Grading filter

A technology of filter and filter cylinder, which is applied in the direction of fixed filter element filter, filter separation, separation method, etc., can solve the problems of increasing the difficulty of processing, and achieve the effects of simple structure, improved filtration efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

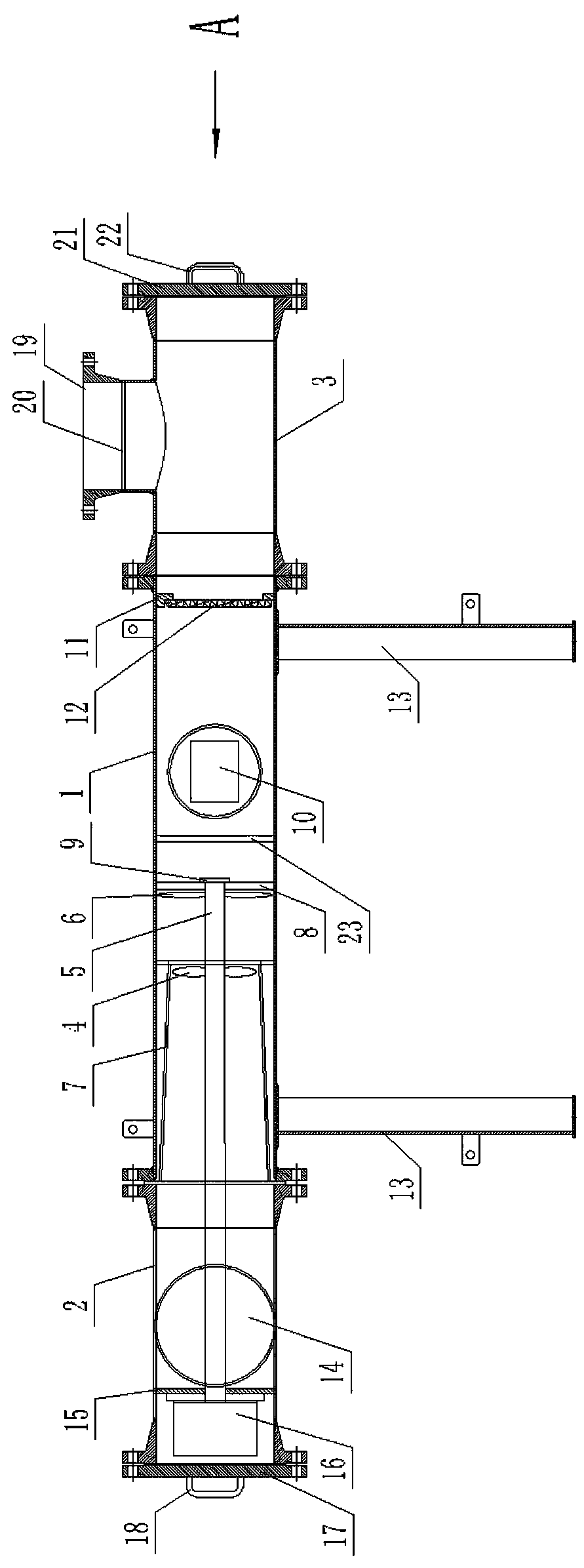

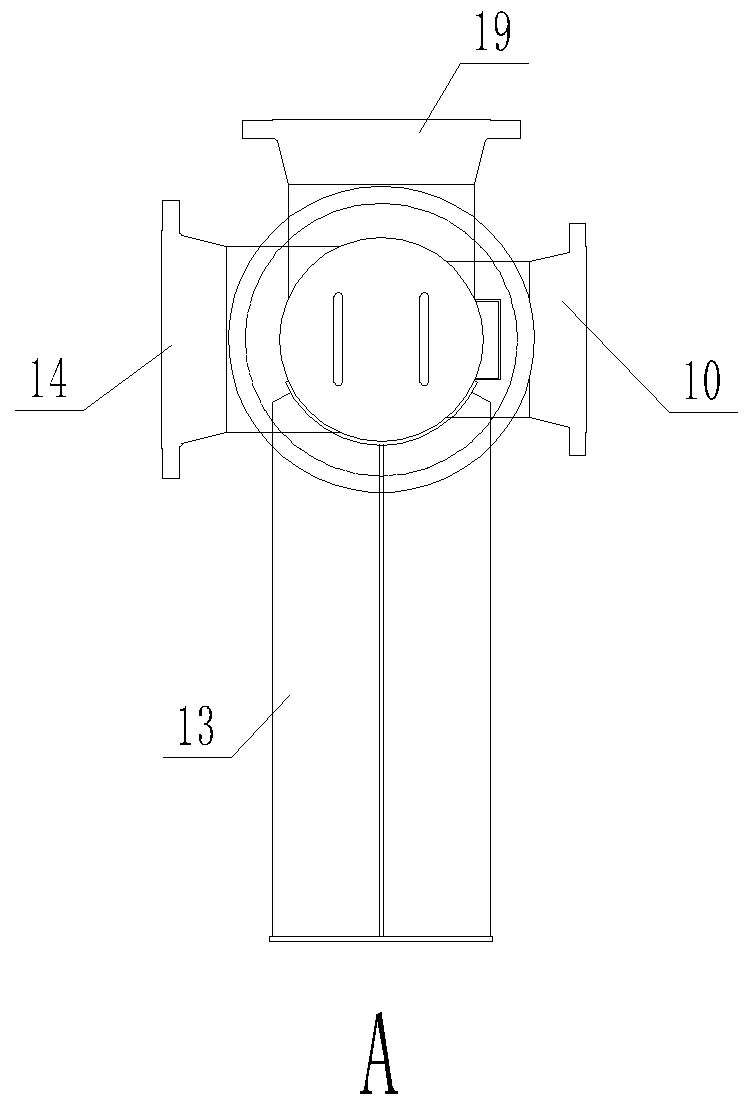

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] as attached Figure 1-2 As shown, a graded filter includes a feed cylinder 2, a filter cylinder 1 and a backwash cylinder 3 fixedly installed together in sequence; the filter cylinder 1 is sequentially fixed with a primary filter cylinder 7, The secondary filter screen 8, the steady flow filter screen 23 and the one-way flow piece, the side of the filter cylinder 1 is provided with a discharge port 10; Position boss 11 and a flap 12 hinged on the limit boss 11 at one end; the flap 12 is unidirectionally turned over to the front of the filter cylinder 1; the discharge port 10 is located between the steady flow filter screen 23 and the The outer side of the filter cylinder 1 of the flow-through part; the feed cylinder 2 is provided with a motor 16 and a stirring shaft 5 connected to the rotating shaft of the motor 16, and the stirring shaft 5 passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com