Patents

Literature

52results about How to "Processing is not difficult" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

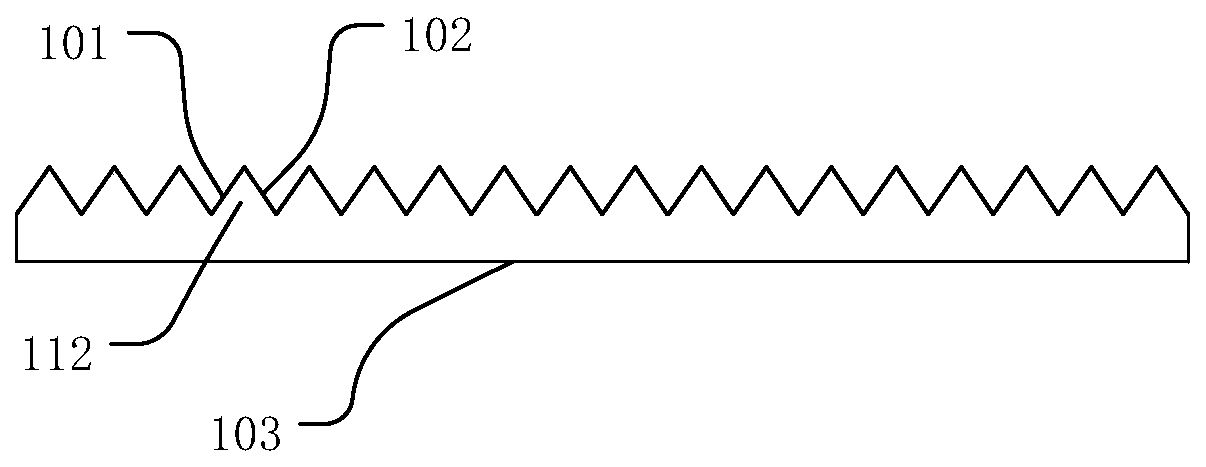

Efficient solar energy thermal absorber based on optical-thermal absorbing cone structure

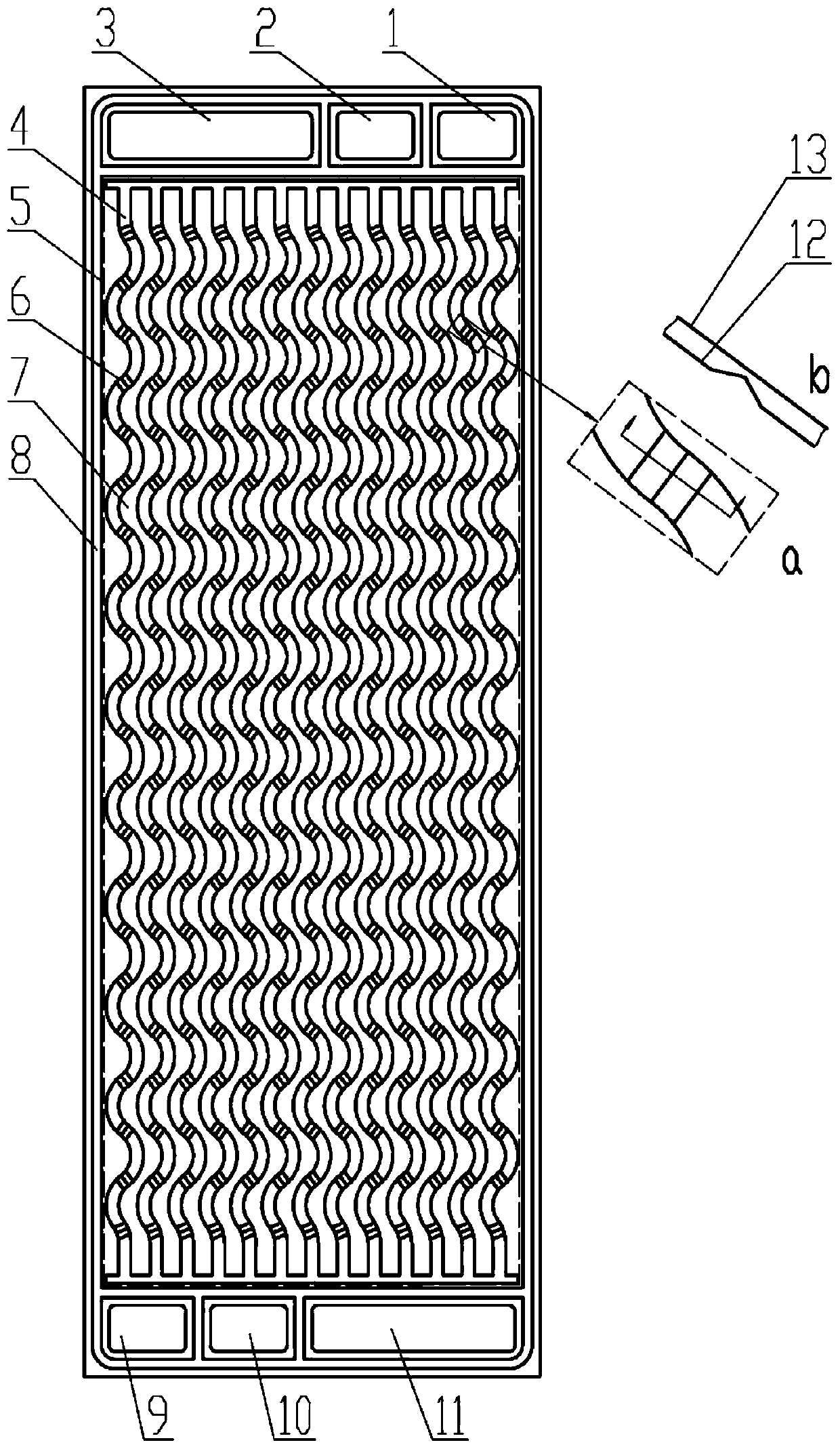

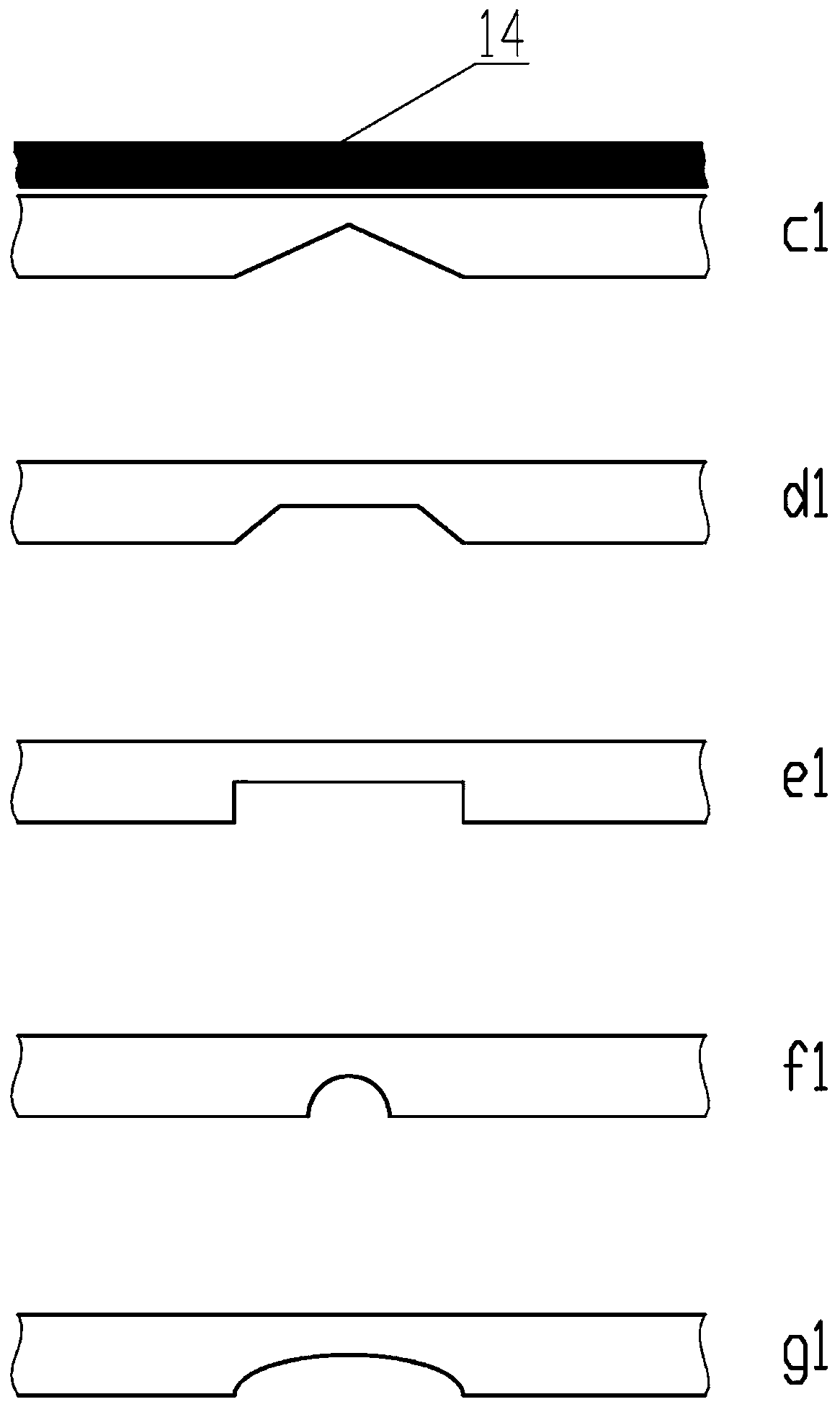

ActiveCN103123175AReduce reflection lossProcessing is not difficultSolar heating energySolar heat devicesGlass coverPorous medium

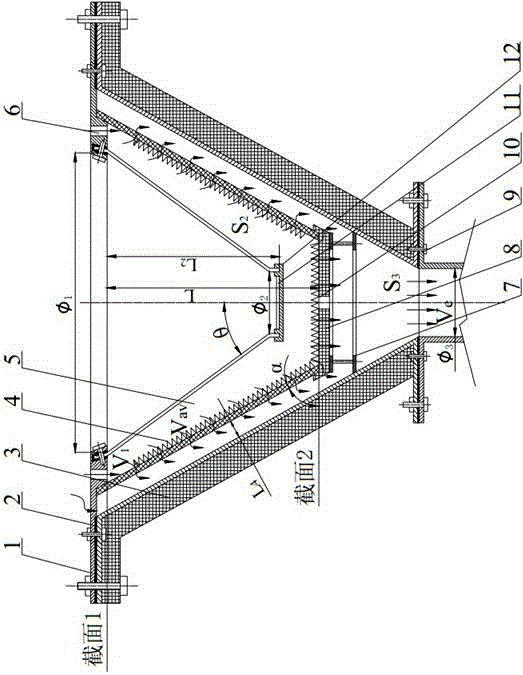

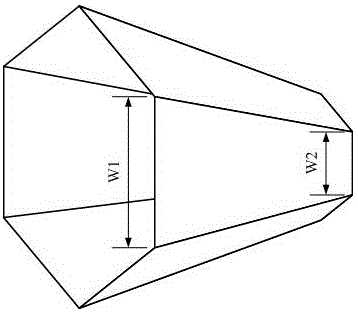

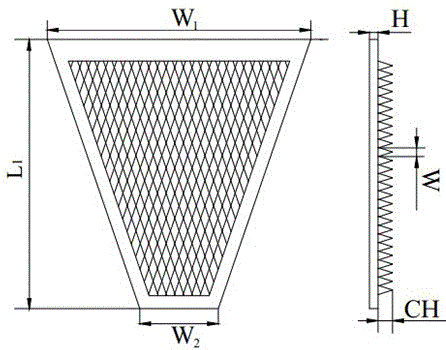

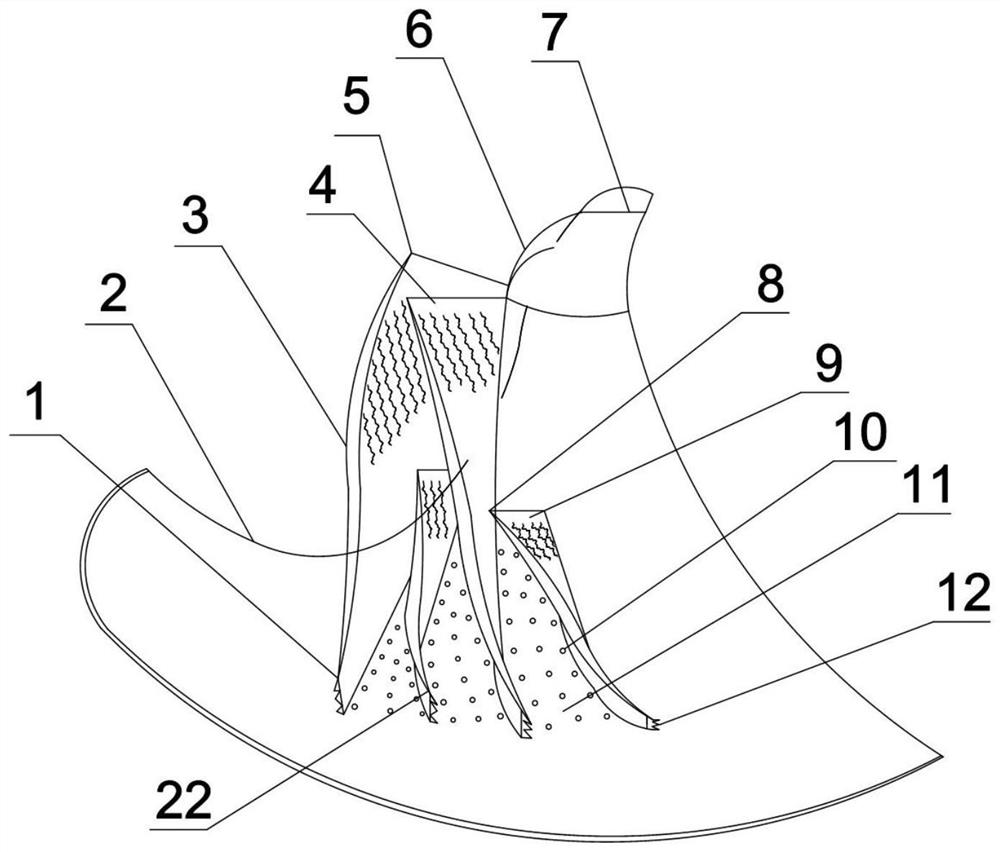

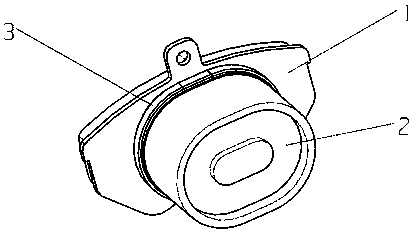

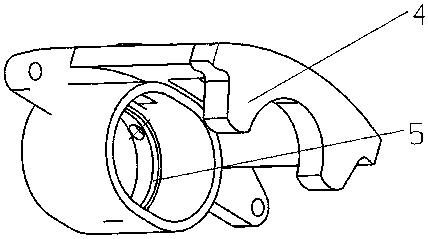

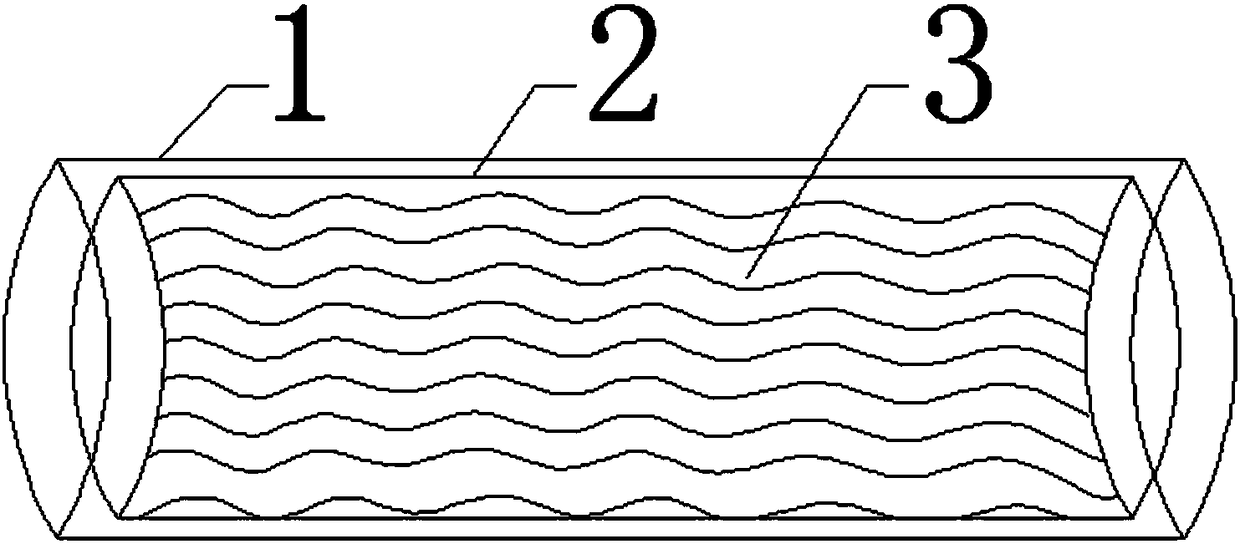

The invention relates to an efficient solar energy thermal absorber based on an optical-thermal absorbing cone structure. The efficient solar energy thermal absorber based on the optical-thermal absorbing cone structure comprises a sealing cover, an insulating tube sleeve, an airflow tube, a thermal absorbing body, a glass cover and a thermal absorbing fastening piece. The efficient solar energy thermal absorber is characterized in that the thermal absorbing body is in a truncated prism structure and each plane can be manufactured separately. Each plane is respectively an optical-thermal absorbing conic board, a plurality of sharp pyramids are distributed on a surface of each plane and each plane is made of a high thermal conductive porous material. The glass cover is in a circular truncated cone shape. A closed containing cavity is formed by the sealing cover, the thermal absorbing body and the glass cover. Air enters into the containing cavity through an air inlet of the sealing cover and is heated through each porous medium optical-thermal absorbing conic board so that solar energy is taken and finally flows out from an outlet end of the thermal absorber along the airflow tube. The efficient solar energy thermal absorber based on the optical-thermal absorbing cone structure has the advantages of solving the problems that an existing thermal absorber is low in thermal absorbing efficiency, difficult to process, large in loss in inner flow and the like, being used independently and in a combined mode through connectors, being mainly applicable to a solar energy thermoelectric conversion system and guaranteeing efficient operation of the system.

