Marine vertical deep well liquid cargo pump

A liquid cargo pump, vertical technology, applied in the field of marine vertical deep well liquid cargo pump, can solve the problems of medium leakage, inconvenience, sealing element failure, etc., and achieve the effect of convenient maintenance and repair, long service life and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

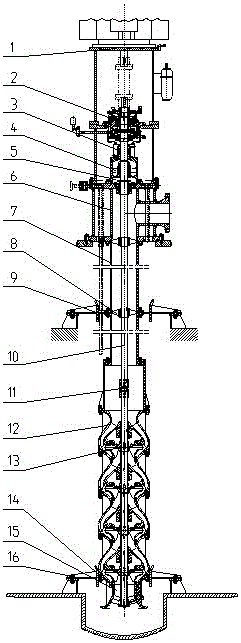

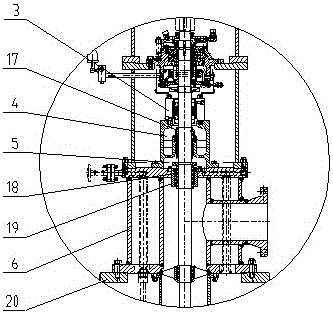

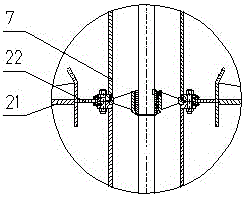

[0019] Such as figure 1 As shown, the marine vertical deep well liquid cargo pump of the embodiment of the present invention consists of a motor assembly 1, a bearing component 2, a mechanical seal 3, a gaseous cold insulation chamber 4, a buffer chamber 5, an outlet section 6, a support pipe 7, and an intermediate support frame 8 , shaft 10, connecting shaft assembly 11, middle limit assembly 9, bottom end limit assembly 16, guide shell 12, impeller 13, inducer 15, and suction section 14. Between the mechanical seal 3 and the outlet section 6, a gaseous cold insulation chamber 4 and a buffer chamber 5 are arranged in sequence from top to bottom; between the outlet section 6 and the buffer chamber 5, between the outlet section 6 and the support pipe 7, and between the two support pipes 7 Sliding bearings are set at the front and rear positions of the impellers 13 of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com