Tappet rod type high pressure co-rail electric-controlled oil ejector

A high-pressure common rail, electronically controlled fuel injection technology, applied in machines/engines, fuel injection devices, engine components, etc., can solve the problems of radial gap leakage, inability to establish high pressure, and impossible to achieve ultra-high pressure injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

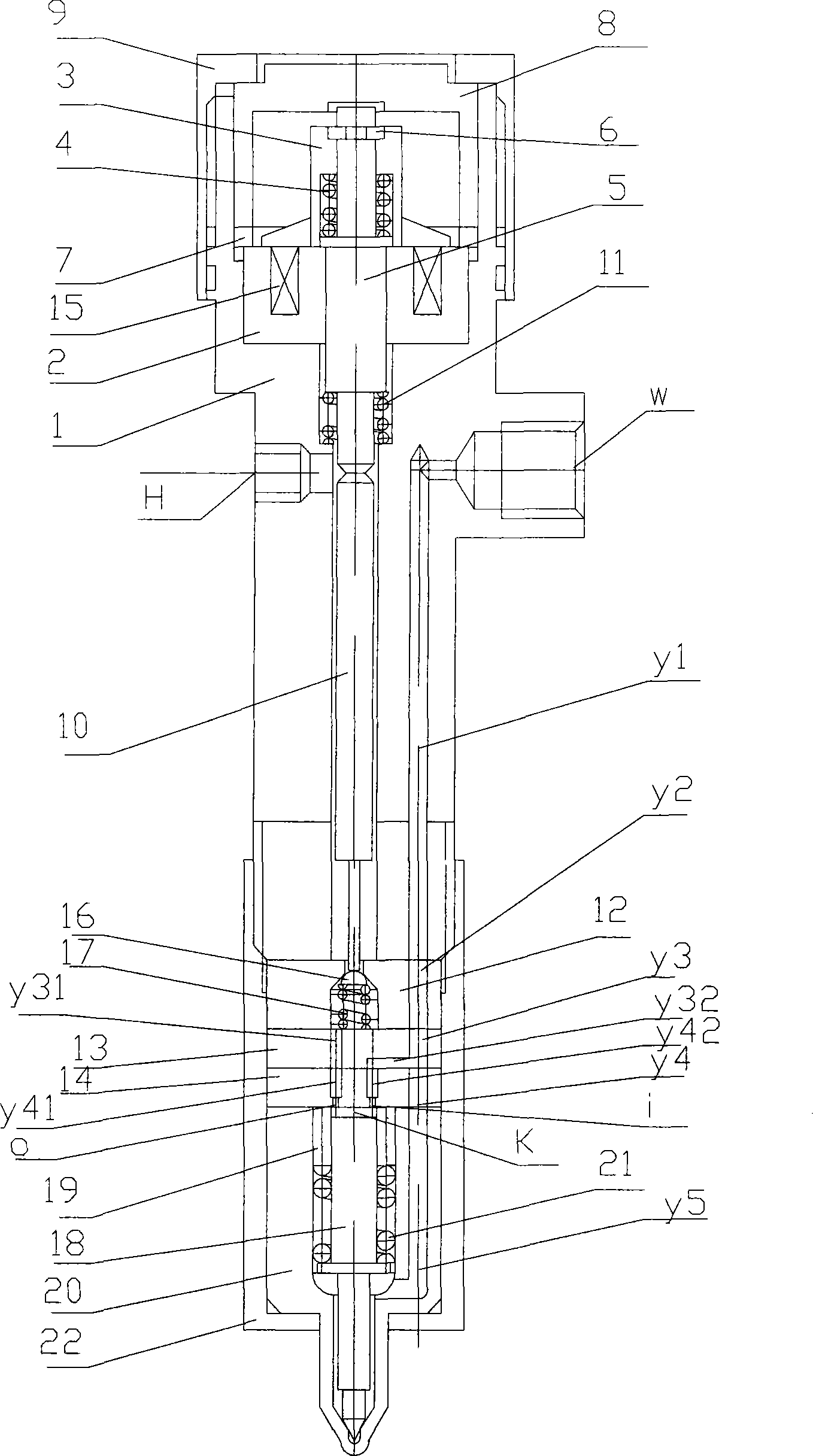

[0023] The specific structure of the present invention is as figure 1 shown. The high-speed electromagnet is a high-speed switch electromagnet, which is composed of a static iron core 2, a moving iron core 3 and a return spring 4. Exciting coil 15 is arranged in static iron core. When the moving iron core 3 of the high-speed electromagnet reciprocates under the driving of the drive circuit, the push rod 5 connected to it is driven to move up and down, and then the tappet 10 is driven to move up and down, so that the hemisphere 16 and the back-moving spring can be made to move up and down. The two-position two-way switching valve formed by 17 realizes opening and closing.

[0024] There is an oil inlet w for high-pressure fuel on the injector body, and an oil return port H for low-pressure fuel. The fuel from the high-pressure common r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com