Owner:南京凌日星能源科技有限公司

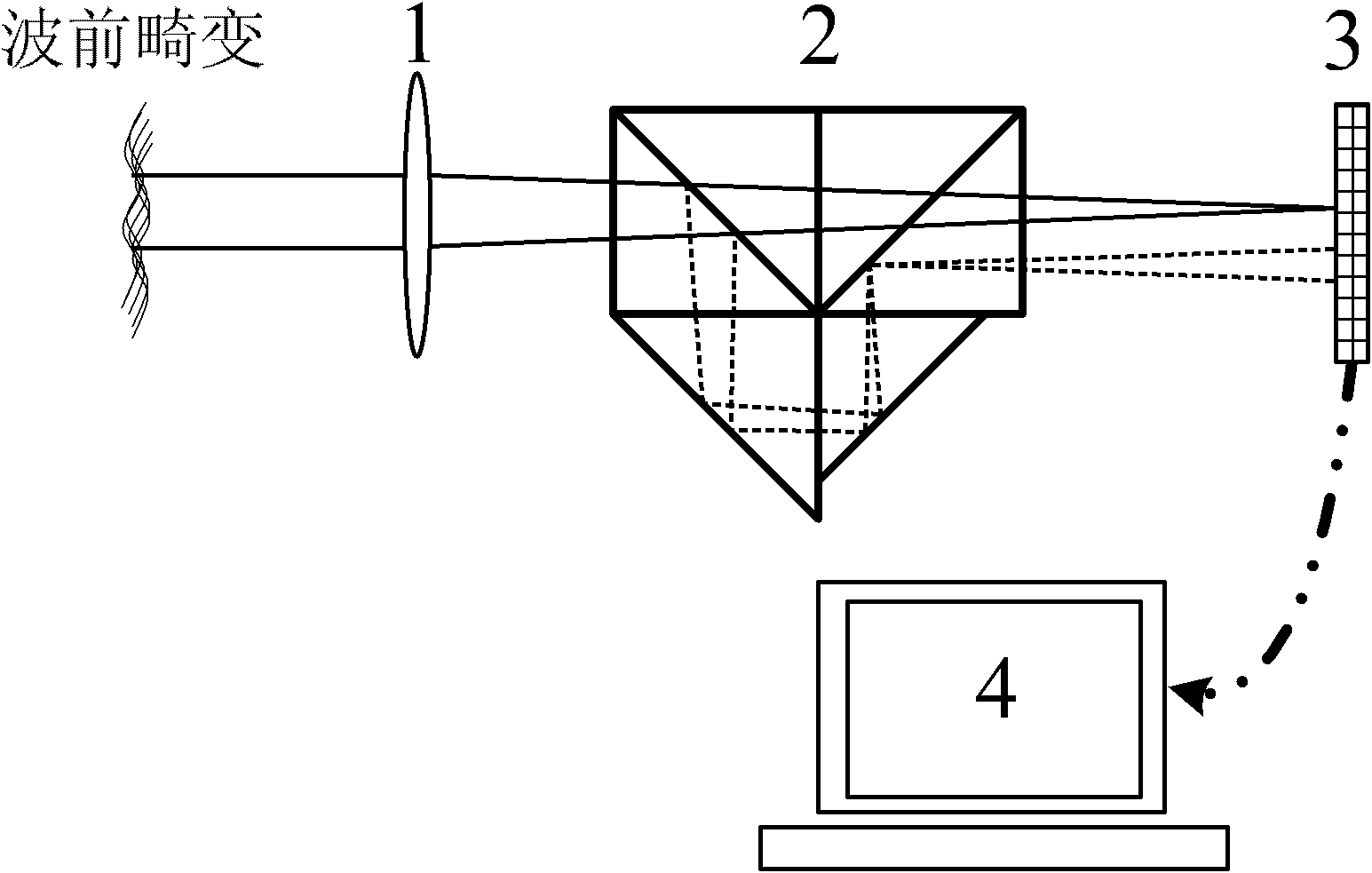

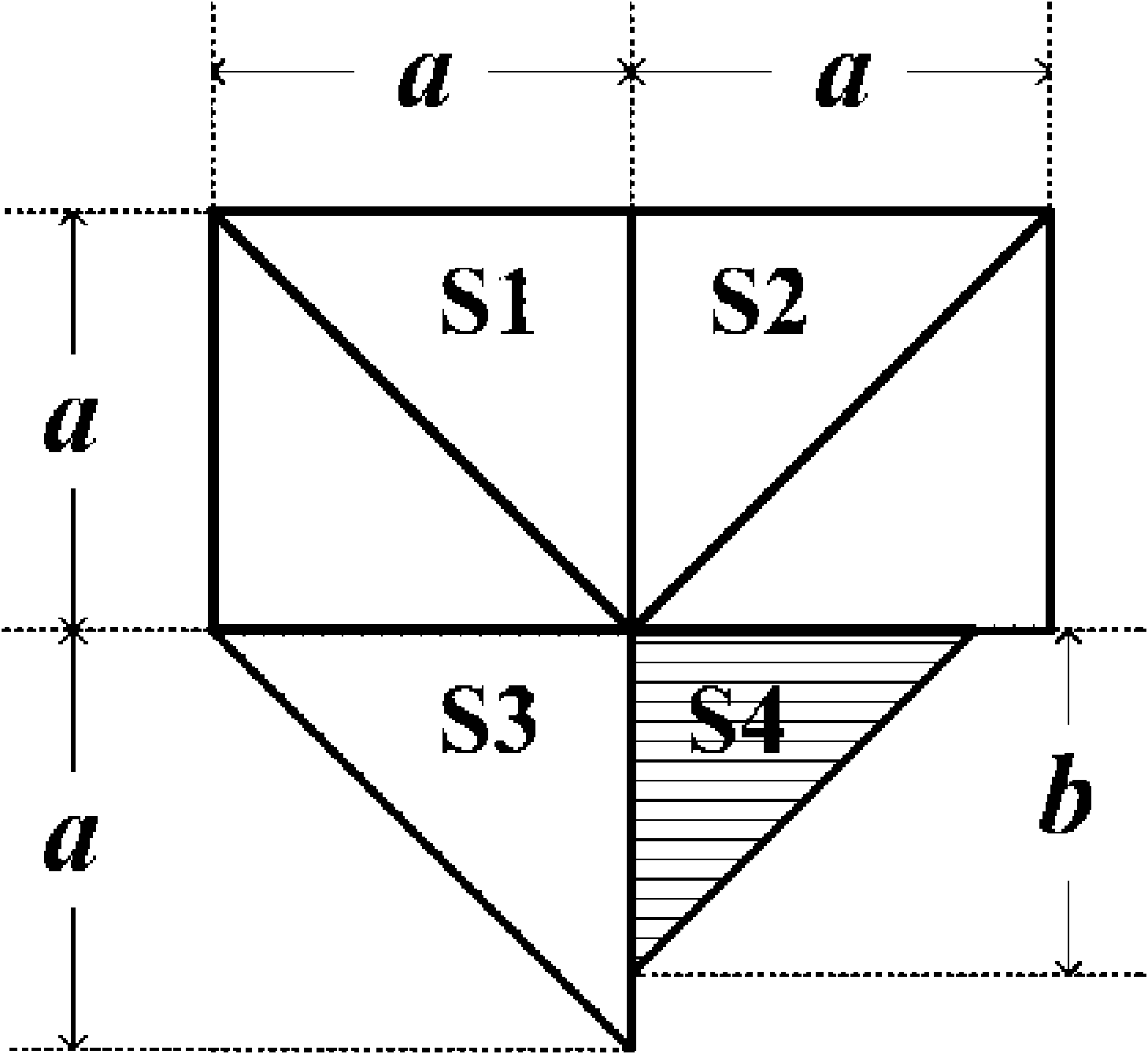

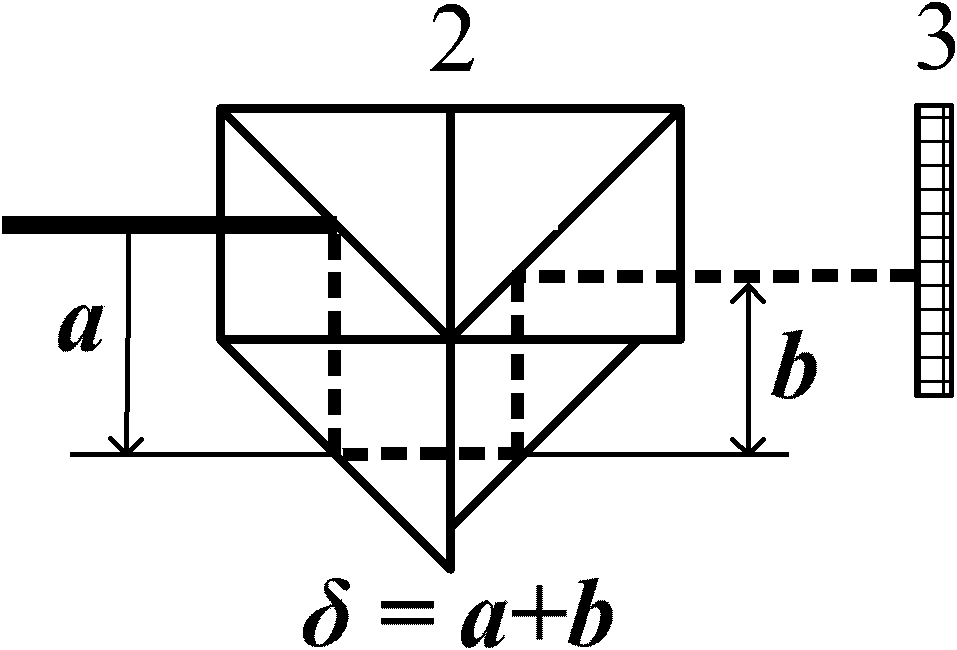

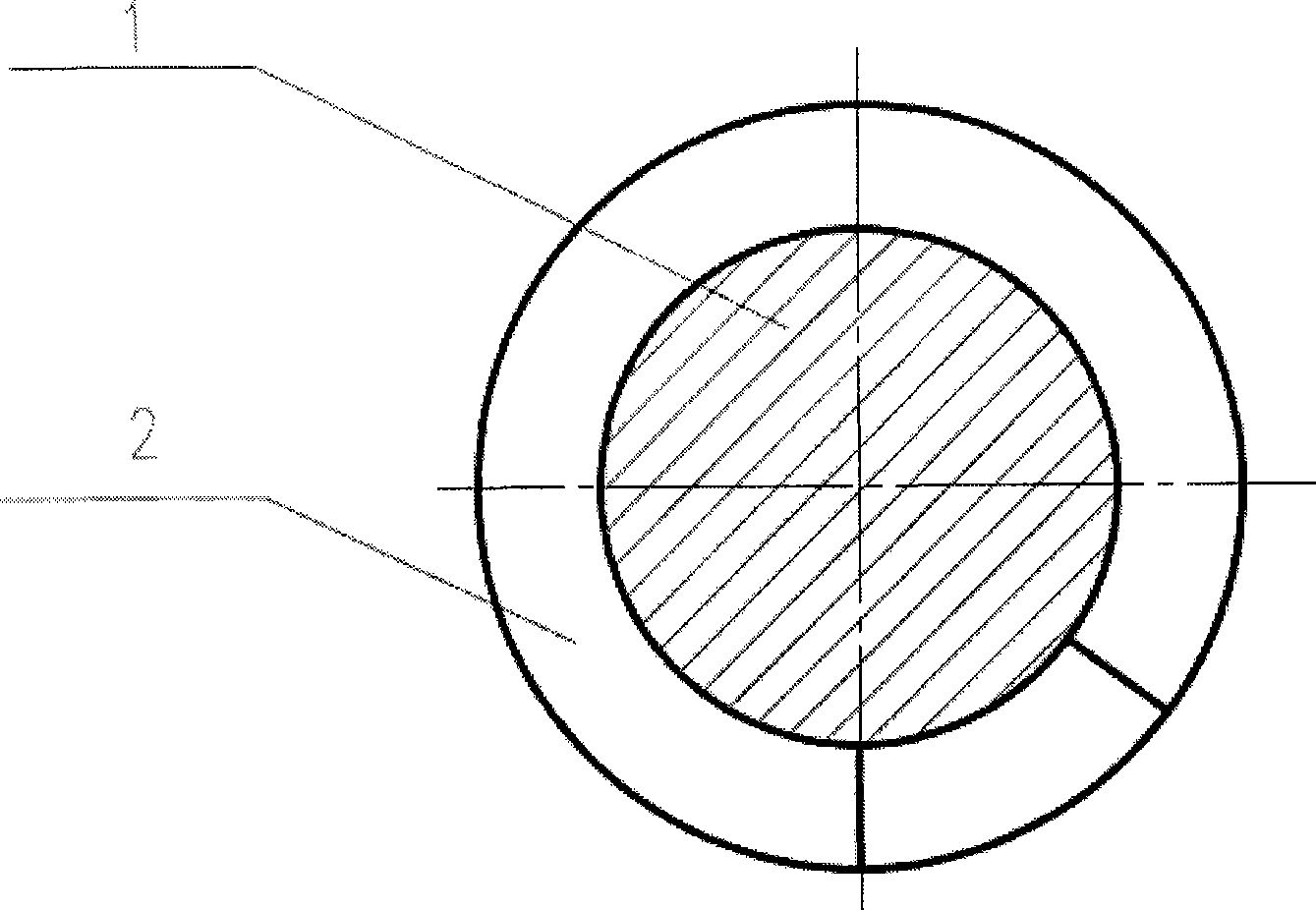

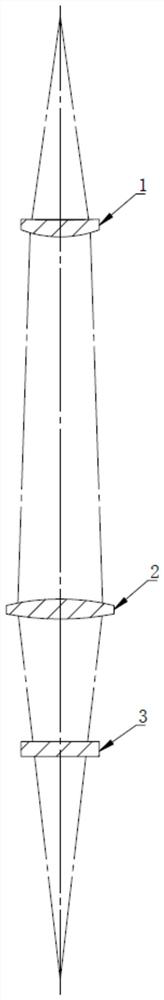

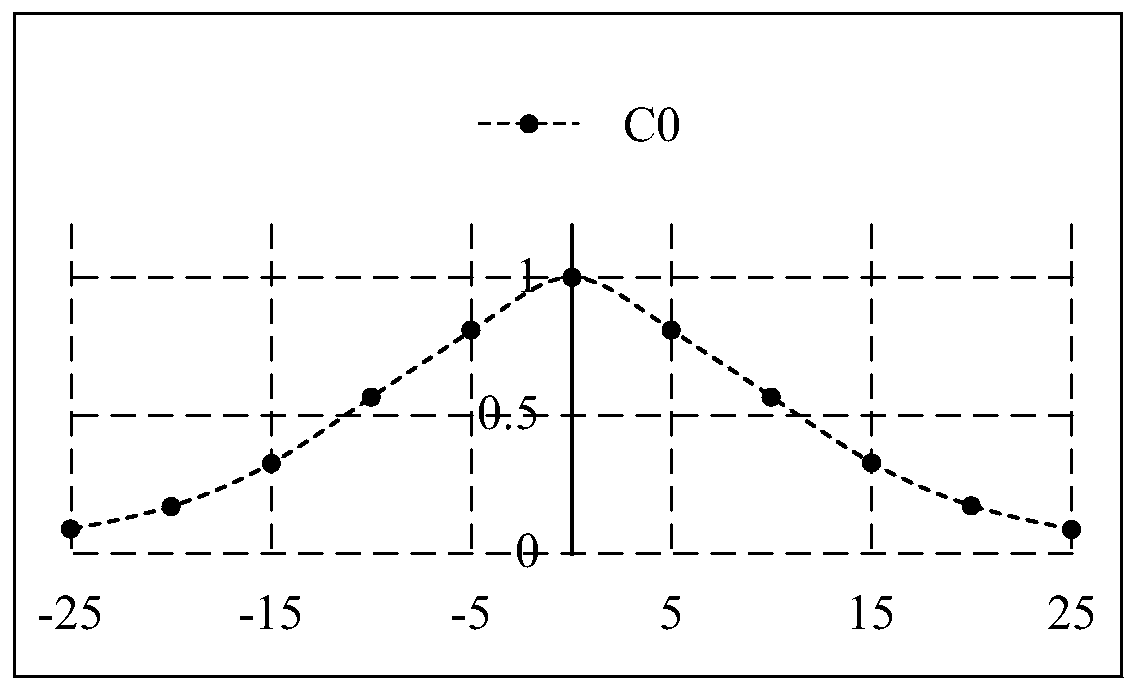

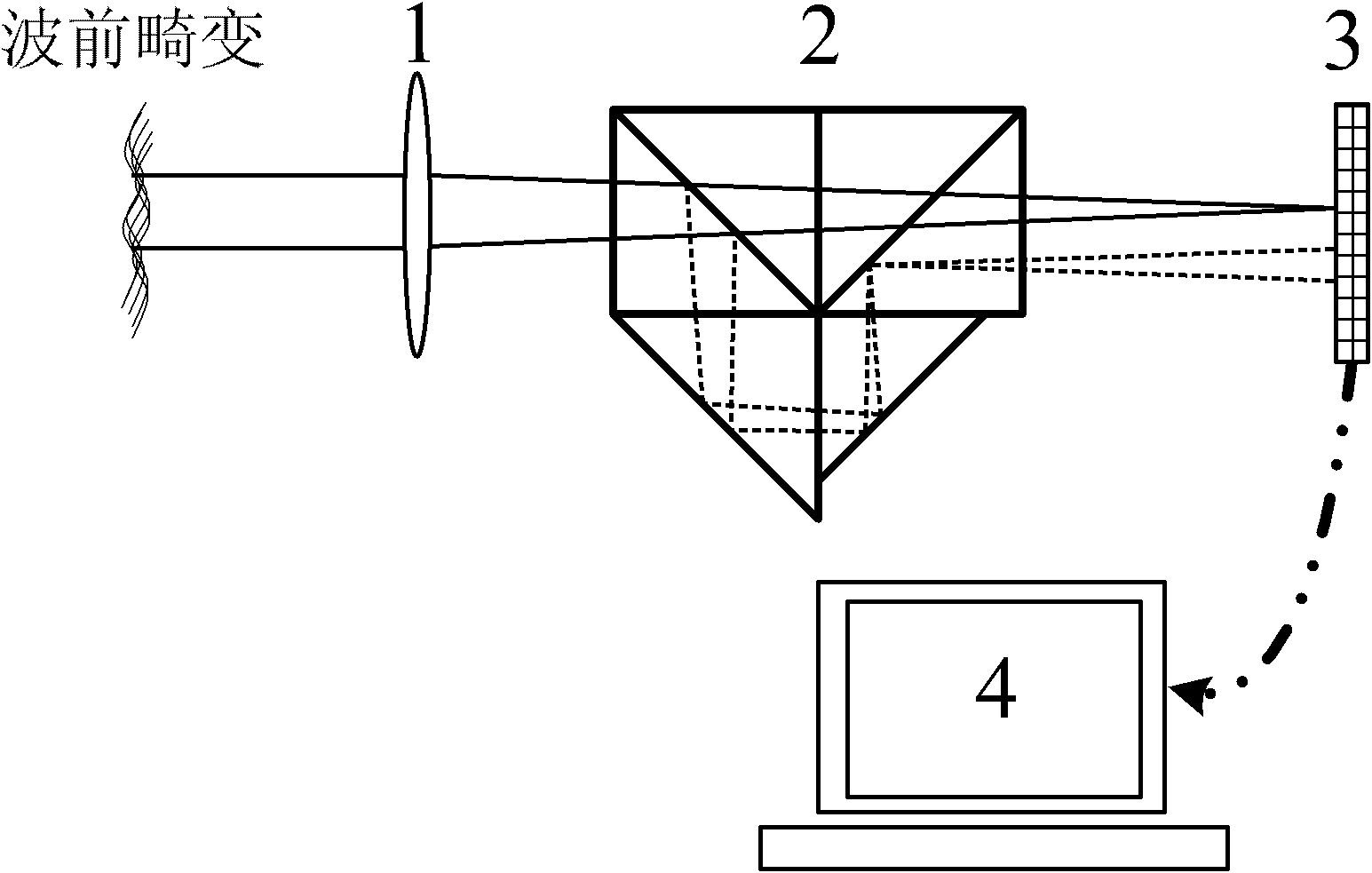

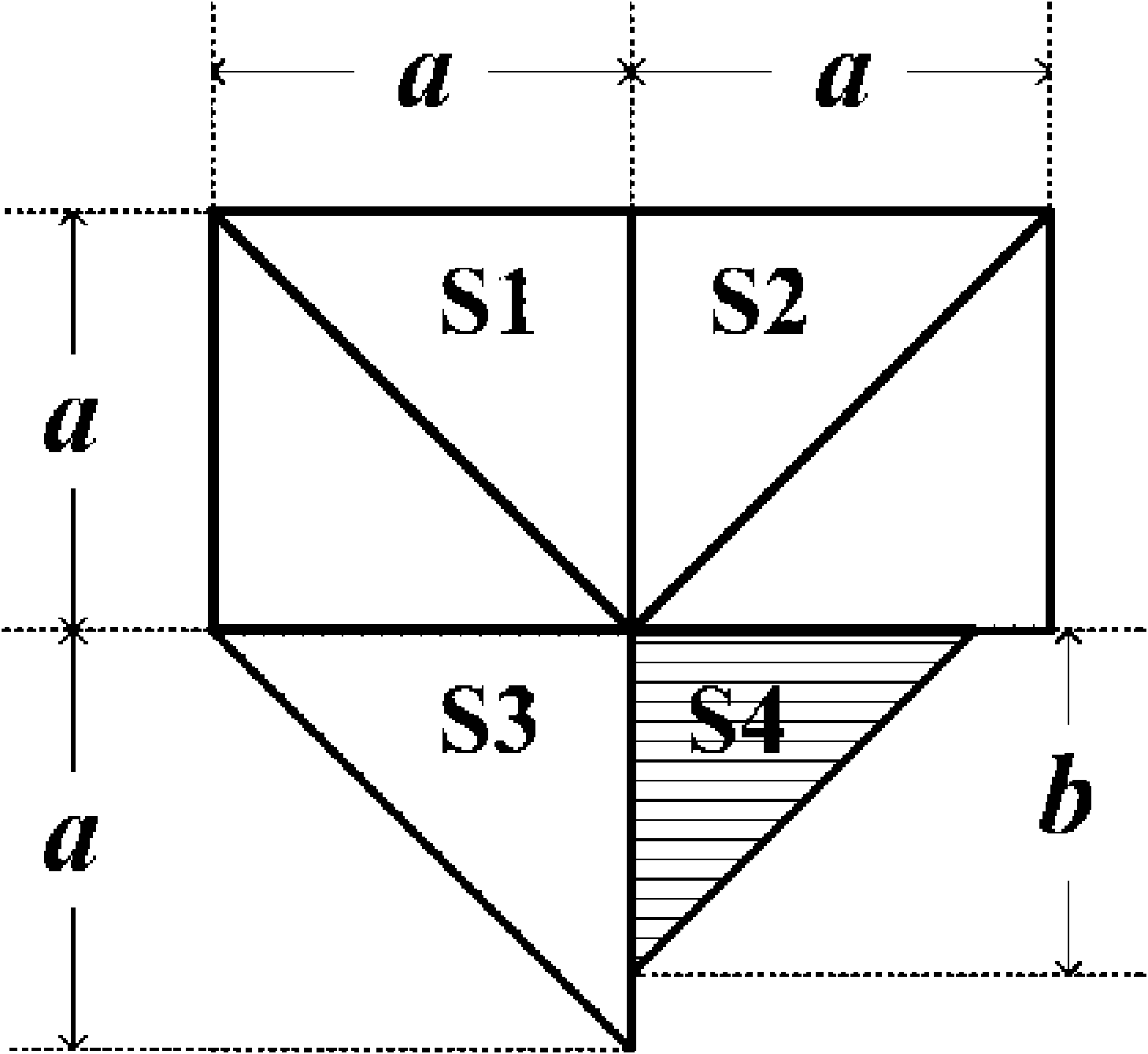

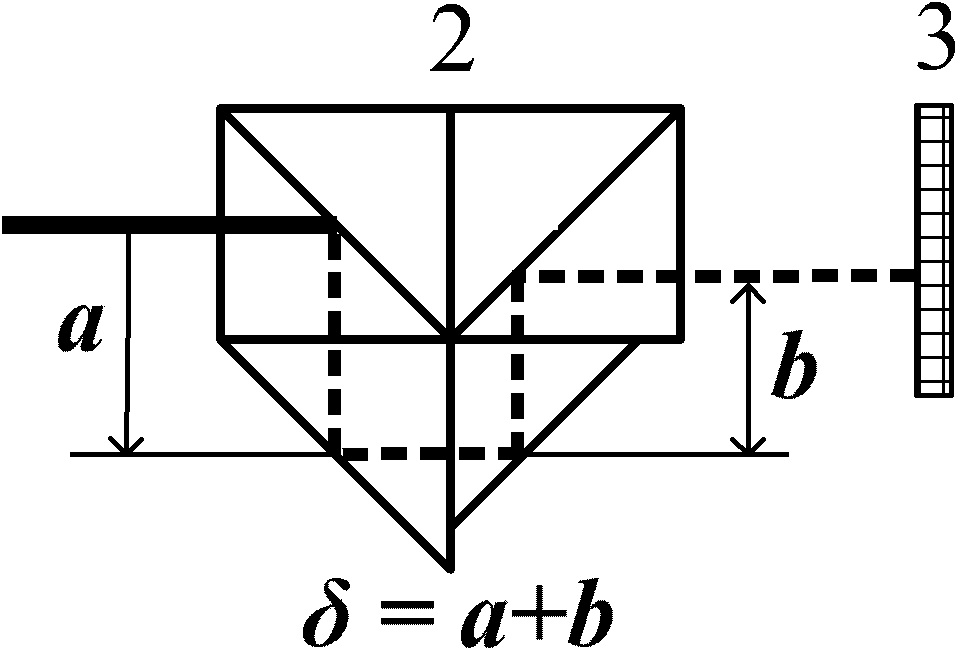

Component prism-based phase diversity wavefront sensor

ActiveCN102564612ASimple optical structureReduce processing difficultyOptical measurementsOptical elementsWavefront sensorHigh resolution imaging

The invention relates to a component prism-based phase diversity wavefront sensor comprising a lens, a component prism, a CCD imaging detector, and a computer system. After a parallel light beam containing wavefront distortion passes through the lens and is focused, the focused light beam is vertically irradiated on a front surface of the component prism; after the light beam passes through the component prism, an incident light beam is split into two beams of lights; and two beams of lights emitted by the component prism are imaged on a CCD photosensitive surface, wherein there is a fixed light path difference between the two beams of lights. According to the invention, the optical structure of the sensor is simple; the CCD imaging detector can simultaneously collect a focal plane light intensity distribution image and a defocused light intensity distribution image, so that the synchronism and the real-time property of the two images can be ensured as well as detection precision of the phase diversity wavefront sensor on dynamic aberration and restorability on an expansion object can be effectively improved; and moreover, the provided phase diversity wavefront sensor has obvious advantages in fields like optical detection, adaptive optics, high resolution imaging and the like.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

