Concentrated automatic control switching type feeding system and control method thereof

A feeding system and switching technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of increased labor and labor intensity of operators, uncoated optical fibers, waste of raw materials, etc., to avoid manpower and material waste, eliminating the phenomenon of wrong paint replacement, reducing the effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

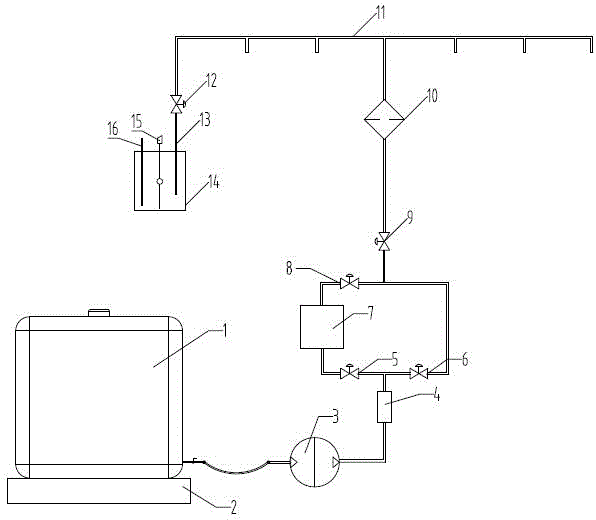

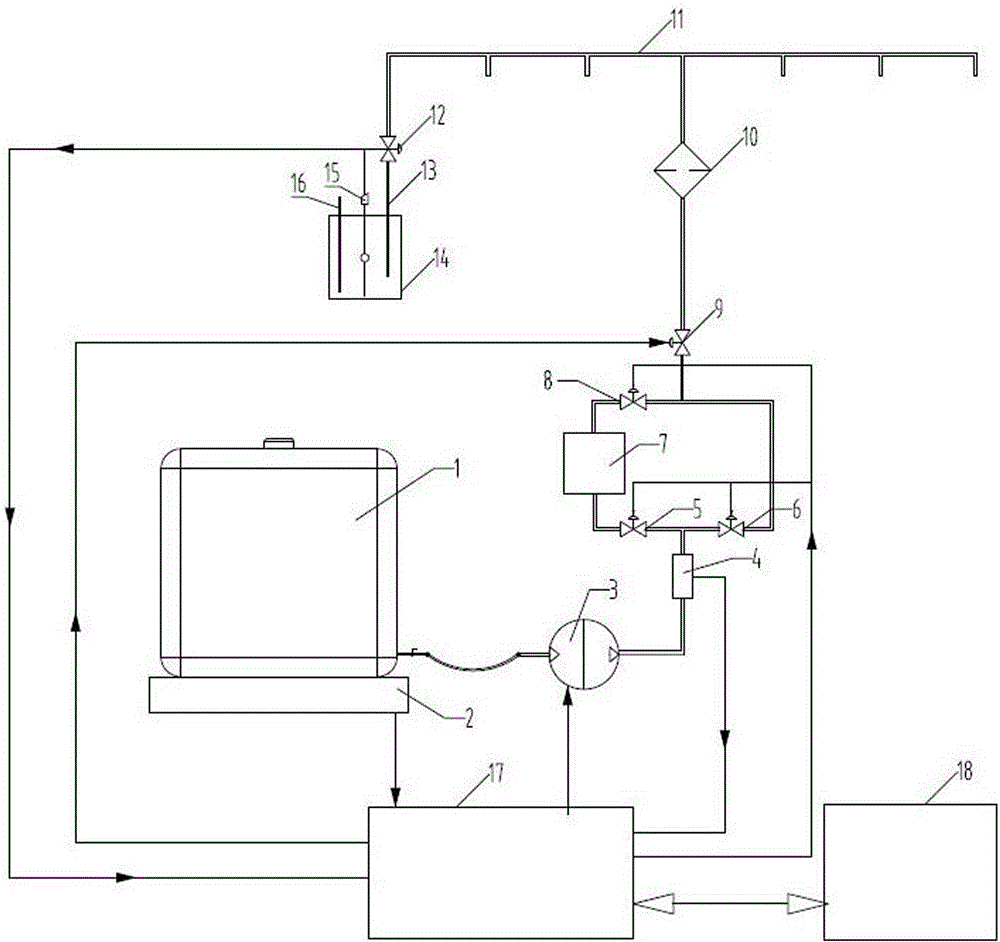

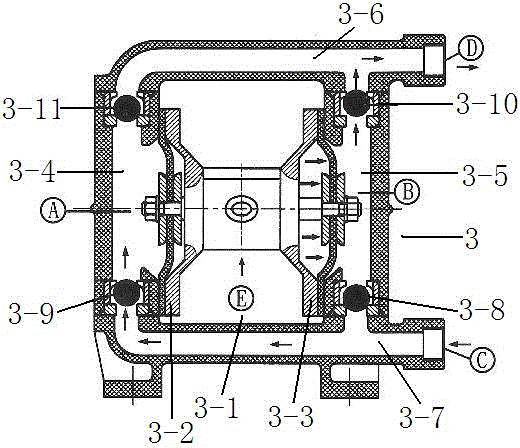

[0042] refer to Figure 1-4 , a centralized automatic control switching feeding system includes a central material tank (1), a weighing device (2), a diaphragm pump (3), an air bubble warning device (4), a control valve one (5), and a control valve two (6), control valve three (8), control valve four (9), defoaming device (7), paint filter (10), main pipeline (11), control valve five (12), paint bucket (14) , feed pipe (13), paint liquid level sensor (15), discharge pipe (16), central controller (17), central upper computer (18).

[0043] refer to figure 2 A centralized automatic control switching feeding system, the central material tank (1) is placed on the weighing device (2), the central material tank and the diaphragm pump (3) are connected through a metal hose using a quick connector, and the diaphragm pump ( 3) The outlet is connected to the bubble warning device (4), and the bubble warning device (4) is respectively connected to the control valve one (5) and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com