Integral pump

A composite pump, pump body technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of easy failure, short service life, small liquid flow, etc., to achieve low failure rate, long service life, and low noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

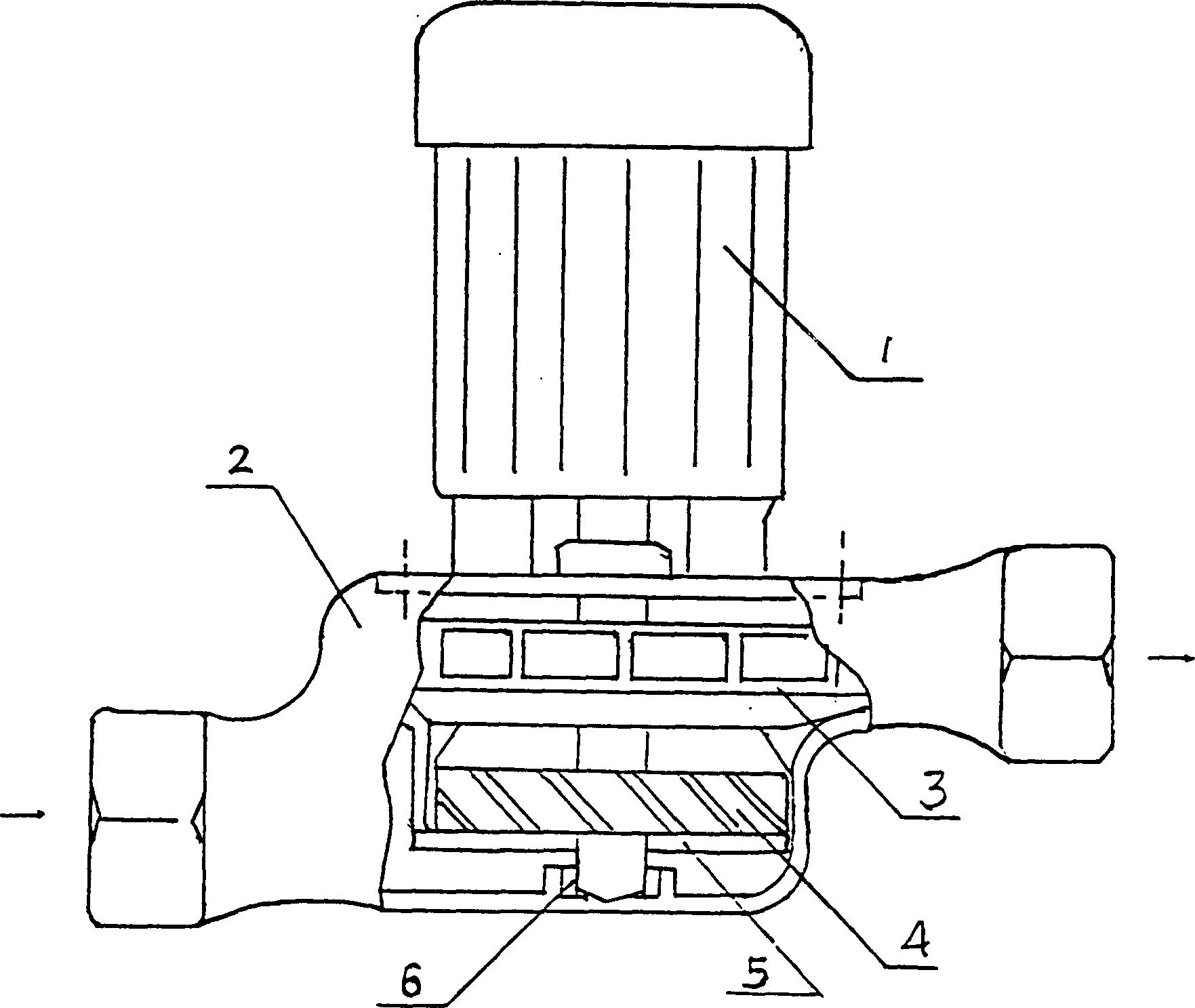

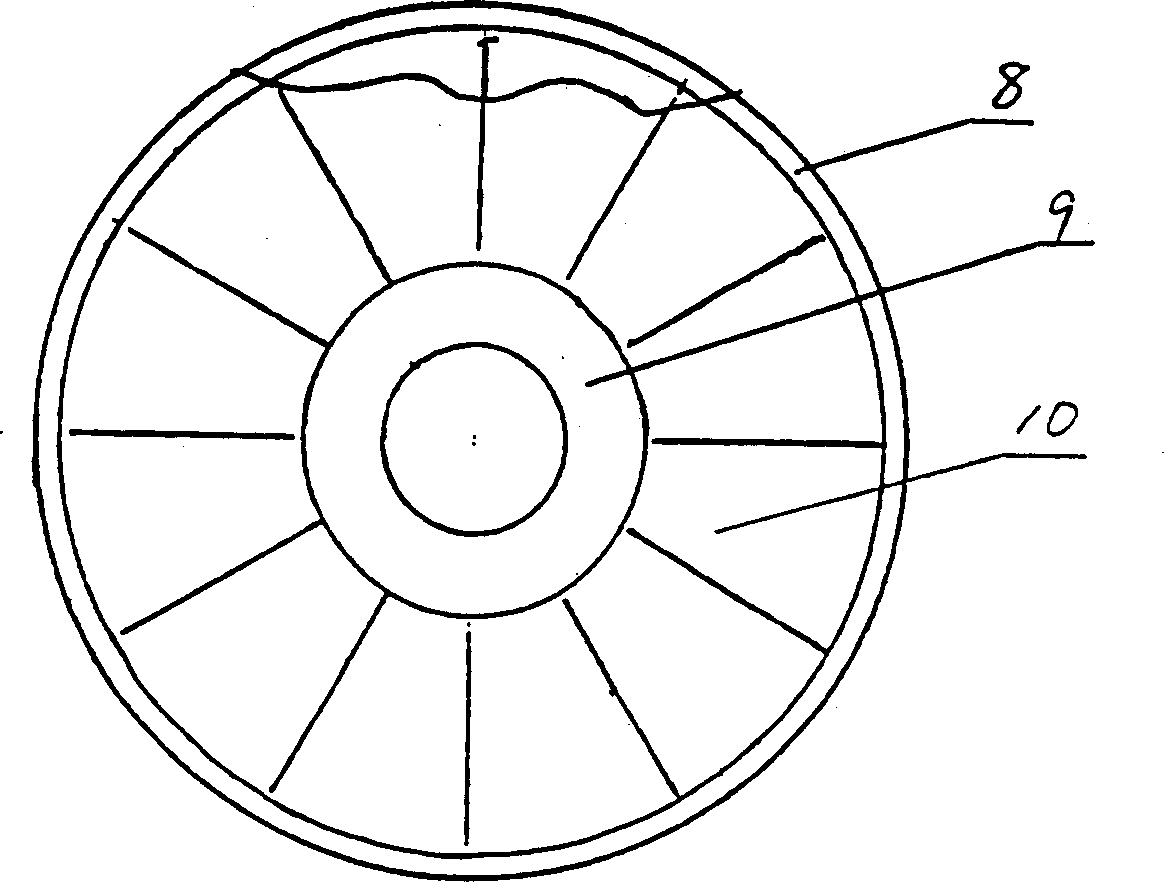

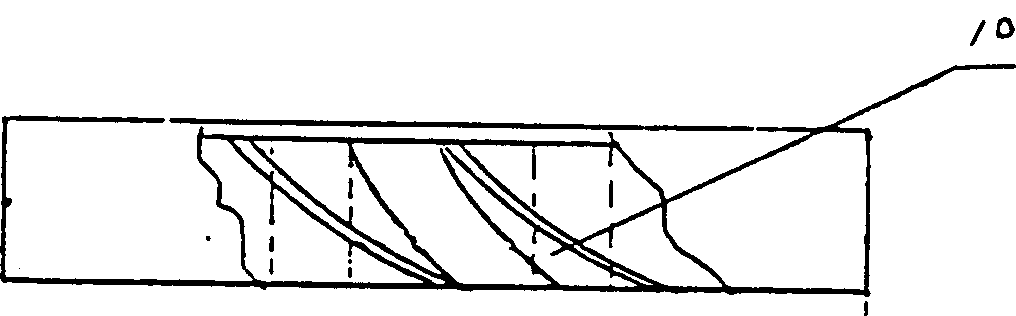

[0011] The centrifugal impeller 3 of the present invention is a radial centrifugal water wheel; the rotary impeller 4 is such as figure 2 Shown is a wheel body with rotating blades 10 between the outer ring 8 and the hub 9; the racer disk 5 is a sheet-shaped disk with a plurality of through holes 7, and the outer circle is a threaded body.

[0012] During installation, the centrifugal impeller and rotary impeller that penetrate into the pump body on the motor shaft in turn are fixed and connected with keys or screws. The vanishing disc is fixed on the bottom of the pump body by threads or screws to maintain a small gap with the rotary impeller. Wear-resistant bearings Installed on the inner bottom surface of the pump body to support the motor shaft.

[0013] When in use, the motor drives the centrifugal impeller and the rotary impeller to rotate, and the liquid is conveyed through the rotary impeller and the centrifugal impeller; the anti-rotation disc fixed on the pump body is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com