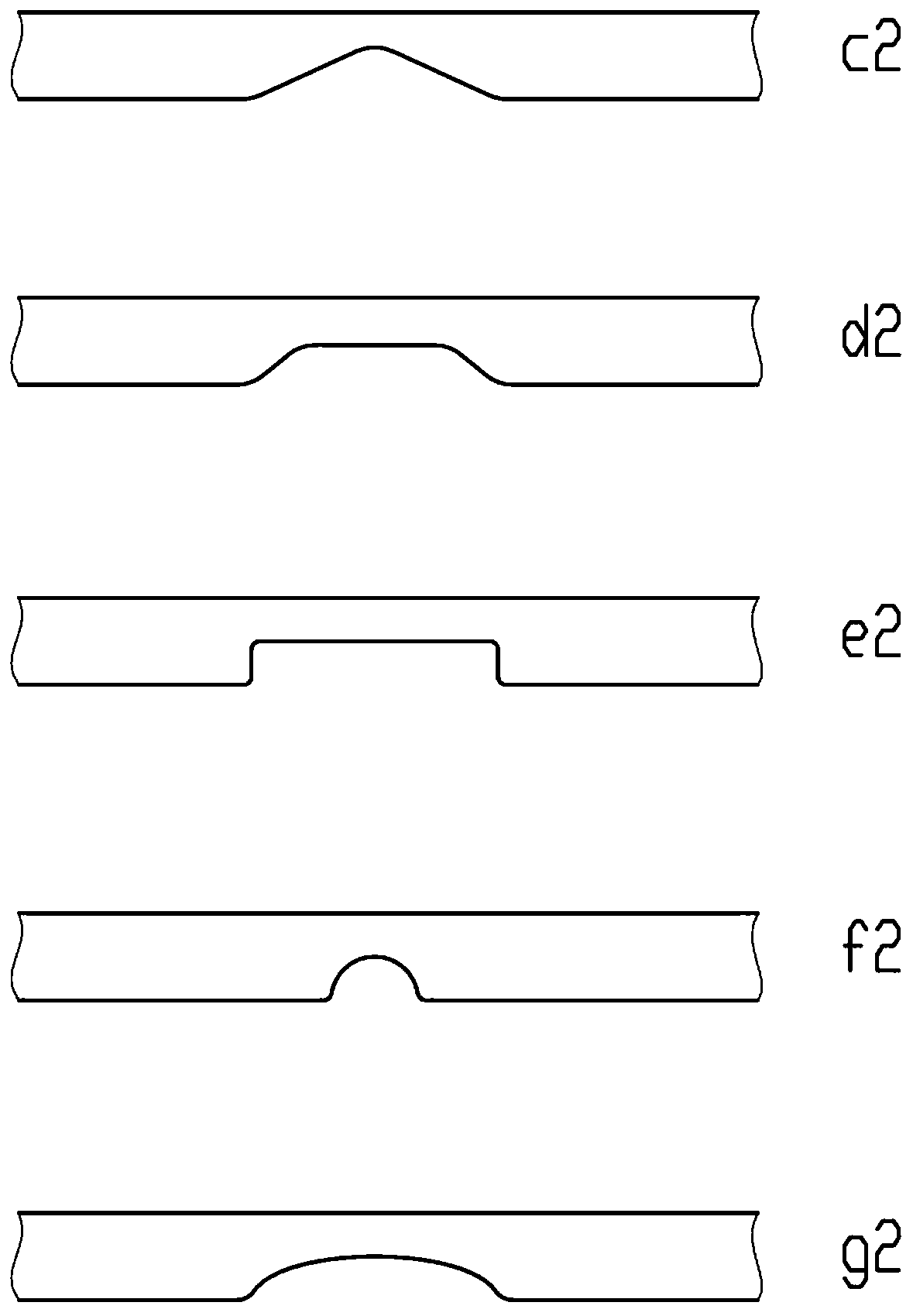

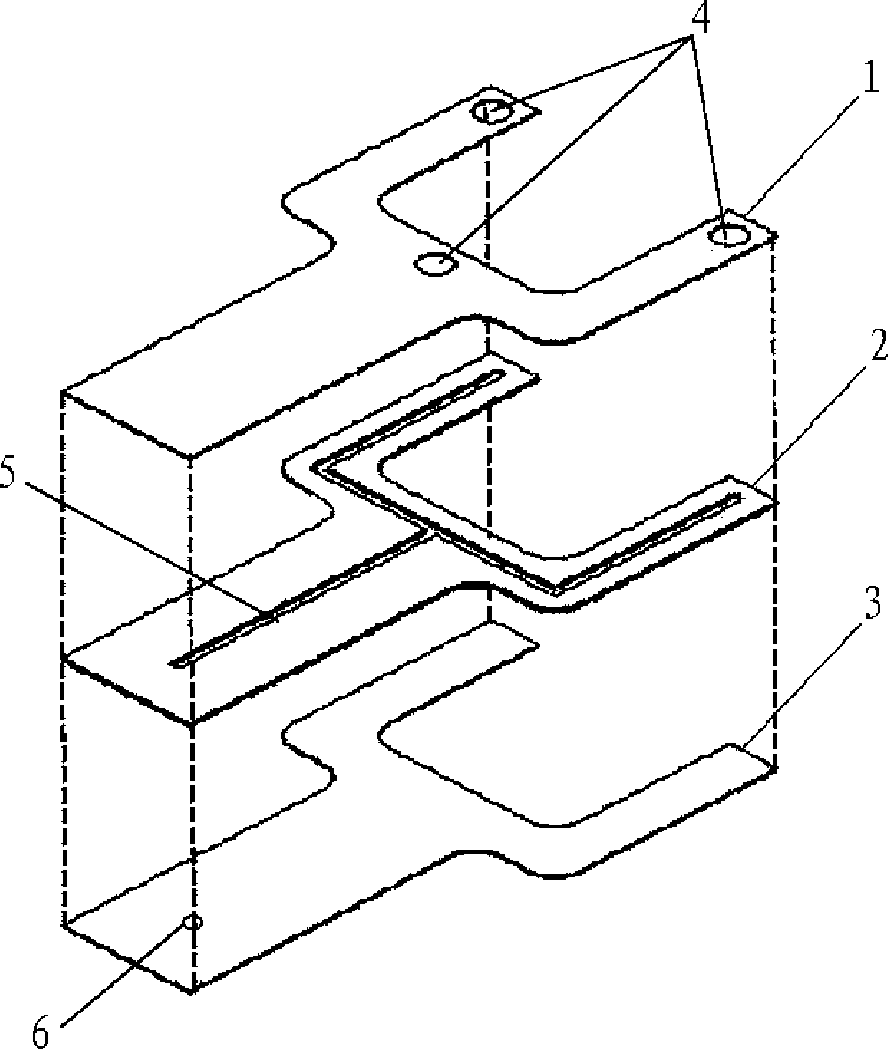

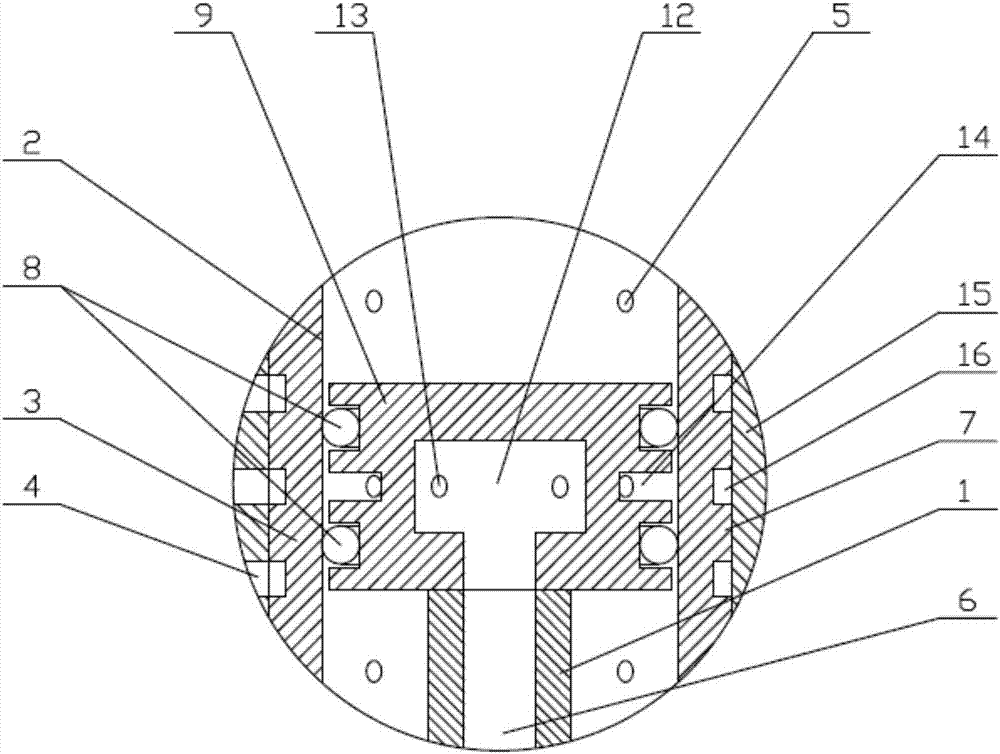

Metal bipolar plate flow field runner structure of fuel cell

ActiveCN110993985AEnhanced access to and from membrane electrodesSpeed up entryCollectors/separatorsFuel cellsMechanical engineering

The invention provides a metal bipolar plate of a fuel cell. The bipolar plate comprises a fuel gas inlet, a fuel gas outlet, an oxidant inlet, an oxidant outlet, an oxidant flow field and a fuel gasflow field, the oxidant flow field and the fuel gas flow field are respectively positioned on the left side and the right side of the bipolar plate, each of the oxidant flow field and the fuel gas flow field comprises M flow channels, and M is an integer greater than or equal to 1; and n discrete type protruding parts are arranged in each flow channel, the protruding parts are formed by protrudingbipolar plates located at the bottoms of the flow channels, N is an integer, and N is larger than or equal to 1. The oxidant inlet and the oxidant outlet are communicated through a flow channel in the oxidant flow field, and the fuel gas inlet and the fuel gas outlet are communicated through a flow channel in the fuel gas flow field. Through the plurality of convex parts arranged in the flow field flow channel, the mass transfer capability of the fuel cell is improved, and the performance of the fuel cell is further improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

