Suck-back prevention and deposition prevention grouting process and device for deep waterlogged sand layer

A grouting device and anti-suckback technology, which is applied in infrastructure engineering, construction, etc., can solve the problems of shortening of the effective layer of grouting holes and grouting pipes, impossibility of secondary grouting, poor grouting effect, etc. , to achieve good curing effect, controllable grouting process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

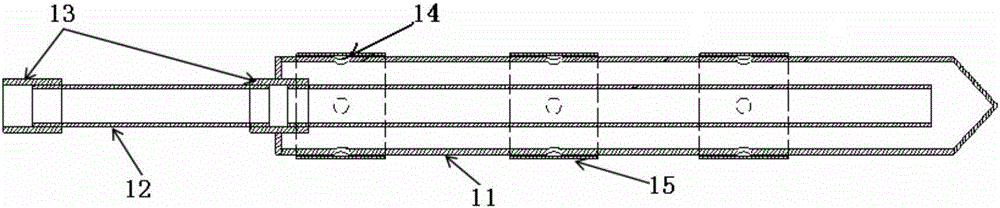

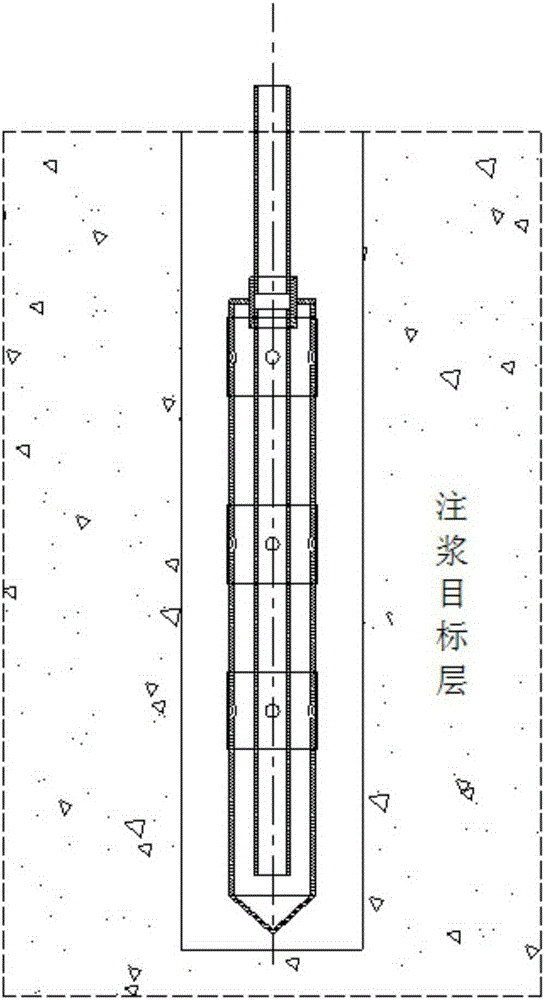

[0030] see figure 1 , shows the anti-suckback and anti-sedimentation grouting device of the present invention in deep and thick water-saturated sand layers.

[0031] The grouting device includes a grouting outer pipe 11 and a grouting core pipe 12, one end of the grouting outer pipe 11 is closed, and the other end is open and sleeved on the grouting core pipe 12, wherein the grouting The middle part of the core pipe 12 is inserted into the grouting outer pipe 11 through a threaded sleeve 13. Optionally, the other end of the grouting core pipe 12 is sleeved with another threaded sleeve 13 to provide multiple The grouting core pipes 12 are sequentially socketed to adapt to different lengths and ranges.

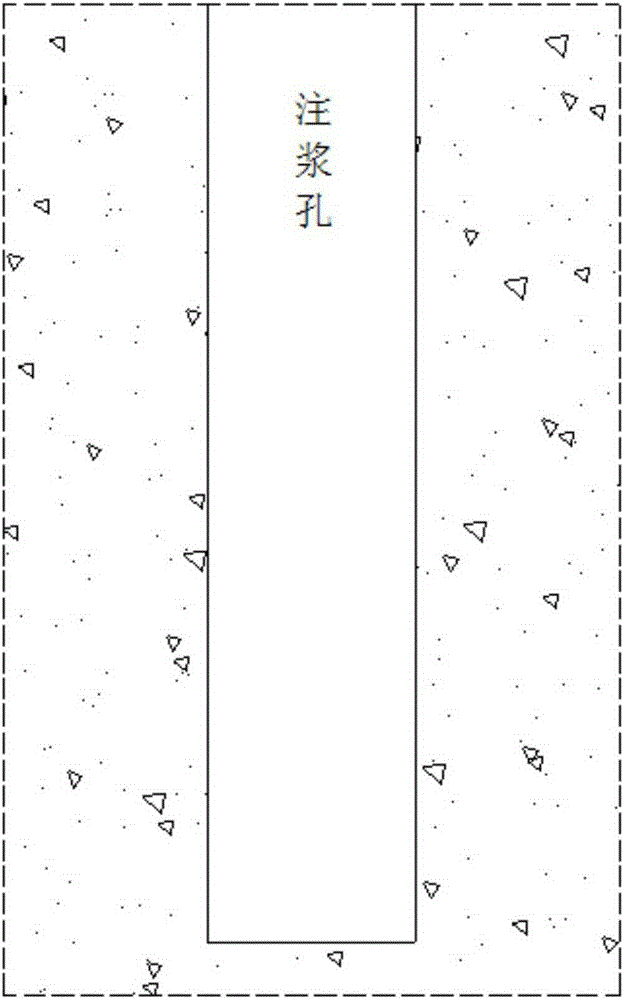

[0032] Wherein, the periphery of the grouting outer pipe 11 is dug with multiple groups of grout holes 14, two or four groups of grout holes 4 may be arranged in the same radial direction, and multiple groups of grout holes in the axial direction 14 can be equally spaced or un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com