Molding cooling device for processing outer insulating layer of power cable

A technology of outer insulation layer and power cable, which is applied in the direction of conductor/cable insulation, cable/conductor manufacturing, circuit, etc., can solve the problem of high processing temperature of outer insulation layer of power cable, inability to cool the outer insulation layer of cable, low cooling efficiency, etc. problems, to achieve high social use value and application prospects, avoid waste of water resources, and improve the effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

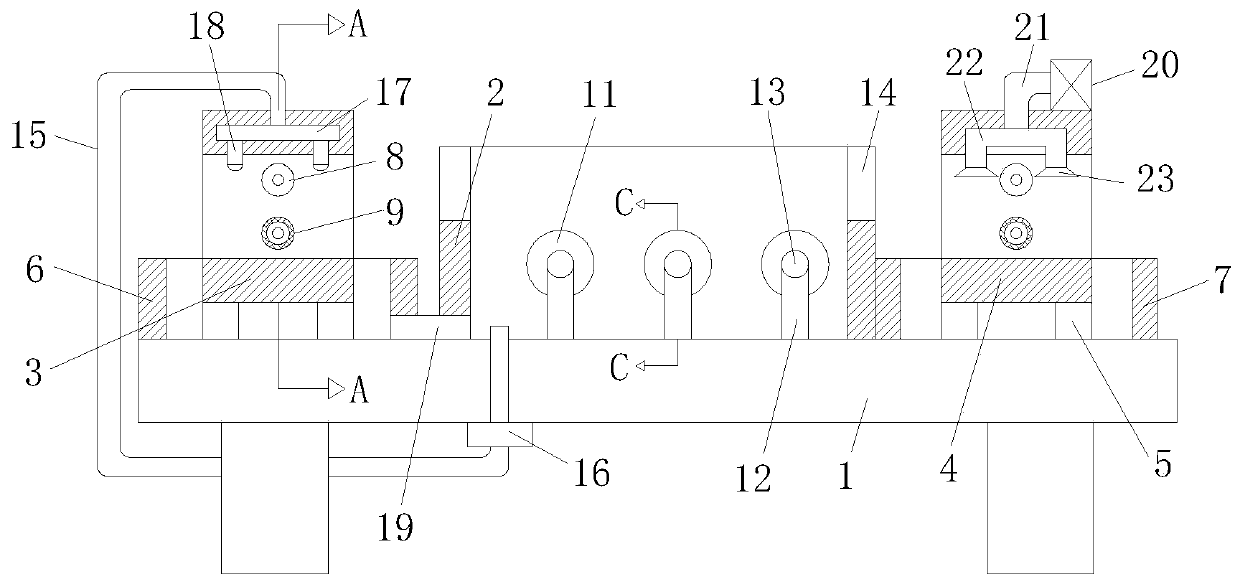

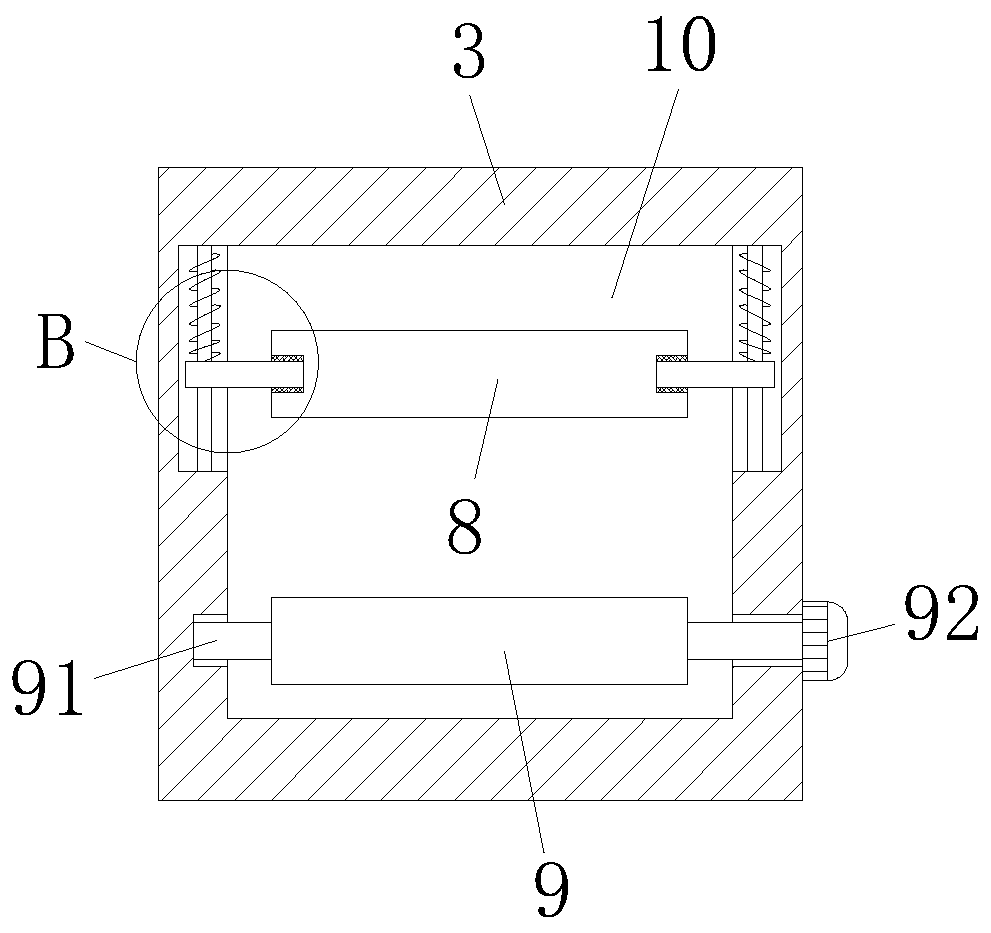

[0030] refer to Figure 1-2 , Figure 4-6 , a plastic cooling device for processing the outer insulating layer of a power cable, comprising a workbench 1 and, the upper end of the workbench 1 is provided with a spray chamber 3, a temperature-reducing water tank 2 and an air-drying chamber 4 in sequence from left to right. The bottoms of the chamber 3 and the air-drying chamber 4 are respectively fixedly connected with a fixed frame 5, the upper end of the workbench 1 and the outside of the spray chamber 3 are provided with a water storage tank 6, and several rollers 11 are equidistantly arranged in the cooling water tank 2, And the two ends of the roller 11 are respectively horizontally connected