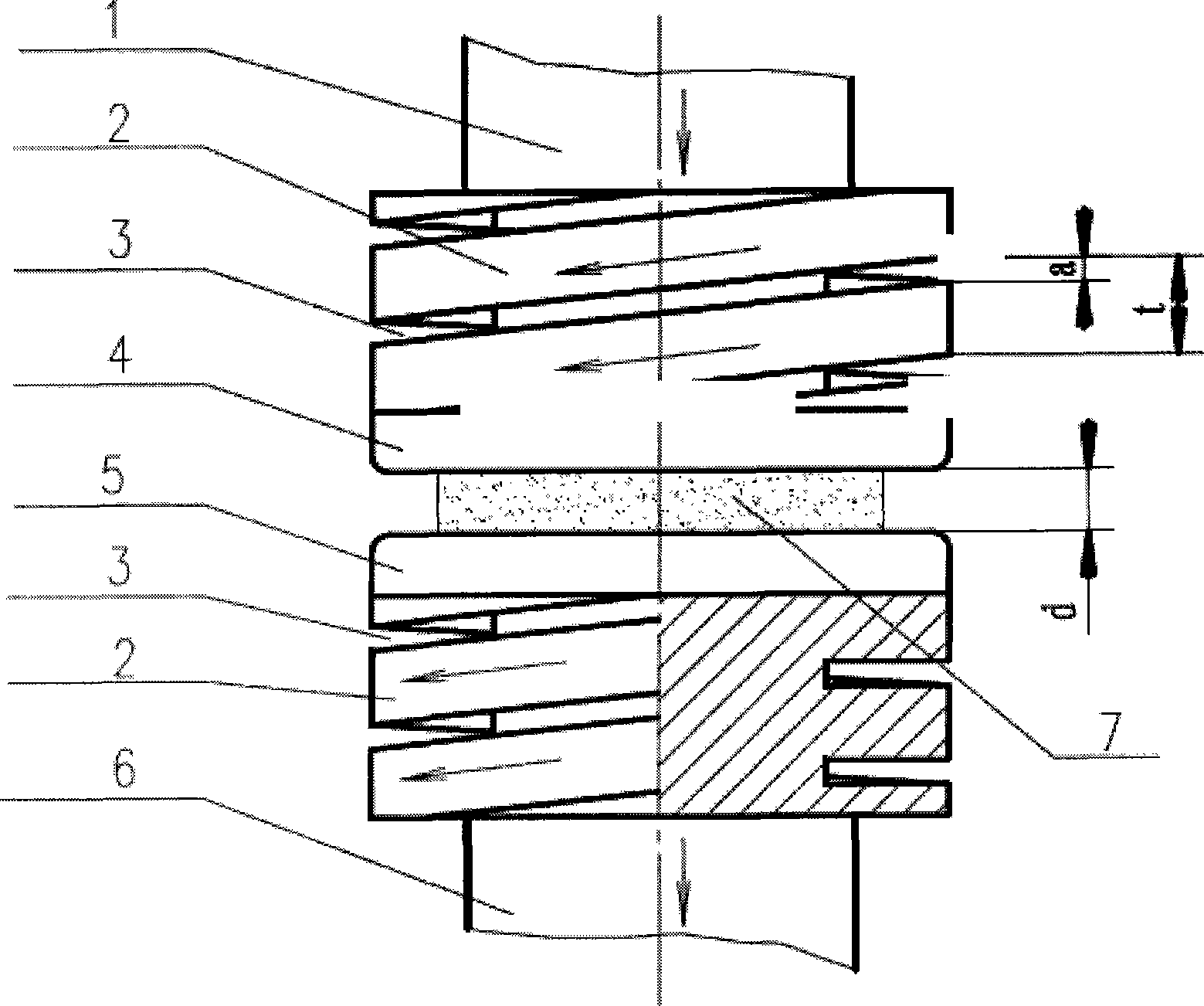

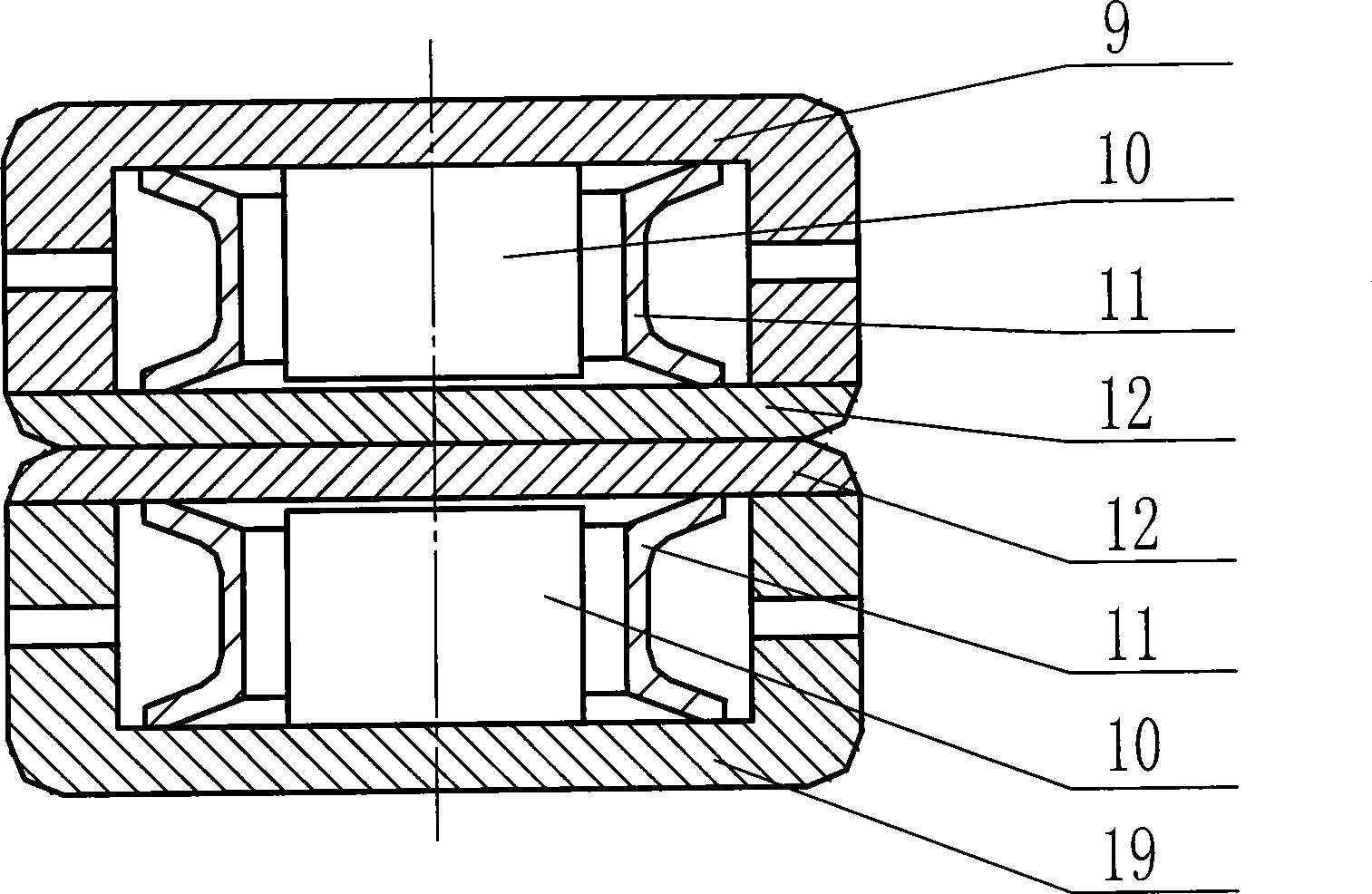

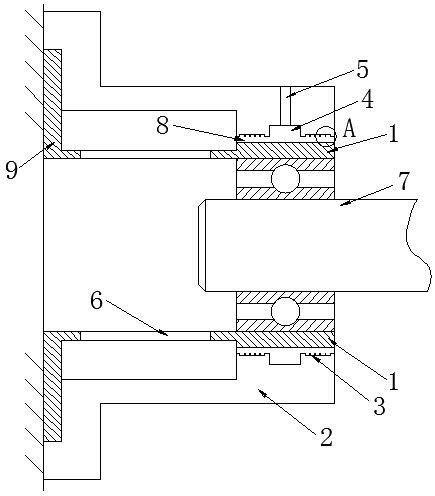

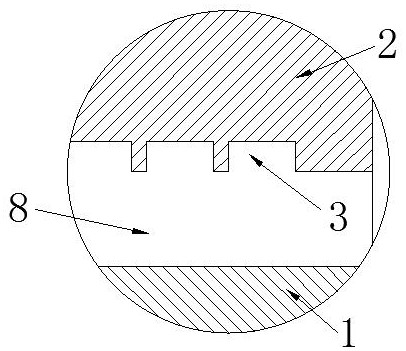

Vacuum switch tube for helical coil longitudinal magnetic field electrode

InactiveCN101425424AObvious superioritySignificant current pathHigh-tension/heavy-dress switchesAir-break switchesEngineeringVacuum switch

The invention provides a thread-coil type longitudinal magnetic field electrode vacuum switching tube which relates to the technical field of vacuum switches. The invention aims at providing a vacuum switching tube which has the arrangement disposal of the thread-coil type longitudinal magnetic field electrode so that the contradiction between the current conduction capacity and the short circuit current on-off capacity can be solved better. The vacuum switching tube comprises a moving conducting rod, a fixed conducting rod, a spiral coil, a spiral groove, a moving contact and a fixed contact which form a conducting loop. A coil of the vacuum switching tube takes the shape of a spiral body, and the turning direction of two thread coils arranged on a moving conductor and a fixed conductor is the same, and the moving contact and the fixed contact connected with the two thread coils are oppositely and longitudinally arranged. In the invention, the produced longitudinal magnetic field causes the vacuum arc produced between the contacts to keep in a non-aggregated state during the live cut-off; and the vacuum arc is extinguished when the current of an external circuit exceeds zero point, thereby the on-off of the circuit is finished.

Owner:湖北汉光科技股份有限公司

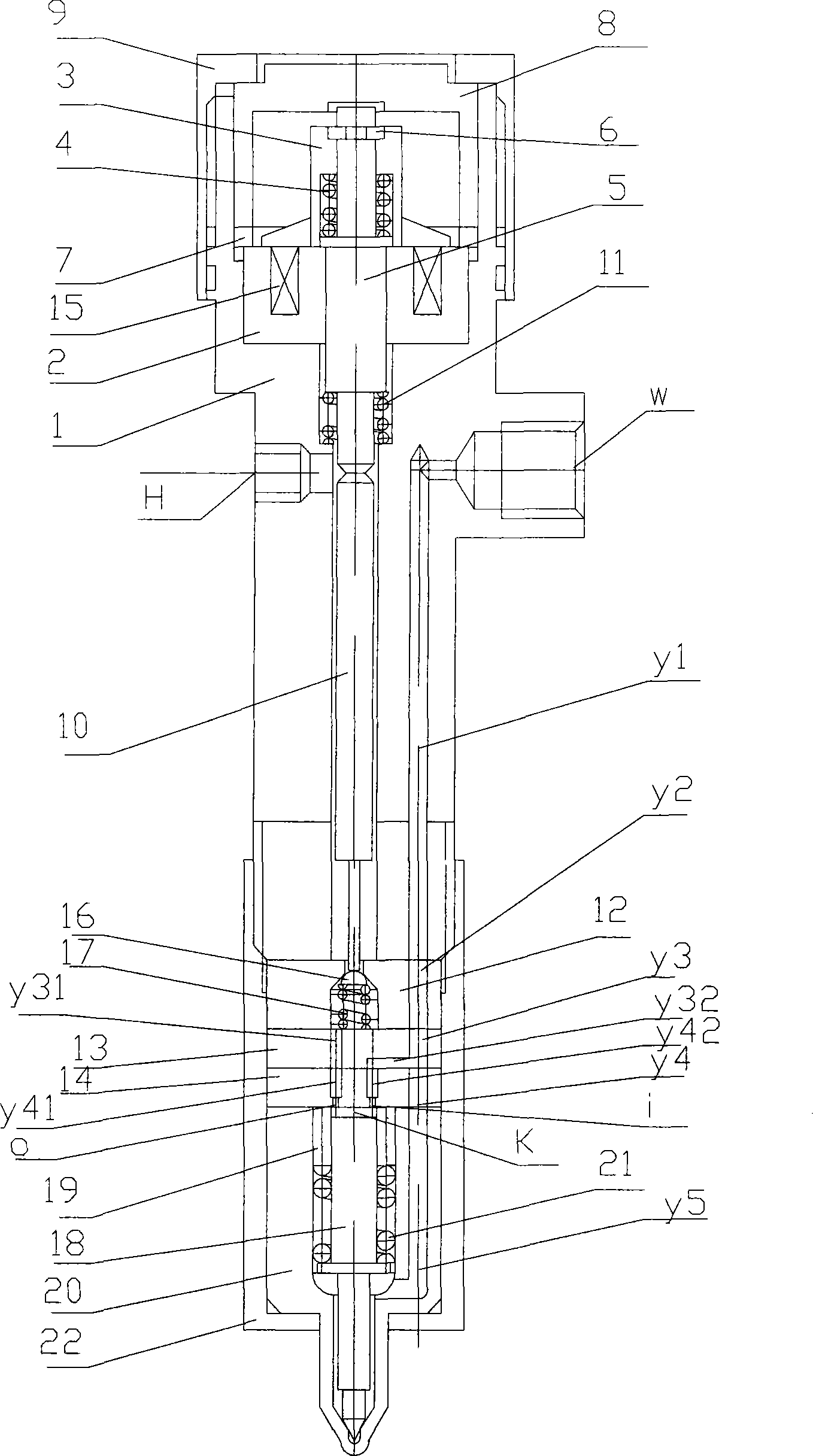

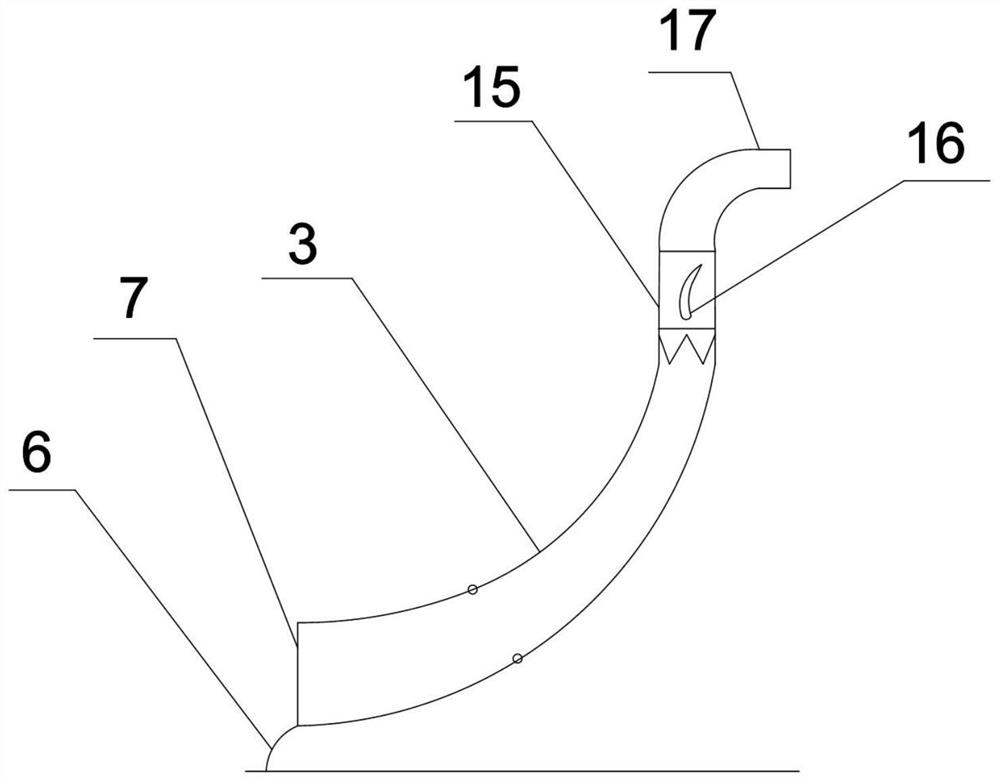

Tappet rod type high pressure co-rail electric-controlled oil ejector

InactiveCN101251067AReduce processing difficultyProcessing is not difficultFuel injection apparatusMachines/enginesCommon railEngineering

The invention provides a tappet type high pressure common rail injector, consisting of an injector body, a high-speed electromagnet, a tappet, a pin valve component, a two-position two-way switch valve and a middle cushion block component, wherein, a central lathy pylome of the injector body is a cascade circular hole, the tappet is arranged inside a small-diameter circular hole of the injector body, the high-speed electromagnet comprises a static iron core, a movable iron core and an offsetting spring. The tappet type high pressure common rail injector has simple structure, greatly reduces the leakage of the high pressure fuel, is easy to establish the high pressure inside the injector body, and realizes the high pressure or the supervoltage fuel injection, thereby satisfying the requirements of much more stringent emission regulations of a diesel engine.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

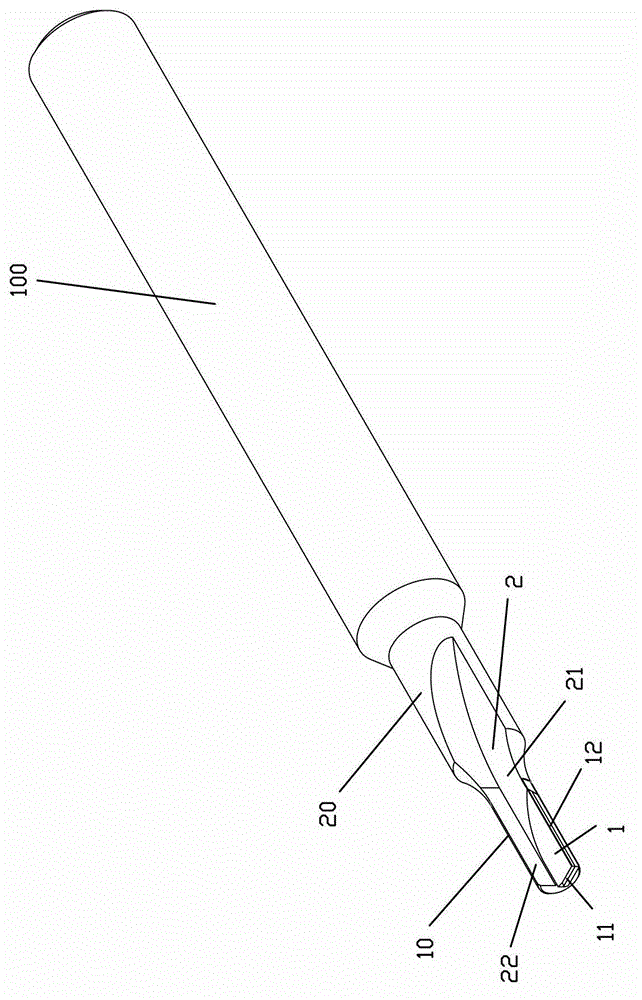

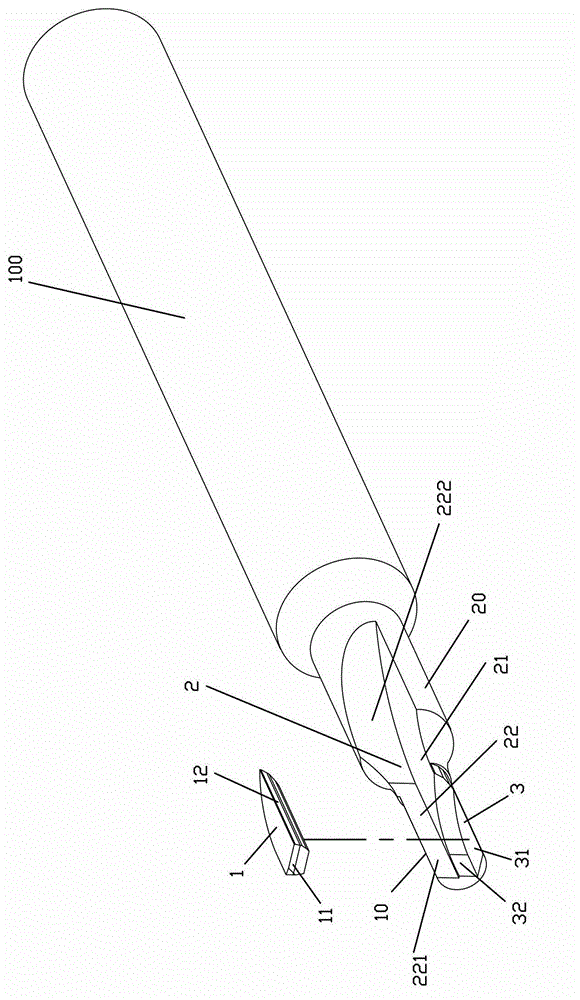

Miniature ultra-hard drilling and milling cutter special for machining ceramic materials and machining method thereof

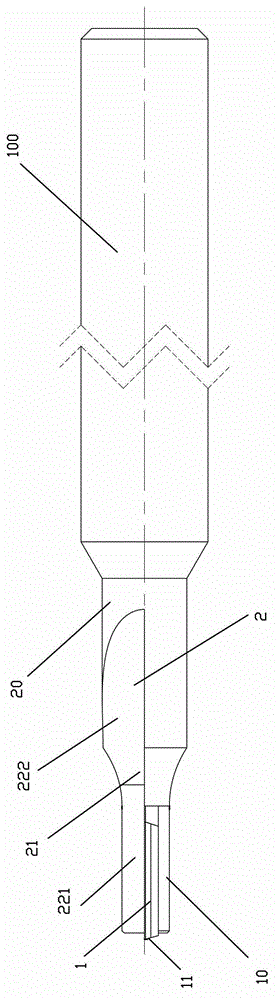

InactiveCN103934906AIncrease drilling speedReduce processing costsStone-like material working toolsMilling cutterPolycrystalline diamond

The invention discloses a miniature ultra-hard drilling and milling cutter special for machining ceramic materials and a machining method of the miniature ultra-hard drilling and milling cutter. The miniature ultra-hard drilling and milling cutter is a round stick made of a hard alloy. One end of the round stick is provided with a chip groove which extends inwards from the tip. A blade groove is further formed downwards in the chip groove. A polycrystalline diamond compact is fixedly connected into the blade groove. The polycrystalline diamond compact is provided with a first side face and a second side face which are perpendicular to each other. The first side face of the polycrystalline diamond compact protrudes out of the round stick in the axial direction of the round stick and forms a bottom cutting edge of the drilling and milling cutter. The second side face of the polycrystalline diamond compact protrudes out of the round stick in the radial direction of the round stick and forms a circumference cutting edge of the drilling and milling cutter. According to the miniature ultra-hard drilling and milling cutter of the structure, holes of the ceramic materials such as aluminum oxide and zirconium oxide can be machined in a drilling and milling mode, defects existing in the prior art can be overcome, and the miniature ultra-hard drilling and milling cutter has the advantages of being high in drilling speed, low in machining difficulty and machining cost and good in machining effect.

