Patents

Literature

33results about How to "Applicable delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

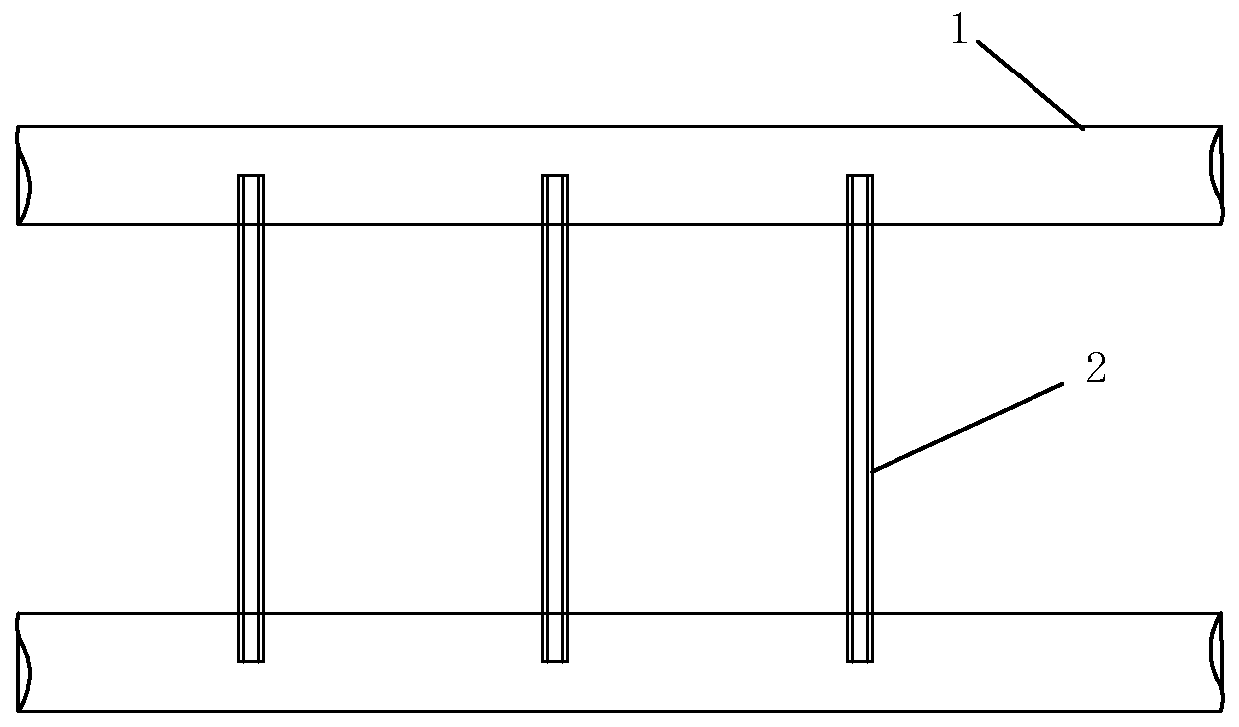

Enhancement ultra-high molecular weight polyethylene wound pipe and manufacture method therefor

InactiveCN101016965AIncrease stressIncreased ring stiffnessRigid pipesHigh intensityAntistatic Materials

