Fan assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

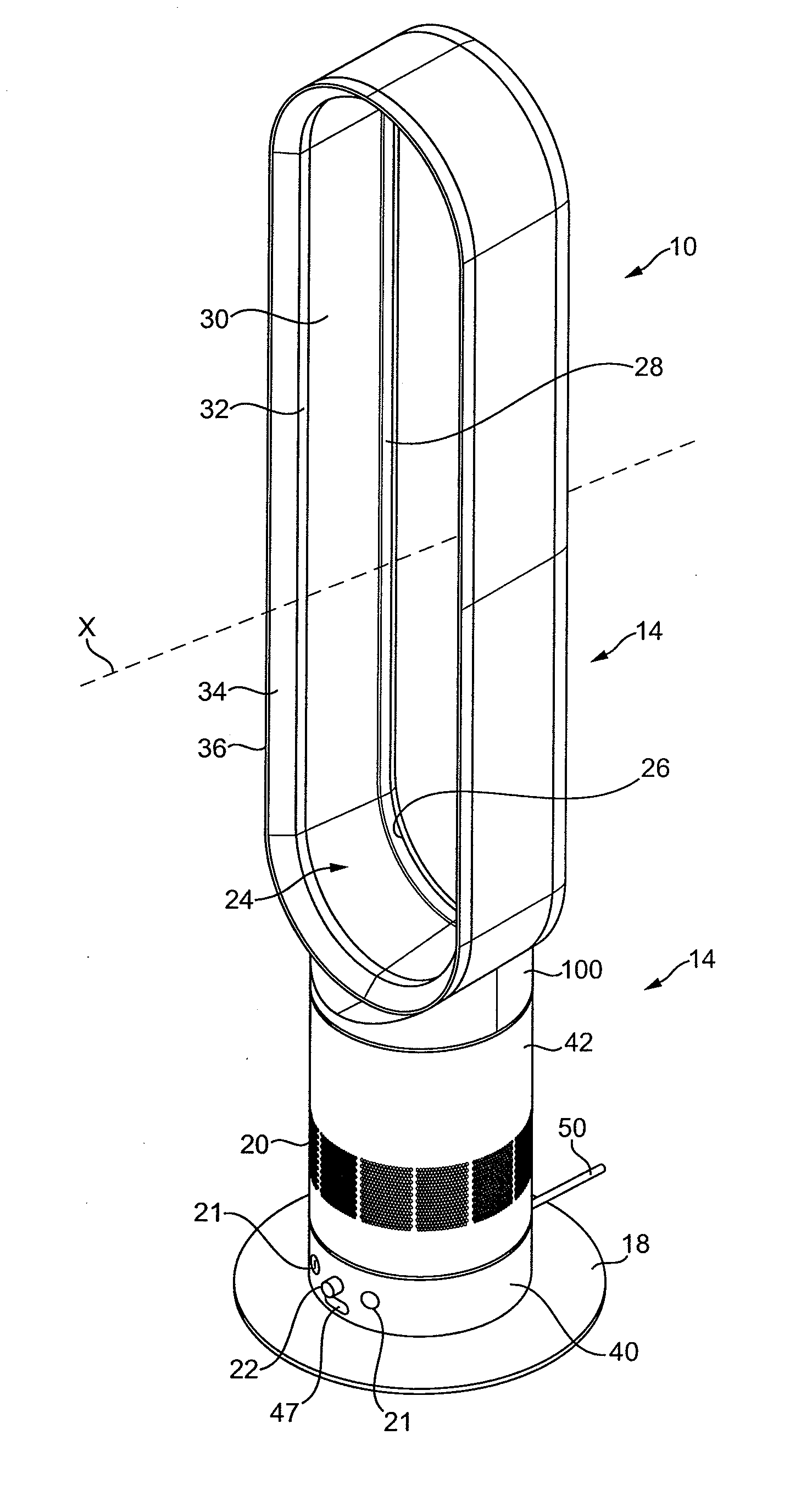

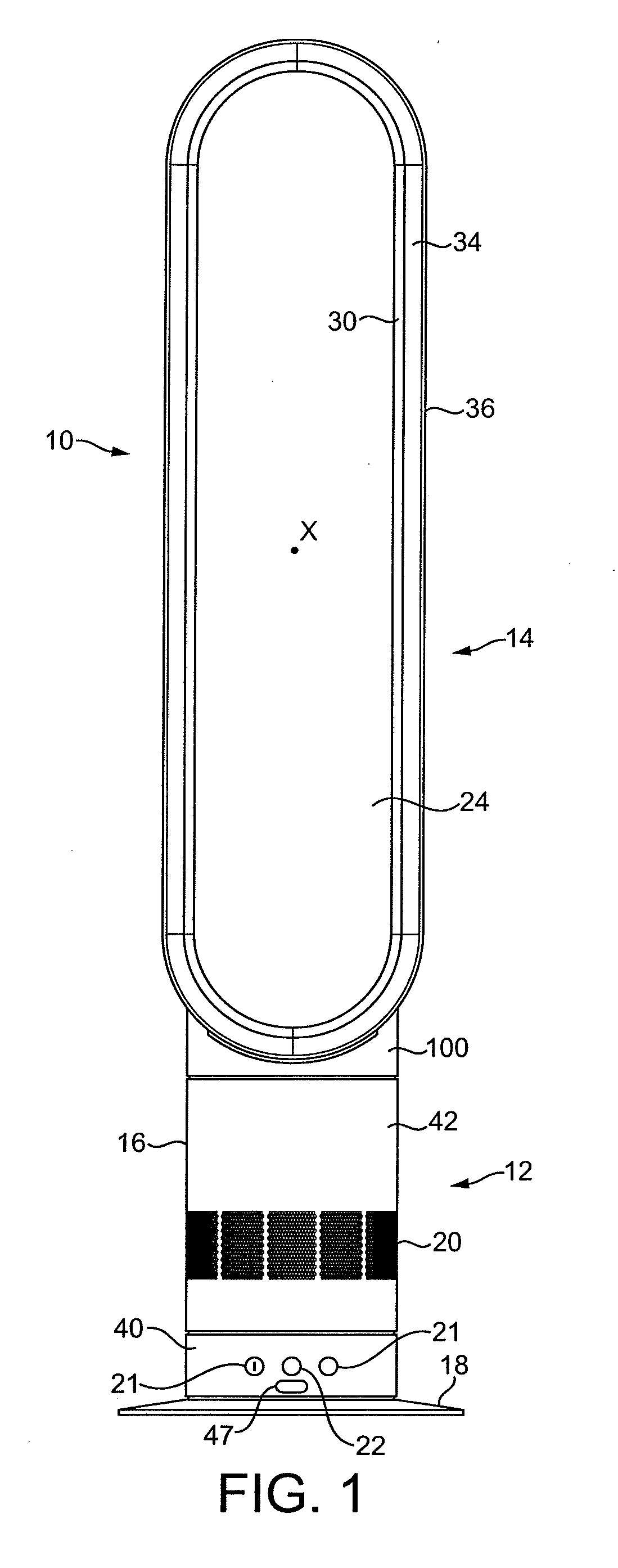

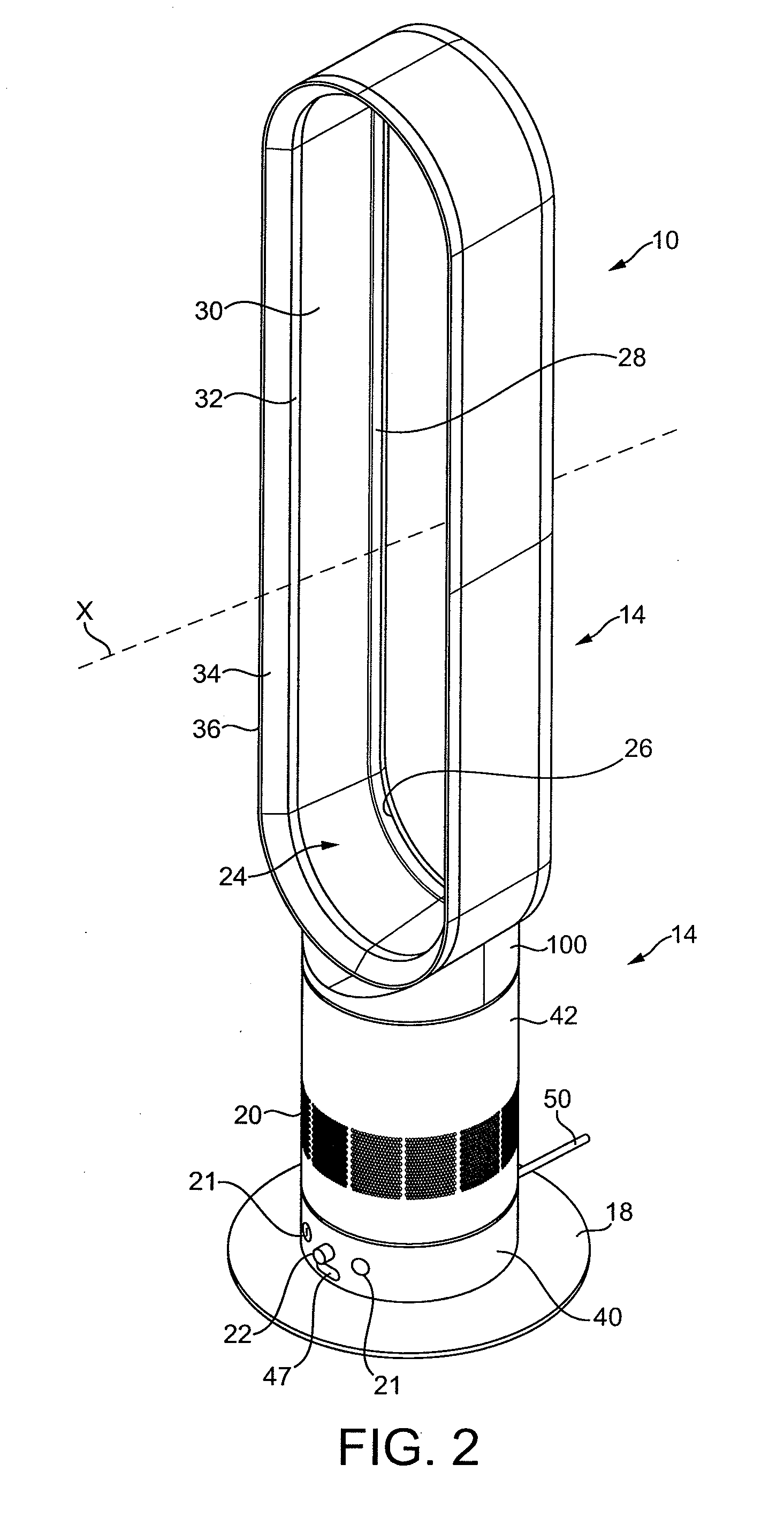

[0040]FIGS. 1 and 2 illustrate an embodiment of a bladeless fan assembly. In this embodiment, the bladeless fan assembly is in the form of a domestic, portable tower fan 10 comprising a base 12 and an air outlet in the form of a nozzle 14 mounted on and supported by the base 12. The base 12 comprises a substantially cylindrical outer casing 16 mounted optionally on a disc-shaped base plate 18. The outer casing 16 comprises a plurality of air inlets 20 in the form of apertures formed in the outer casing 16 and through which a primary air flow is drawn into the base 12 from the external environment. The base 12 further comprises a plurality of user-operable buttons 21 and a user-operable dial 22 for controlling the operation of the fan 10. In this embodiment the base 12 has a height in the range from 100 to 300 mm, and the outer casing 16 has a diameter in the range from 100 to 200 mm.

[0041]The nozzle 14 has an elongate, annular shape and defines a central elongate opening 24. The noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com