Owner:XIAMEN TUNGSTEN +1

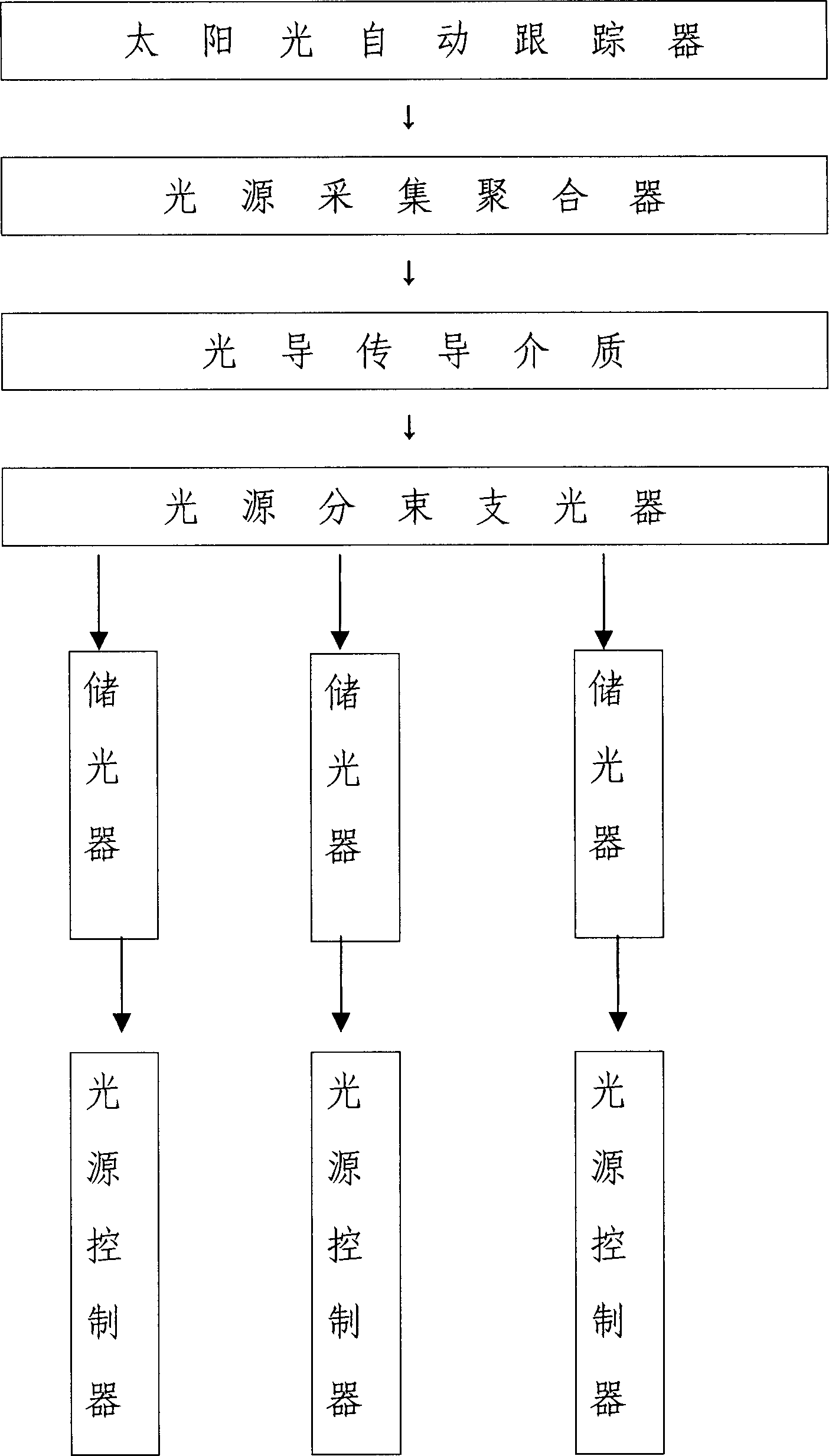

Illumination and illuminator with light as conduction

InactiveCN1818500AGood optical contactGood optical interfaceSolar heat devicesUsing daylightBeam splitterLight guide

In the invention, the sunlight is concentrated into a light beam by automatic tracking, collecting and chemical polymerizing and through the total reflection inside the light-guide medium it makes the light wave go forward along the shaft line to reach the other end of the light-guide medium and be projected into a light source branch beam splitter, and then is distributed into several light collectors made of the light-storage material of aluminates, silicate and sulfide systems.

Owner:刘洋

Longitudinal magnetic field electrode vacuum switch tube with low loop resistance

InactiveCN101459013AShort conductive pathLarge conductive cross sectionHigh-tension/heavy-dress switchesAir-break switchesElectrical resistance and conductanceBlock match

The invention provides a vacuum interrupter with an axial magnetic field electrode with low circuit resistance, which has the low circuit resistance similar as a plate electrode and the strong breaking capacity similar as an axial magnetic field electrode and excellently resolves the conflict between the current conducting capacity and the short-circuit current breaking capacity. A conductive circuit related portion of the vacuum interrupter comprises a movable conducting rod, a contact base, an elastic contact support, an auxiliary current conducting block, a contact and a static conducting rod. The elastic contact support and the auxiliary current conducting block are disposed in an electrode formed by a movable contact, a static contact, a movable contact base and a static contact base, and the movable contact and the static contact are axially arranged correspondingly. The auxiliary current conducting block is cylindrical or circular, and is located inside or outside the elastic contact support. The elastic contact support and the auxiliary current conducting block match in shape, thereby forming an envelope structure. The elastic support is an elastic body axially disposed, and the thickness of the elastic support ranges from 1mm to 5mm. By applying the invention, the circuit resistance of the existing axial magnetic field vacuum interrupter with larger circuit resistance can be obviously reduced.

Owner:湖北汉光科技股份有限公司

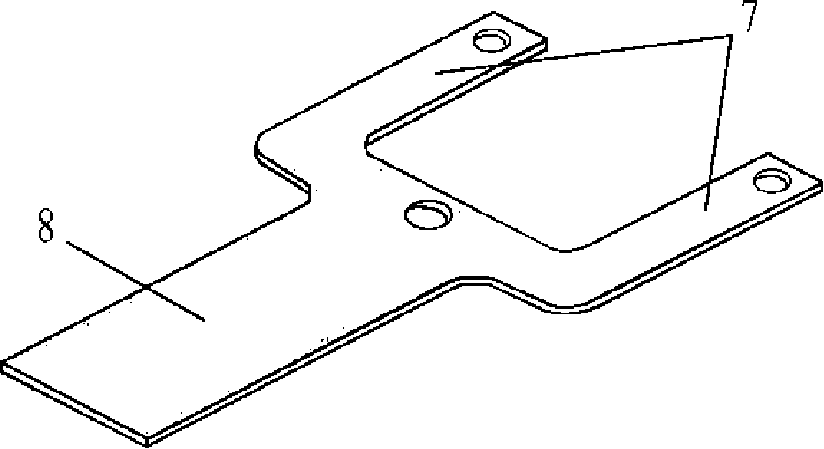

Semiconductor special-purpose equipment wafer grabbing device

InactiveCN101209554AHard to GripSolve problems that are prone to wafer damageGripping headsSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention provides a wafer gripping device which is the equipment specially used for semiconductor, comprising a wafer gripping plate and a vacuum system which is connected with the wafer gripping plate. The wafer gripping plate is a thin-piece shaped integration structure which is bonded by three layers: a gripping panel, a mainbody core plate and a sealing cover plate; the mainbody core plate is provided with a through trough; the gripping panel is provided with a wafer adsorption hole which is correspondingly communicated with the through trough; the position of the sealing cover plate corresponding to the through trough is provided with a vacuum interface. The wafer gripping plate is a fork-shape or claw-shape; the vacuum interface is arranged on a fork handle or a fork handle; wherein, at least two wafer adsorption holes are arranged on a fork tooth or a claw tooth respectively; at least one wafer adsorption hole is arranged on the common boundary position between the fork tooth or claw tooth and the fork handle or claw handle. The device has low requirement to the surface smoothness of an object article to be gripped, reduces manufacture difficulty, has the advantages of simple structure, convenient application, low cost and energy saving, and can be widely applied to the gripping operation of wafer in the equipment specially used for a semiconductor.

Owner:THE 45TH RES INST OF CETC

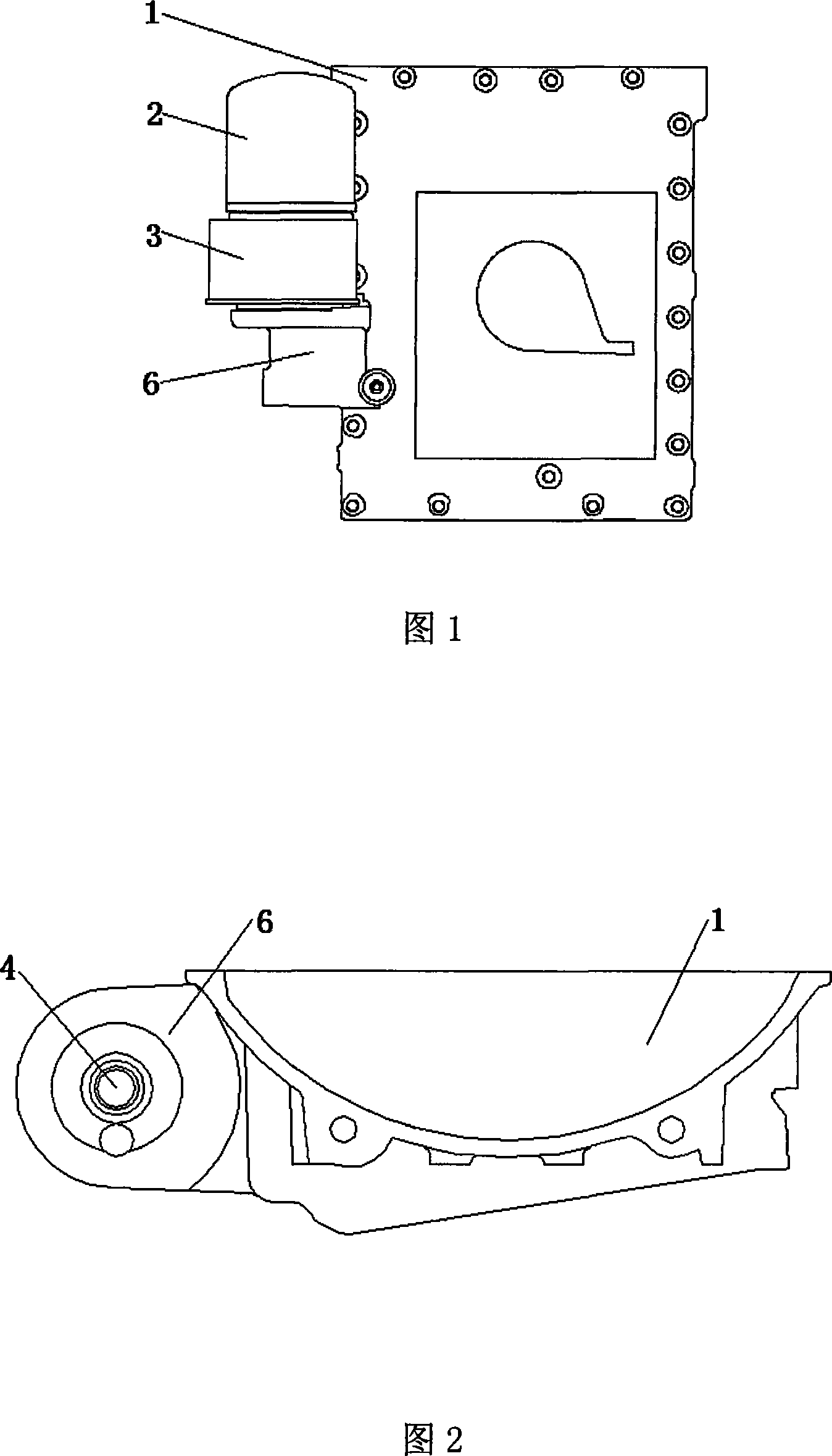

Engine oil bottom case

ActiveCN101144401AMeet functional requirementsGuaranteed reasonablenessMachines/enginesPressure lubricationSpatial structureCylinder block

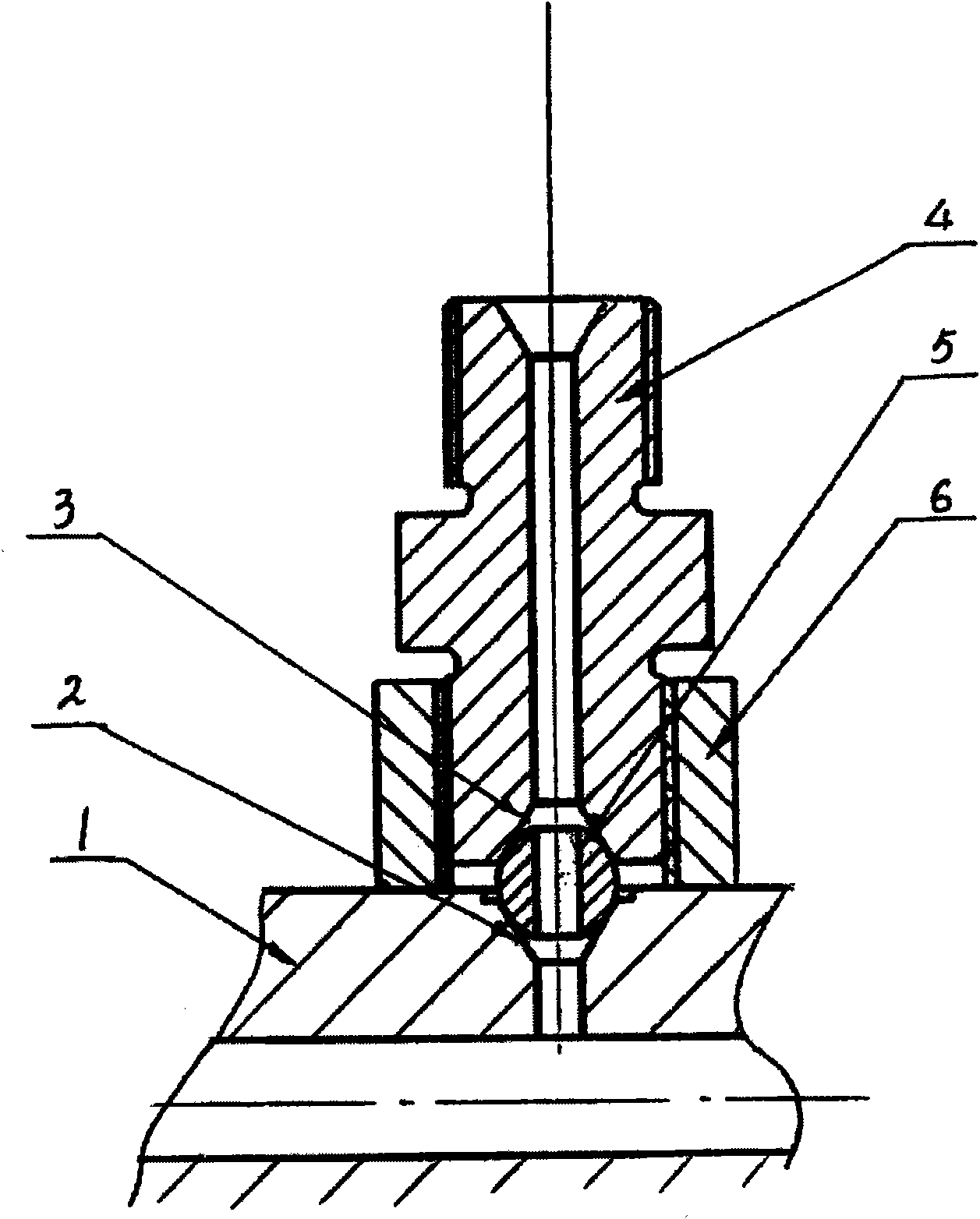

The invention discloses an engine oil sump, and is arranged below the cylinder body of the engine. An oil filter (2) is arranged on the oil sump (1), and the oil filter (2) is tightly connected with the oil sump (1) through a filter mounting dummy club (6) which is integral with the oil sump (1). The position arrangement of the oil filter (2) of the invention is more reasonable, thereby meeting the need of the space structure of the engine, simplifying the engine cylinder body with a more complex structure, the processing difficulty of the oil sump is increased little, and simultaneously the requirements that the processability of product structure as well as the processing technology are optimized.