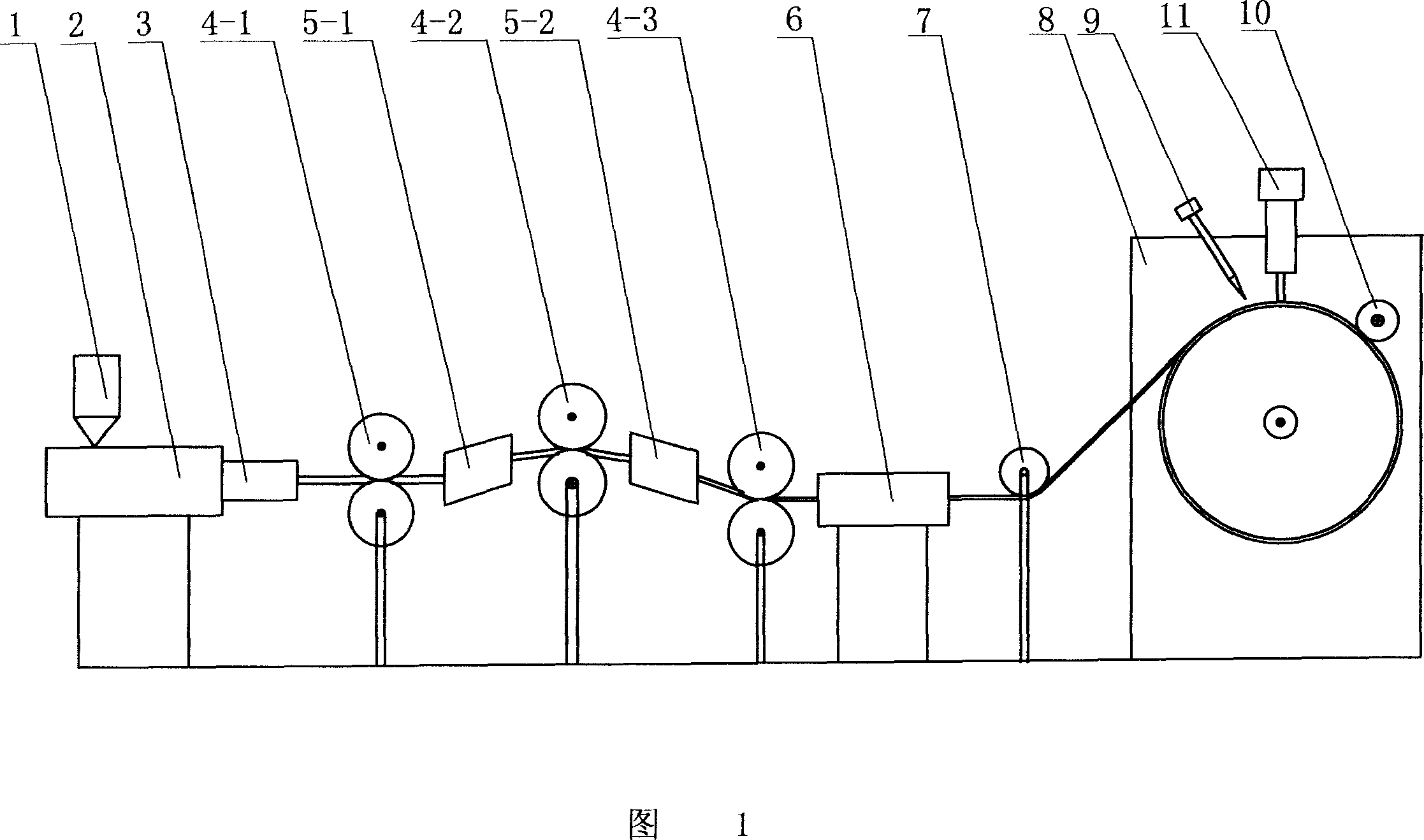

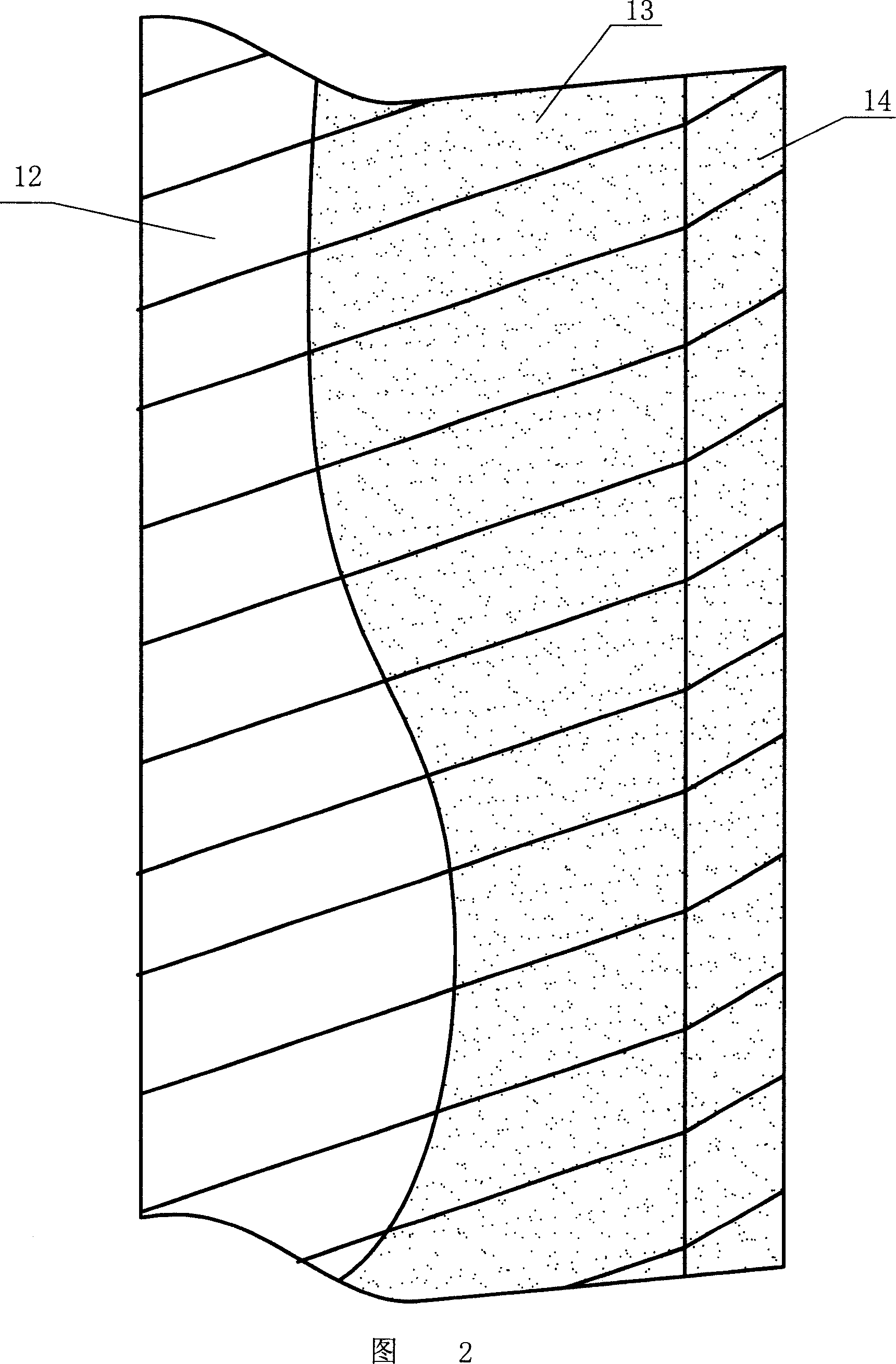

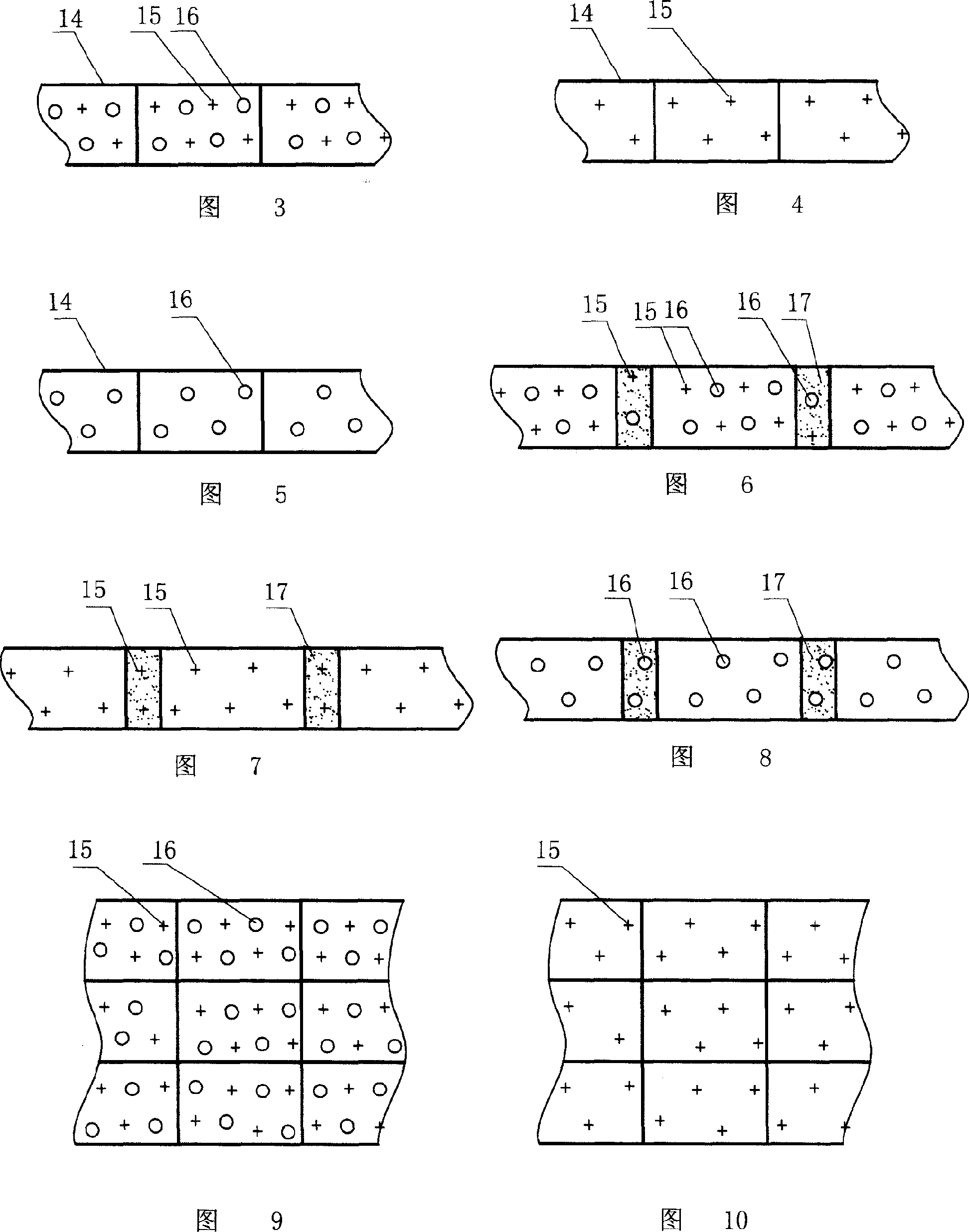

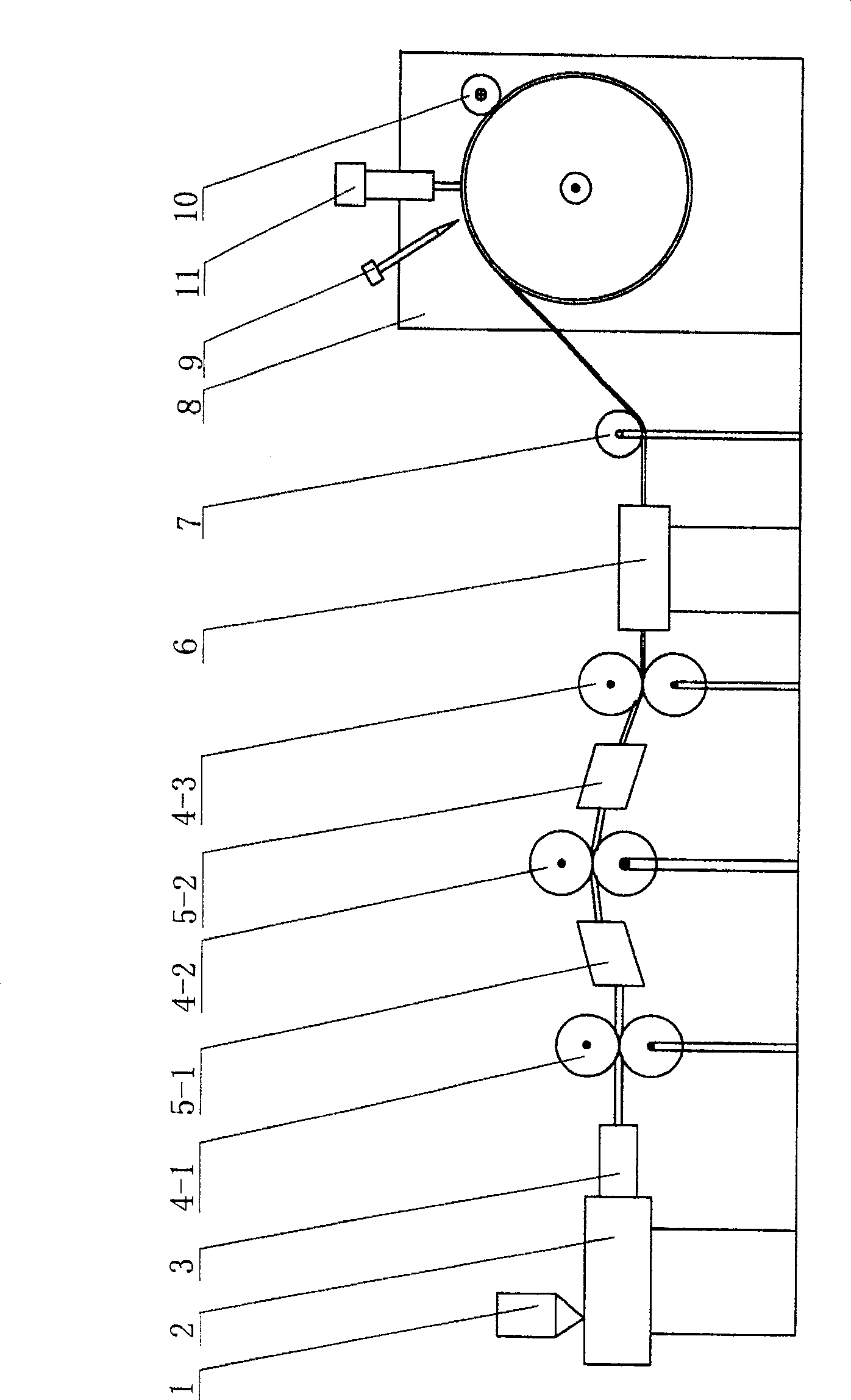

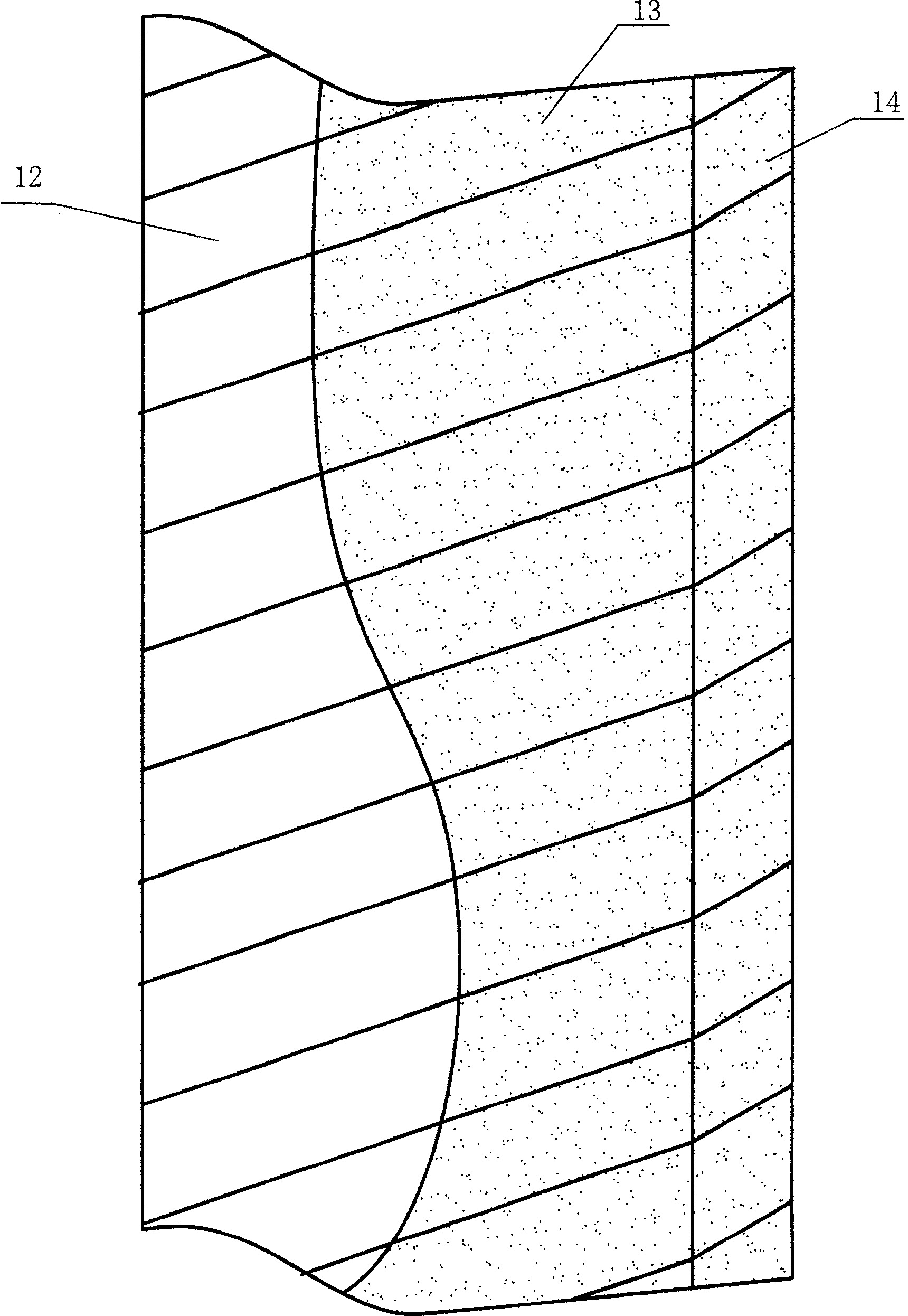

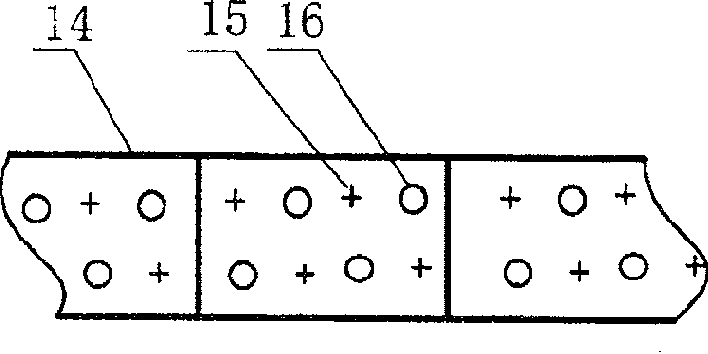

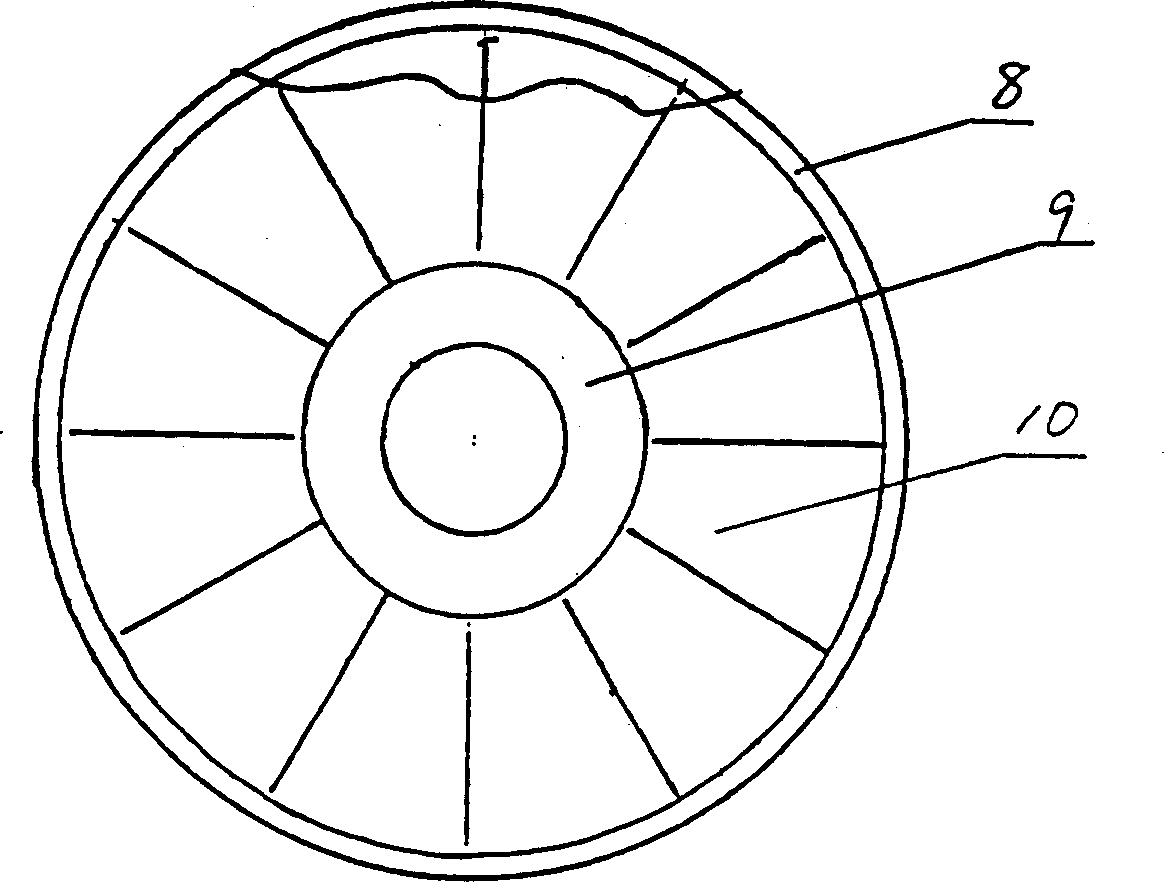

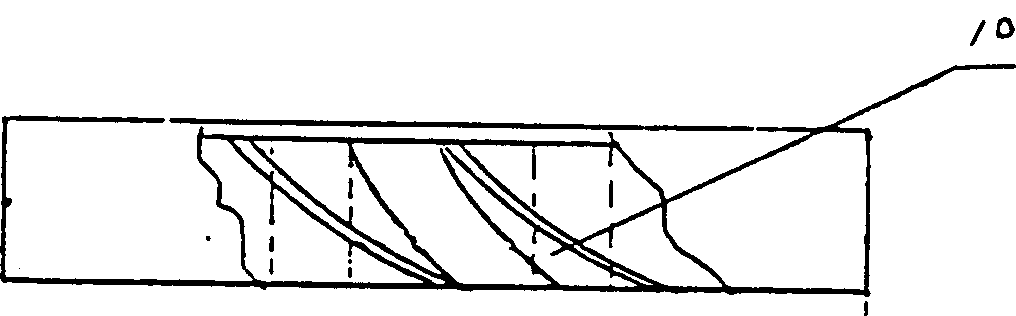

The invention relates to method for producing strengthen macromolecule polyethylene coil tube, which uses at least one layer of macromolecule polyethylene section material as coil material alternatively or irregularly arranged, and nearby side walls are fused to connected or adhered by fused material, to be screwed to form tube wall. The coil material is drawn to direct the molecule longitudinally. The macromolecule polyethylene base material is added with strength material and / or flameproof material and / or static resistance composed. The fusing connecting material is plastic polymer or added with strength material and / or flameproof material and / or static resistance, to form plastic fused material. The strength material is distributed in the coil material and / or fusing connecting material, directionally distributed along the screw of high-strength coil tube. The invention has high strength, flameproof property and static resistance.

Owner:淄博寿山特种塑料有限公司

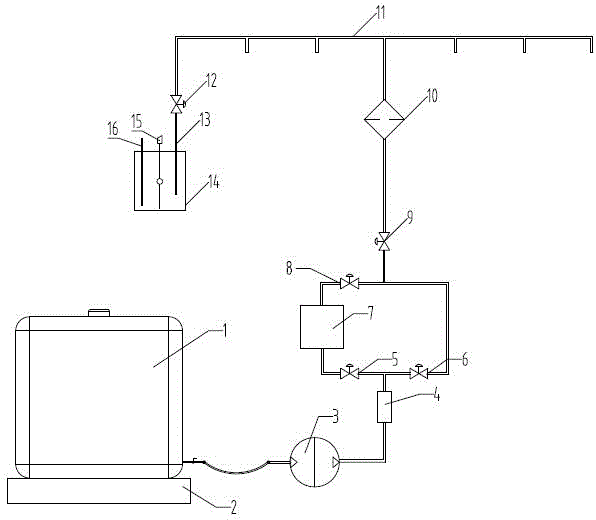

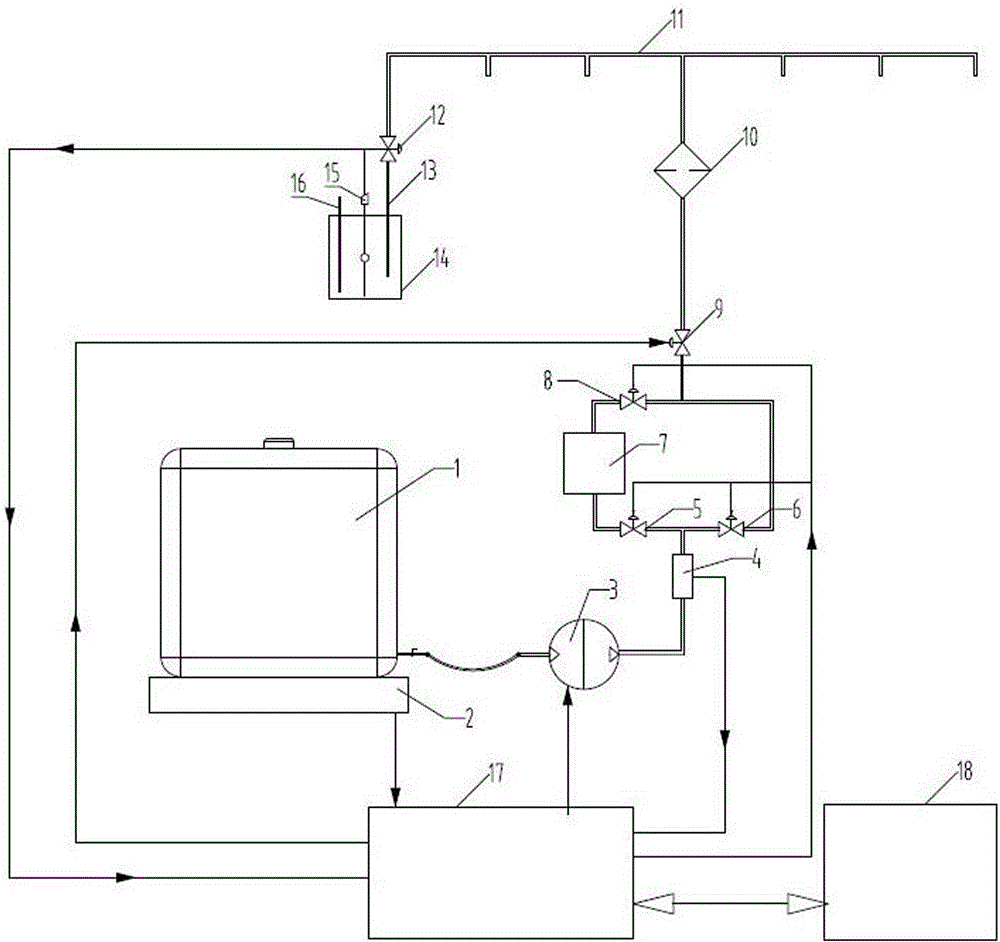

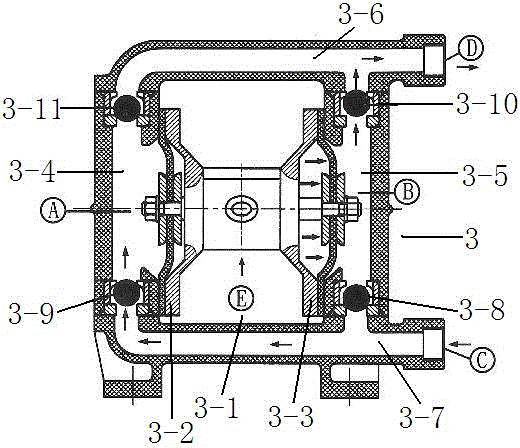

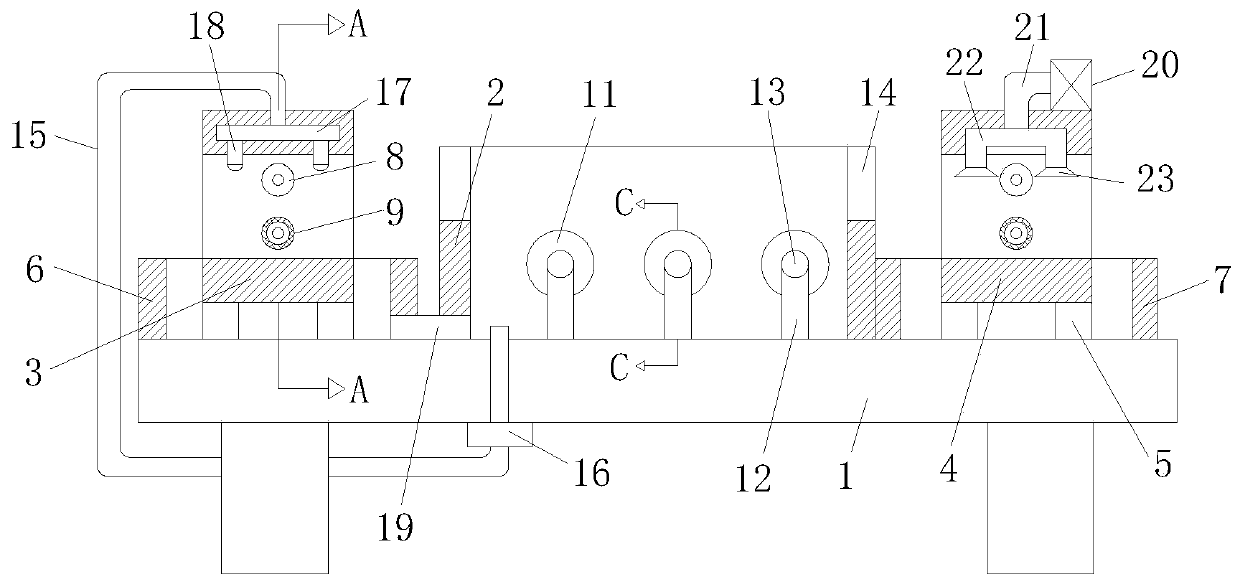

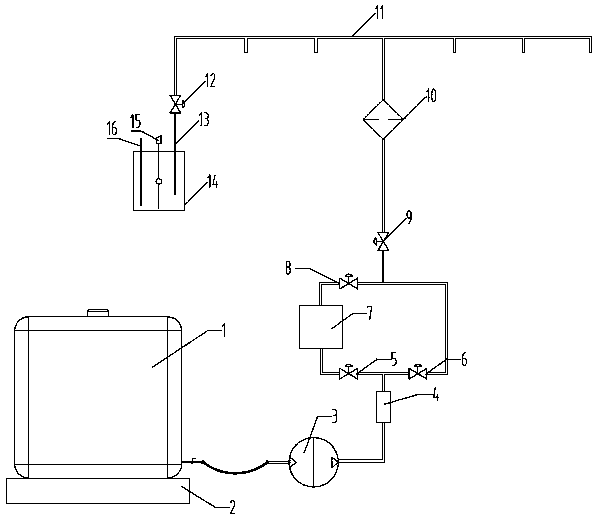

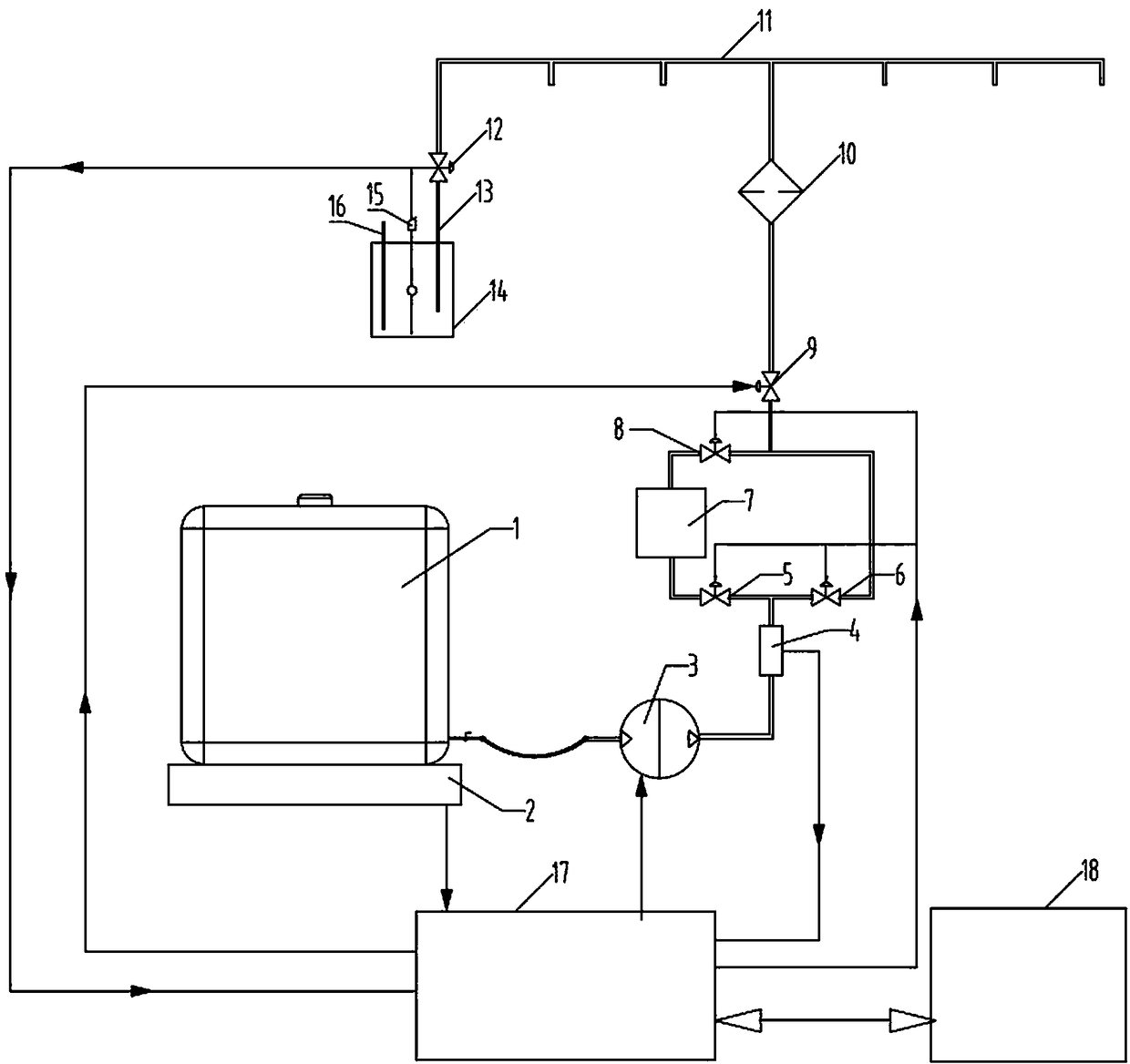

Concentrated automatic control switching type feeding system and control method thereof

ActiveCN105327839AReduce the temperatureNo dischargeLiquid surface applicatorsCoatingsDiaphragm pumpAutomatic control

The invention relates to a concentrated automatic control switching type feeding system and a control method thereof in the field of manufacturing of optical fiber. The system comprises a central material tank, a weighing device, a diaphragm pump, an air bubble early warning device, a control valve I, a control valve II, a control valve III, a control valve IV, a defoaming device, a coating filter, a main pipeline, a control valve V, a coating barrel, a charging pipe, a coating liquid level sensor, a discharging pipe, a central controller and an upper computer; the central material tank is placed on the weighing device and is connected with the diaphragm pump by a hose through a connector, the outlet of the diaphragm pump is connected with the air bubble early warning device, the coating filter is connected with the main pipeline, branches of the main pipeline are respectively connected with the coating barrel in each line, and the central controller is jointed with the upper computer.

Owner:ZHONGTIAN TECH FIBER OPTICS +2

Production method of stainless steel brazing composite seamless pipe fittings

The invention relates to a production method of a stainless steel brazed composite seamless pipe fitting. The production method comprises the following steps: firstly selecting a carbon steel seamless steal pipe and machining the inner surface of the carbon steel seamless steal pipe; then selecting a stainless steel pipe with the same length as the carbon steel seamless steal pipe, and machining the outer surface of the stainless steel pipe; placing the machined stainless steel pipe into the machined carbon steel seamless steal pipe, and filling a brazing material between two layers of the steel pipes, wherein, the brazing material is a Ag-Cu-Ni high-temperature silver-based brazing material with a high silver content; and machining the obtained composite pipe according to the pipe fitting desired to be produced to obtain the finished pipe fitting with the desired size and shape, wherein, the heating temperature is 910-960 DEG C. The production method has the advantages of producing the stainless steel brazed composite seamless pipe fitting with high bonding strength and being applicable to middle-pressure pipe transportation and high-pressure pipe transportation.

Owner:JIANGYIN CHEM MASCH CO LTD

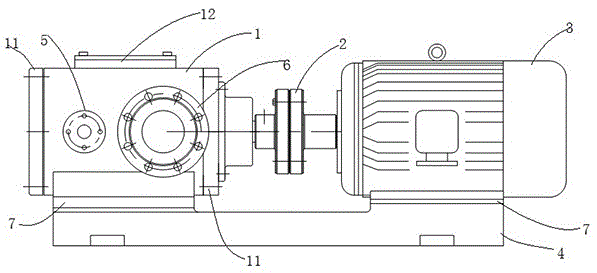

Screw pump for pitch conveying

InactiveCN105526162AEasy to disassemble and replaceRealize all aspects of heating and heat preservationRotary piston pumpsRotary/oscillating piston combinationsEngineeringScrew pump

The invention discloses a screw pump for pitch conveying. The screw pump comprises a screw pump body, a coupler, a motor and a base, wherein the screw pump body and the motor are fixed to the base with bolts; heat preservation layers are arranged at the two sides of the screw pump body through first flanges; a cover plate is arranged at the upper end of the screw pump body; a mechanical sealing layer is arranged between the cover plate and the upper end of the screw pump body; and an oil filling hole and a relief valve are formed in and arranged at the upper end of the screw pump body.

