Ground conveying pump and material conveying method

A technology for ground transportation and materials, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve the problems that ground pumps are not easy to clean, easy to stick materials, and contain air, and achieve easy disassembly and cleaning, small agitation, and avoid material pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

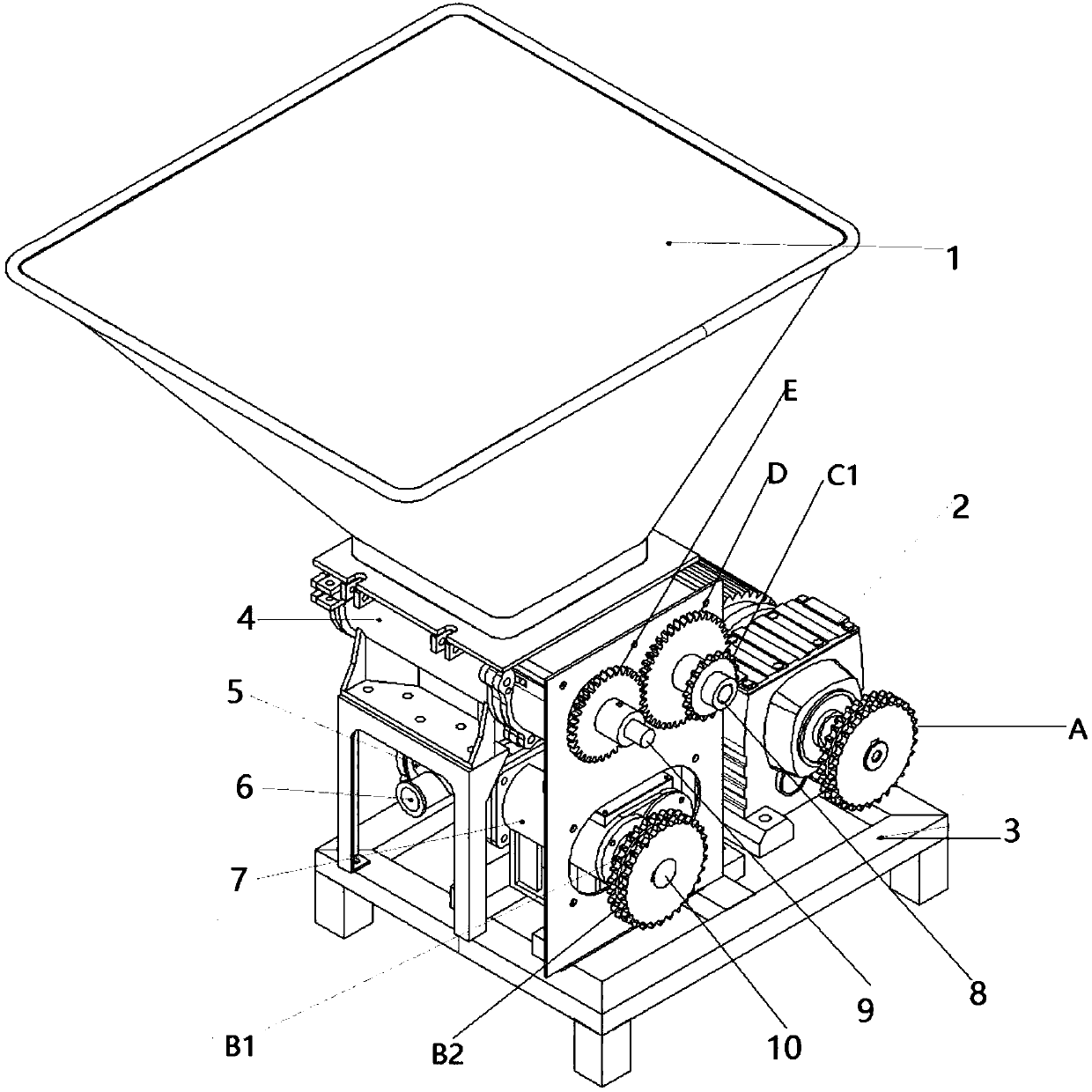

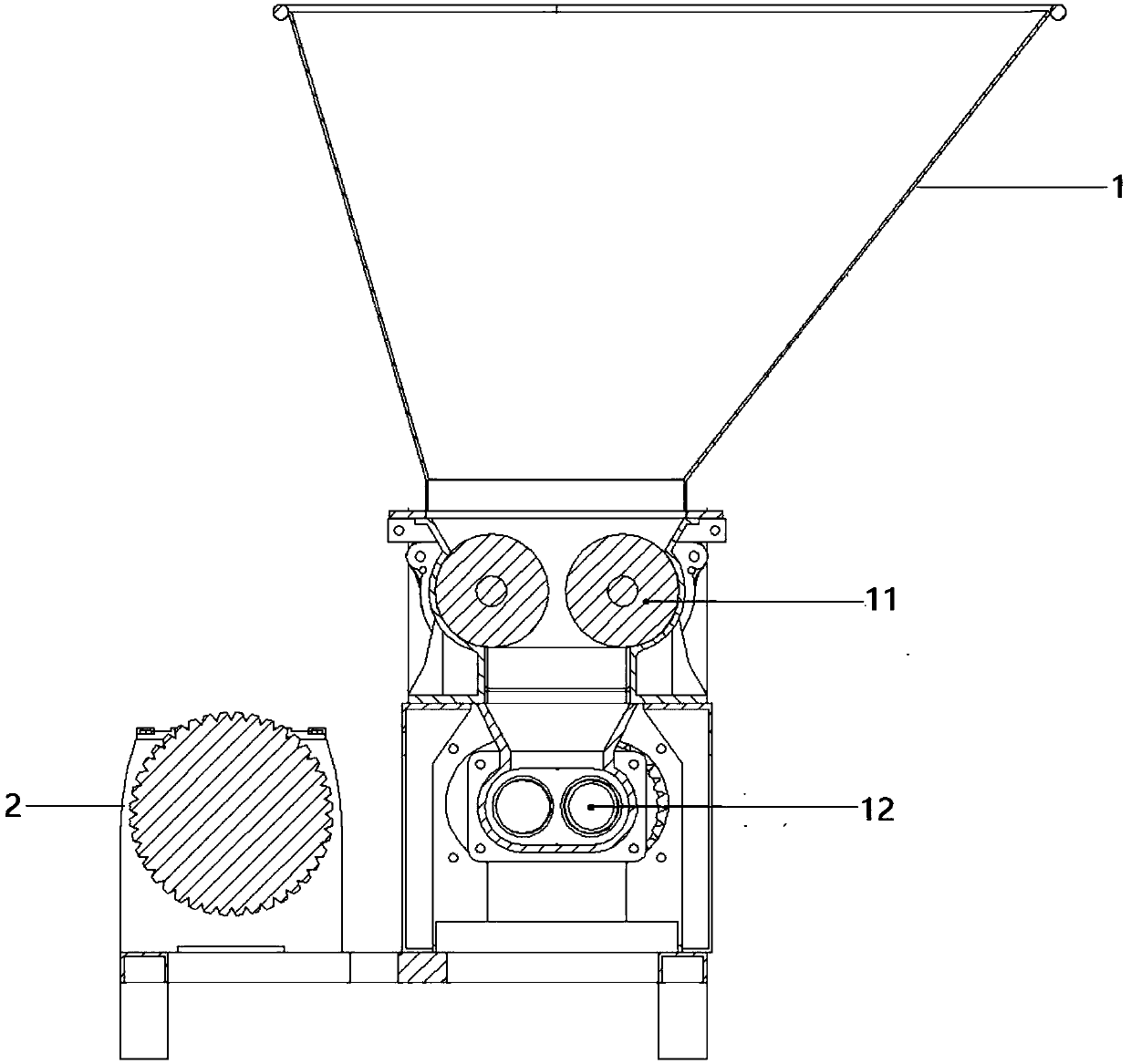

[0033] Such as figure 1 , figure 2 , Figure 5 As shown, a ground conveying pump includes a feeding device 1, a ground conveying pump body 12, a driving motor 2, and a roller mechanism arranged between the feeding device 1 and the ground conveying pump body 12. The roller mechanism is set In the drum box 4, the pump body 12 of the surface delivery pump is arranged in the pump body box 5, and the rotating element is arranged in the pump body, and the described feeding device 1 is connected with the drum box 4, and the roller box 4 is connected with the pump body box 5. Connected, the driving motor 2 is connected with the drum mechanism and the pump body 12 of the ground delivery pump through a sprocket gear transmission system.

[0034] The roller mechanism is a double-roller type, consisting of two rollers, a certain roller distance is formed between the rollers, and the gap between the rollers and the roller box is very small; the rollers are installed on the roller box 4 ...