Owner:安庆福莱克斯动力科技有限公司

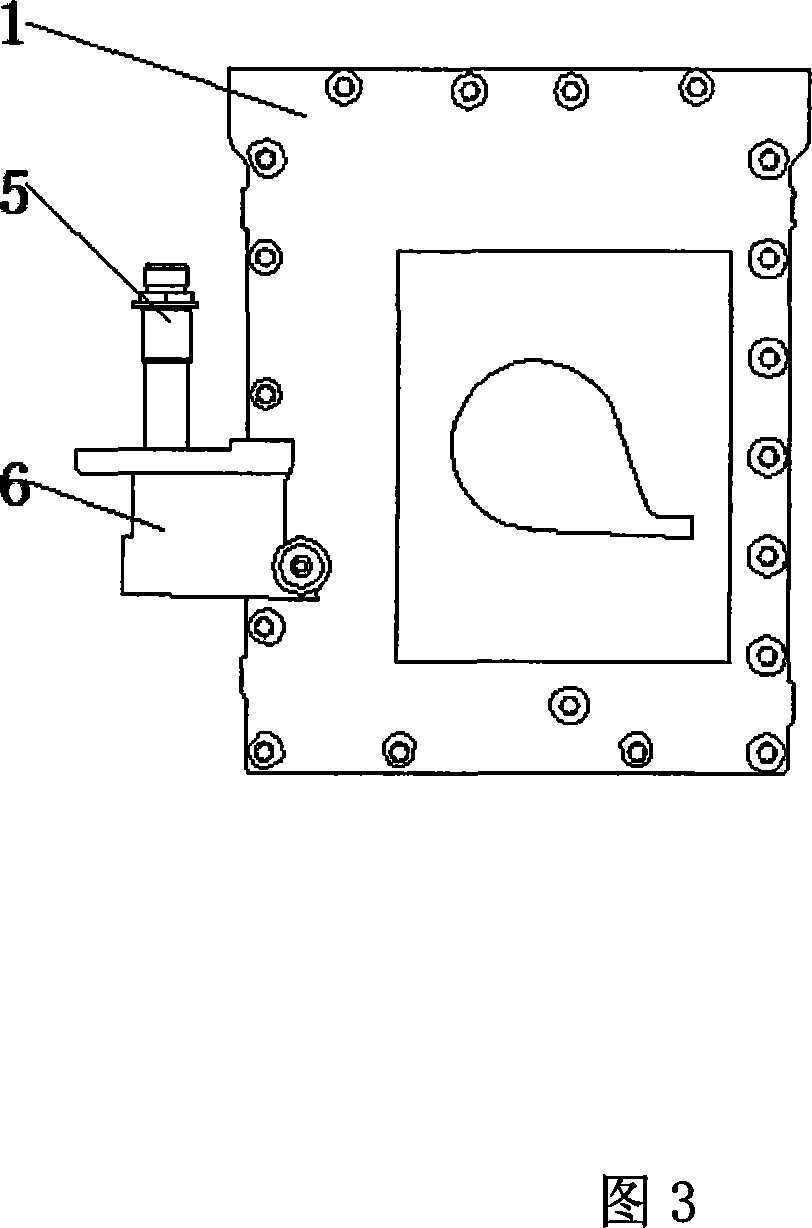

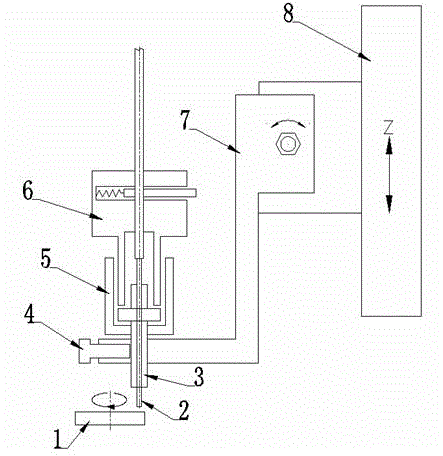

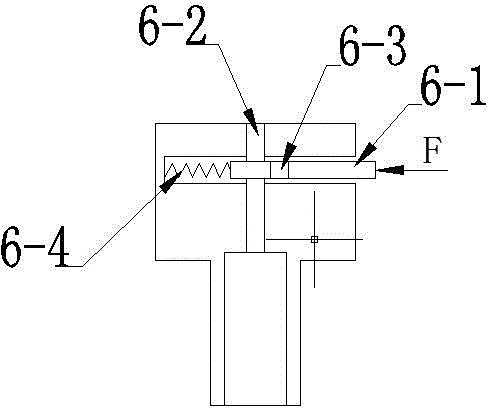

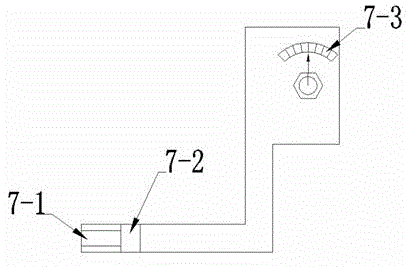

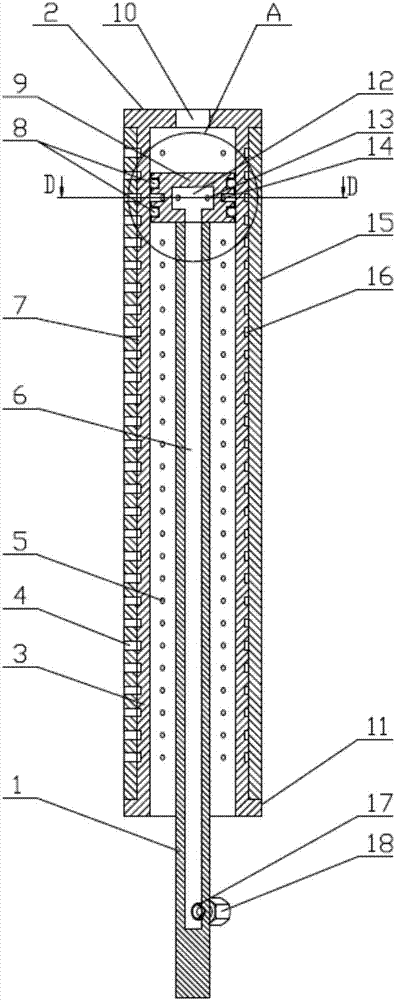

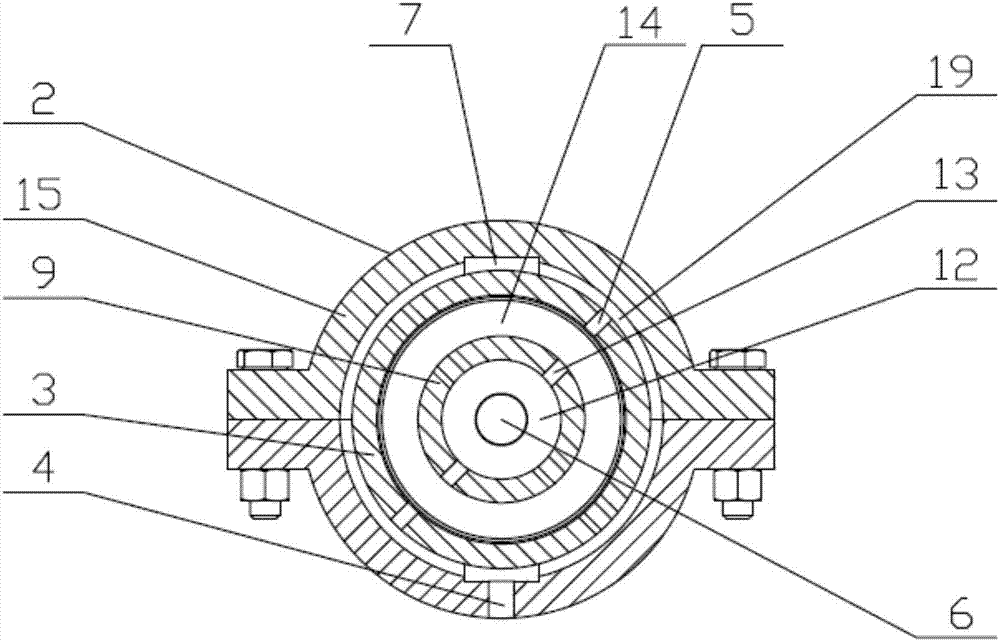

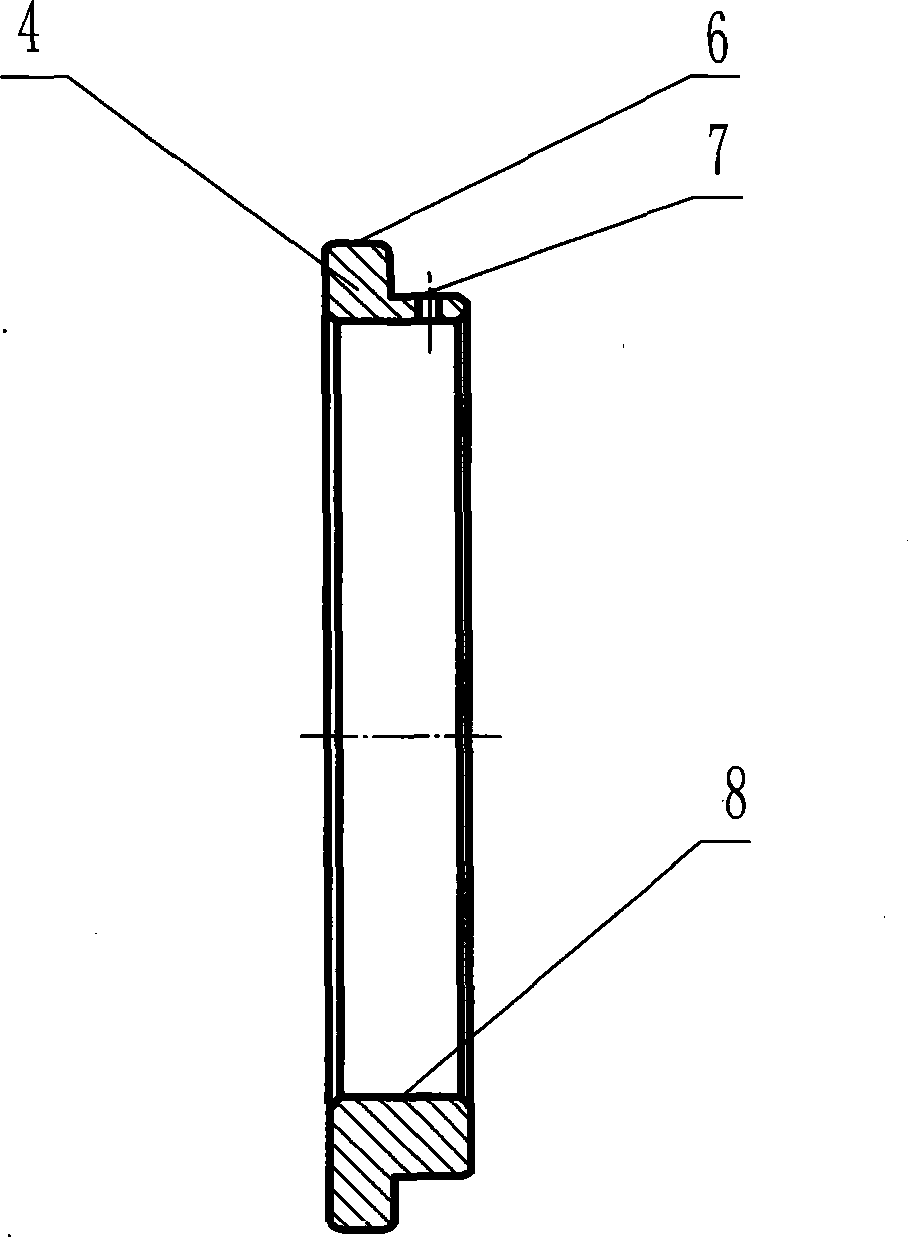

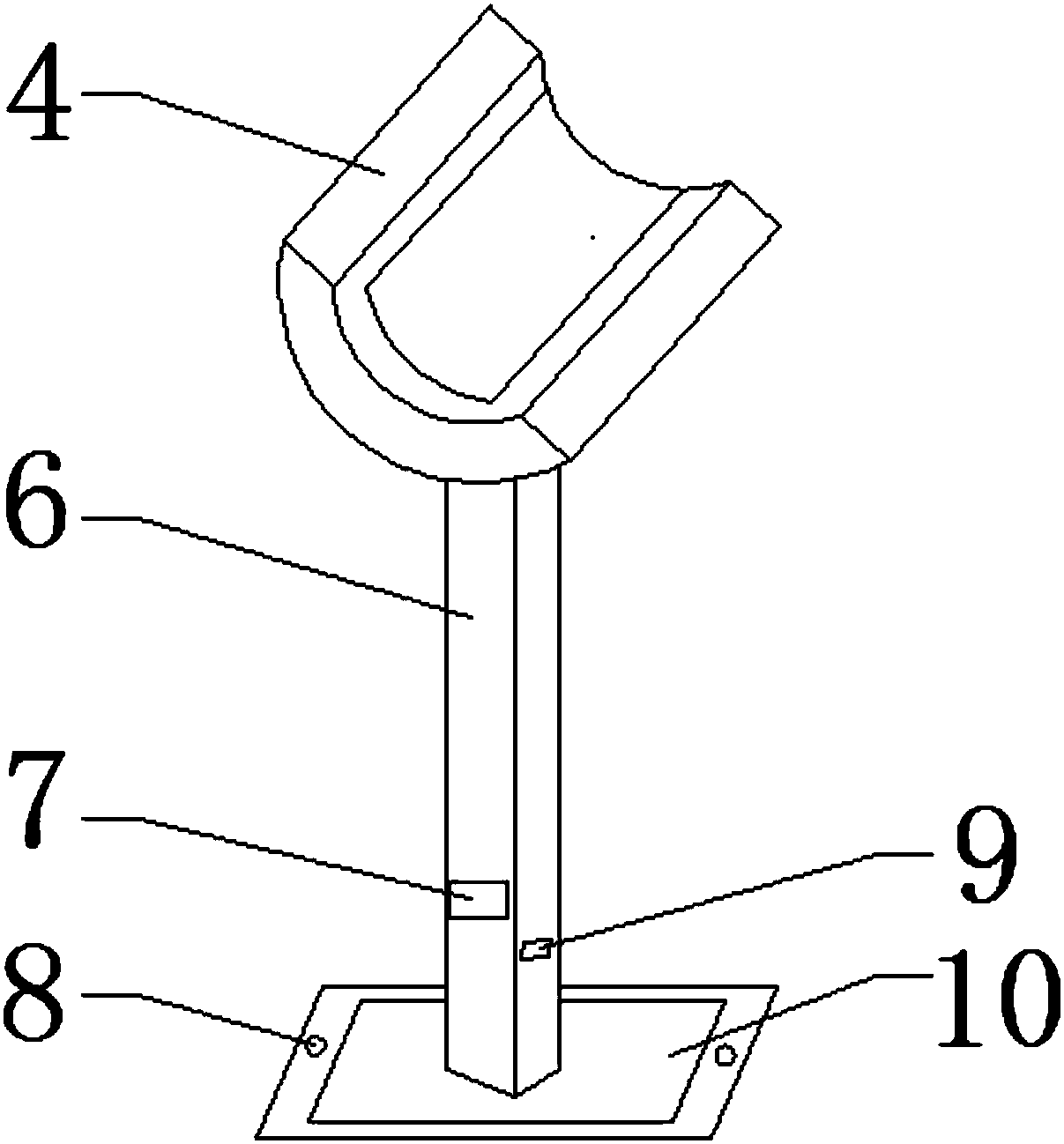

Large-core optical fiber end face processing device and processing method thereof

The invention relates to a large-core optical fiber end face processing device and a processing method thereof. The device comprises a core insert (3) penetratingly connected in a support mechanism (7), a grinding disc (1) is arranged below the core insert (3), the core insert (3) is a ceramic core insert, a large-core optical fiber (2) with a stripped coating layer is inserted in the core insert (3) which is sleeved with a connecting mechanism (5), a guiding mechanism (6) is arranged on the connecting mechanism (5), and the large-core optical fiber (2) with the coating layer is inserted in the guiding mechanism (6). The large-core optical fiber end face processing device and the processing method thereof are convenient to operate and good in grinding effect.

Owner:JIANGSU FASTEN OPTOELECTRONICS TECH

Efficient solar energy thermal absorber based on optical-thermal absorbing cone structure

ActiveCN103123175BReduce reflection lossProcessing is not difficultSolar heating energySolar heat devicesGlass coverPorous medium

The invention relates to an efficient solar energy thermal absorber based on an optical-thermal absorbing cone structure. The efficient solar energy thermal absorber based on the optical-thermal absorbing cone structure comprises a sealing cover, an insulating tube sleeve, an airflow tube, a thermal absorbing body, a glass cover and a thermal absorbing fastening piece. The efficient solar energy thermal absorber is characterized in that the thermal absorbing body is in a truncated prism structure and each plane can be manufactured separately. Each plane is respectively an optical-thermal absorbing conic board, a plurality of sharp pyramids are distributed on a surface of each plane and each plane is made of a high thermal conductive porous material. The glass cover is in a circular truncated cone shape. A closed containing cavity is formed by the sealing cover, the thermal absorbing body and the glass cover. Air enters into the containing cavity through an air inlet of the sealing cover and is heated through each porous medium optical-thermal absorbing conic board so that solar energy is taken and finally flows out from an outlet end of the thermal absorber along the airflow tube. The efficient solar energy thermal absorber based on the optical-thermal absorbing cone structure has the advantages of solving the problems that an existing thermal absorber is low in thermal absorbing efficiency, difficult to process, large in loss in inner flow and the like, being used independently and in a combined mode through connectors, being mainly applicable to a solar energy thermoelectric conversion system and guaranteeing efficient operation of the system.

Owner:南京凌日星能源科技有限公司

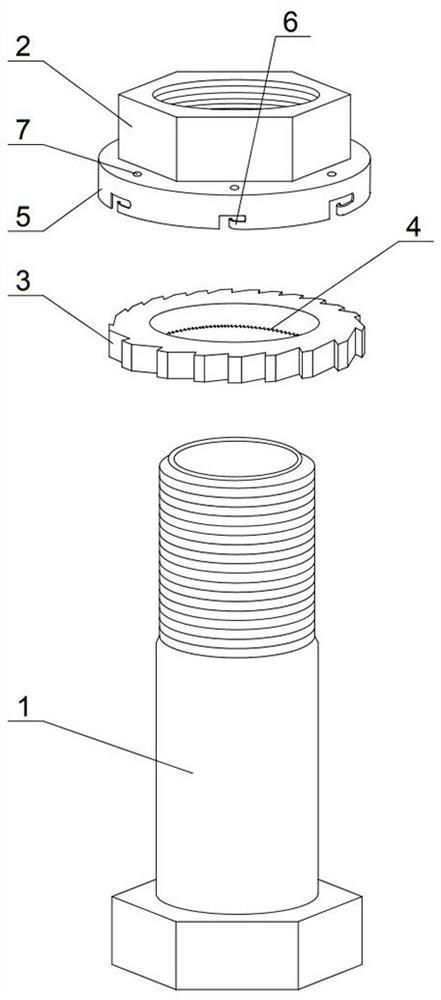

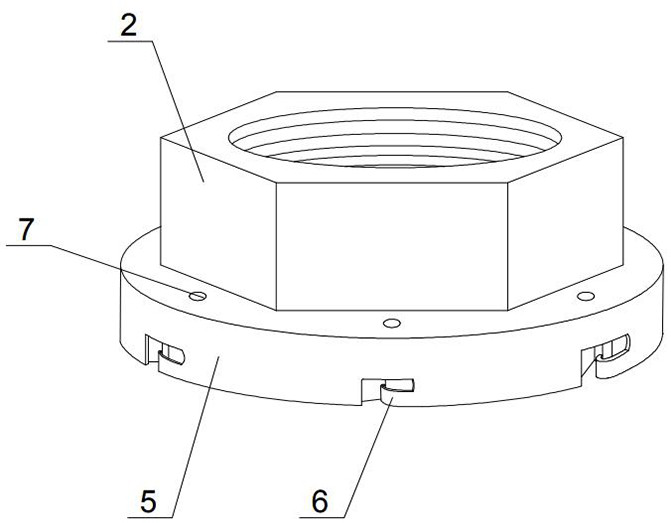

Combined anti-loosening fastener

The invention discloses a combined anti-loosening fastener, and relates to the technical field of fasteners. The fastener comprises a bolt, a nut and an anti-loosening washer; the upper end surface of the anti-loosening washer is coaxially and fixedly connected with a ratchet wheel, the outer diameter of the ratchet wheel is smaller than that of the anti-loosening washer, radial wedge-shaped teeth are annularly arranged on the lower end surface of the anti-loosening washer, the orientation direction of the side end surfaces of the wedge-shaped teeth is consistent with the unscrewing direction of the nut, the bottom end of the nut is fixedly connected with a female cover, the female cover can cover the ratchet wheel, the bottom end of the female cover can be pressed on the upper end surface of the anti-loosening washer, a plurality of pawls matched with the ratchet wheel are arranged on the side wall of the female cover, and one end of the rod part of the bolt can sequentially penetrate through a workpiece, the anti-loosening washer, the ratchet wheel, the female cover and the nut to be connected with the workpiece in a fastened mode. When being used for fixing an object, the anti-loosening fastener can effectively prevent loosening, and is convenient to assemble and relatively low in machining difficulty.

Owner:蒋建伟 +1

High-frequency pulse injection device

ActiveCN106988927AImproved injectionImproved Blending TechnologyContinuous combustion chamberRam jet enginesCompound structureEngineering

The invention provides a high-frequency pulse injection device and relates to the technical field of stamping type engines. The front end of a cylinder body is provided with a through hole, and the cylinder body is of a compound structure as a whole and is composed of a rectification barrel and a rectification sleeve in a wedged and sleeved manner; a piston rod is of a hollow pillar-shaped structure, the upper end of the piston rod is welded to a piston, and the bottom end of the piston rod is sealed; the position, close to the bottom end closed position, of the piston rod is provided with an oil injection hole communicating with the pillar-shaped hollow portion, and the oil injection hole is provided with a threaded transition connector; the piston is of a blind hole structure with a cavity, the cavity communicates with the pillar-shaped hollow portion, a groove in the middle of the piston is an injection hole slot, and the injection hole slot is internally provided with first injection through holes communicating with the cavity; the outer side of the rectification barrel is symmetrically provided with two columns of positioning platforms with rectangular cross sections; and second injection through holes in the inner wall of the rectification barrel communicate with second rectification slots of the rectification sleeve, the second rectification slots of the rectification sleeve are in one-to-one correspondence with the second injection through holes in the rectification barrel, the rectification sleeve is provided with third uniform injection through holes in columns, and the third injection through holes communicate with first rectification slots and the second rectification slots. The high-frequency pulse injection device is used for the stamping type engines.