Owner:太仓液压元件有限公司

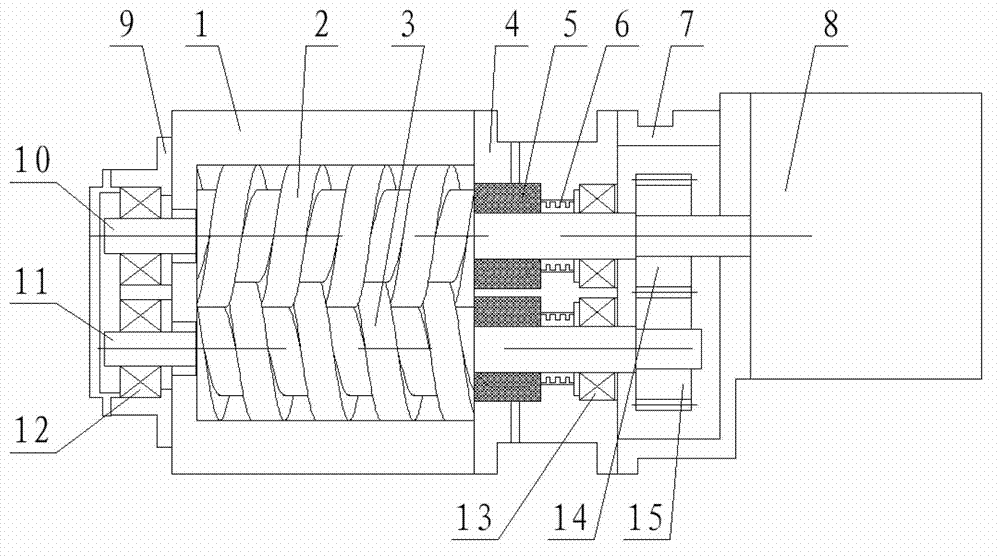

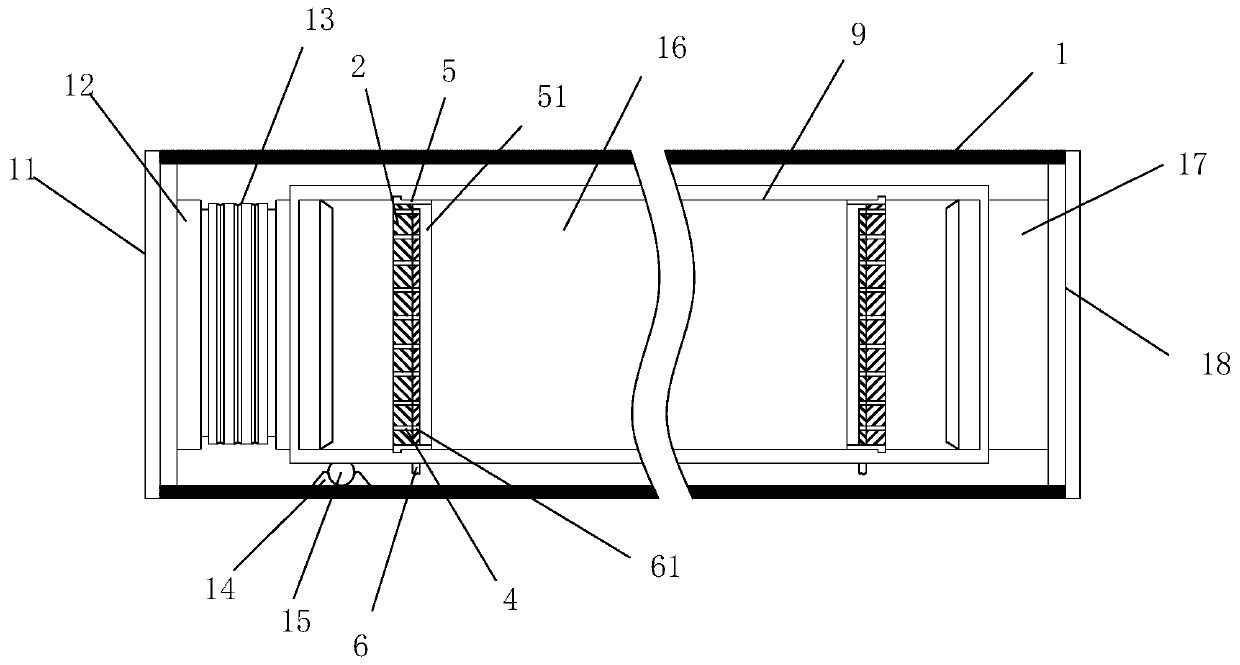

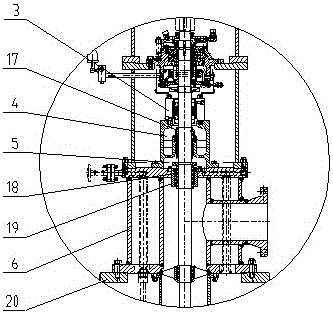

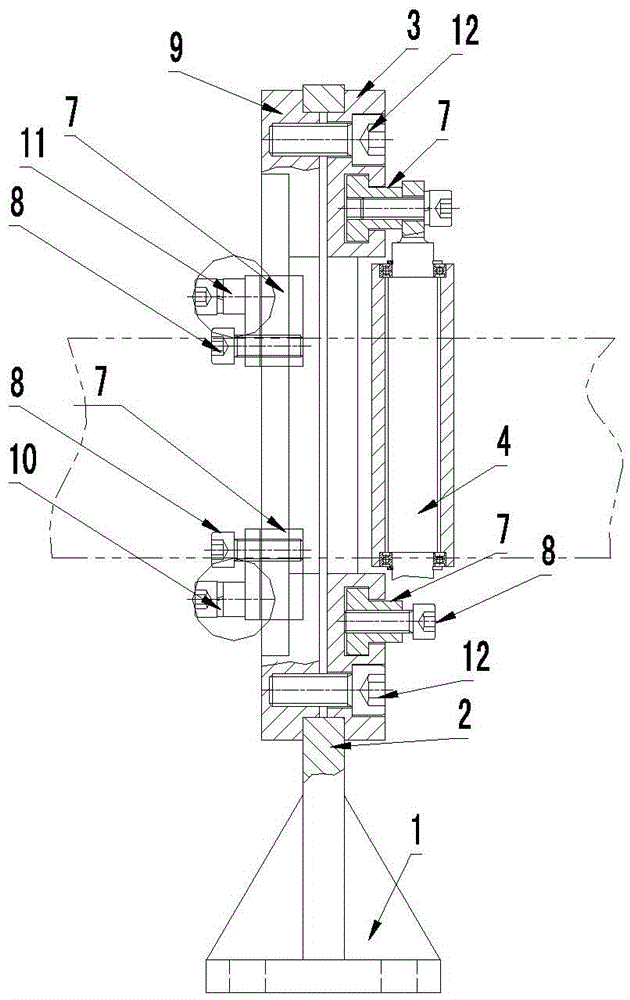

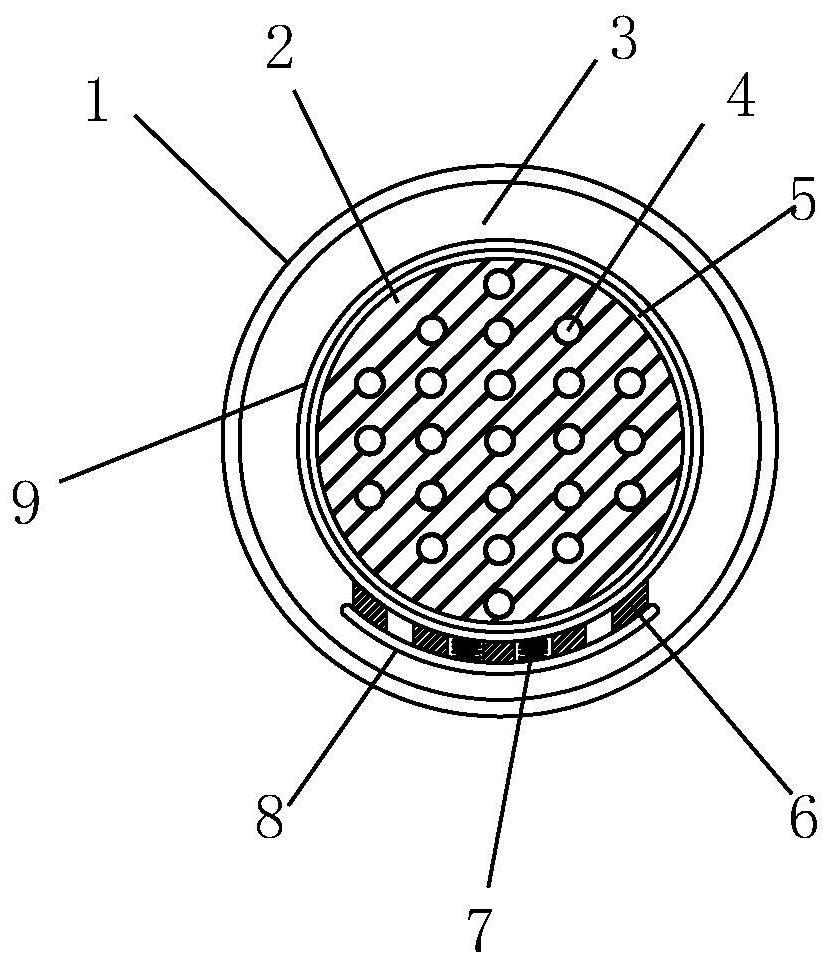

Screw vacuum pump adopting dry gas seal

InactiveCN103047142ASuitable for deliveryApplicable deliveryToothed gearingsRotary piston pumpsDry gas sealEngineering

The invention relates to a vacuum pump in the vacuum field, in particular to a screw vacuum pump adopting a dry gas seal. The vacuum pump comprises a cavity body, a driving rotor shaft, a driven rotor shaft, a driving rotor, a driven rotor, a transmission unit, a middle frame, the dry gas seal, a labyrinth type seal and a motor, wherein one side of the cavity body is connected with the middle frame; both the driving rotor shaft and the driven rotor shaft are arranged in the cavity body; the driving rotor and the driven rotor are arranged on the driving rotor shaft and the driven rotor shaft respectively; one end of the driving rotor shaft penetrates through the cavity body, the middle frame and the motor successively; one end of the driven rotor shaft penetrates through the middle frame to be connected with the driving rotor shaft through the transmission unit; and the driving rotor shaft and the driven rotor shaft are sleeved with the dry gas seal and the labyrinth type seal in the middle frame successively. According to the dry gas seal screw vacuum pump, a pump cavity is completely isolated from the outside through a combination mode of the dry gas seal and the labyrinth type seal, so that a medium is sealed in the pump cavity completely, and the vacuum pump is applicable to working conditions of poisonous and harmful media of petroleum and chemicals.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

Unsized composite pipe and manufacture thereof

InactiveCN1614281AComposite tightReduced corrosion resistanceLayered productsRigid pipesFluid transportPolyvinyl chloride

A non-adhesive composite pipe for delivering hot fluid or gas is composed of a metallic pipe, and two surficial layers which are the polyvinyl chloride layer with directional thermal shrinking memory function. Its advantages are high strength, light weight, and long service.

Owner:徐益鑫

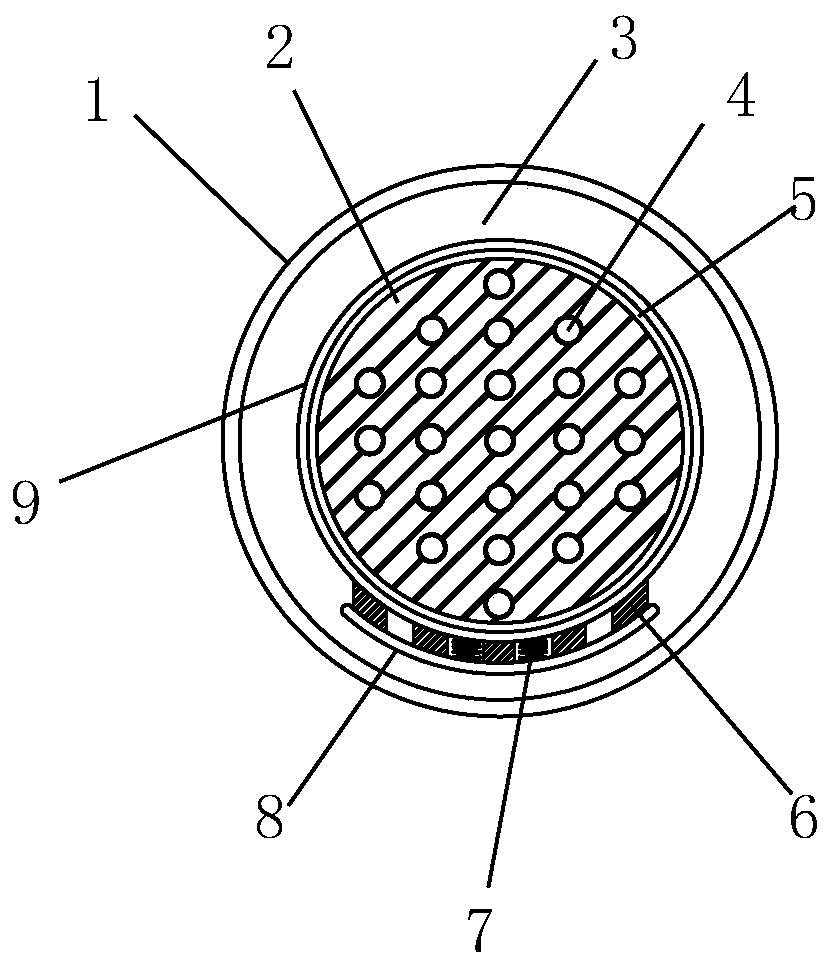

Composite conveying pipeline

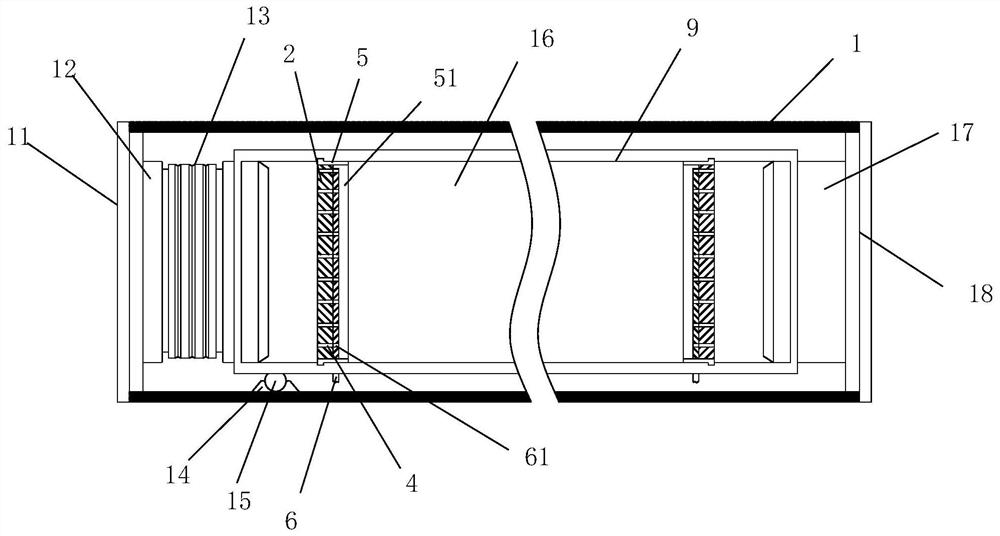

ActiveCN110260058AApplicable deliveryGood heat insulationThermal insulationPipe elementsEngineeringPetroleum

The invention discloses a composite conveying pipeline. The composite conveying pipeline comprises an outer pipe and an inner pipe, wherein the inner pipe is arranged in a hollow cavity in the outer pipe in a suspended mode; a first sealing cover is arranged on one side of the outer pipe; a second sealing cover is arranged on the other side of the outer pipe; the first sealing cover and the second sealing cover seal two sides of the whole outer pipe; an inner conveying channel is arranged in the middle of the inner pipe; a first assembling convex part is arranged at the end part of the inner side of the first sealing cover; a second assembling convex part is arranged at the end part of the inner side of the second sealing cover; the first assembling convex part and the second assembling convex part seal the whole inner conveying channel; one or more sealing devices are arranged in the inner conveying channel at equal distances; and a soft section is arranged in the middle of the first assembling convex part. The composite conveying pipeline is particularly suitable for conveying fluid products such as petroleum, crude oil can be filtered, the fluidity of the crude oil can be guaranteed, and if the middle of a pipeline is cut off, oil leakage does not occur, the rapid blocking can be realized, and the waste of resources is reduced.

Owner:义乌市丹航科技有限公司

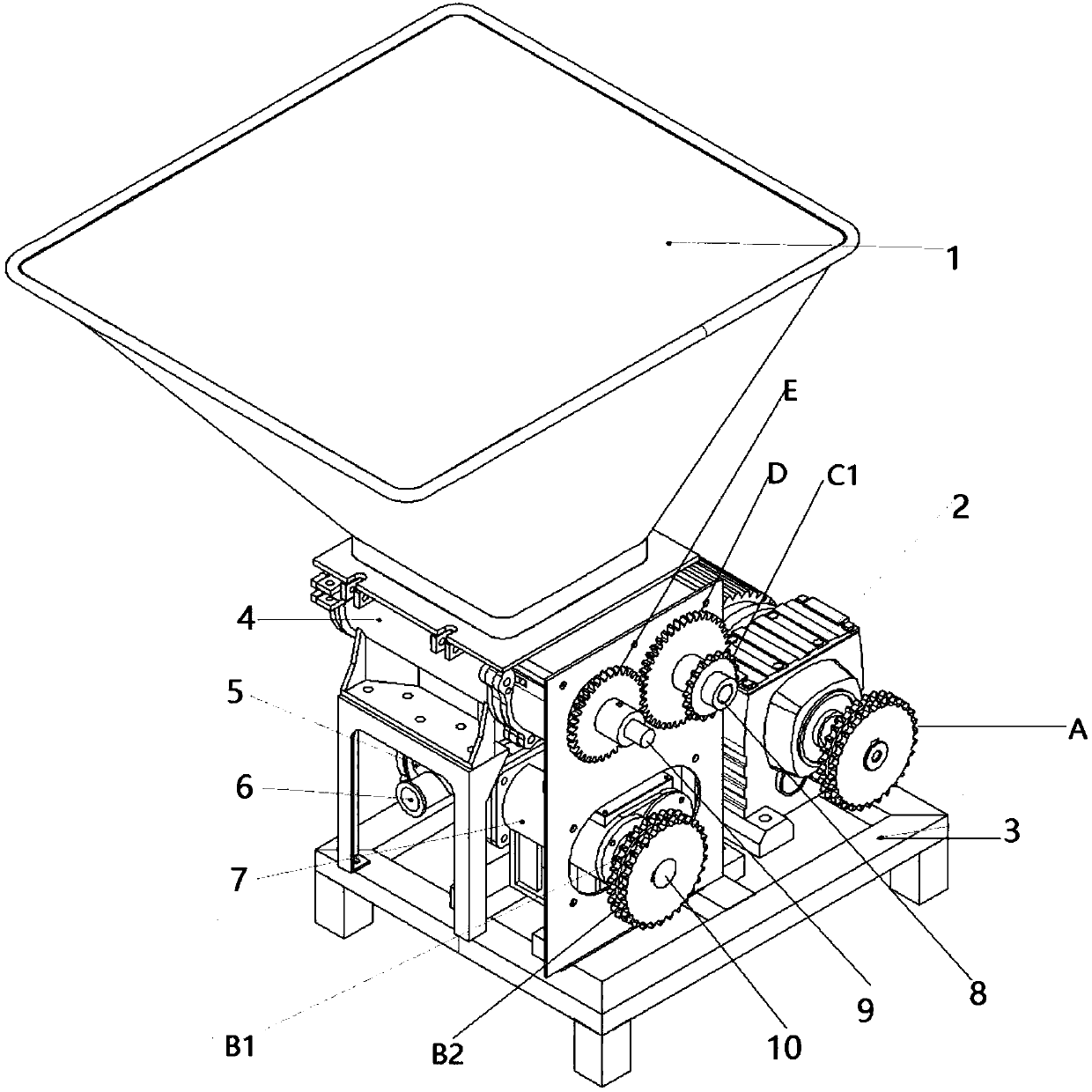

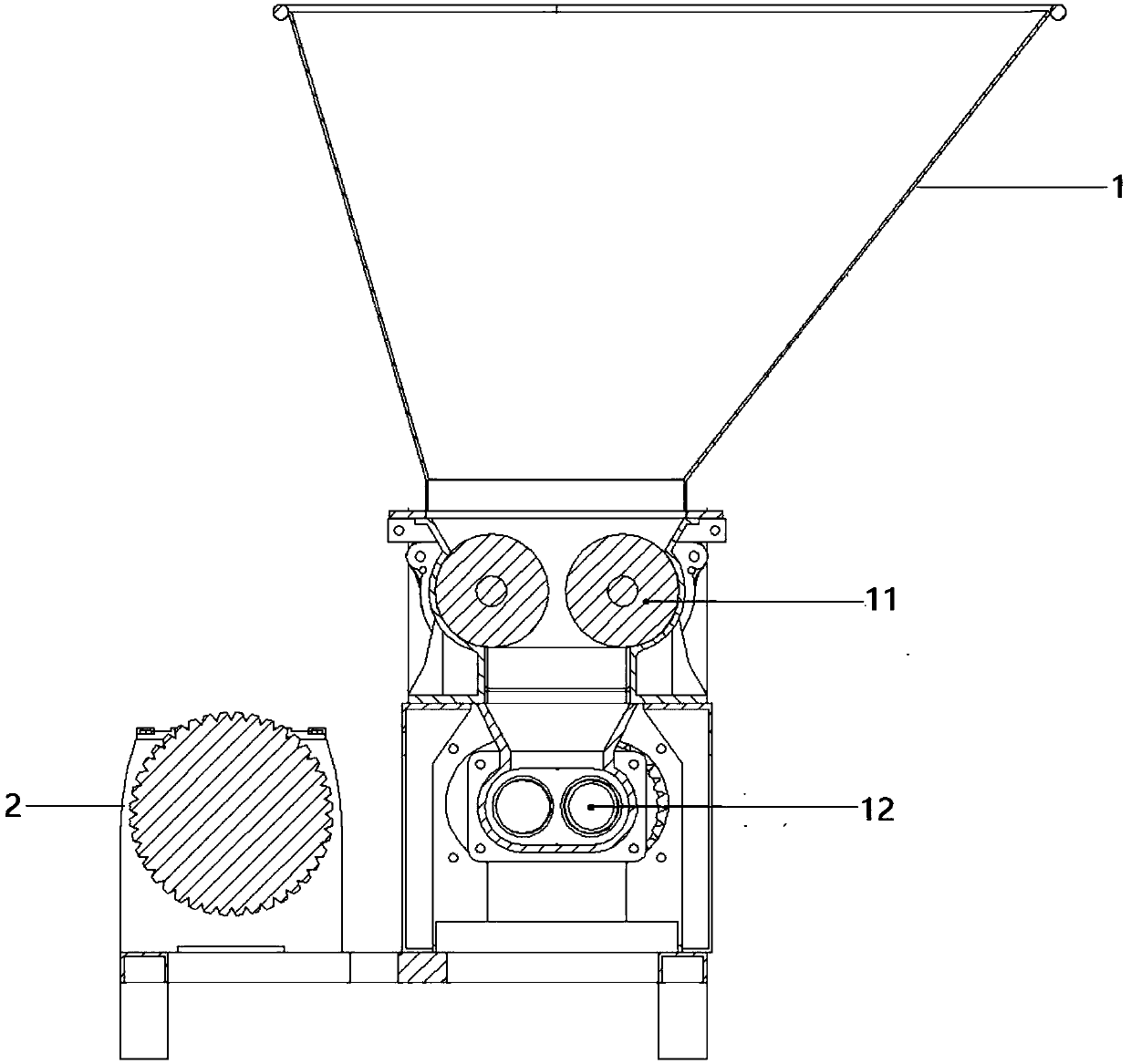

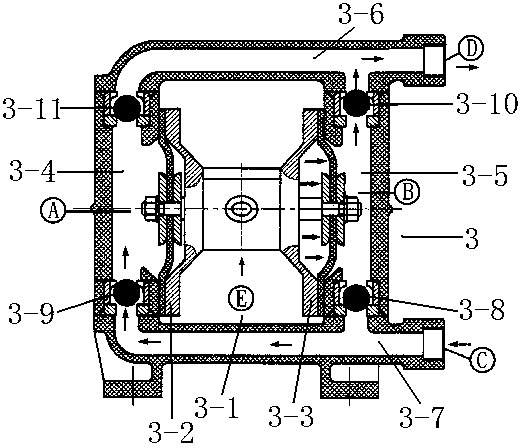

Ground conveying pump and material conveying method

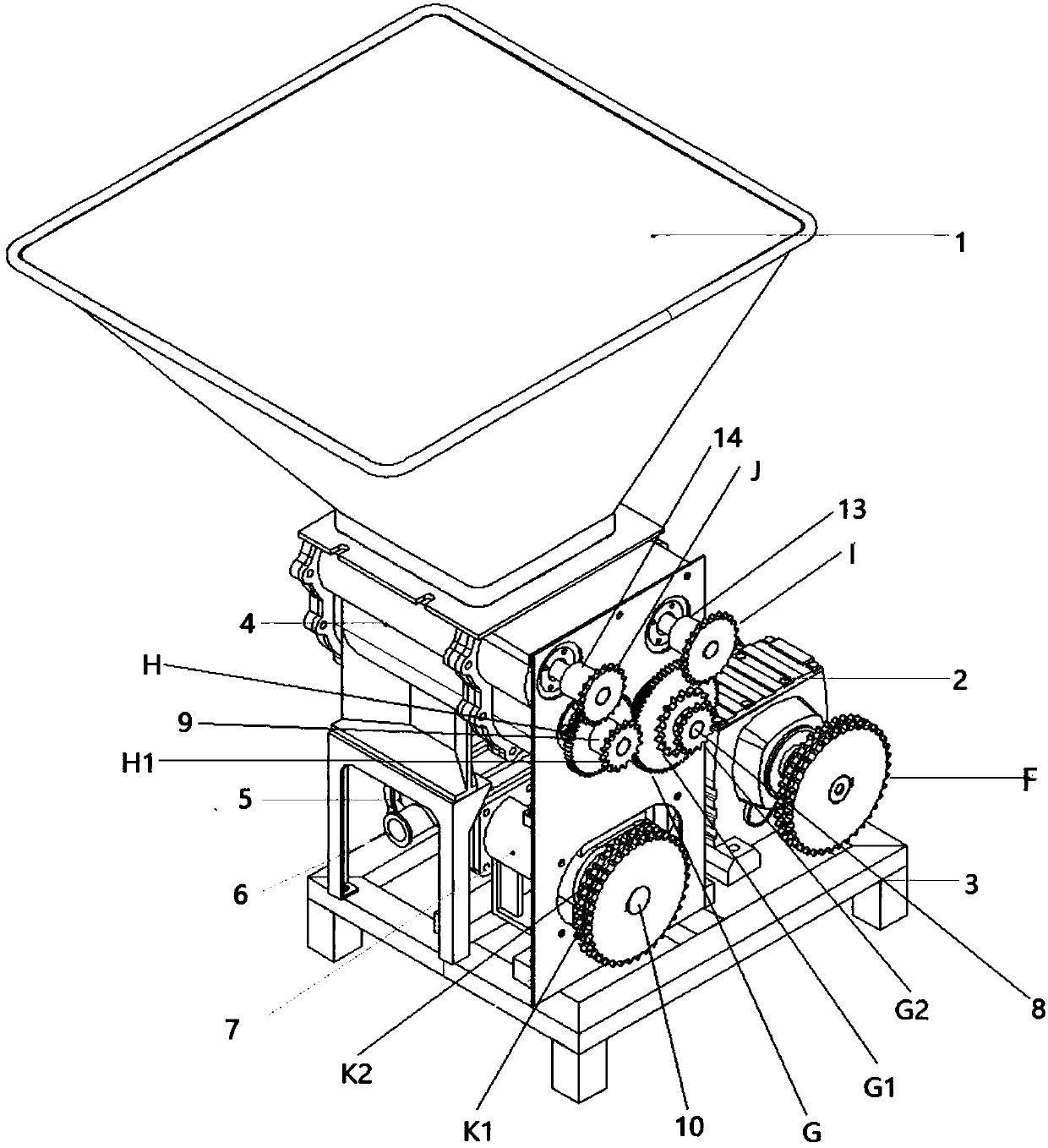

PendingCN107867569AInto a stableEasily control discharge volumeLoading/unloadingGear wheelElectric machinery

The invention provides a ground conveying pump, in particular to a ground conveying pump for conveying food materials with certain viscosity. The ground conveying pump comprises a feeding device, a ground pump body and a driving motor and further comprises a roller mechanism arranged between the feeding device and the ground pump body. A rotating element is arranged in the pump body, the feeding device is connected with a roller box, the roller box is connected with a pump body box, the driving motor drives the roller and the pump body through a sprocket gear transmission system, and the roller mechanism can be in a two-roller mode or a four-roller mode. The invention further provides a material conveying method using the ground conveying pump. By means of the method, before being conveyedto a rotor pump, materials are made to pass through the roller mechanism, so that bubbles and air contained in the materials are effectively exhausted, and the materials can be conveyed into the pumpbody at a stable speed and prevented from being polluted in the pump body and then are discharged out of the pump body and conveyed to a next treating mechanism.