with a connecting shaft 13, the outer wall of the connecting shaft 13 is sleeved with a fixed rod 12, and the fixed rod 12 is fixed on the inner bottom of the temperature-reducing water tank 2, and the spray chamber 3 and the air-drying chamber 4 are respectively A transmission openi...

Embodiment 2

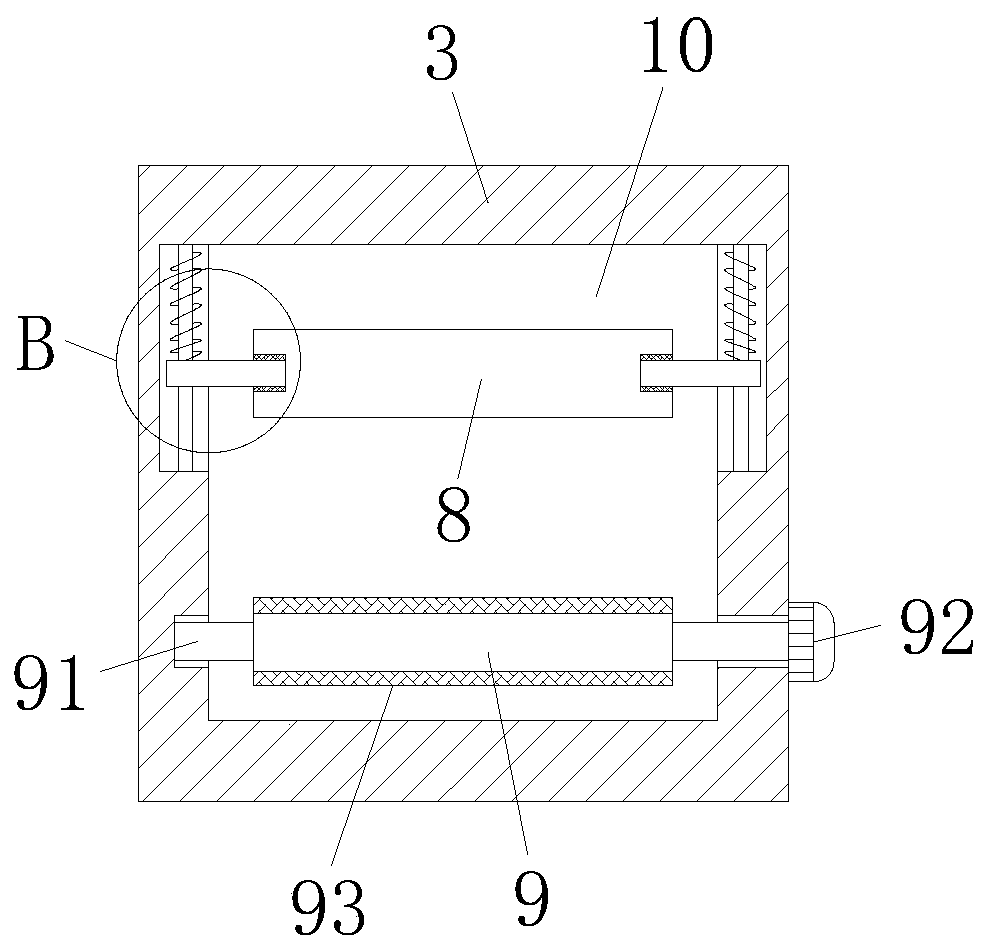

[0038] refer to figure 1 and Figure 3-6 , The difference between this embodiment and Embodiment 1 is that, wherein, the outer wall of the conveying roller 9 is provided with a layer of anti-slip rubber pad 93, and the anti-slip rubber pad 93 is a member made of rubber material, and the outer wall of the anti-slip rubber pad 93 is provided with anti-skid lines , Increase the surface friction of the conveying roller 9, which helps the transmission of the cable.

[0039] Refer to Example 1 for other undescribed structures.

[0040] Working principle: In the present invention, in the present invention, when in use, the cable to be cooled enters through the spray chamber 3, and passes through the cooling water tank 2 and then is output from the drying chamber 4. When the cable enters the spray chamber 3, The pinch roller 8 presses down the cable to the outer wall of the transmission roller 9. Since both ends of the pinch roller 8 are horizontally connected with connecting shafts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com