Owner:YINGSHANG LONGYUYANG IND & TRADE

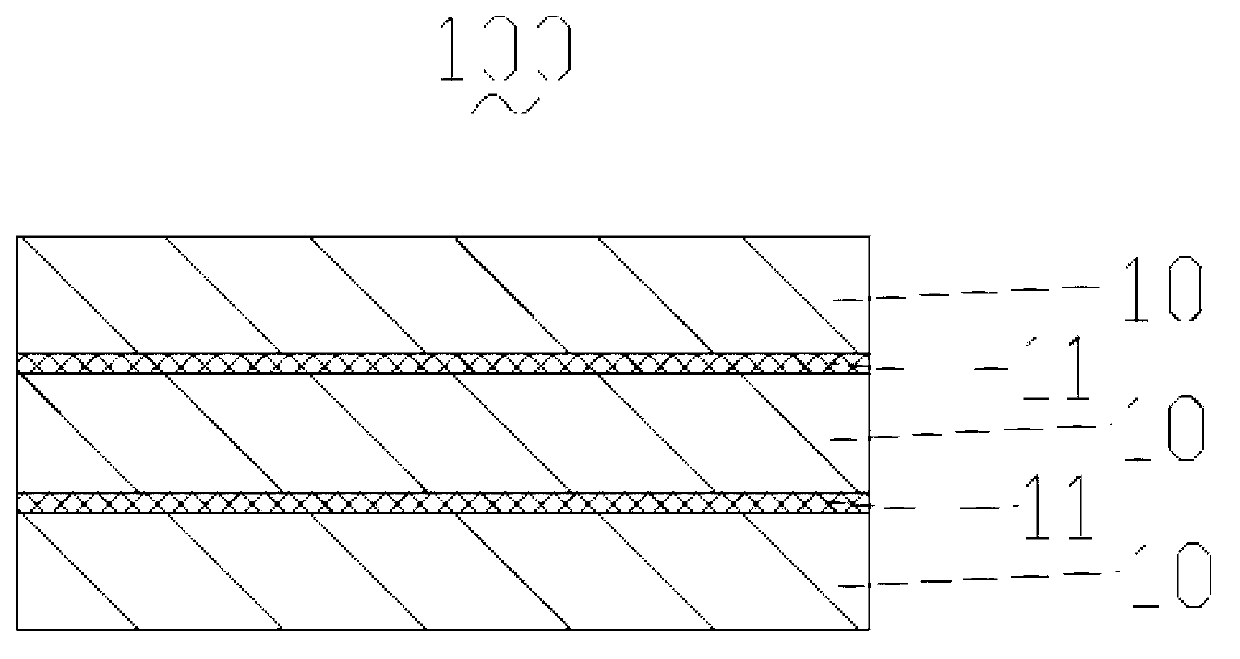

Preparation process of thermal insulation composite sheet material

ActiveCN101863153ASimple preparation processReduce manufacturing costSynthetic resin layered productsLaminationThermal insulationReflectivity

The invention discloses a preparation process of a thermal insulation composite sheet material, which comprises the steps of: preparing materials, mixing, milling, calendering into sheets, compounding, rolling and packaging. The invention has the advantages of simple preparation process, low production cost and low processing difficulty, effectively improves the sheet sound insulating quantity, photo-thermal radiant reflectance and coefficient of heat conductivity, enhances the product performance, provides effective safeguard for the building thermal insulation, integrates compounding and calendering steps into a whole, saves working procedures and the investment in production equipment, reduces the production cost for the industries, and increases the additional value of products.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

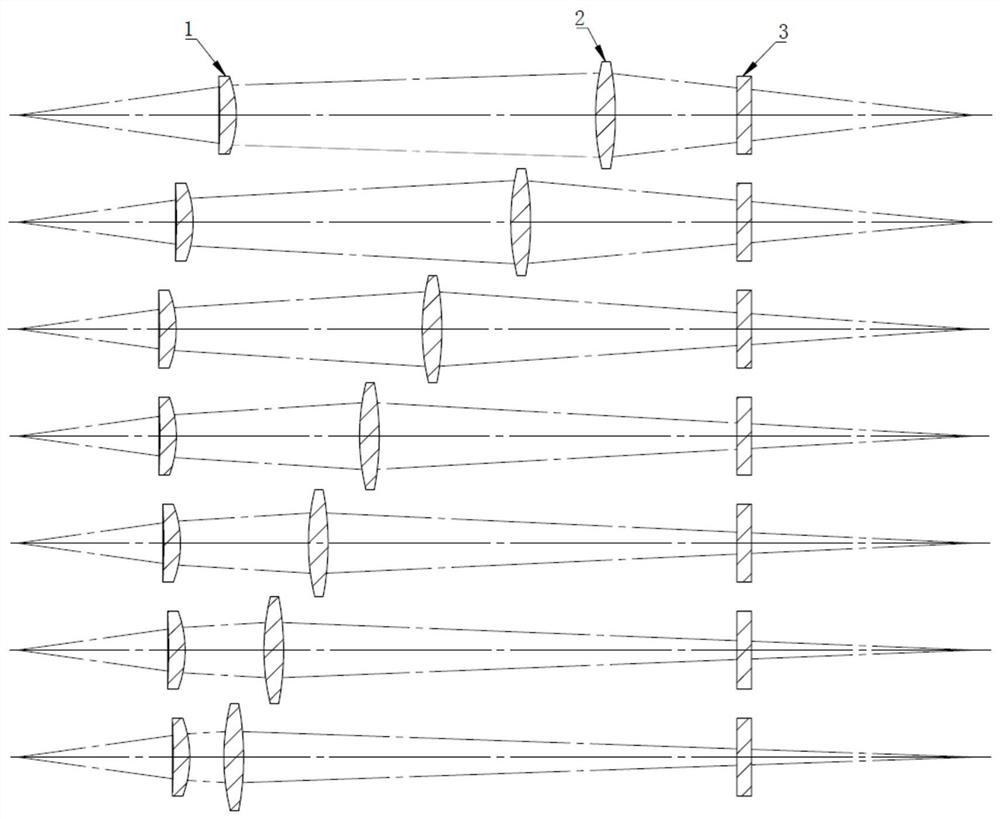

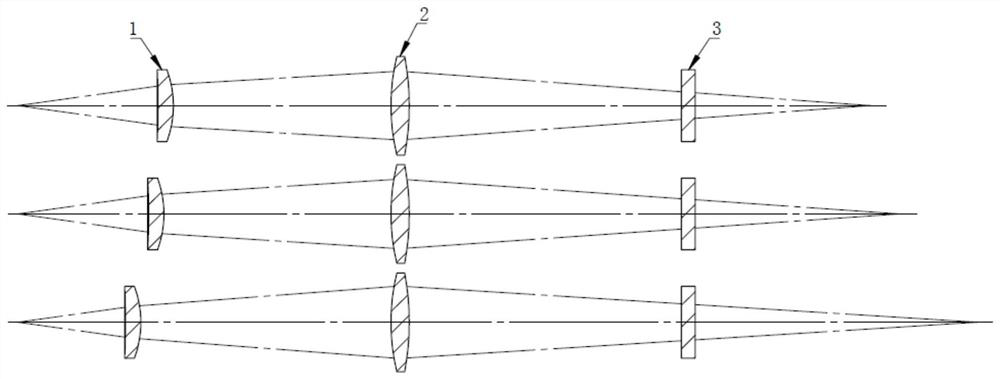

Double-piece aspheric mirror ZOOM optical system

InactiveCN111736329AReduce in quantityNovel structural designMountingsCondensersImaging qualityLight spot

The invention discloses a double-piece aspheric mirror ZOOM optical system which comprises an aspheric positive meniscus mirror, an aspheric biconvex mirror and a protective mirror. The system is novel in structural design, and a full aspheric mirror optical system is adopted. Based on the advantages of few aspheric mirrors and good aberration elimination effect, based on the zoom characteristic of a zoom lens to a focusing light spot and the focusing characteristic of a focusing compensation lens to a focusing point, based on aberration-eliminating diffraction limit image quality under a large numerical aperture and based on the relation between the coating damage threshold value and the mirror surface light spot size and reduction of the thermal lens effect, continuous adjustment of thefocusing light spot size, the divergence angle size and the focus position is achieved through position matching adjustment of the focusing compensation mirror and the zoom lens. The system is suitable for high-power optical fiber laser cutting application, and is particularly compatible with the cutting speed and quality of thin, medium and thick plates.

Owner:SHANGHAI EMPOWER AUTOMATION TECH CO LTD

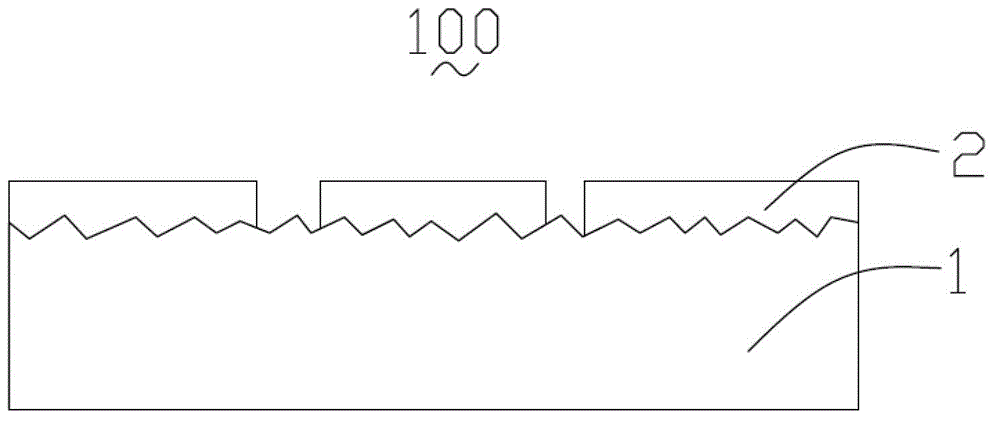

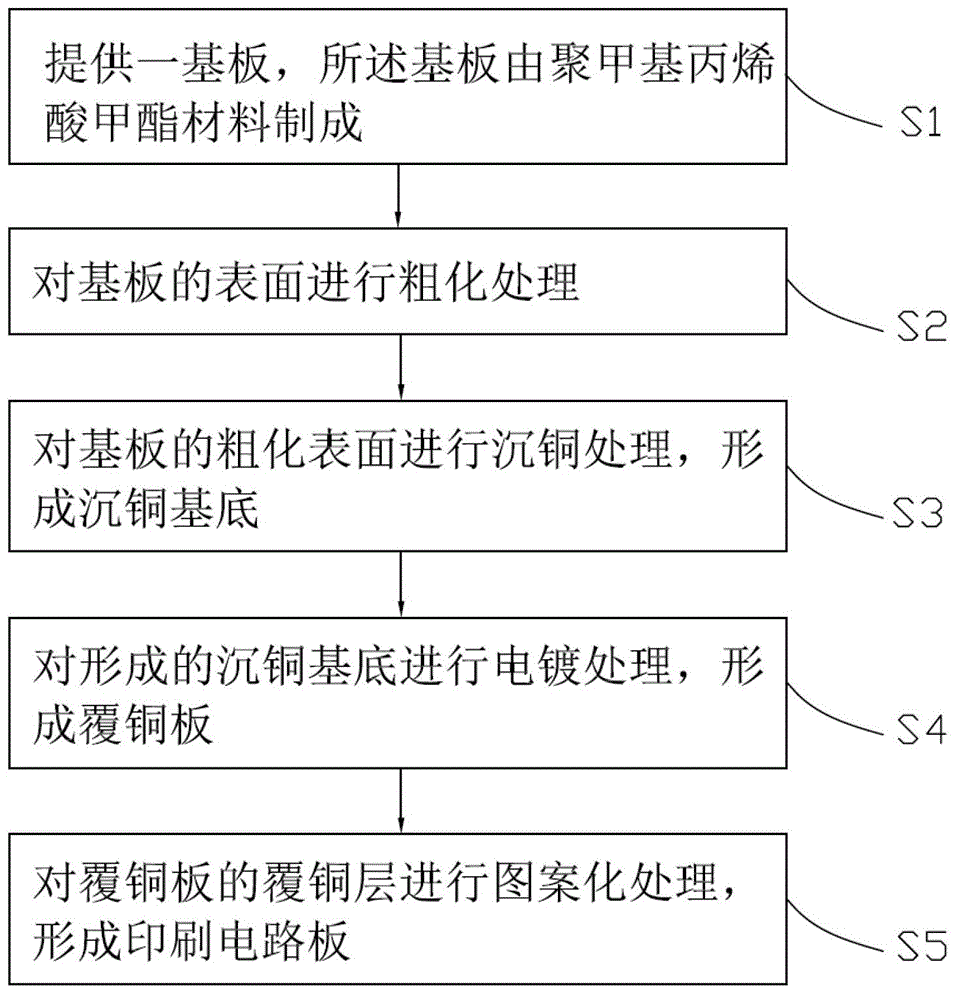

Electrolytic copper-clad plate by taking polymethyl methacrylate as medium, printed circuit board and manufacturing method thereof

InactiveCN102975429AEasy to manufactureImprove insulation performanceInsulating substrate metal adhesion improvementLamination ancillary operationsPolymethyl methacrylatePrinted circuit board

The invention relates to a method for manufacturing a copper-clad plate. The method comprises the following steps of: providing a substrate; manufacturing a polymethyl methacrylate material, and roughening the surface of the polymethyl methacrylate material; performing electroless plating copper treatment on the roughened surface of the polymethyl methacrylate material, and forming an electroless plating copper substrate; electroplating the formed electroless plating copper substrate, and forming the copper-clad plate. The invention also provides a method for manufacturing a circuit board on the basis of the method for manufacturing the copper-clad plate. The invention further provides a copper-clad plate and a printed circuit board. The printed circuit board has the advantages of excellent electrical properties and mechanical properties, wide application range and low cost.

Owner:SHENZHEN WUZHU TECH

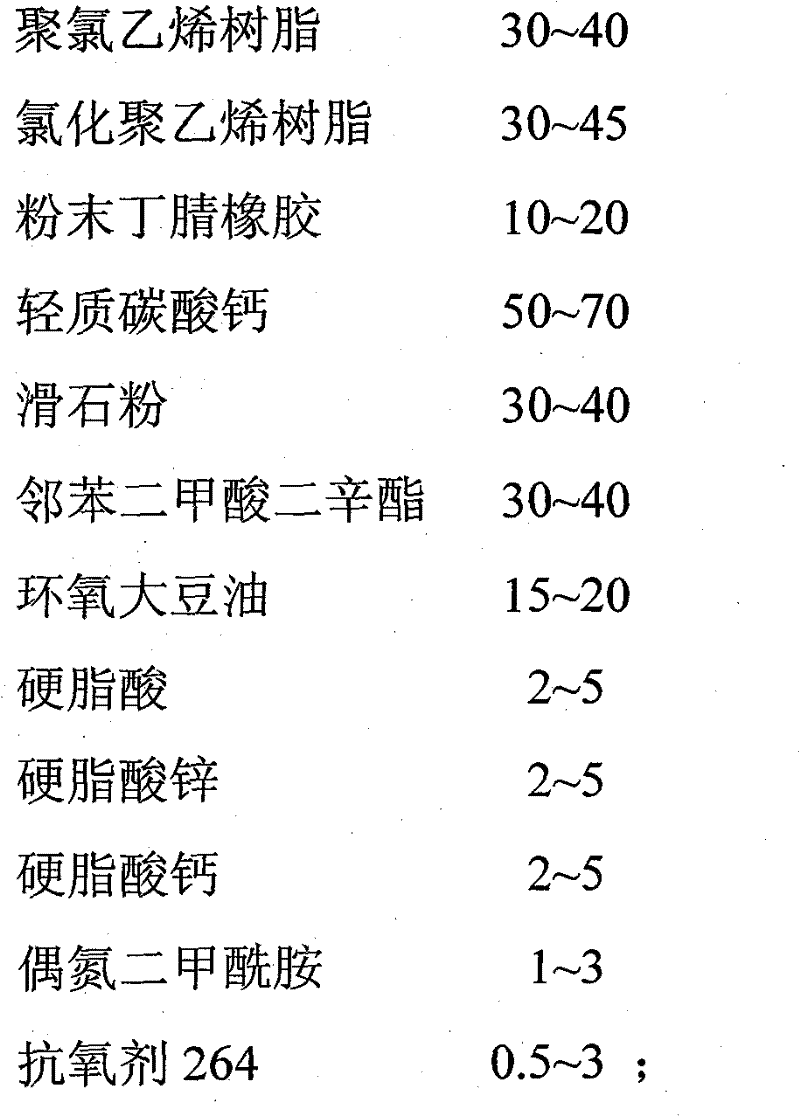

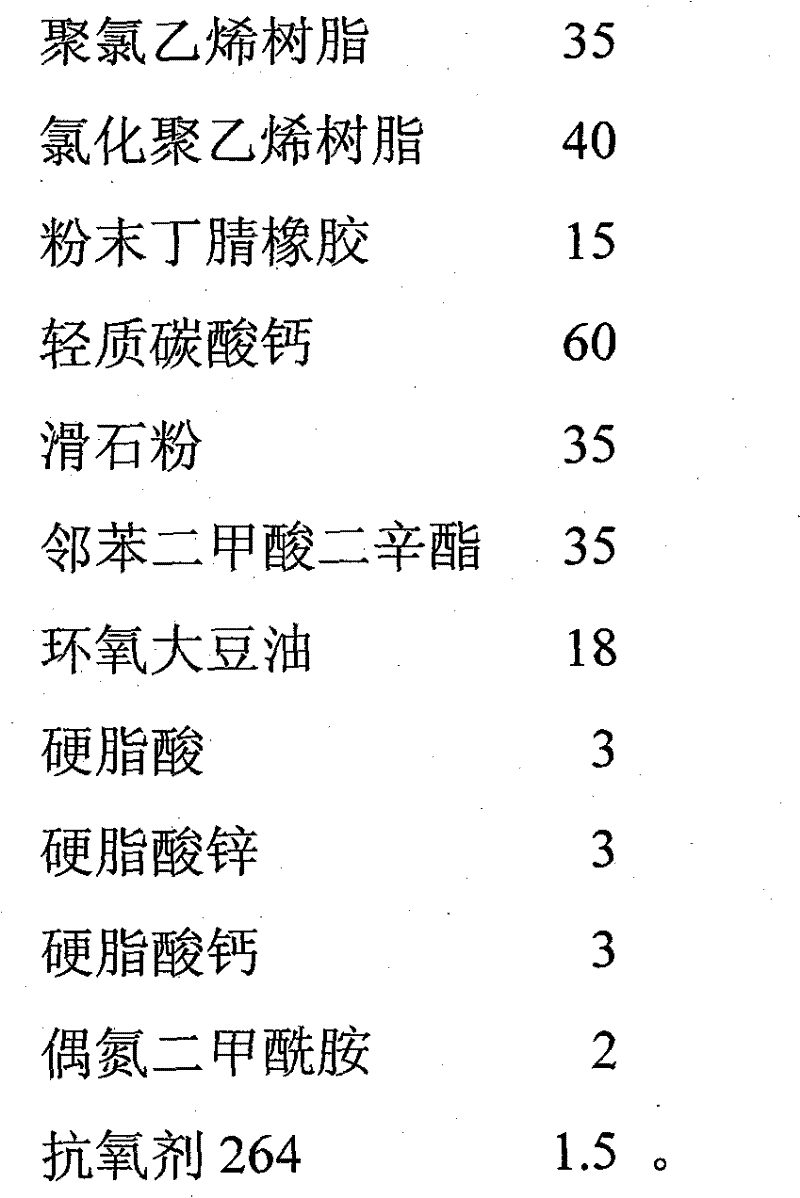

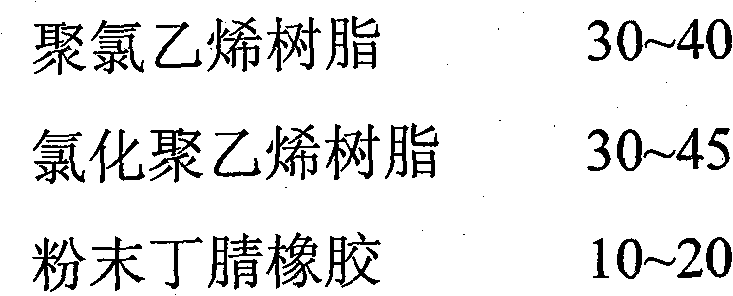

Preparation process of waterproof enhancement sheet in modified polyvinylchloride