Owner:BEIJING AEROSPACE ORIENTAL TECH DEVCO

Safety guardrail with adjustable protection height

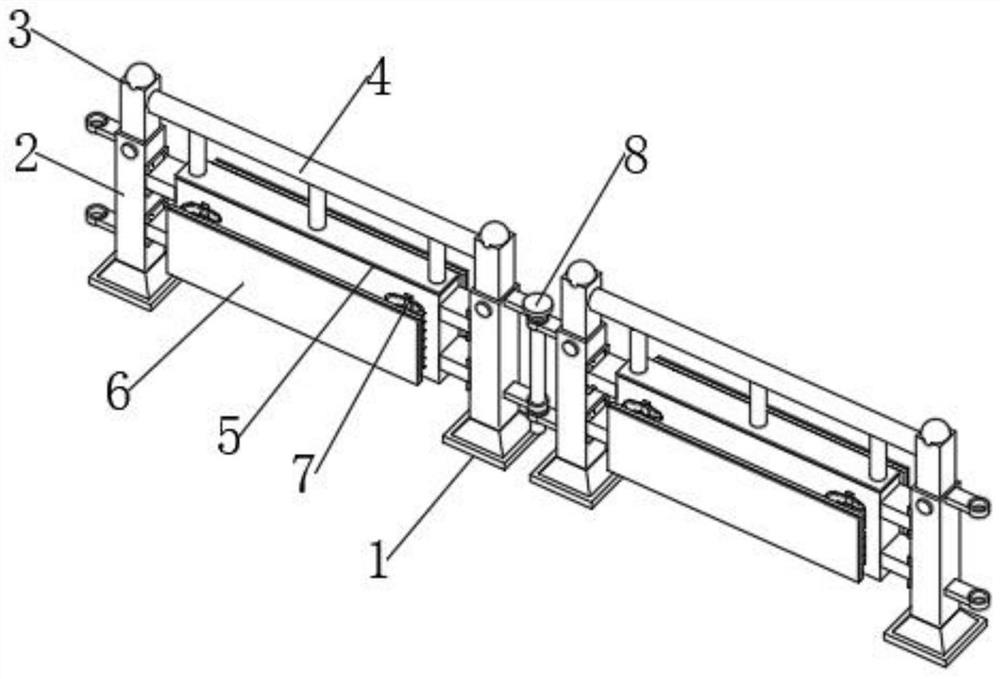

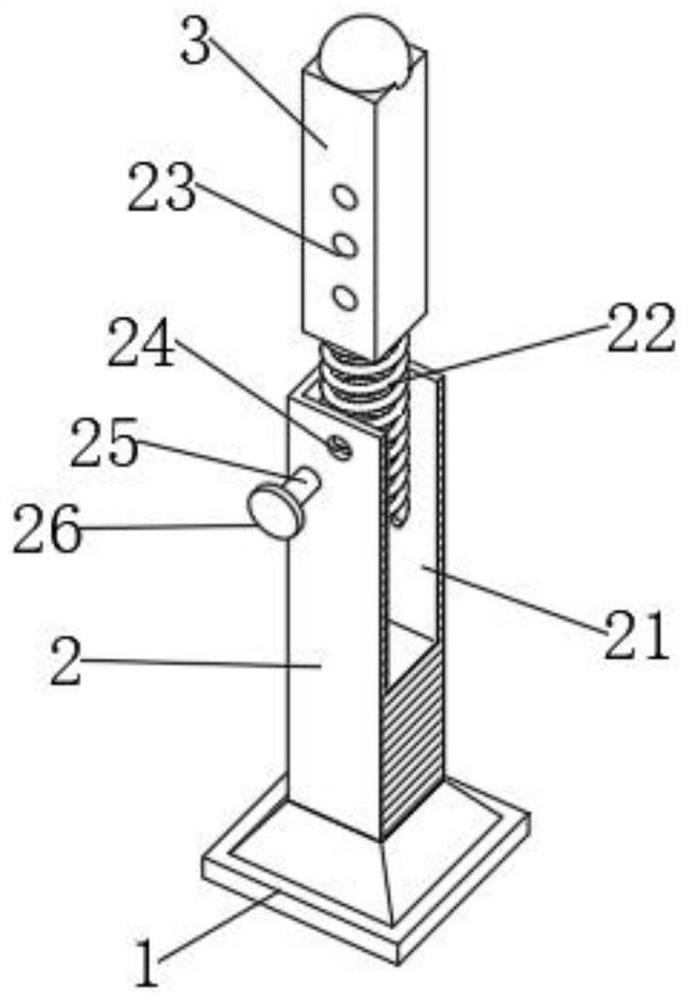

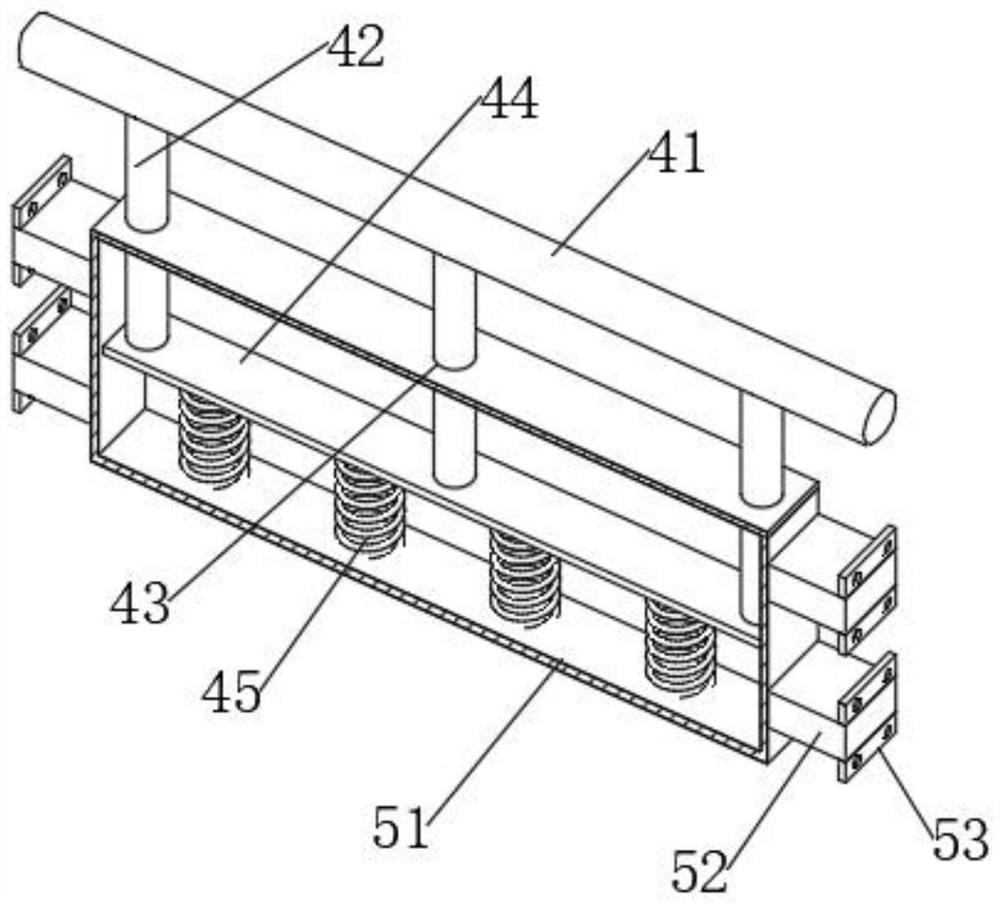

InactiveCN112160276AHeight adjustableCounteract gravityRoadway safety arrangementsControl theoryBilateral symmetry

The invention discloses a protective-height-adjustable safety guardrail which comprises at least two bases, stand columns are fixedly installed at the upper ends of the bases, lifting rods are arranged at the upper ends of the stand columns, and a lower protective mechanism is fixedly connected between the two stand columns. An upper protection mechanism is fixedly connected between the two lifting rods jointly, two buffer devices are fixedly installed at the front end and the rear end of the lower protection mechanism in a bilateral symmetry mode, and anti-collision plates are fixedly installed at the ends, away from the lower protection mechanism, of the two buffer devices located in front of and behind the lower protection mechanism jointly. A connecting piece is further arranged between every two adjacent stand columns. According to the safety guardrail capable of adjusting the protection height, the height of the guardrail can be effectively adjusted, operation is easy and convenient, the guardrails are connected with one another, the placing angle can be adjusted at will, and the safety guardrail has good anti-collision performance when colliding occurs and is suitable for being widely used and popularized.

Owner:扬州维工科技有限公司

Enhancement ultra-high molecular weight polyethylene wound pipe and manufacture method therefor

The invention belongs to reinforced ultra-high molecular weight polyethylene winding pipe and its preparation method. One or more layers of ultra-high molecular weight polyethylene profiles are used as winding materials, arranged in regular, mirror image or phase dislocation, and melted between adjacent side walls / periphery Interconnected or adjacent side walls / peripherals are fusion-bonded with frit material applied, and spirally wound to form the pipe wall; the wound material is stretched to orient the molecules along the longitudinal direction of the profile; reinforcement is applied to the UHMWPE base material materials and / or wear-resistant materials and / or flame-retardant materials and / or antistatic materials; welding materials are plastic polymers, or are reinforced and / or wear-resistant and / or flame-retardant and / or antistatic materials are applied to form plastic Melted co-extrusion; the distribution of reinforcing materials in the winding material and / or welding material is oriented in the helical direction along the axis of the high-strength winding pipe. It has higher impact resistance, yield strength, wear resistance, flame retardancy and antistatic ability, and can produce large-diameter pipes with small equipment.

Owner:淄博寿山特种塑料有限公司

Molding cooling device for processing outer insulating layer of power cable

InactiveCN110491604AApplicable deliveryRealize pre-coolingInsulating conductors/cablesPower cableFixed frame

The invention discloses a molding cooling device for processing an outer insulating layer of a power cable. The device comprises a workbench; a spraying chamber, a cooling water tank and an air dryingchamber are sequentially arranged at the upper end of the workbench from left to right. The bottom of the spraying chamber and the bottom of the air drying chamber are fixedly connected with fixing frames correspondingly. A water storage tank is arranged at the upper end of the workbench and located outside the spraying chamber. A plurality of rolling shafts are arranged in the cooling water tankat equal intervals, the two ends of each rolling shaft are horizontally connected with connecting shafts correspondingly, the outer walls of the connecting shafts are sleeved with fixing rods, the fixing rods are fixed to the inner bottom of the cooling water tank, conveying openings are formed in the spraying chamber and the air drying chamber correspondingly, and pressing rollers and conveyingrollers are arranged at the upper ends and the lower ends in the conveying openings correspondingly. The molding cooling device overcomes the defects in the prior art, is reasonable in design, conducts pre-spraying before the cable enters the cooling water tank, improves the cooling efficiency, can recycle spraying water, saves water resources, and has high social use value and application prospects.

