Machining process of large duplex stainless steel impeller

A duplex stainless steel and processing technology is applied in the processing technology of large-scale duplex stainless steel impeller, impeller processing technology, and the field of producing large-scale duplex stainless steel impeller for nuclear power, which can solve the problems of difficult control of processing process and large deformation of processing size. Achieve the effect of meeting the drawing size requirements and technical requirements, good processing dimensional accuracy, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] a. For impeller casting, mix molten steel according to ASTM 890 Gr5A standard, and cast the workpiece, and test block of molten steel in the same furnace; the size of the test block is implemented according to ASTM A370 standard; the cutting cap is cleaned and polished; use zx5-1250 air planer to cut quickly Riser to ensure casting size;

[0040] b. Deformation protection before heat treatment, place the workpiece obtained from the above casting on a flat bracket, and hoist the flat bracket when the workpiece enters and exits the furnace to prevent thermal deformation of the workpiece during hoisting;

[0041] c. Solution treatment, heat the above-mentioned protected workpiece to 1120°C±10°C and keep it warm for 7H, then quickly take it out of the furnace, quench and cool it in water, and re-inspect the test block for heat treatment in the same furnace;

[0042] d. Rough grinding I, cleaning and rough grinding the workpiece after the above solution treatment, and visua...

Embodiment 2

[0057] In the step c, keep warm for 9H, then quickly take out the furnace and quench in water; in the step j, keep warm for 30H, and other steps are the same as in Example 1.

Embodiment 3

[0059] In the step c, keep warm for 5H, and then quickly take it out of the furnace and quench in water; in the step j, keep warm for 36H, and other steps are the same as in Example 1.

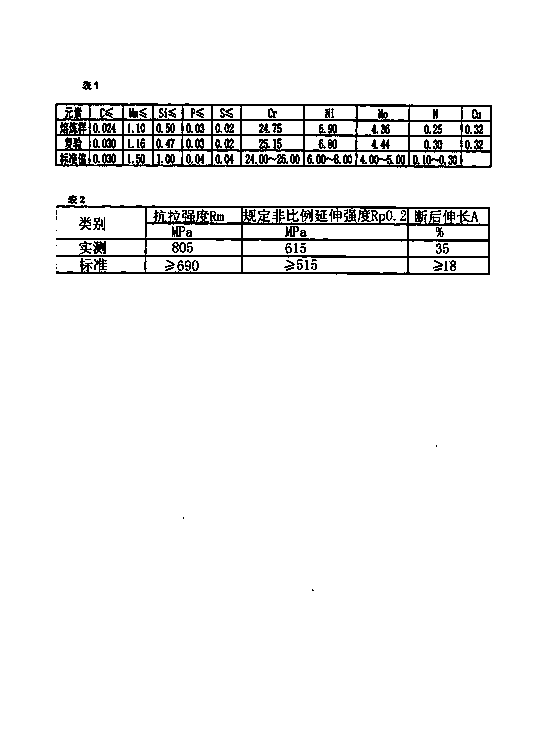

[0060] The composition weight percent composition of molten steel in the step a of the present invention is as shown in Table 1, and the remaining composition is iron and unavoidable trace elements.

[0061] The mechanical properties of the present invention are as shown in table 2 after inspection.

[0025] In the step f, according to the ASME SE1030 metal radiography inspection standard test method, the rest of the surface liquid penetration inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com