Novel plastic uptake forming machine

A blister molding machine, a new type of technology, applied in the field of blister machines, can solve problems such as affecting the effect, increasing production costs, and uneven surface of the sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

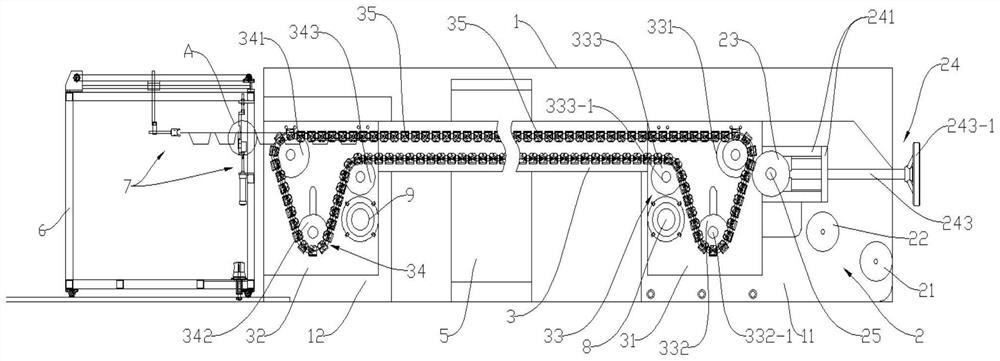

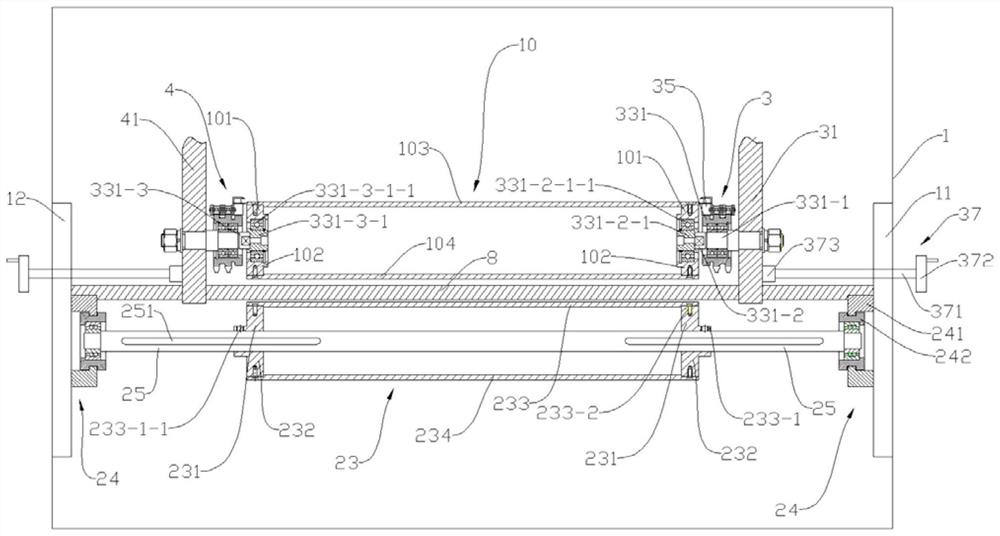

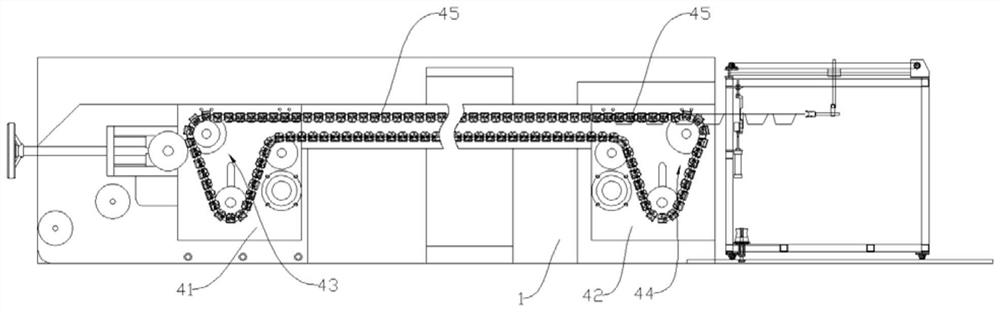

[0044] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following will combine figure 1 - Image 6 The accompanying drawings describe the present invention in further detail.

[0045] refer to figure 1 , figure 2 As shown, a new type of plastic forming machine includes a forming working frame 1, a set of feeding guide rollers 2, a first material clamping transmission mechanism 3, a second material clamping transmission mechanism 4, a forming module 5 and a molding module arranged on the forming working frame 1 The outer blanking frame 6 and clamping mechanism 7, the first clamping transmission mechanism 3 and the second clamping transmission mechanism 4 are symmetrically arranged on both sides of the length direction of the forming working frame 1, and the blanking frame 6 is arranged on the forming frame 1, the material clamping mechanism 7 reciprocates in the blanking frame 6 along the length direction of the forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com