Owner:涌纬集团股份有限公司

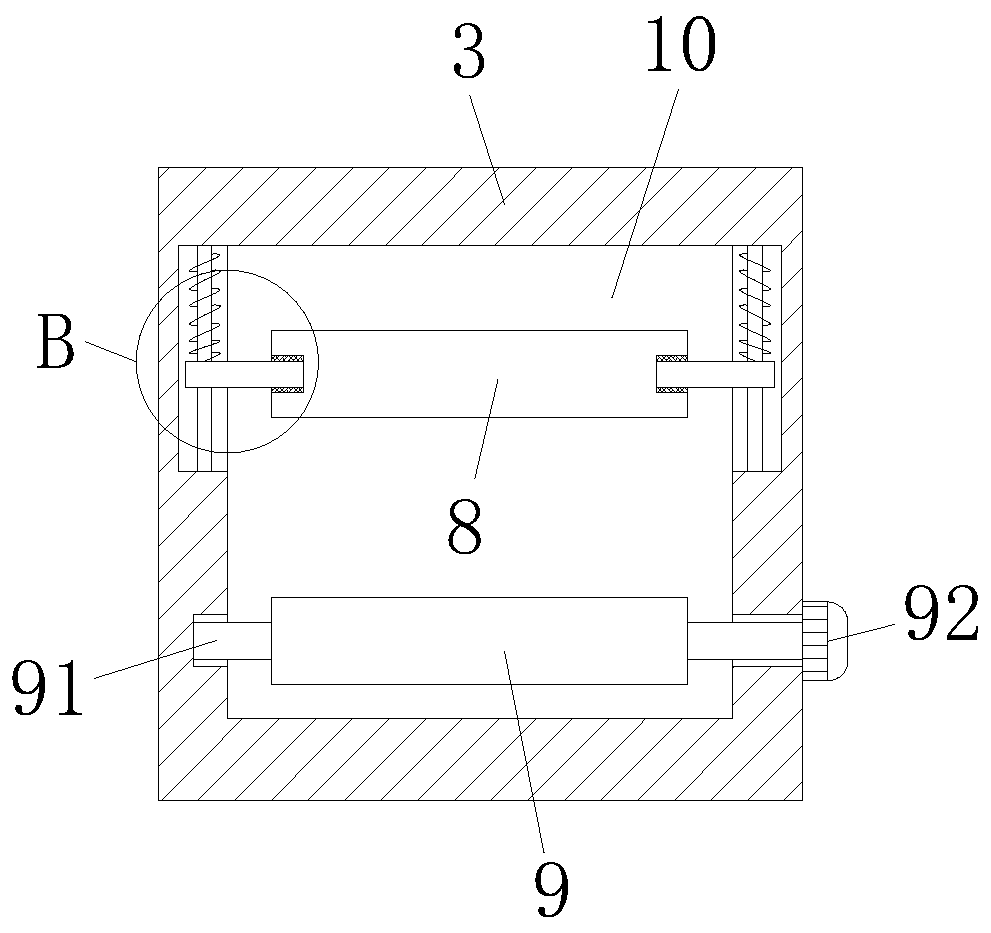

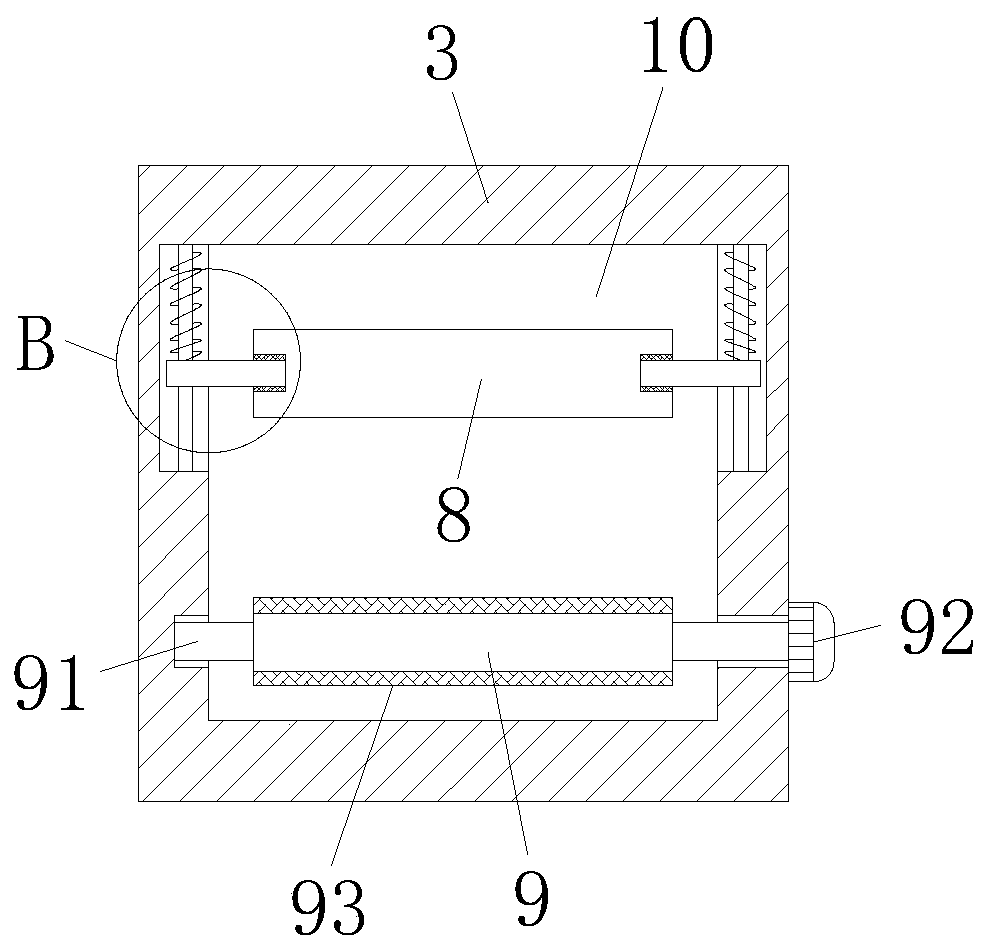

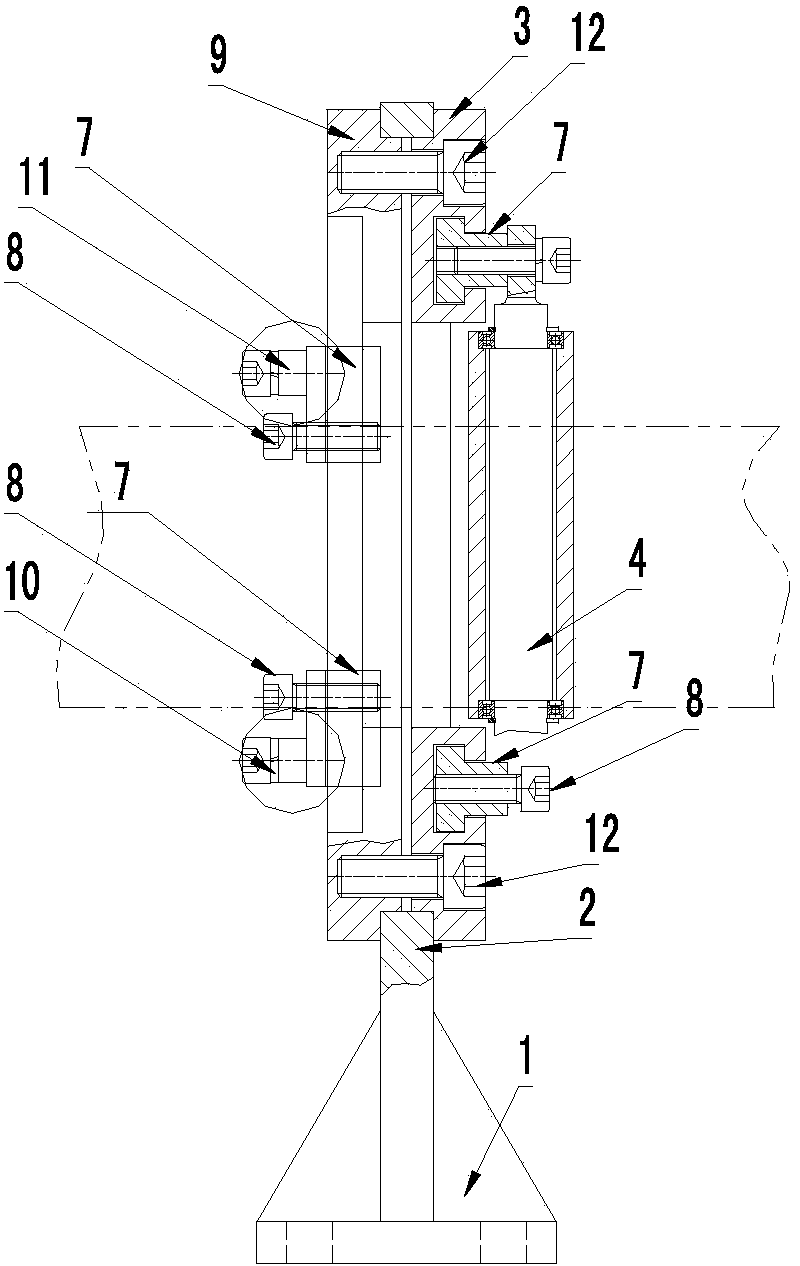

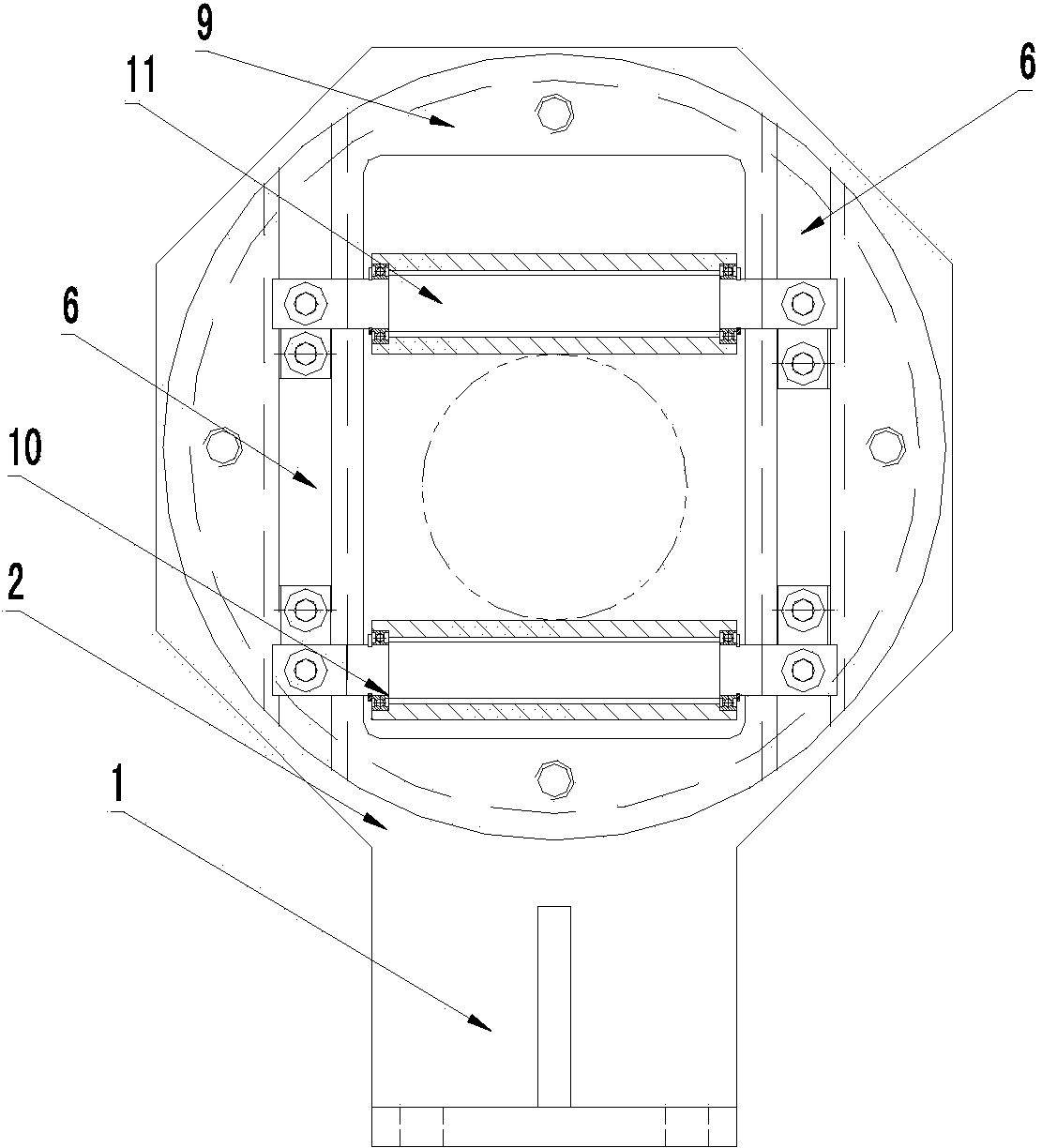

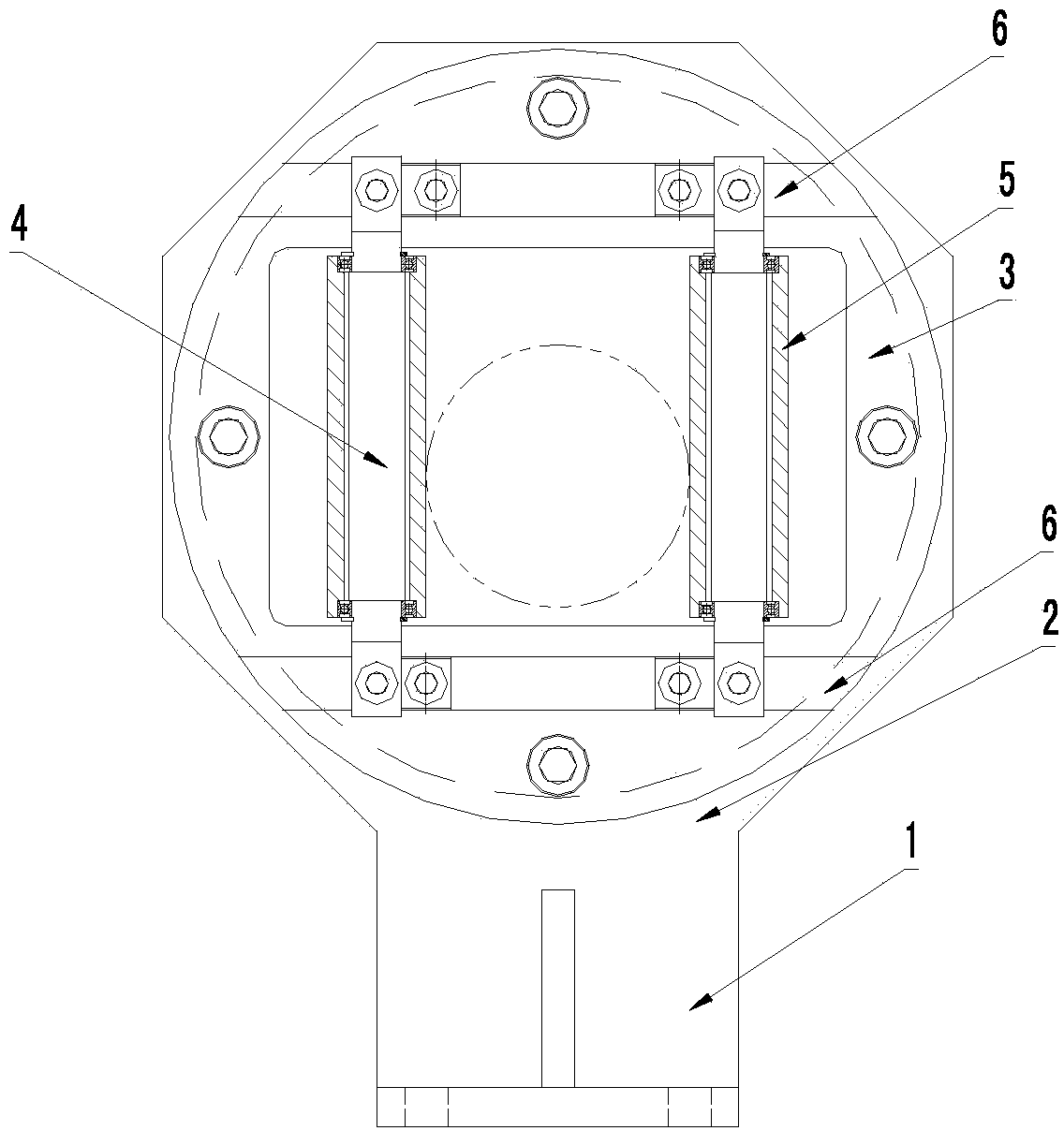

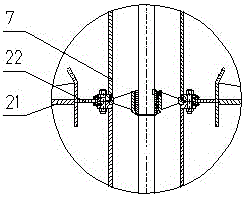

Carrier roller

ActiveCN103738695APrevent bouncing up and downEasy to transportRollersEngineeringMechanical engineering

The invention discloses a carrier roller which can prevent materials from jumping in the conveying process. The carrier roller comprises a base. An installation plate is vertically arranged on the base. A through hole for the materials to pass is formed in the installation plate. A lower carrier roller for bearing the materials and an upper carrier roller for limiting jumping of the materials are arranged on the installation plate and the arrangement position of the upper carrier roller can be adjusted relative to the lower carrier roller.

Owner:张家港市中悦冶金设备科技有限公司

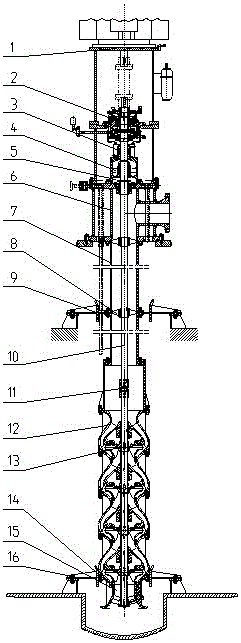

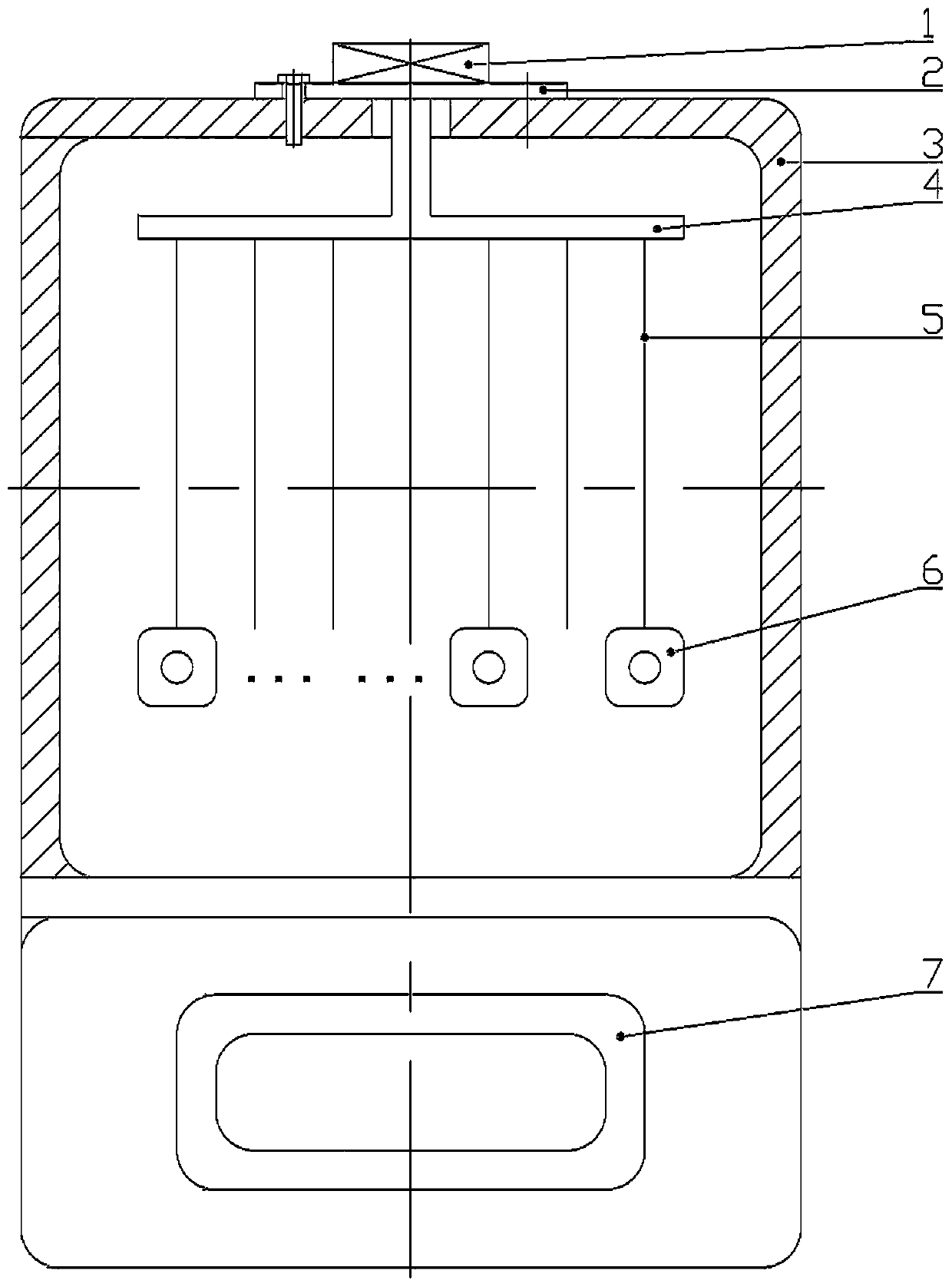

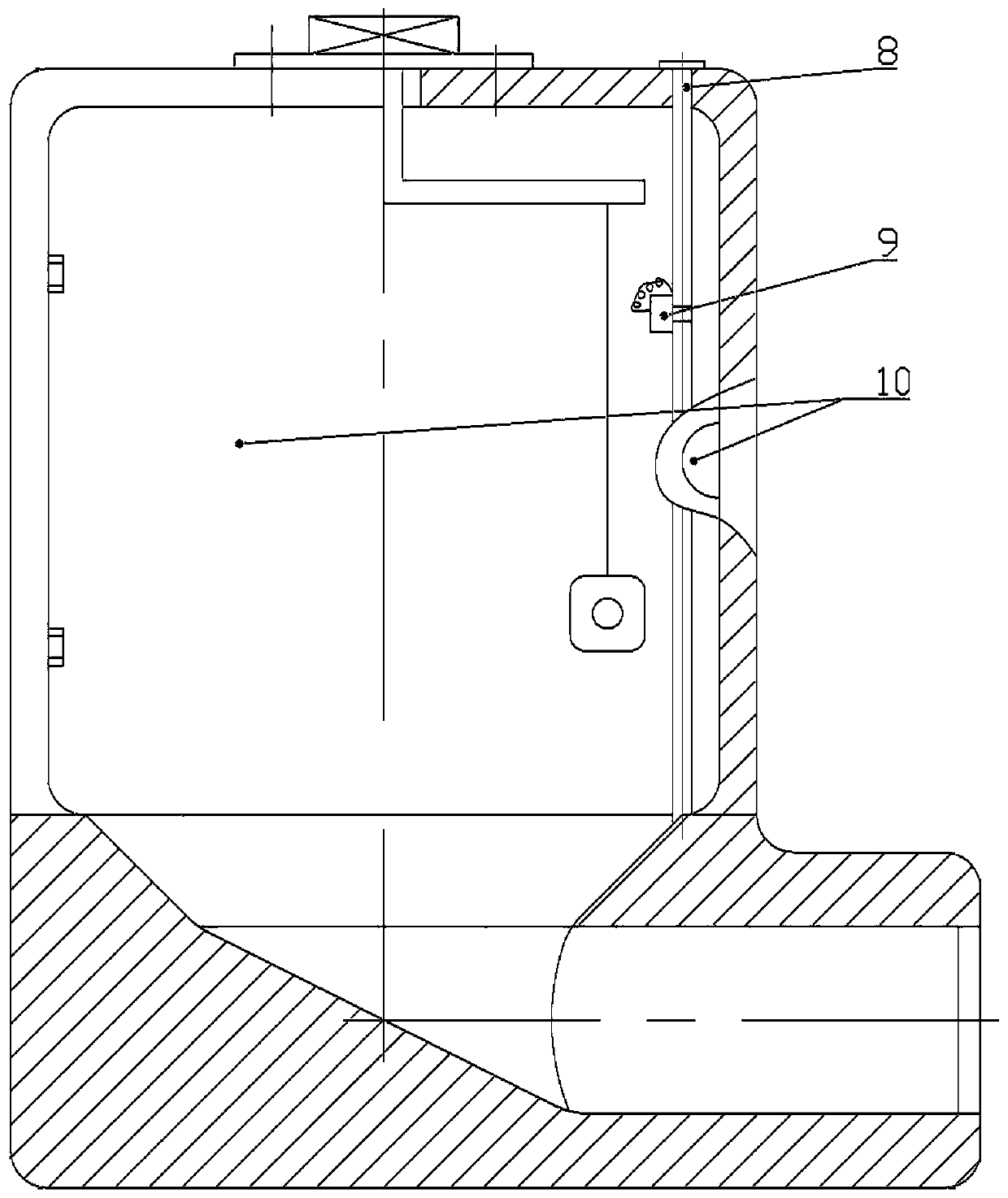

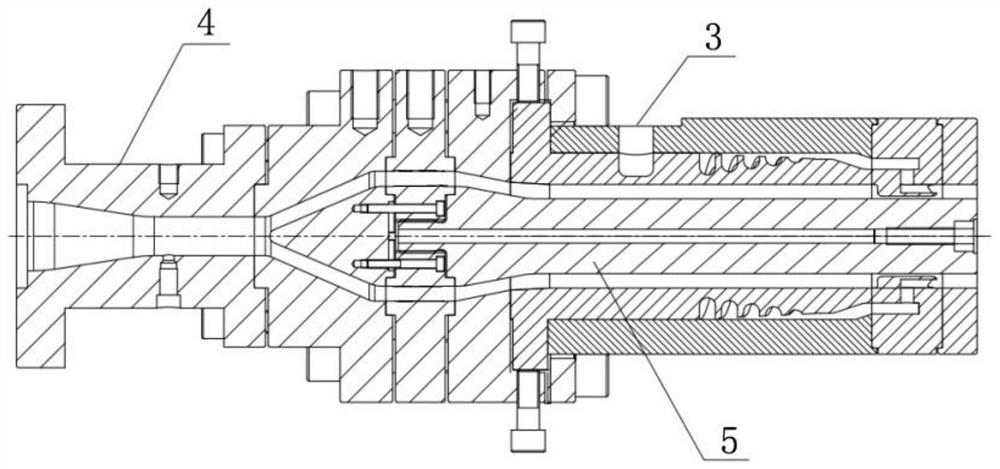

Marine vertical deep well liquid cargo pump

ActiveCN104514723BLow temperature failure does not occurSafe operation does not occurSpecific fluid pumpsPump componentsImpellerWorking temperature

The invention discloses a marine vertical deep well liquid cargo pump which comprises a motor component, a bearing component, a mechanical seal, an exit section, a support pipe, a middle support frame, a shaft, a shaft connecting component, a multistage flow guide housing, an impeller, an inducer, a suction section and the like, wherein a gaseous cold insulation cavity and a buffer cavity are sequentially arranged between the mechanical seal and the exit section from the top down to form two mechanical seal protection barriers; a multipoint sliding bearing support is arranged between a pump rotor and a casing; a middle limiting component is arranged in the middle of the pump; a bottom end limiting component is arranged at the undermost end of the pump; deviation of the whole pump due to swaying is avoided; the support pipe capable of sliding up and down is arranged at a shaft connecting part of a lower shaft; the shaft connecting component is dismounted by using a vacated space; and further, a whole lower shaft component can be taken out for maintenance. According to the pump, the service life of the seal can be prolonged, the swaying of the pump is avoided, the pump is convenient to dismount, as well as operates stably and is safe and reliable and long in service life under the working condition of length being 20m and working temperature being subzero 165 DEG C when liquid is pumped, and the pump is applicable to conveying LNG (Liquefied Natural Gas), LEG (Liquid Ethylene Gas) and LPG (Liquefied Petroleum Gas).

Owner:DALIAN DEEP BLUE PUMP CO LTD

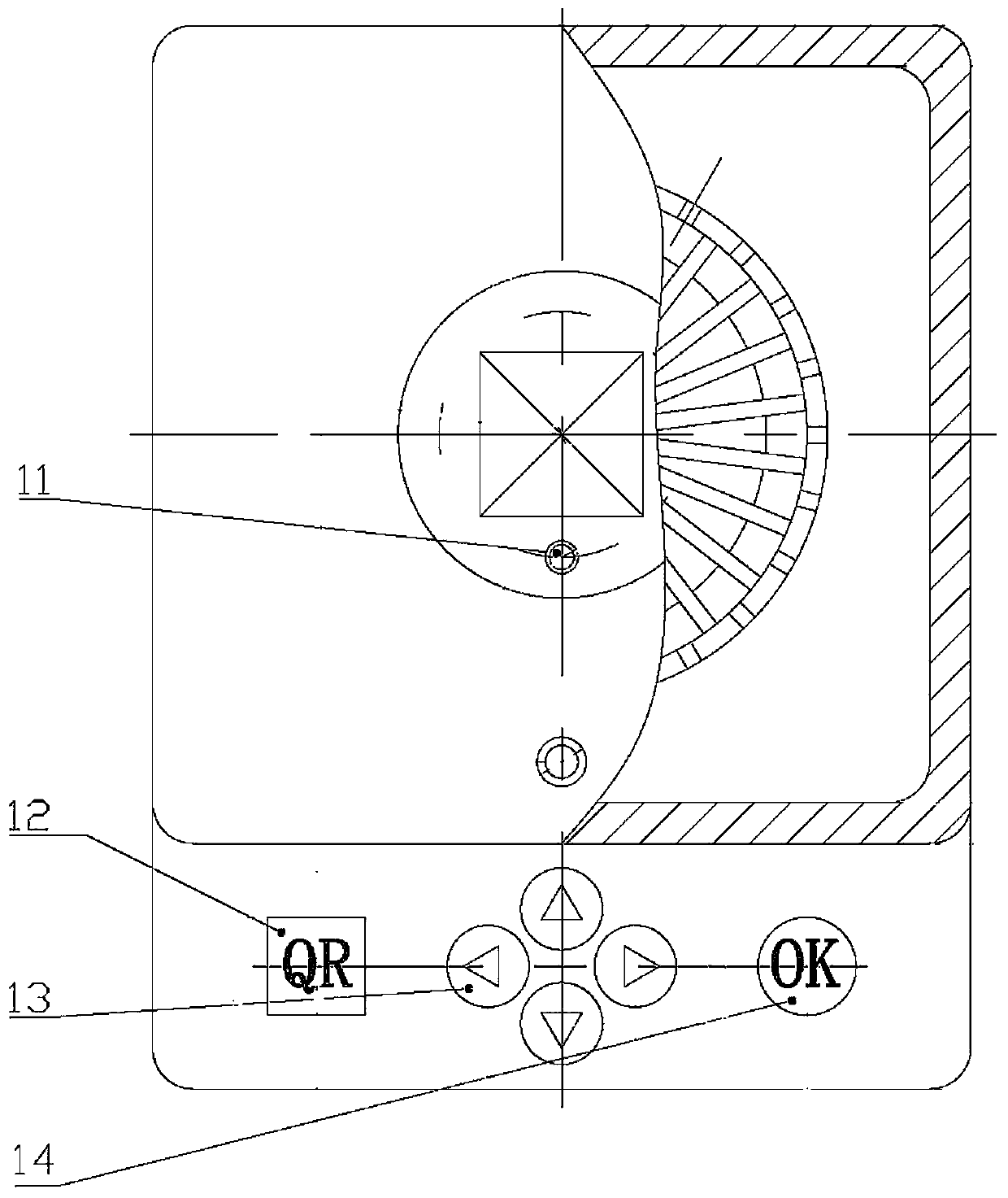

Book self-service borrowing and returning device

PendingCN110264646AEliminate magnetization and degaussingApplicable deliveryCash registersCircular discEngineering

The invention discloses a book self-service borrowing and returning device. The device comprises a box body, a rotating shaft extending into the box body, and a rotating motor used for driving the rotating shaft to rotate. The rotating shaft is connected with a disc. A number of ropes are circumferentially arranged on the disc. Each rope is connected with a magnetic buckle used for clamping a book. A vertical rod is arranged in the front of the cavity of the box body. The vertical rod is provided with an electromagnet capable of moving up and down relative to the vertical rod. The electromagnet is adhered to a magnetic buckle which is aligned with the electromagnet, and the magnetic buckle can be opened and closed. The book self-service borrowing and returning device provided by the invention has the advantages of simple structure and convenient operation, and is suitable for being used in a subway station.

Owner:NANJING NORMAL UNIVERSITY

a roller

ActiveCN103738695BPrevent bouncing up and downPrevent sliding left and rightRollersEngineeringMechanical engineering

The invention discloses a carrier roller which can prevent materials from jumping in the conveying process. The carrier roller comprises a base. An installation plate is vertically arranged on the base. A through hole for the materials to pass is formed in the installation plate. A lower carrier roller for bearing the materials and an upper carrier roller for limiting jumping of the materials are arranged on the installation plate and the arrangement position of the upper carrier roller can be adjusted relative to the lower carrier roller.

Owner:张家港市中悦冶金设备科技有限公司

Plastic pipe for chemical wastewater delivery and production method of plastic pipe

The invention discloses a plastic pipe for chemical wastewater delivery and a production method of the plastic pipe and relates to the technical field of plastic pipe production. The plastic pipe is prepared from raw materials in parts by mass as follows: 85-90 parts of a tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer, 20-25 parts of polyphenylene sulfate, 12-15 parts of nano silicon carbide, 10-13 parts of polyvinyl alcohol, 7-9 parts of white carbon black, 5-8 parts of diatomite, 3-5 parts of seaweed gel, 3-5 parts of epoxidized soybean oil, 2-3 parts of calcium stearate, 2-3 parts of zinc stearate, 1-3 parts of graphite powder, 1-3 parts of dibutyl phthalate, 0.5-2 parts of an ultraviolet light absorber, 30-40 parts of polyethylene glycol and 40-45 parts of water. The plastic pipe produced with the method has excellent wear resistance, corrosion resistance, high-temperature resistance, shock resistance and the like, adhesion to the inner wall is avoided, and the plastic pipe is prevented from being blocked after long-term usage, so that the plastic pipe is long in service life, wide in application range and applicable to delivery of all kinds of chemical wastewater.

Owner:DONGZHI QUNSHENG CHEM EQUIP CO LTD

Novel material for mash pump

InactiveCN113637924AImprove corrosion resistanceImprove wear resistanceEconomic benefitsWear resistance

The invention discloses a novel material for a mash pump. The novel material comprises the following chemical components including, by weight, 0.45% to 0.55% of C, 4.0% to 6.0% of Ni, 17.0% to 09.0% of Cr, 1.9% to 2.1% of Mo, 0.4% to 0.6% of Co, less than or equal to 0.03% of P, less than or equal to 0.03% of S and the balance Fe. According to the novel material for the mash pump, on the basis of reducing the cost, the wear resistance and the corrosion resistance of the mash pump are greatly improved, the service life of the mash pump is prolonged, and the economic benefit is improved.

