Microwave catalytic oxidation apparatus for landfill leachate treatment

A microwave catalytic oxidation and equipment technology, applied in water/sewage multi-stage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc. Short, discontinuous microwave heating and other problems, to achieve the effect of improving microwave utilization efficiency, prolonging service life, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

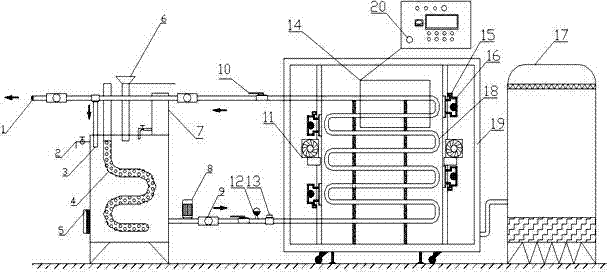

[0030] Microwave catalytic oxidation equipment see figure 1 , Mainly including mixing water tank, microwave reactor, water cooling device, circulation system, automatic control system. The upper part of the mixing water tank is provided with an overflow valve 2, a water inlet 6, and a dosing tank 7, and a water level gauge 5 and an aeration pipe 4 are provided in the mixing water tank. The microwave reactor is surrounded by a shell 19, in which an outer wire 11, a magnetron 16, a transformer 15, and a coil 18 are arranged, and the microwave reactor is connected to a cooling system 17. The circulation system is provided with a forward connection pipeline connecting the mixing water tank and the microwave reactor, on which a circulating water pump 8, a solenoid valve 9, and a flow meter 12 are provided. The connecting pipeline is connected to the lower end of the coil 18 of the microwave reactor; the circulation system is also provided There is a return connecting pipe connecting...

Embodiment 2

[0035] Using the microwave catalytic oxidation equipment of Example 1 to treat landfill leachate, the method is as follows:

[0036] (1) Fully mix and aerate the waste leachate to be processed and iron-carbon (30 mesh) at 100:1 (mass ratio), and adjust the pH to 5.0 to obtain a reaction mixture;

[0037] (2) The reaction mixture is pumped into the coil in the microwave reactor;

[0038] (3) Set the temperature of the microwave reactor to 80°C and the operating time to 30 minutes, and turn on the automatic operating system;

[0039] (4) Press the garbage leachate into the mixed water tank during operation: 30%H 2 O 2 (Volume ratio)=100: 3 minutes 5 times dosing H 2 O 2 Solution

[0040] (5) Adjust the pH value of the landfill leachate after microwave catalytic oxidation treatment to 9.0, and let it stand for 25 minutes.

[0041] (6) Take the supernatant to determine its COD Cr . COD Cr From 6720mg / L before treatment to 429mg / L after treatment, the removal rate was 93.6%.

Embodiment 3

[0043] Using the microwave catalytic oxidation equipment of Example 1 to treat landfill leachate, the method is as follows:

[0044] (1) Fully mix and aerate the waste leachate to be processed and iron-carbon (40 mesh) at 200:1 (mass ratio), and adjust the pH to 4.0 to obtain a reaction mixture;

[0045] (2) The reaction mixture is pumped into the coil in the microwave reactor;

[0046] (3) Set the temperature of the microwave reactor to 70°C and the running time to 15 minutes, and turn on the automatic running system;

[0047] (4) Press the garbage leachate into the mixed water tank during operation: 30%H 2 O 2 (Volume ratio)=100: 1 minute 4 times dosing H 2 O 2 Solution

[0048] (5) Adjust the pH value of the landfill leachate after microwave catalytic oxidation treatment to 8.0, and let it stand for 15 minutes.

[0049] (6) Take the supernatant to determine its COD Cr . COD Cr From 19260mg / L to 958mg / L, the removal rate was 95.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com