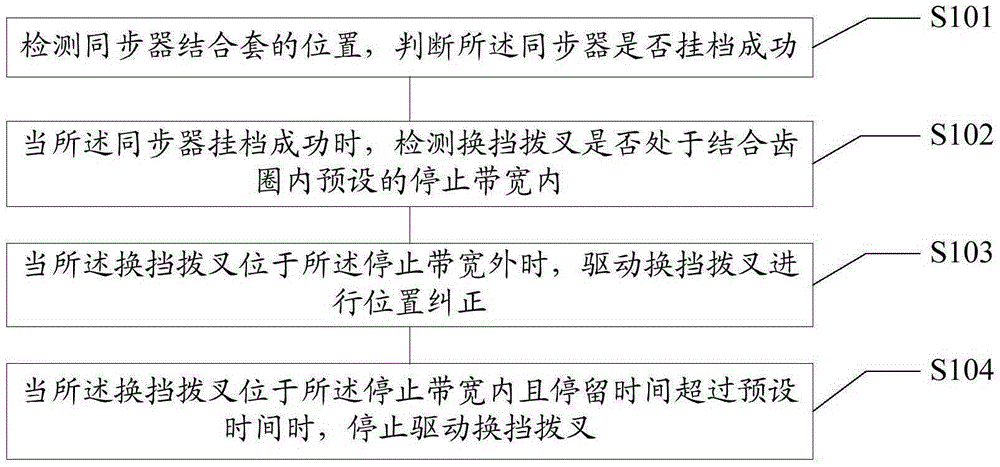

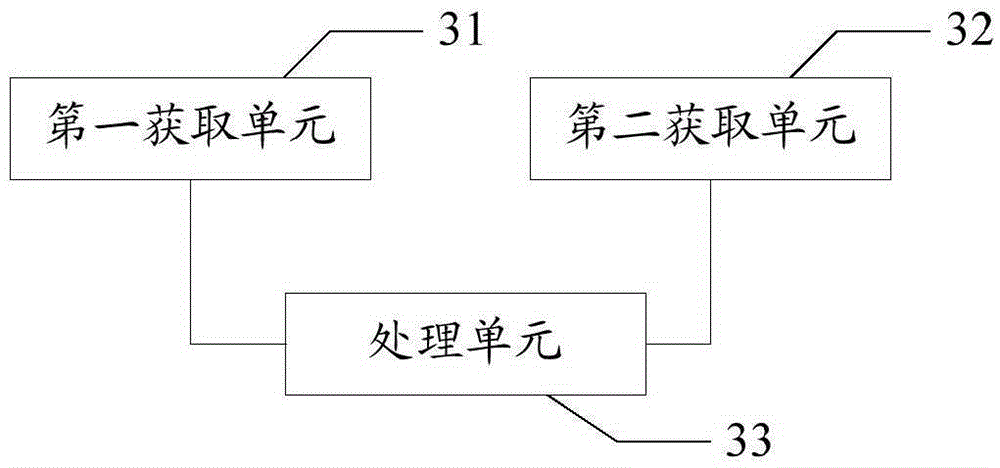

[0024] The embodiment of the present invention realizes the in-gear maintenance of the shift actuator—the shift fork by introducing the active control method of bandwidth control, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com