Owner:靖江市中信特种机械泵阀厂

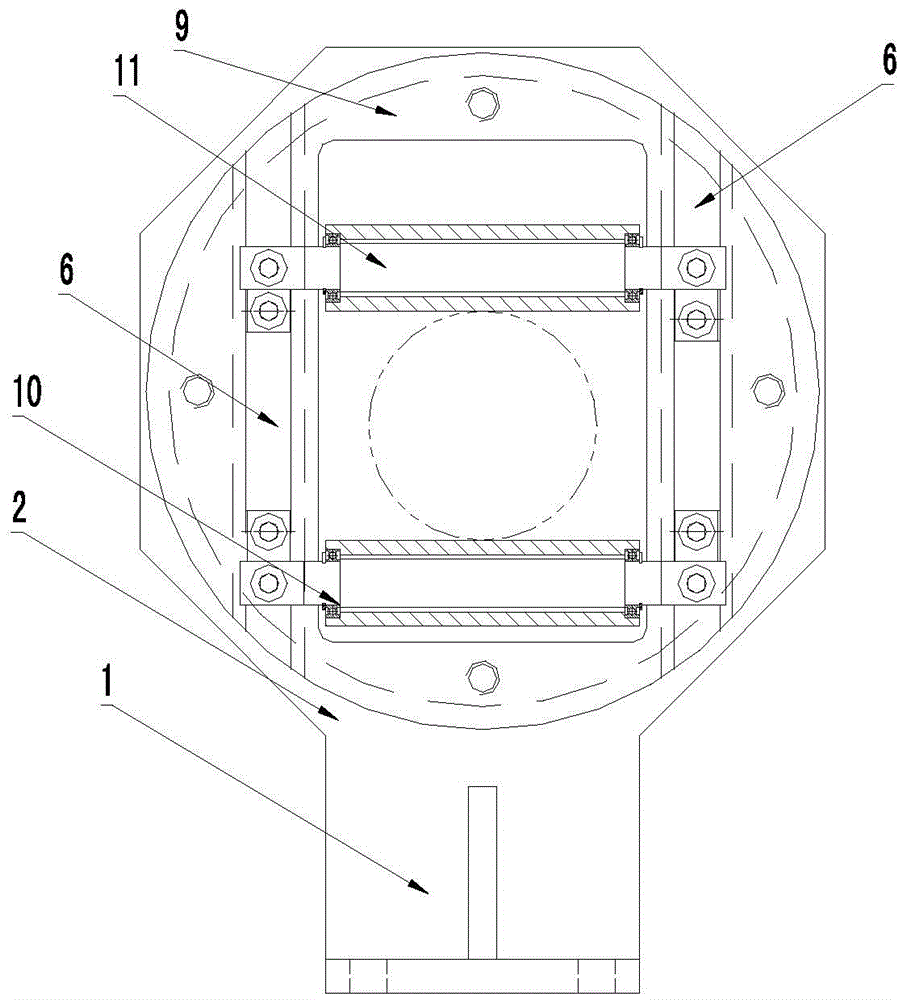

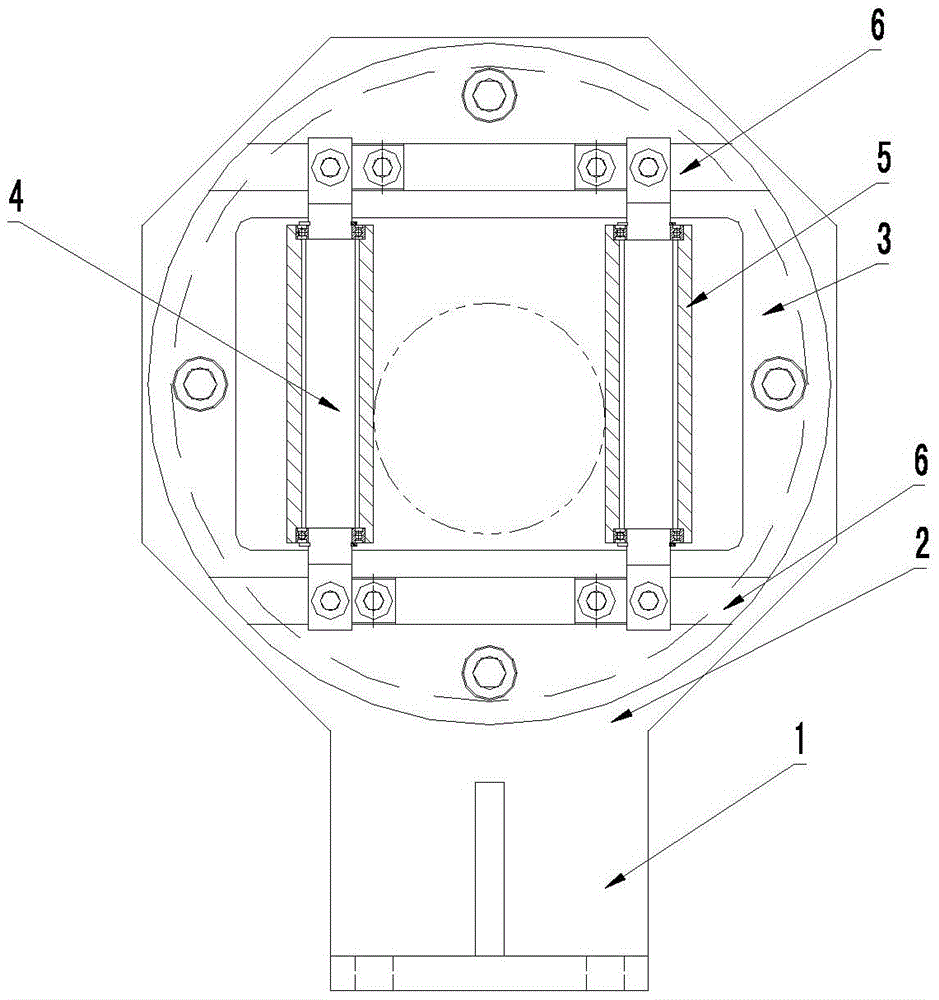

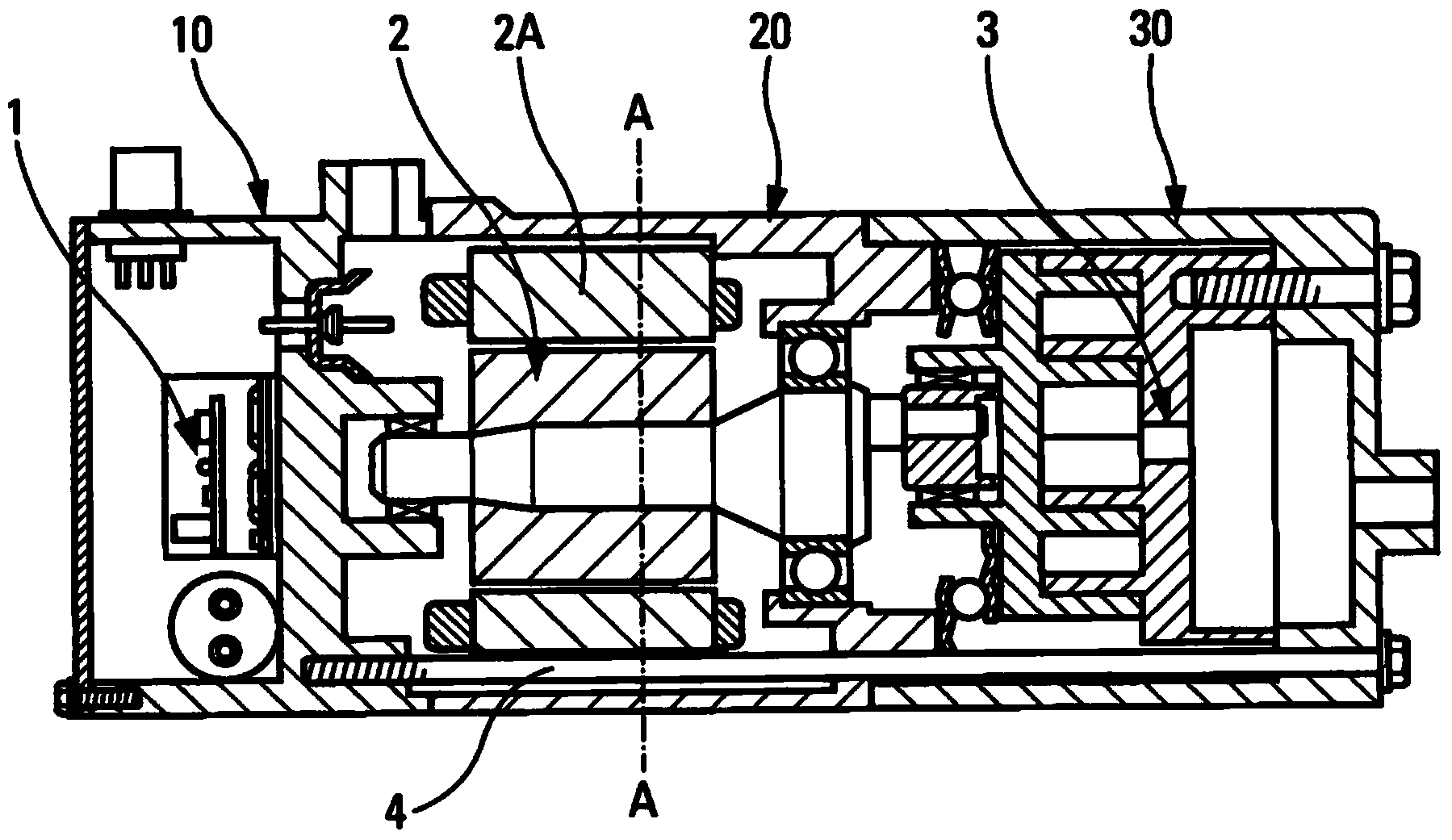

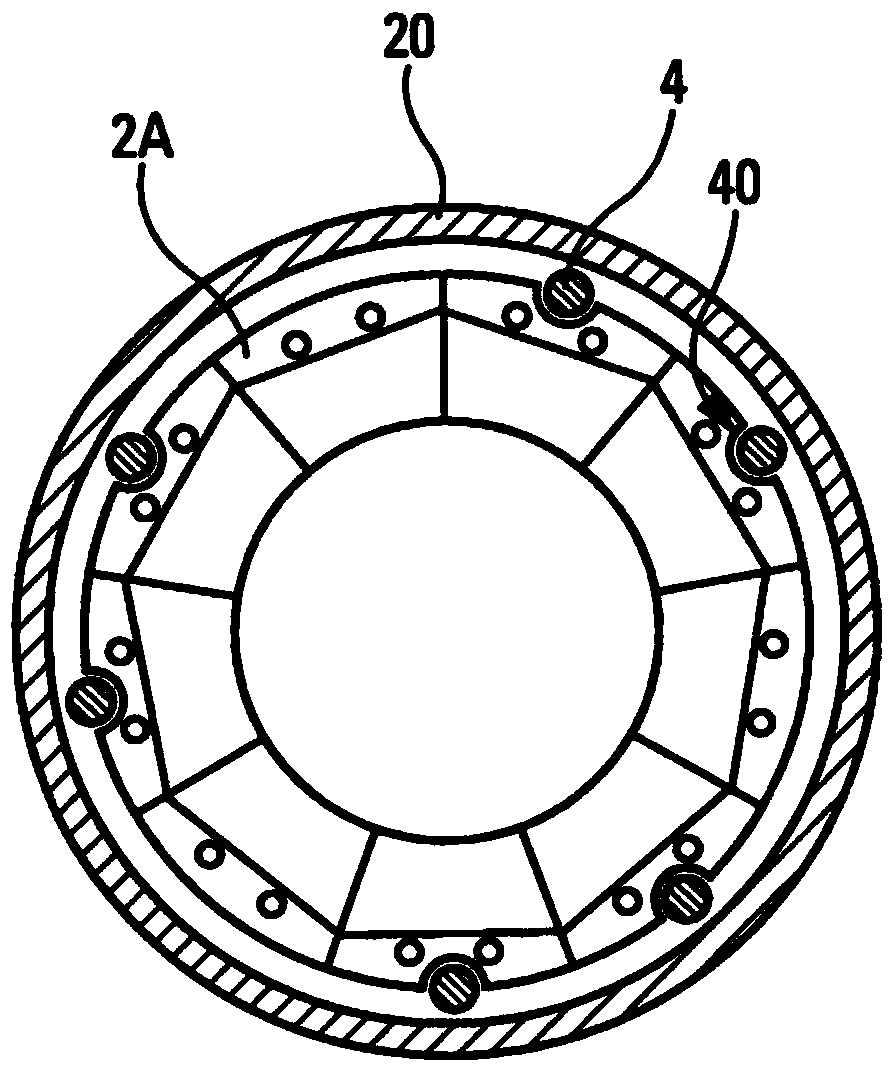

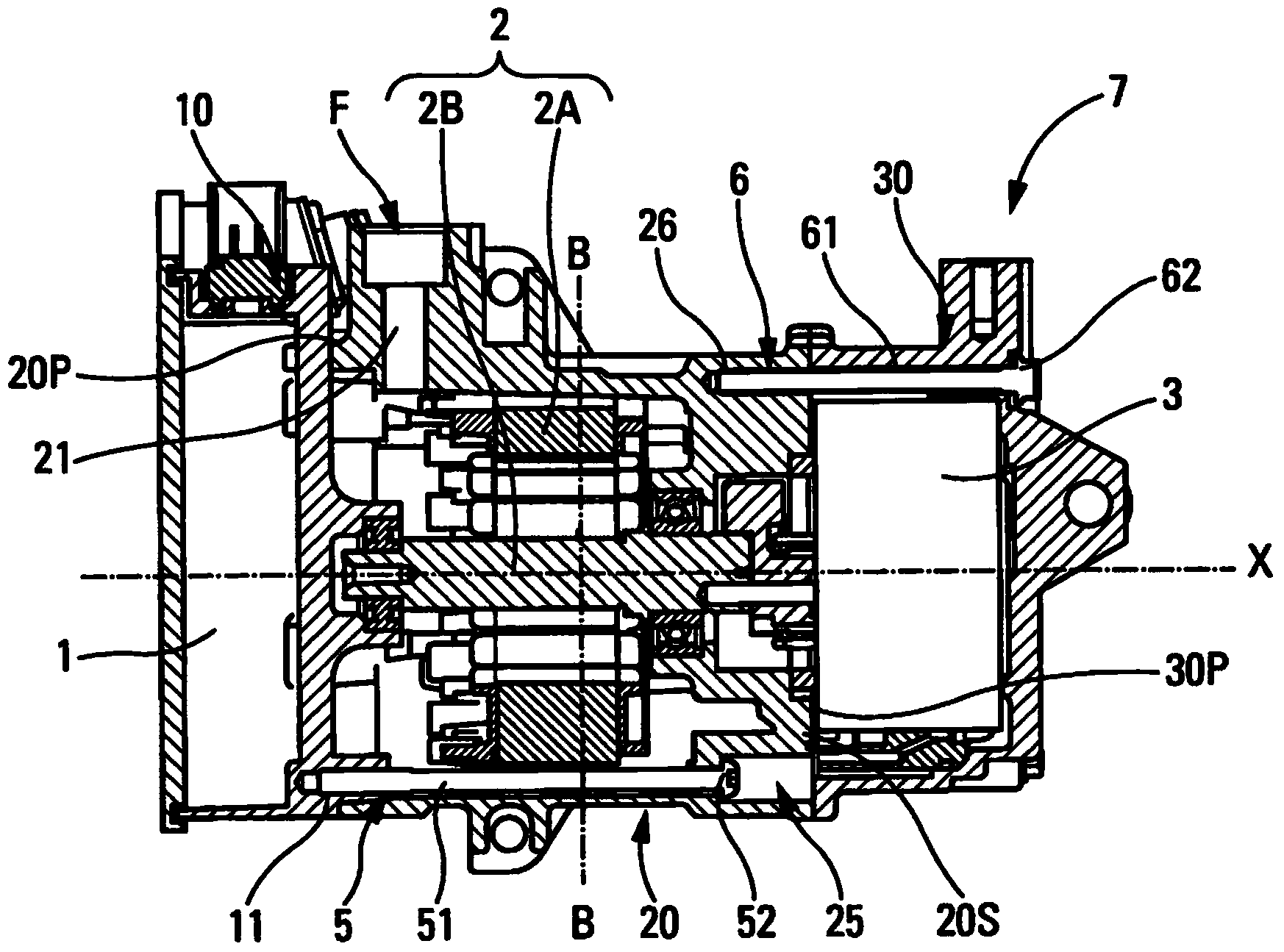

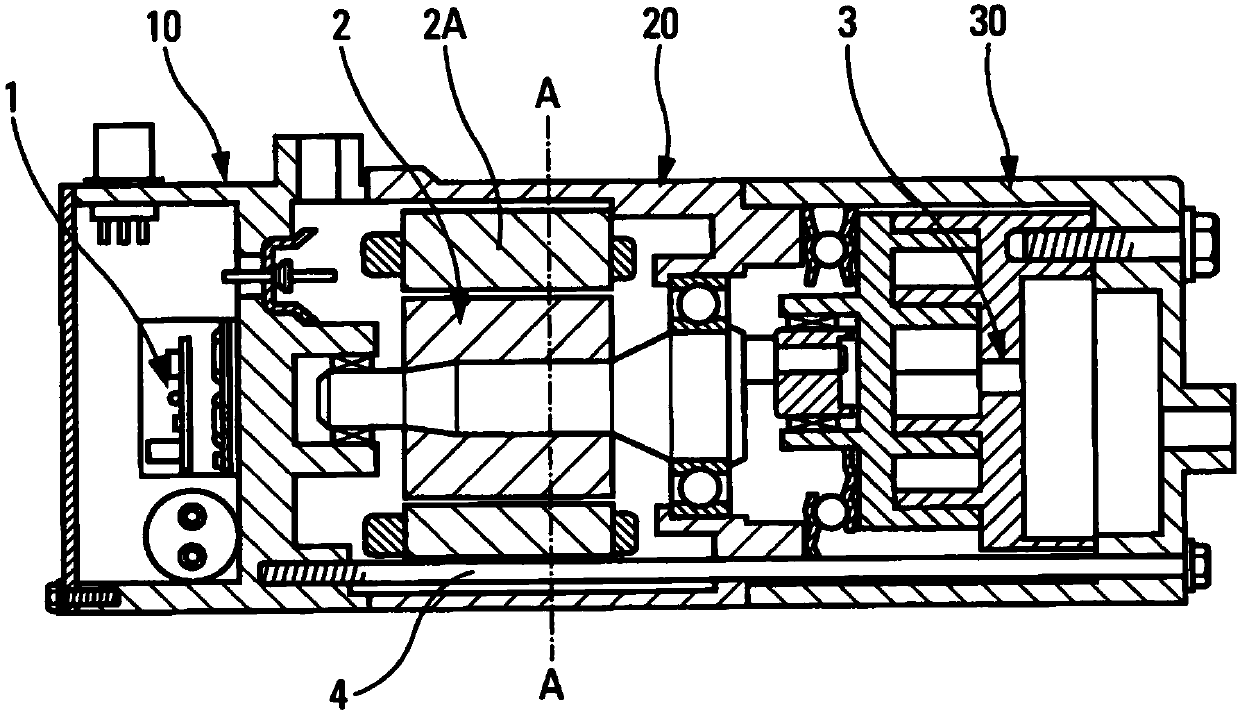

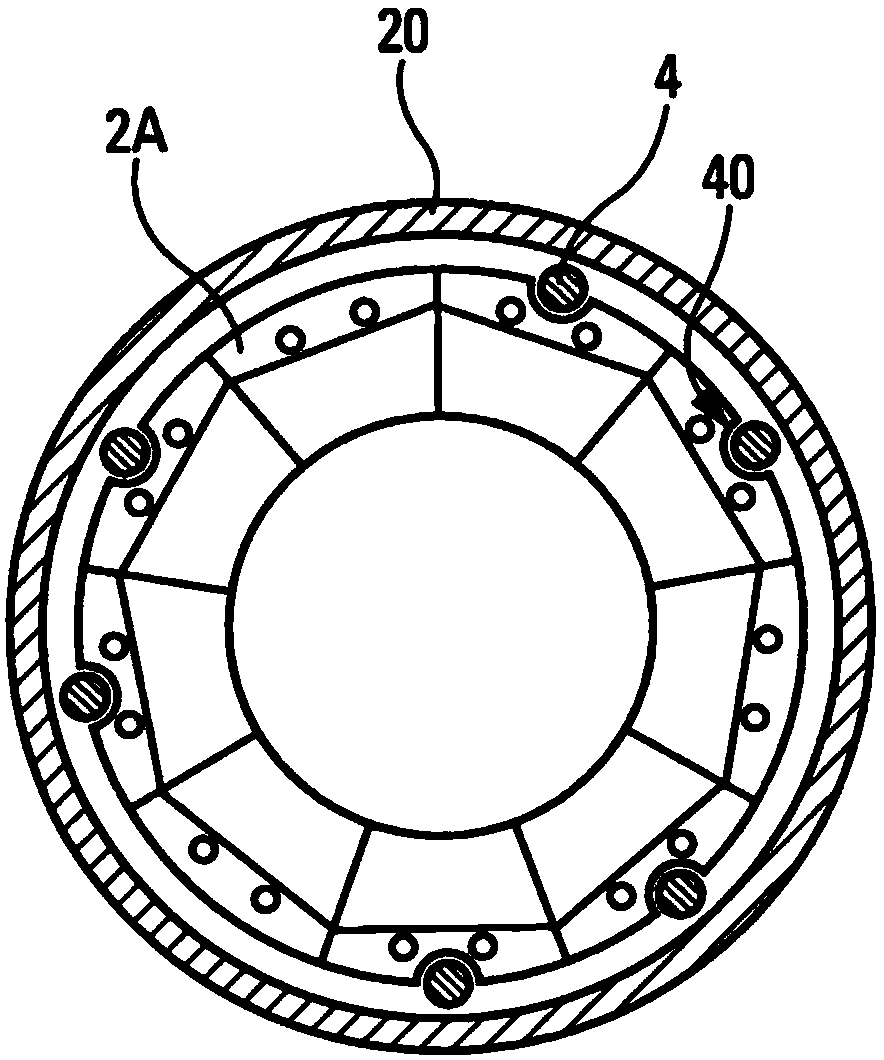

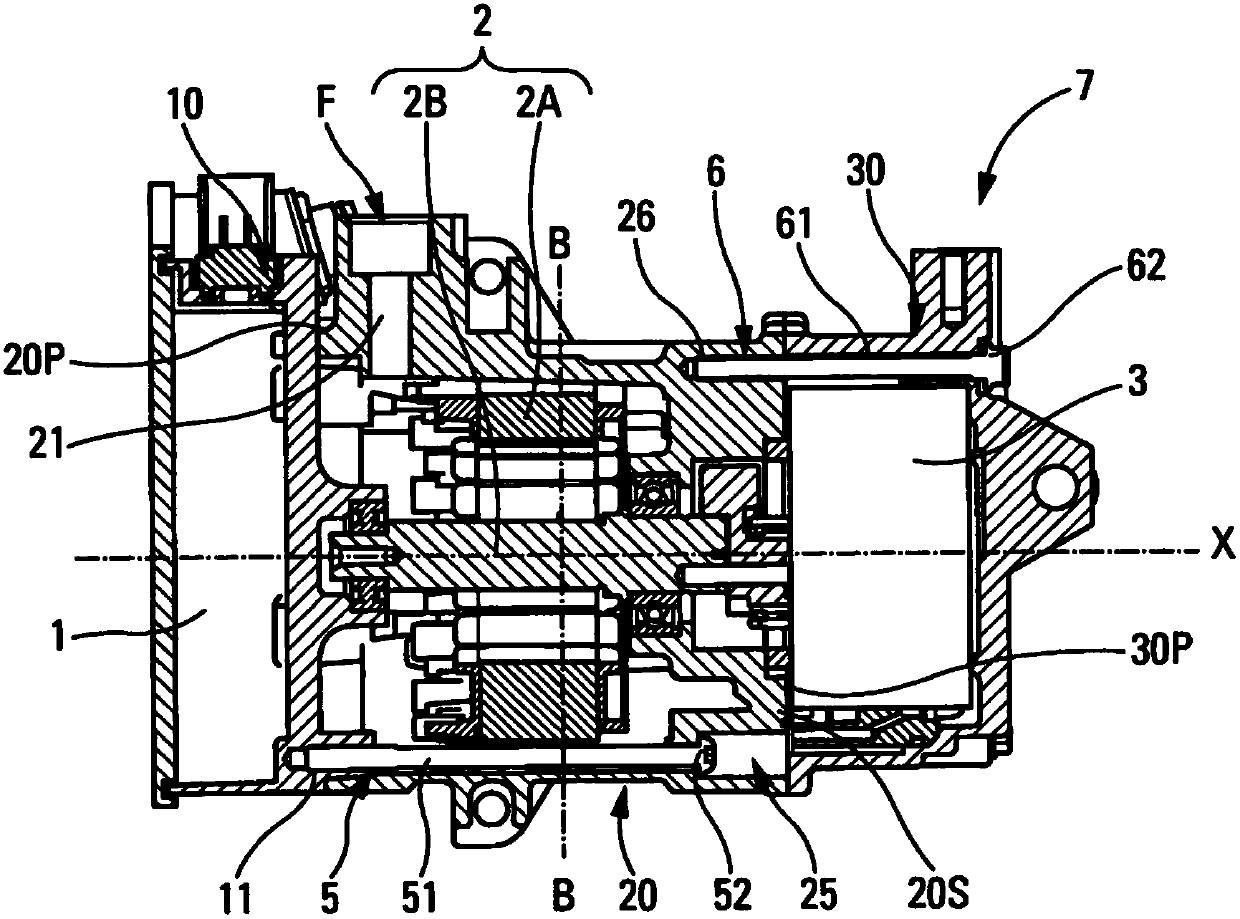

Modular electric compressor including an assembly device

InactiveCN103703249AImprove magnetic efficiencyReduce volumeRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringElectric motor

The invention relates to an electric compressor (7) comprising: a compression mechanism (3); an electric motor (2) for driving the compression mechanism (3), the electric motor having an axis of rotation (X); and an electric motor (2) power supply inverter (1). The inverter (1) is mounted in an inverter housing (10), while the electric motor (2) is mounted in a housing (20) extending longitudinally along the axis of rotation (X) and having a first end (20P) connected to the inverter housing (10) by a plurality of securing devices (5). According to the invention, the motor (2) comprises a stator (2A) of circular periphery. Moreover, the internal periphery of the motor housing (20) is provided with a plurality of protuberances (23) that are in contact with the circular periphery of the stator (2A), and the internal periphery of the motor housing (20) is provided with a plurality of openings (29), between two consecutive protuberances (23), with at least one securing device (5) extending through the openings.