Embodiment 2

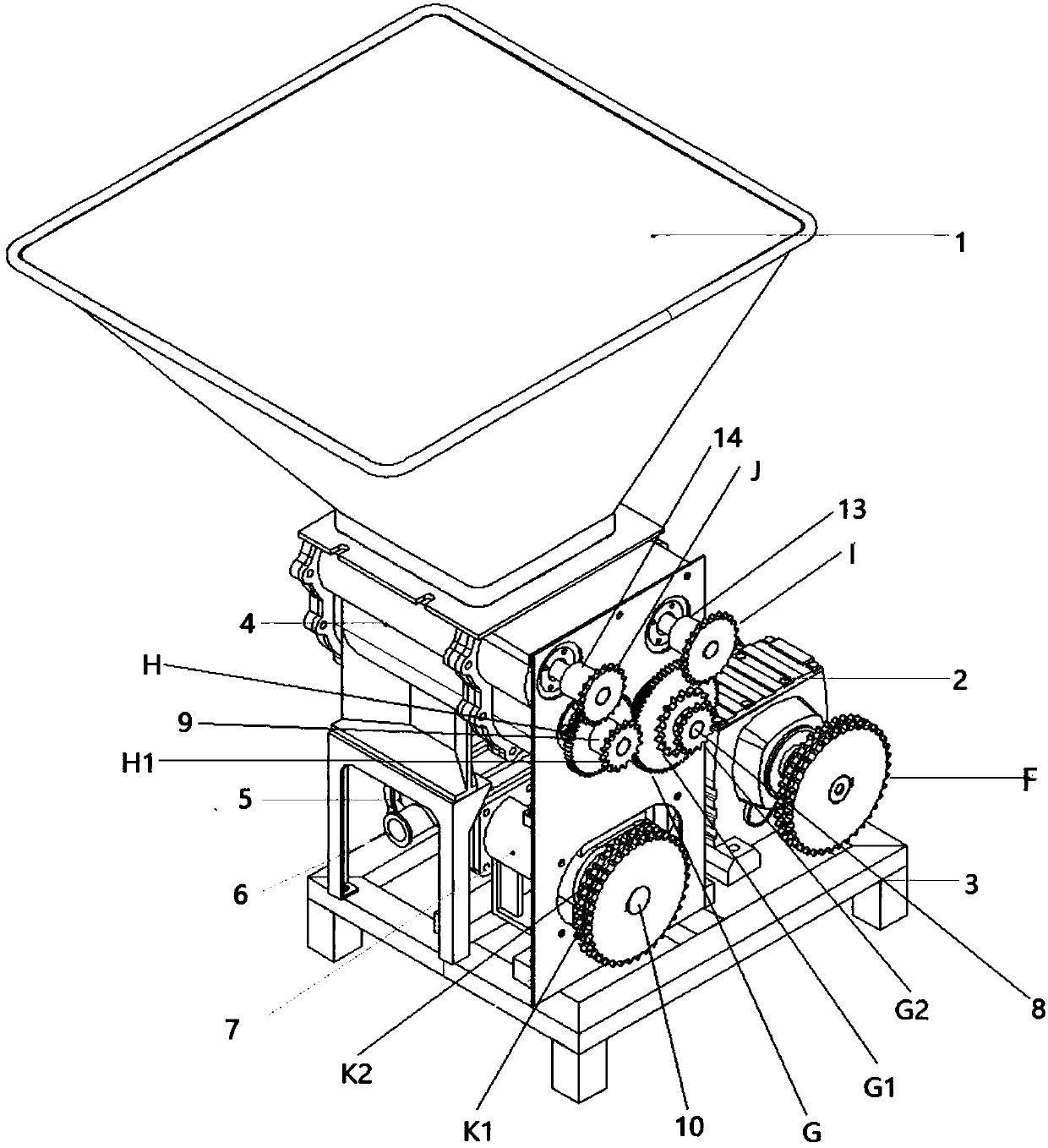

[0047] Such as image 3 , Figure 4 , Figure 5 As shown, compared with Example 1, the technical solution of this embodiment is different in that the described roller mechanism is a four-drum type, consisting of four rollers, and the rollers are installed on the roller box through the transmission shaft; one group of two The roller is arranged on the top of the roller box 4, and another group of two rollers is arranged on its lower part; the roller distance between the upper two rollers is larger than the roller distance between the following two rollers.

[0048] Further, the transmission device of the four-drum ground delivery pump is a sprocket gear transmission system, which consists of the third sprocket F arranged on the drive motor 2 and the fourth chain arranged on one of the roller drive shafts 8 of the rollers. Wheel G1, the fifth sprocket G2 and the third gear G, the seventh sprocket H1, the fourth gear H on the other drum drive shaft 9, and the sixth sprocket I o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com