Owner:VALEO JAPAN CO LTD

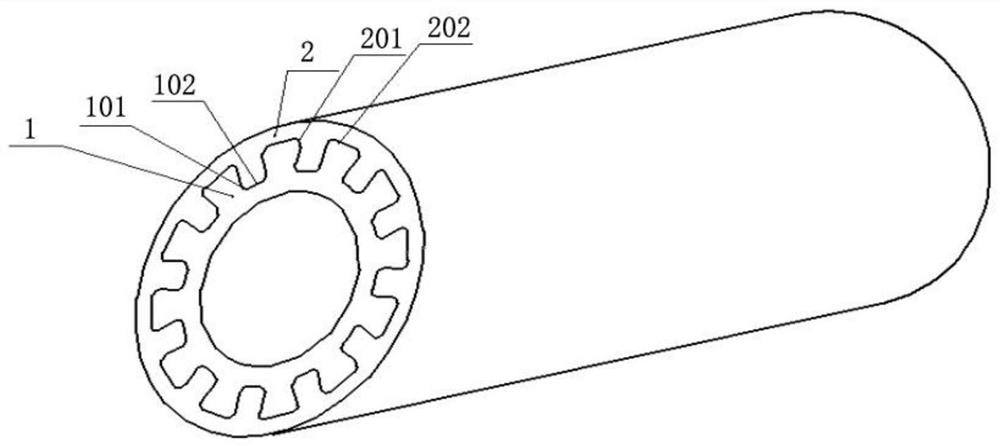

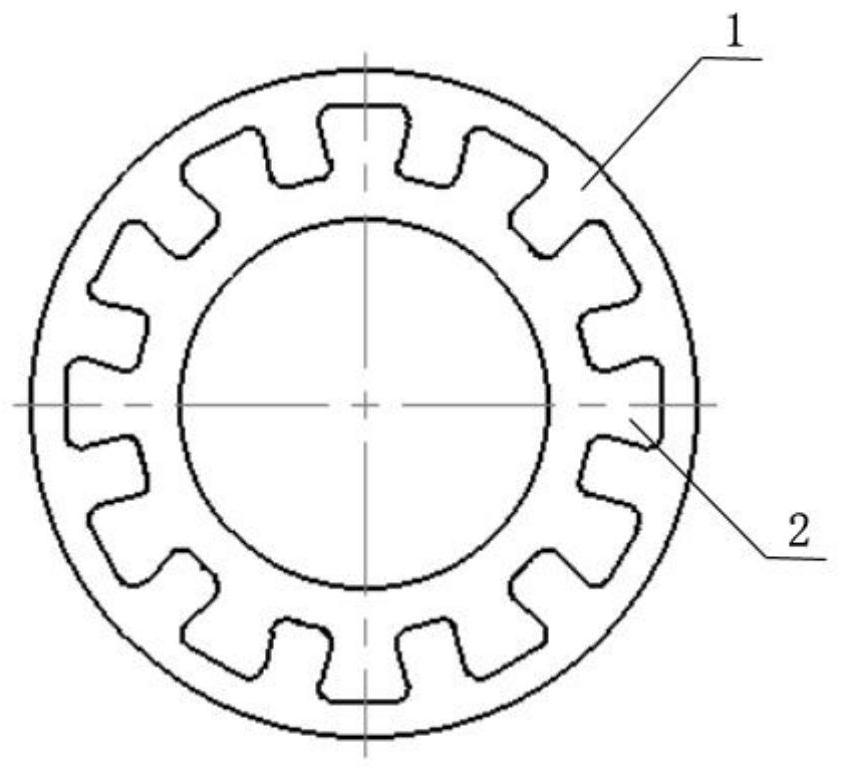

Rib type coupled wear-resistant composite lining repair pipe and lining repair method

ActiveCN114877168AApplicable deliveryExcellent wear resistanceGeneral water supply conservationRigid pipesElastomerPolyolefin

The invention discloses a rib type coupled wear-resistant composite lining repair pipe and a lining repair method.The rib type coupled wear-resistant composite lining repair pipe comprises an inner layer and an outer layer, the inner wall of the inner layer is a smooth annular wall face, and a plurality of groove structures arranged in the axial direction are formed in the outer wall of the inner layer in the circumferential direction of the inner layer; a rib structure is formed between every two adjacent groove structures on the outer wall of the inner layer, and the outer layer wraps the peripheries of the groove structures and the rib structures of the inner layer. The inner layer of the lining repair pipe is prepared from a polyolefin elastomer wear-resistant material Si-TPE by adopting an advanced polymer modification technology, the lining repair pipe has excellent wear resistance and processability, the wear-resistant mechanism of the lining repair pipe is that impact and cutting of solid particles on the inner surface of the pipe are buffered through elastic deformation by applying the material characteristics of an elastomer, and the wear resistance of the lining repair pipe is improved. The double-phase medium conveying device can be well suitable for conveying solid-phase and liquid-phase media.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD +1

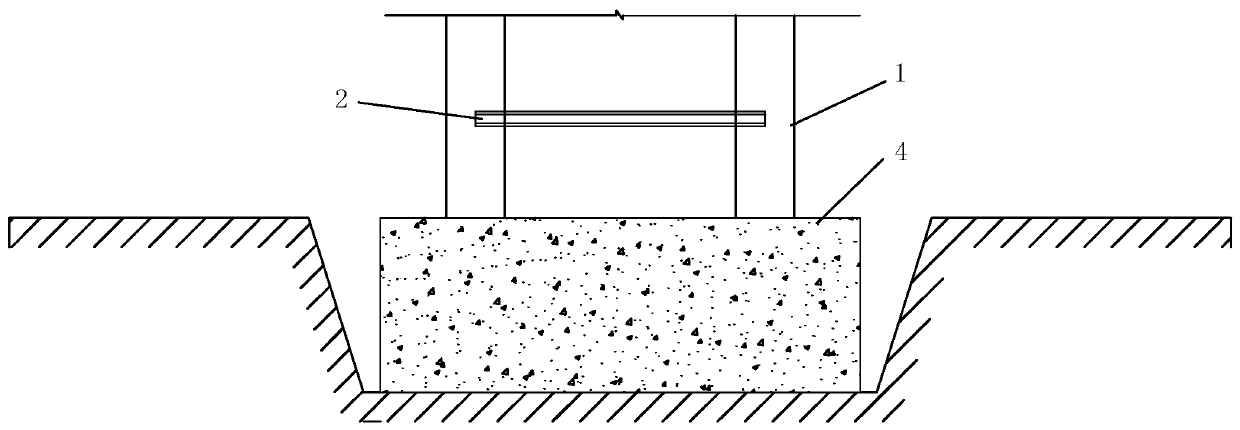

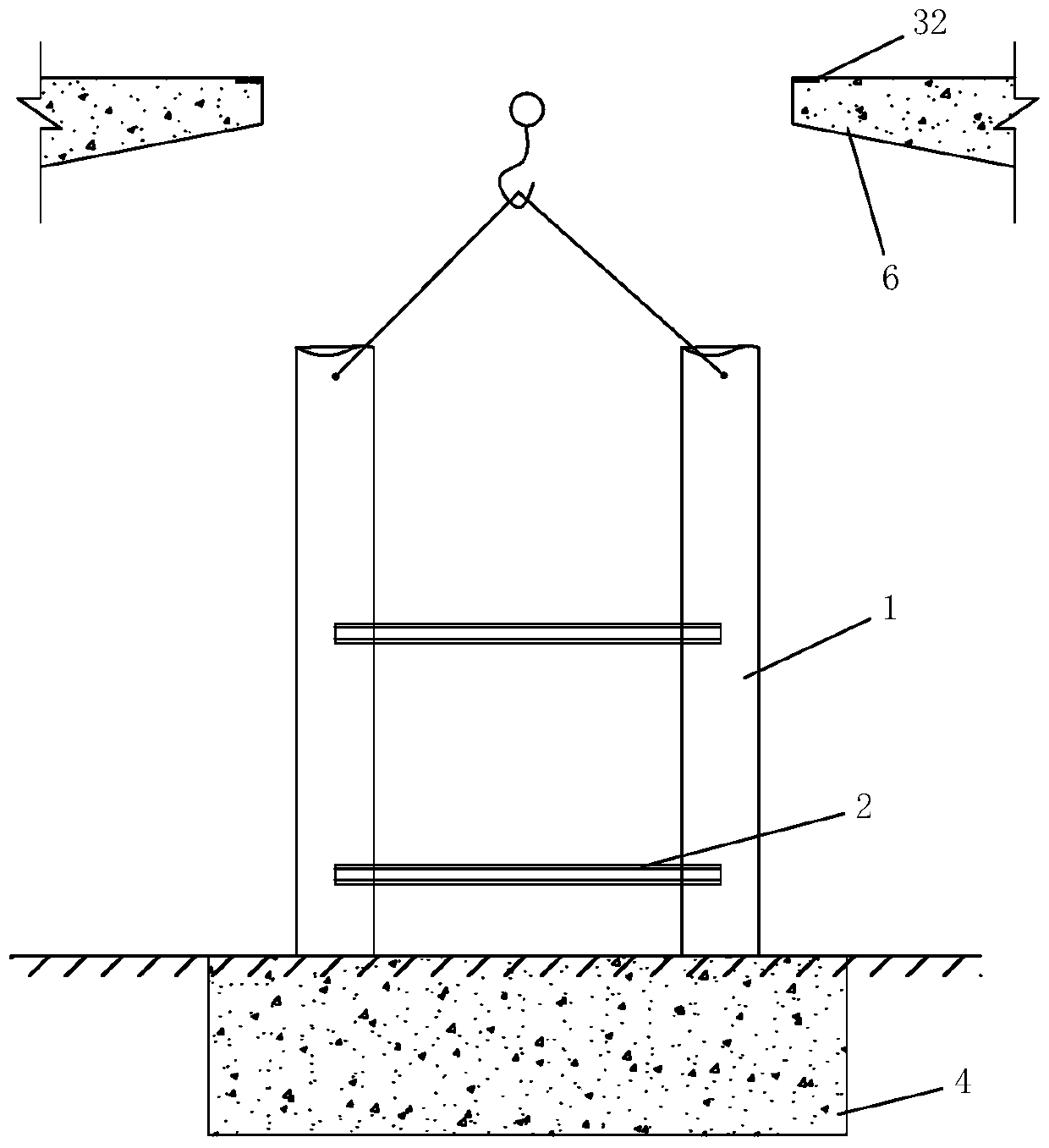

Overhead attached type vertical steel pipe truss for assisting in mounting pump pipe and construction method thereof

PendingCN110878528AImprove carrying capacityImprove stabilityBridge erection/assemblyBuilding material handlingEngineeringPipe

The utility model discloses an overhead attached type vertical steel pipe truss for assisting in mounting a pump pipe. The truss comprises truss steel pipe stand columns, truss cross rods, truss attachment rods and truss foundations. The number of the truss steel pipe stand columns is two. The two truss steel pipe stand columns are installed on the truss foundation at a certain interval, and the two sides of the opposite faces of the two truss steel pipe stand columns are connected by welding a plurality of truss transverse rods. A full-length truss internal space is formed between the multiple truss cross rods and the two truss steel pipe stand columns, and the truss internal space is used for pump pipe stand pipe installation and maintenance operation. The truss attachment rods are arranged on the upper portions of the truss steel pipe stand columns, located in the middles of the left width and the right width of the main bridge on the top of the truss and fixedly connected with thebridge structure body through embedded iron pieces. The truss is of an assembled structure and has the advantages of being small in size and good in bearing capacity, and therefore the stability of the pump pipe is improved.

Owner:广西建工第五建筑工程集团有限公司

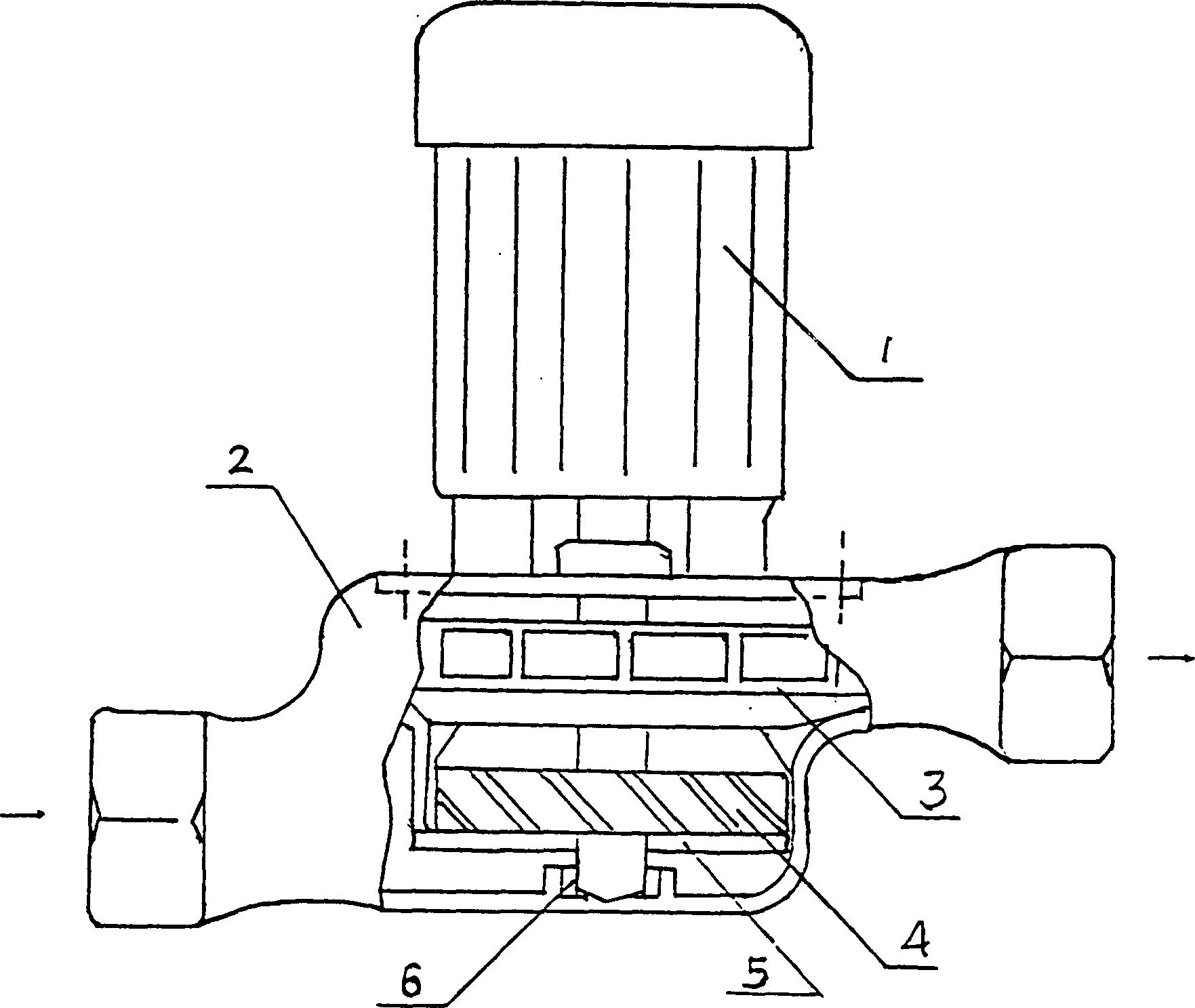

Integral pump

InactiveCN1111256CApplicable deliveryCompact structurePump componentsPump installationsCircular discControl theory

An integrated pump, an improved water pump, features that the long motor shaft fixed to pump body passes sequentically through centrifugal blade wheel, rotary vane wheel and despin disk. Its advantages include compact structure, low rotation speed and noise, high flow and long service life.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

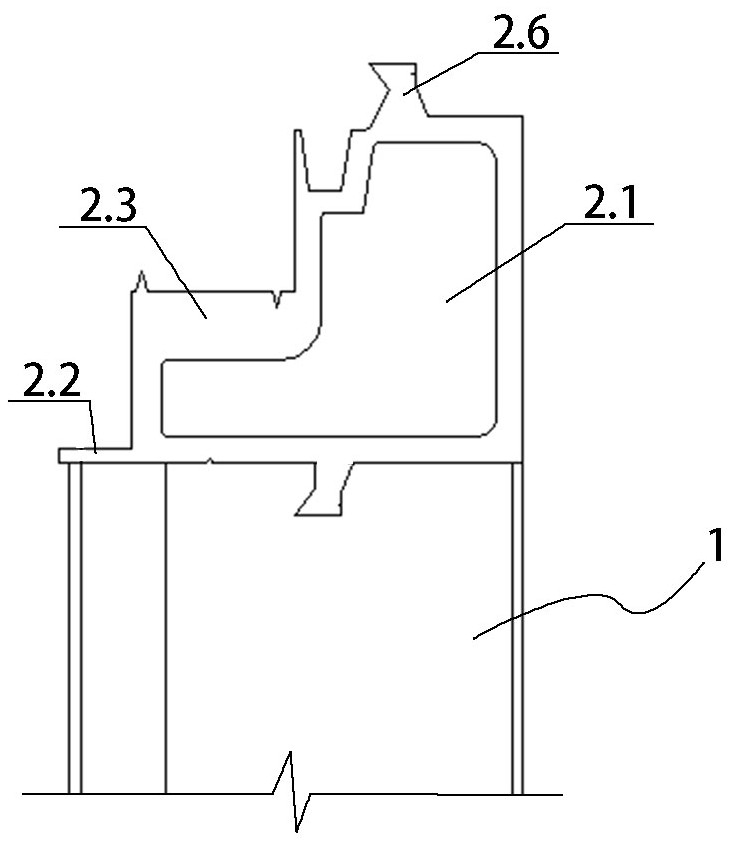

Global modular fast-installation shelters and special-shaped aluminum profiles, butt-joint aluminum profiles and construction methods

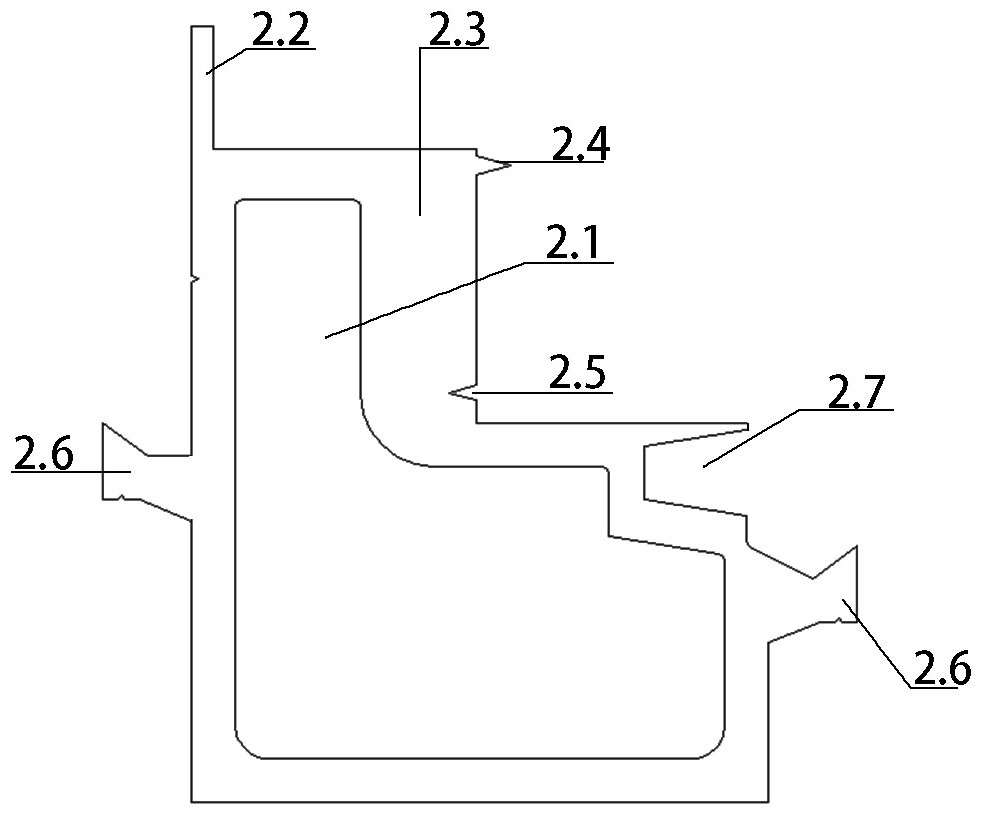

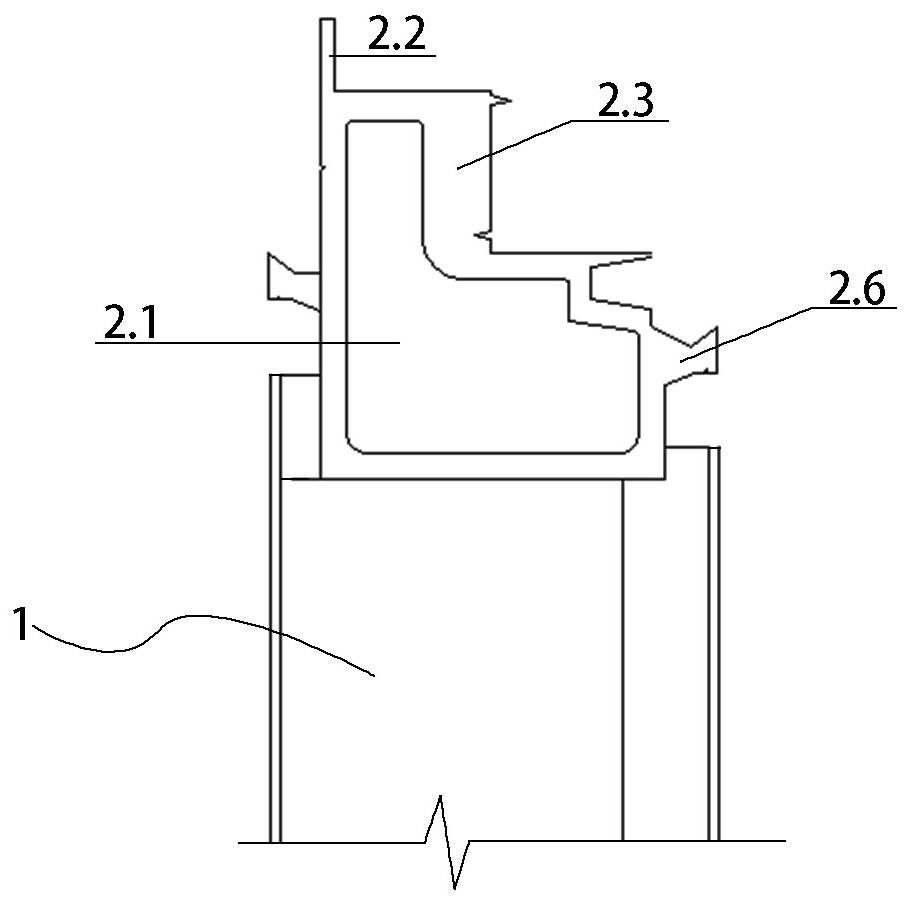

ActiveCN110331814BApplicable deliverySmall footprintBuilding insulationsArchitectural engineeringAir tightness

Global modular fast-installation shelter and special-shaped aluminum profiles, butt aluminum profiles and construction methods, the adjacent panels of the shelter are connected by butt-joint aluminum profiles; butt-joint aluminum profiles include two snap-fit joints of profiled aluminum profiles and buckle covers; The cross-section of the aluminum profile is L-shaped, and the connecting plates of the two special-shaped aluminum profiles are combined and connected by bolts, and the concave and convex parts form a tongue-and-groove connection; Cooperate with the blocking plate to realize the sealing of the connection seam. The invention adopts the method of making modules in the factory and splicing and assembling on site, which has low cost, less land occupation, convenient installation, short construction time, high strength, structural strength and rigidity all meet the requirements, and strong seismic performance; Simple and reliable; the overall keel frame is easy to bear heavy equipment boxes; filled with polyurethane foam, it has good air tightness and high structural strength; there is no special requirement for on-site construction conditions, green and environmentally friendly, and cost-effective.

Owner:衡水通广通信导航设备有限公司

Production method of stainless steel brazing composite seamless pipe fittings

The invention relates to a production method of a stainless steel brazed composite seamless pipe fitting. The production method comprises the following steps: firstly selecting a carbon steel seamlesssteal pipe and machining the inner surface of the carbon steel seamless steal pipe; then selecting a stainless steel pipe with the same length as the carbon steel seamless steal pipe, and machining the outer surface of the stainless steel pipe; placing the machined stainless steel pipe into the machined carbon steel seamless steal pipe, and filling a brazing material between two layers of the steel pipes, wherein, the brazing material is a Ag-Cu-Ni high-temperature silver-based brazing material with a high silver content; and machining the obtained composite pipe according to the pipe fittingdesired to be produced to obtain the finished pipe fitting with the desired size and shape, wherein, the heating temperature is 910-960 DEG C. The production method has the advantages of producing the stainless steel brazed composite seamless pipe fitting with high bonding strength and being applicable to middle-pressure pipe transportation and high-pressure pipe transportation.

Owner:JIANGYIN CHEM MASCH CO LTD

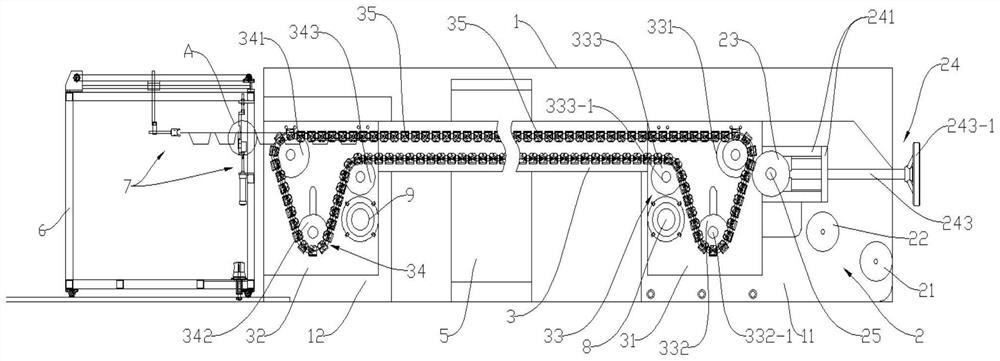

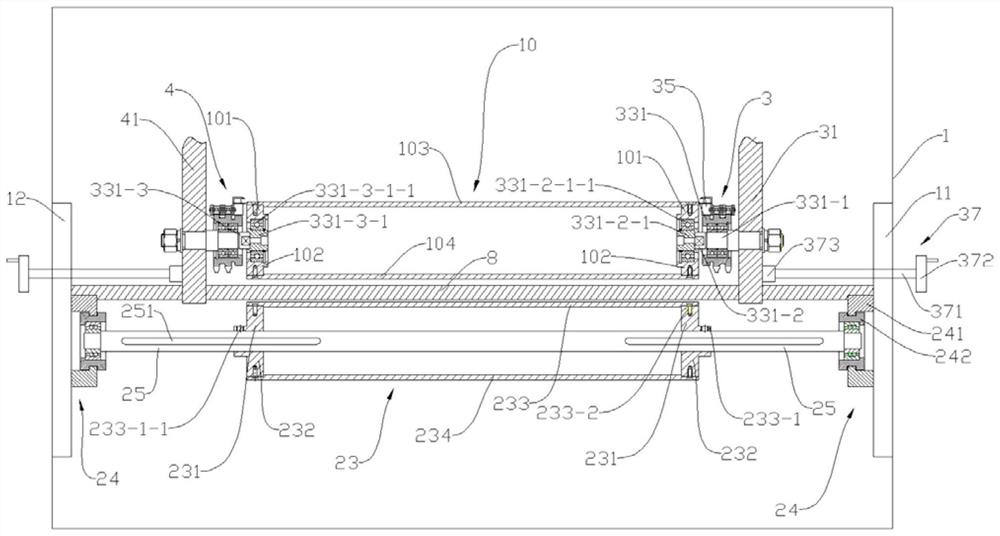

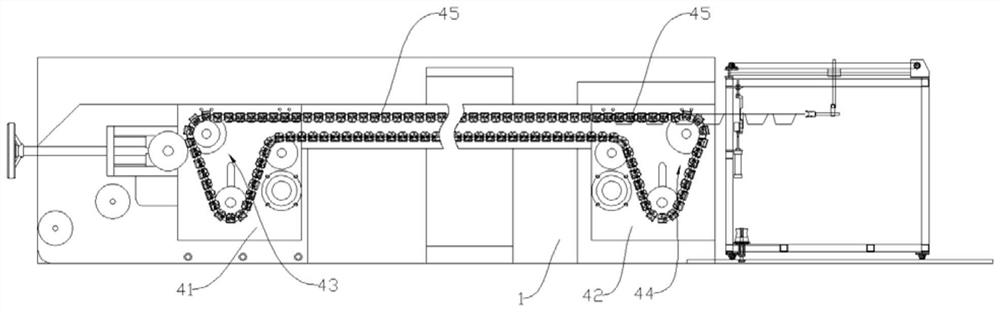

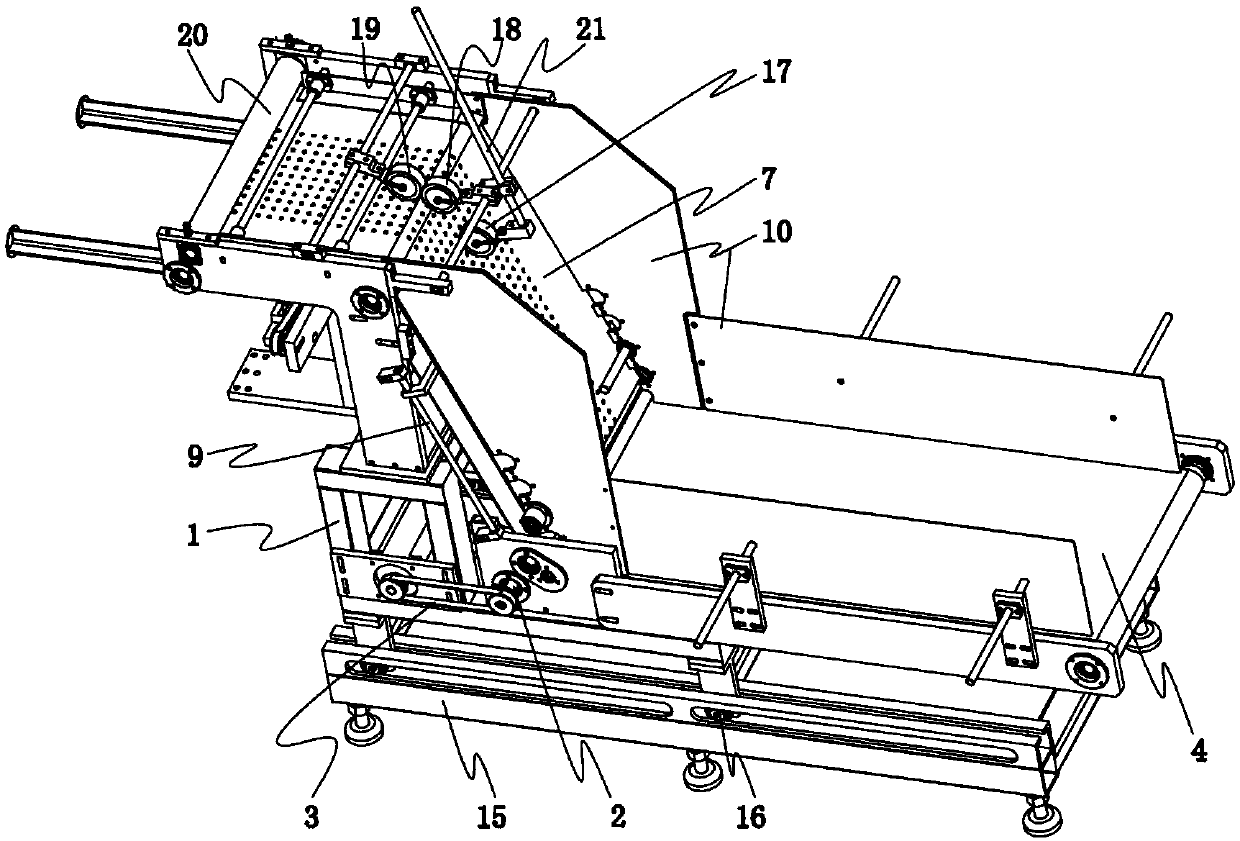

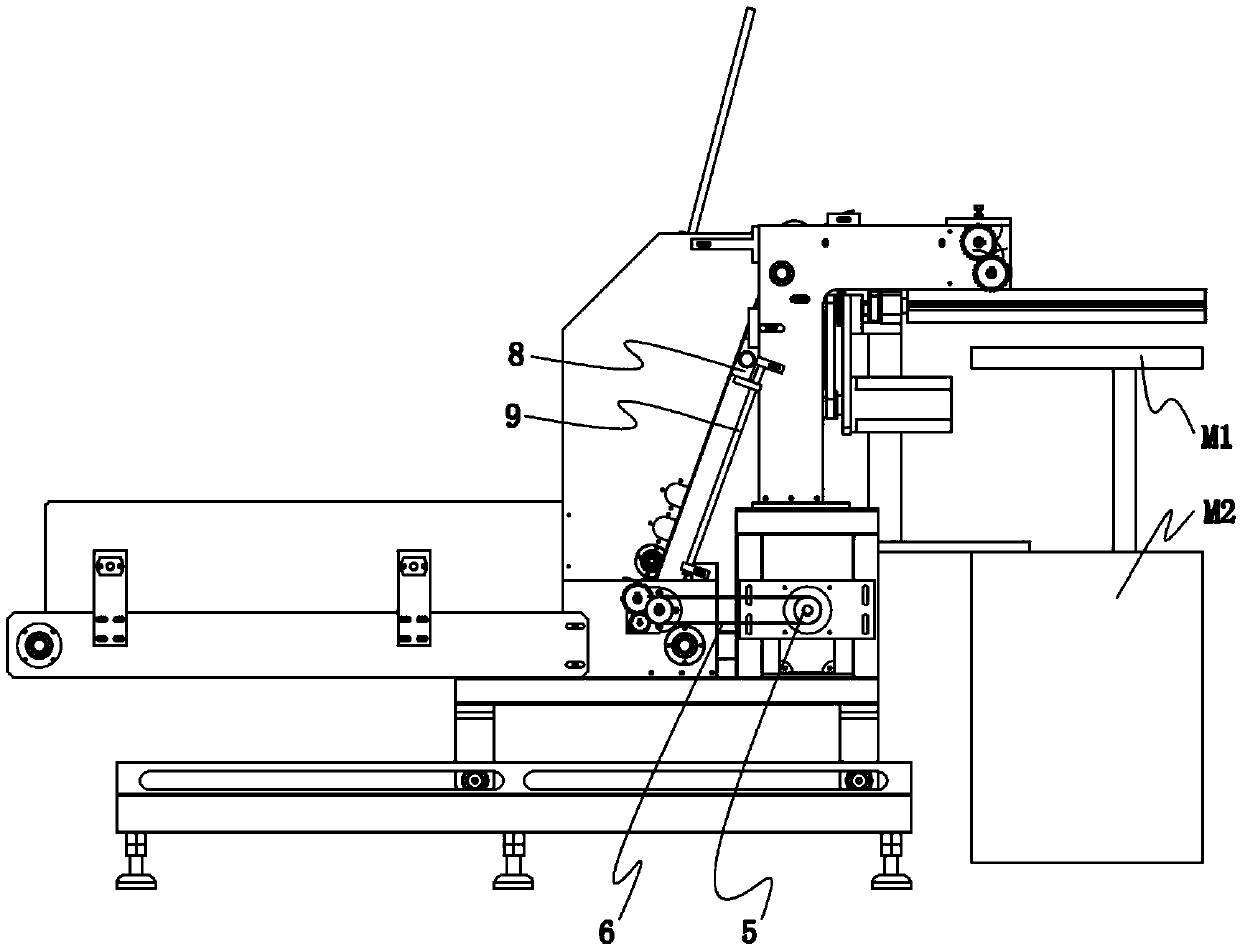

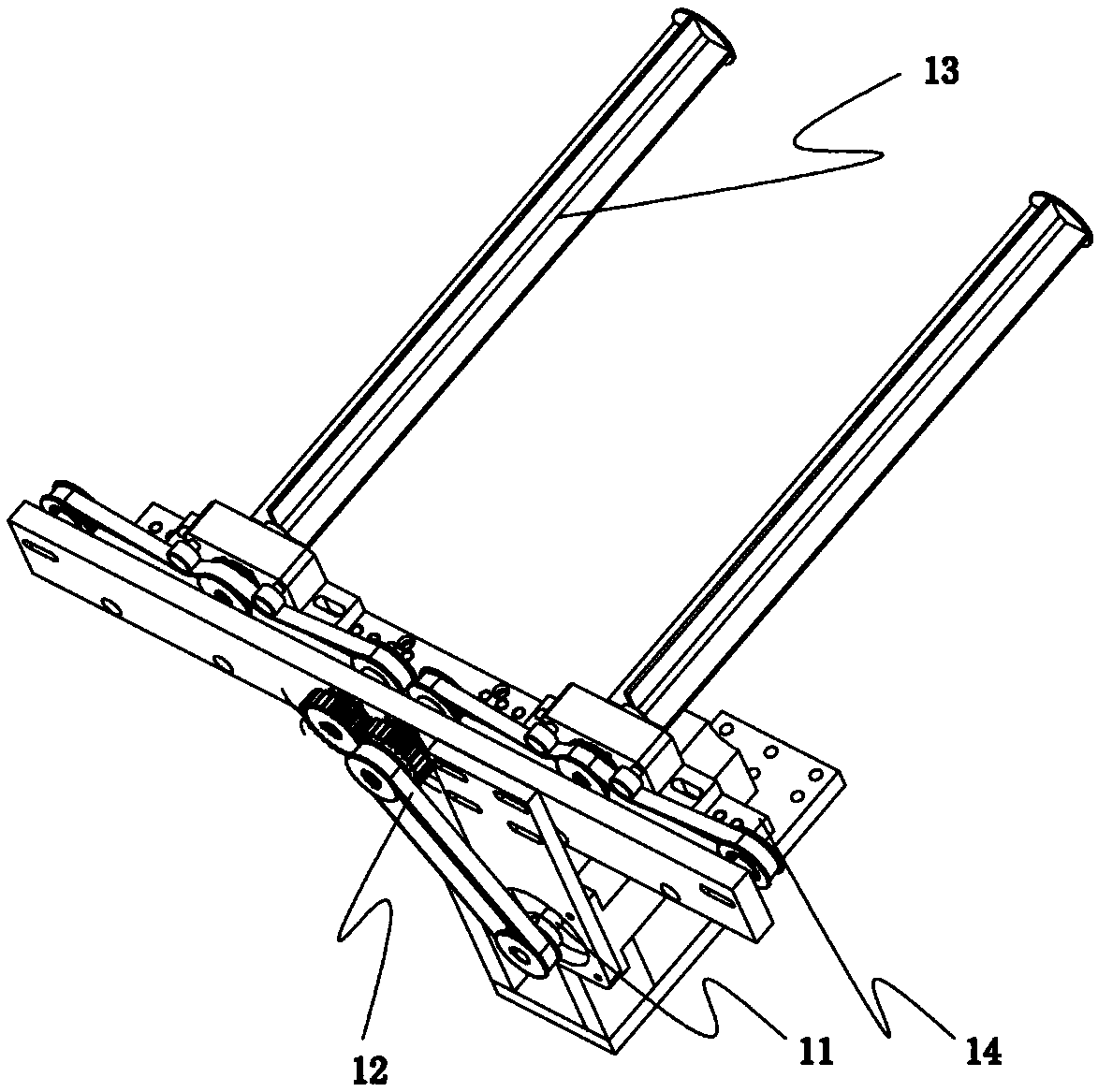

Novel plastic uptake forming machine

The invention discloses a novel plastic uptake forming machine which comprises a forming work frame, a first clamping conveying mechanism, a second clamping conveying mechanism, a forming module, a clamping mechanism, a movable guide roller and a leveling roller, wherein the movable guide roller and the leveling roller are rotationally arranged between the head end of the first clamping conveying mechanism and the head end of the second clamping conveying mechanism, the first clamping conveying mechanism and the second clamping conveying mechanism are symmetrically arranged on the two sides in the length direction in the forming work frame, the clamping mechanism is arranged between the tail end of the first clamping conveying mechanism and the tail end of the second clamping conveying mechanism, and movable mechanisms are arranged between the first clamping conveying mechanism and the two sides in the length direction in the work frame and between the second clamping conveying mechanism and the two sides in the length direction in the work frame. The novel plastic uptake forming machine has the beneficial effects that the device is suitable for processing and slitting sheets with lower hardness, and can quickly adapt to the width requirements of different sheets for adjustment and production.

Owner:SHANTOU LONGSHENG INDAL

Composite pipeline

ActiveCN110260058BApplicable deliveryGood heat insulationThermal insulationPipe elementsStructural engineeringPipe

The invention discloses a composite conveying pipeline. The composite conveying pipeline comprises an outer pipe and an inner pipe, wherein the inner pipe is arranged in a hollow cavity in the outer pipe in a suspended mode; a first sealing cover is arranged on one side of the outer pipe; a second sealing cover is arranged on the other side of the outer pipe; the first sealing cover and the second sealing cover seal two sides of the whole outer pipe; an inner conveying channel is arranged in the middle of the inner pipe; a first assembling convex part is arranged at the end part of the inner side of the first sealing cover; a second assembling convex part is arranged at the end part of the inner side of the second sealing cover; the first assembling convex part and the second assembling convex part seal the whole inner conveying channel; one or more sealing devices are arranged in the inner conveying channel at equal distances; and a soft section is arranged in the middle of the first assembling convex part. The composite conveying pipeline is particularly suitable for conveying fluid products such as petroleum, crude oil can be filtered, the fluidity of the crude oil can be guaranteed, and if the middle of a pipeline is cut off, oil leakage does not occur, the rapid blocking can be realized, and the waste of resources is reduced.

Owner:义乌市丹航科技有限公司

Modular electric compressor including assembly unit

InactiveCN103703249BImprove magnetic efficiencyReduce volumeRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringElectric motor

The invention relates to an electric compressor (7), which includes: a compression mechanism (3); an electric motor (2) for driving the compression mechanism (3), the electric motor having a rotation axis (X); and an electric motor (2) Power supply inverter (1). The inverter (1) is installed in the inverter housing (10), and the electric motor (2) is installed in a housing (20) that extends longitudinally along the rotation axis (X) and has It is connected to the first end (20P) of the inverter housing (10) by a plurality of fixing devices (5). According to the invention, the electric motor (2) includes a stator (2A) with a circular periphery. In addition, the inner periphery of the motor housing (20) is provided with a plurality of protrusions (23) that contact the circular periphery of the stator (2A), and the inner periphery of the motor housing (20) is provided with a plurality of openings (29) ), between two consecutive protrusions (23), at least one fixing device (5) extends through said opening.

Owner:VALEO JAPAN CO LTD

A centralized automatic control switching feeding system and its control method

ActiveCN105327839BWon't happenAvoid Static SparksLiquid surface applicatorsCoatingsDiaphragm pumpAutomatic control

The invention relates to a centralized automatic control switching feeding system and a control method thereof in the field of optical fiber manufacturing. Including central material tank, weighing device, diaphragm pump, air bubble warning device, control valve 1, control valve 2, control valve 3, control valve 4, defoaming device, paint filter, main pipeline, control valve 5, paint bucket, Feed pipe, paint liquid level sensor, discharge pipe, central controller and upper computer; the central material tank is placed on the weighing device, the central material tank is connected to the diaphragm pump through a flexible hose, and the outlet of the diaphragm pump is connected to the air bubble warning The device is connected, the paint filter is connected to the main pipeline, the branches of the main pipeline are respectively connected to the paint buckets of each line, and the central controller is connected to the upper computer.

Owner:ZHONGTIAN TECH FIBER OPTICS +2

Preparation process of wear-resistant elbow material

The invention discloses a wear-resistant elbow material. The formula of the wear-resistant elbow material comprises the following components: 3.3 to 3.7 percent of carbon, 2.3 to 2.8 percent of silicon, 0.5 to 1.0 percent of manganese, 0.4 to 1.0 percent of chromium, 0.03 to 0.06 percent of phosphorus, 0.01 to 0.02 percent of sulfur, 0.03 to 0.05 percent of magnesium, 0.01 to 0.02 percent of cerium, 0.3 to 1.0 percent of vanadium, 0.3 to 1.0 percent of neodymium, 4 to 6 percent of aluminum oxide, 3 to 6 percent of titanium diboride and the balance of iron. The invention further discloses a preparation process of the wear-resistant elbow material. The preparation process comprises the following steps of quantitative weighing, raw material smelting, spheroidizing treatment and inoculation treatment, casting molding, quenching, wear-resistant hard phase overlaying and dip-coating. The wear-resistant elbow material has the beneficial effects that the prepared wear-resistant elbow material is greatly improved, the wear resistance of an elbow is improved through a wear-resistant hard phase formed by mixing aluminum oxide and titanium diboride, and the inner wall of the elbow is dip-coated with a layer of Teflon to reduce material adhesion, so that the wear-resistant elbow is not only suitable for conveying hard substances, but also suitable for conveying soft materials.

Owner:王翔

Unsized composite pipe and manufacture thereof

InactiveCN1314919CComposite tightReduced corrosion resistanceLayered productsRigid pipesFluid transportPolyvinyl chloride

A non-adhesive composite pipe for delivering hot fluid or gas is composed of a metallic pipe, and two surficial layers which are the polyvinyl chloride layer with directional thermal shrinking memory function. Its advantages are high strength, light weight, and long service.

Owner:徐益鑫

Environment-friendly paper bag automatic feeding device and method

PendingCN109572057AApplicable and stableApplicable deliveryContainer making machineryEngineeringMechanical engineering

The invention discloses an environment-friendly paper bag automatic feeding device. The environment-friendly paper bag automatic feeding device comprises a machine frame, a bag conveying mechanism, abag feeding mechanism and a turnover bag falling mechanism, wherein the bag conveying mechanism comprises a bag conveying stepping motor, a first synchronous belt and a bag conveying conveyor belt, the bag feeding mechanism comprises a bag feeding stepping motor, a second synchronous belt, a bag feeding conveyor belt and a bag suction disc, and the turnover bag falling mechanism comprises a turnover stepping motor, a transmission gear set and a turnover rod. The invention further discloses an environment-friendly paper bag automatic feeding method adopted by the device. According to the deviceand the method, a semi-finished paper bag can be stably conveyed to a bag falling station of an environment-friendly paper bag handle sticking machine.

Owner:厦门市创凌包装设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com