The invention discloses a preparation process of a waterproof enhancement sheet in modified polyvinylchloride, comprising the following steps of material preparing, hot mixing, cold mixing, extrusion granulation, and extrusion sheet-forming. The invention has the advantages of simple preparation process, low production cost, low processing difficulty and effective reduction of the production costof enterprises; meanwhile, compared with a waterproof sheet produced by the same type of the production process, the waterproof sheet produced by the process of the invention has better waterproof performance and ageing resistance. The invention effectively improves the tension of the sheet, performance indexes of elongation percentage and low temperature flexibility, and the waterproof performance of the sheet.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

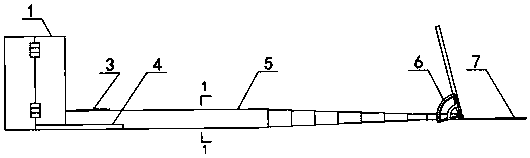

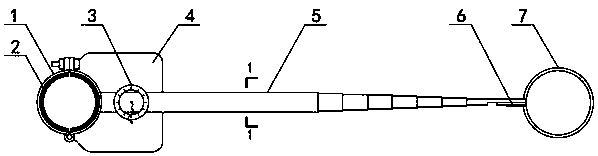

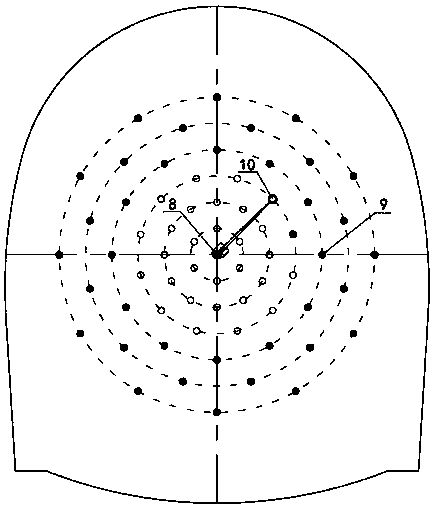

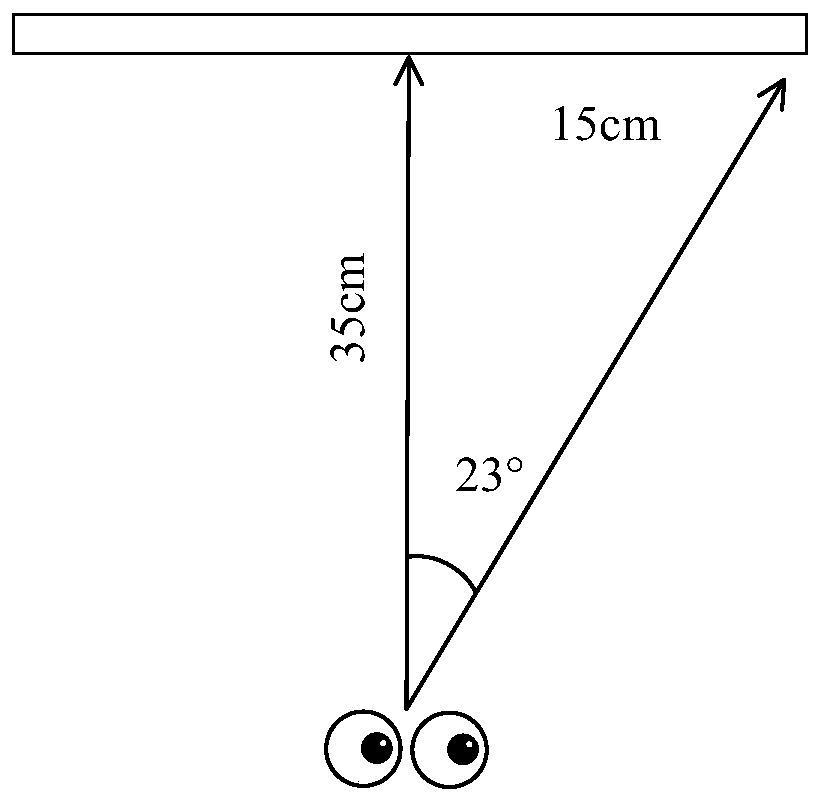

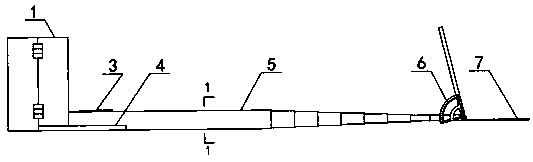

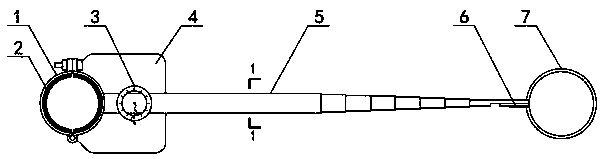

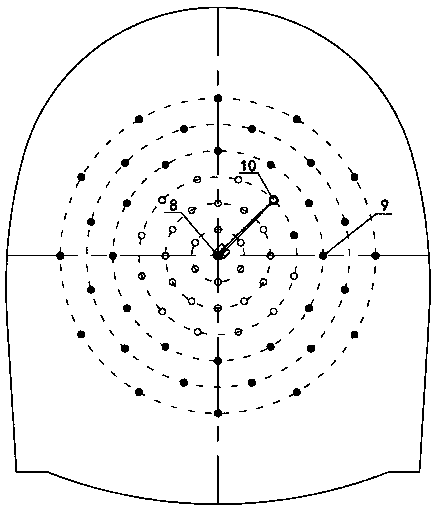

Quick positioning method for tunnel curtain grouting hole

ActiveCN108386208ASimple mechanical structureDifficult to processUnderground chambersTunnel liningProtractorEffective length

The invention relates to a quick positioning method for a tunnel curtain grouting hole. Before using the positioning device, the effective length of a telescopic rod is adjusted according to the construction sequence of the 'first an outer ring and then an inner ring', and then an extension angle is drilled according to the design of each grouting hole position on the outer ring to adjust the inclination of a positioning steel ring; after the positioning device is adjusted, a hoop is nested on an orifice tube; at this time, the positioning steel ring is aligned with the highest position of thegrouting hole in the outer ring, and a circle is drawn along the inner edge of the steel ring to quickly position for a drill pipe to drill; similarly, the telescopic rod is rotated several times andall grouting holes in the outer ring can be sequentially and quickly drawn according to the same included angle; the mode is repeated and the effective length of the telescopic rod is adjusted so that other grouting hole positions can be quickly positioned, the construction radius can be adjusted by changing the length of the telescopic rod, while a plane angle disc and an extension protractor can change the angle of the positioning steel ring. After the length of the telescopic rod and the angle of the extension protractor are determined, the same ring of grouting holes can be quickly positioned, and the construction efficiency is high.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Squeeze film damper with novel outer ring structure

ActiveCN112096783AExpand the working areaReduce leakageRotating vibration suppressionSqueeze filmControl theory

The invention relates to a squeeze film damper with a novel outer ring structure. The squeeze film damper comprises a fixed damper outer ring, a fixed elastic support base and a damper inner ring arranged on the inner ring of the damper outer ring, wherein the damper inner ring is connected with the elastic support base through an elastic support, and a rotor is arranged on the inner ring of the damper inner ring; an oil film is filled between the inner ring of the damper outer ring and the outer ring of the damper inner ring; an oil supply hole communicated with the oil film is arranged on the damper outer ring; a plurality of oil film counter bores are evenly distributed on the inner ring of the damper outer ring in the circumferential direction; and lubricating oil entering the oil filmcan immediately fill the oil film counter bores under the action of vortexes existing in the oil film counter bores; the vortex effect in the oil film counter bores can hinder the flow of the lubricating oil, completeness of the oil film is guaranteed, more vibration energy can be absorbed through the vortex effect of the oil film counter bores, oil film damping is improved, oil film rigidity isreduced, and stability of a rotor system is improved.

Owner:SHENYANG AEROSPACE UNIVERSITY

Concentrating module, backlight module and display device

InactiveCN110133910ASimple structureImprove spotlight effectPrismsNon-linear opticsDisplay deviceEngineering

The application discloses a concentrating module, a backlight module and a display device. The concentrating module comprises a bottom surface, a plurality of first optical surfaces and a plurality ofsecond optical surfaces, wherein the plurality of first optical surfaces and the plurality of second optical face surfaces s are each opposite the bottom surface; the first optical surfaces and the second optical surfaces form ribs, at least part of the regions of the first optical surfaces and / or the second optical surfaces is arranged with a concentrating microstructure, the pattern of the concentrating microstructure comprises at least one of a triangular wave, a sine wave and a trapezoidal wave and is disposed along the direction of the ribs, and the concentrating module can reduce the brightness difference between the edge region and the central region of the display device, and enhance the brightness of the edge region, so that the corresponding display device has better consistencyand superior display effect in the display region.

Owner:KUSN INFOVISION OPTOELECTRONICS

Component prism-based phase diversity wavefront sensor

ActiveCN102564612BSimple optical structureReduce processing difficultyOptical measurementsOptical elementsWavefront sensorHigh resolution imaging

The invention relates to a component prism-based phase diversity wavefront sensor comprising a lens, a component prism, a CCD imaging detector, and a computer system. After a parallel light beam containing wavefront distortion passes through the lens and is focused, the focused light beam is vertically irradiated on a front surface of the component prism; after the light beam passes through the component prism, an incident light beam is split into two beams of lights; and two beams of lights emitted by the component prism are imaged on a CCD photosensitive surface, wherein there is a fixed light path difference between the two beams of lights. According to the invention, the optical structure of the sensor is simple; the CCD imaging detector can simultaneously collect a focal plane light intensity distribution image and a defocused light intensity distribution image, so that the synchronism and the real-time property of the two images can be ensured as well as detection precision of the phase diversity wavefront sensor on dynamic aberration and restorability on an expansion object can be effectively improved; and moreover, the provided phase diversity wavefront sensor has obvious advantages in fields like optical detection, adaptive optics, high resolution imaging and the like.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

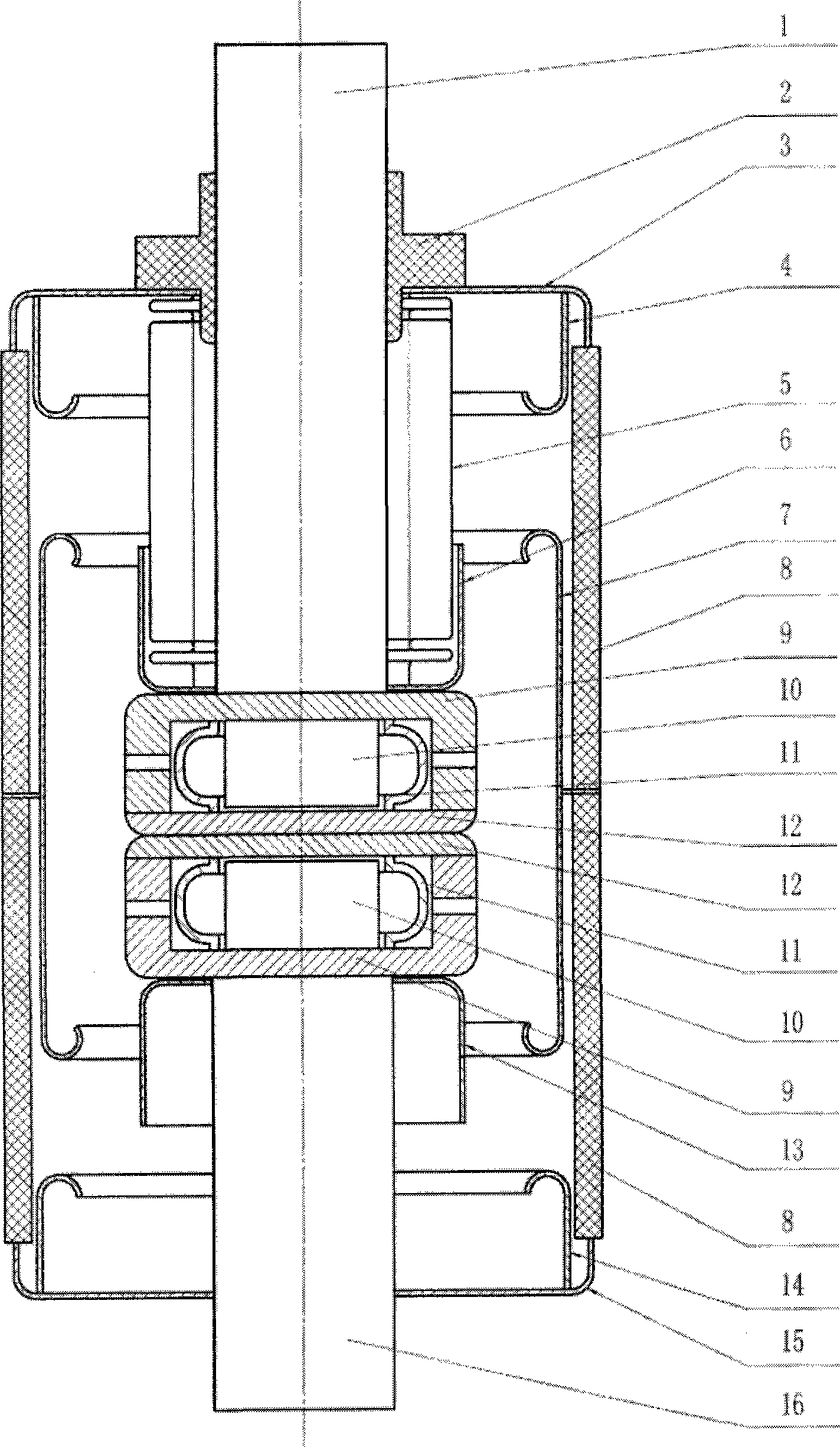

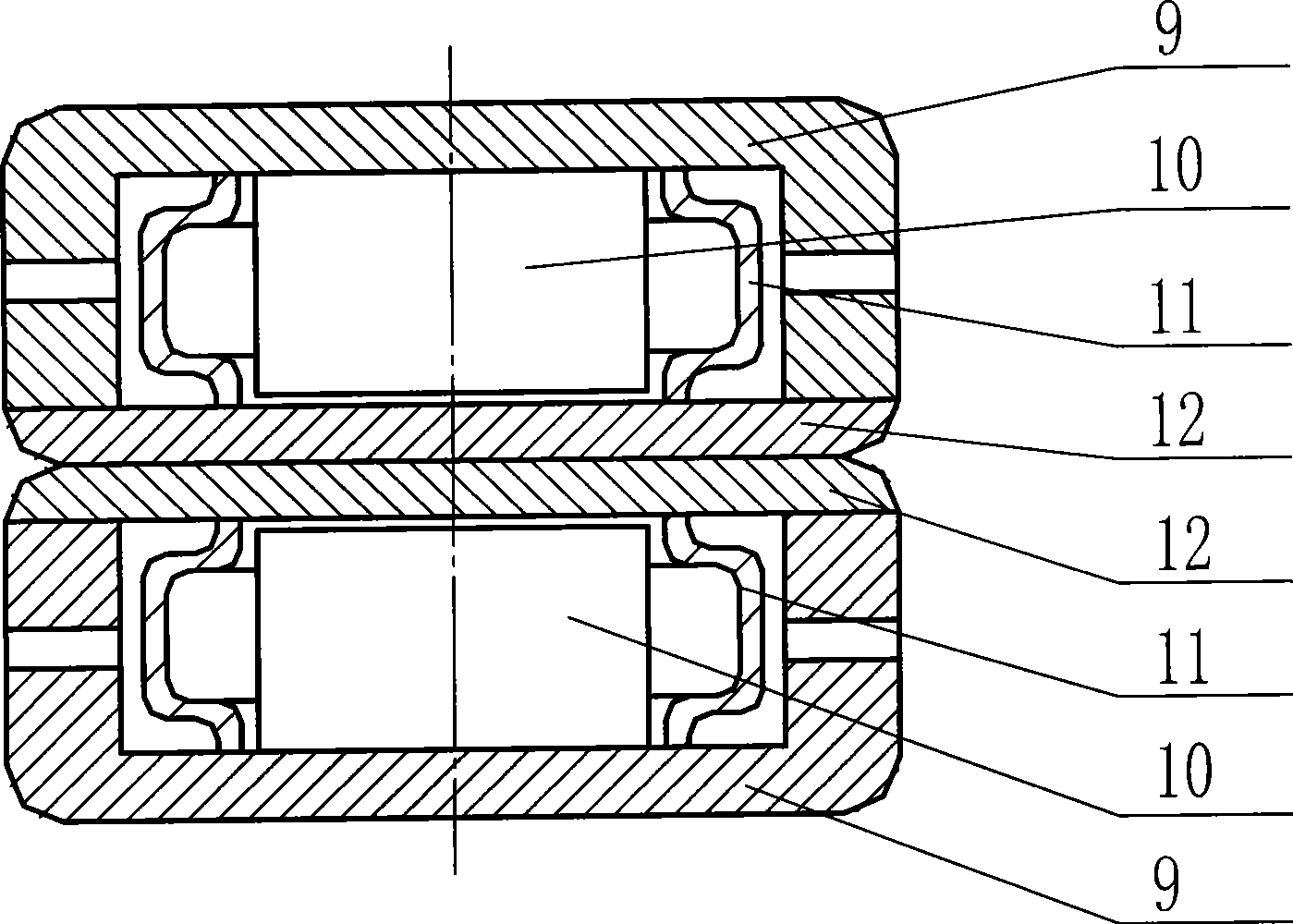

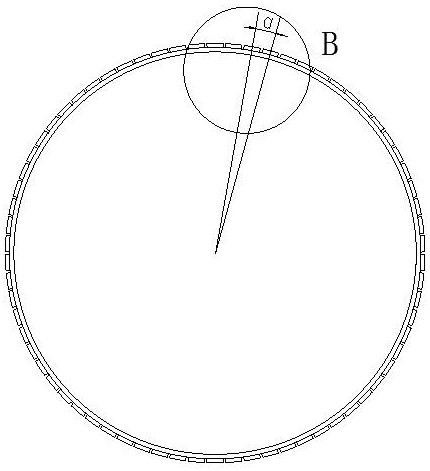

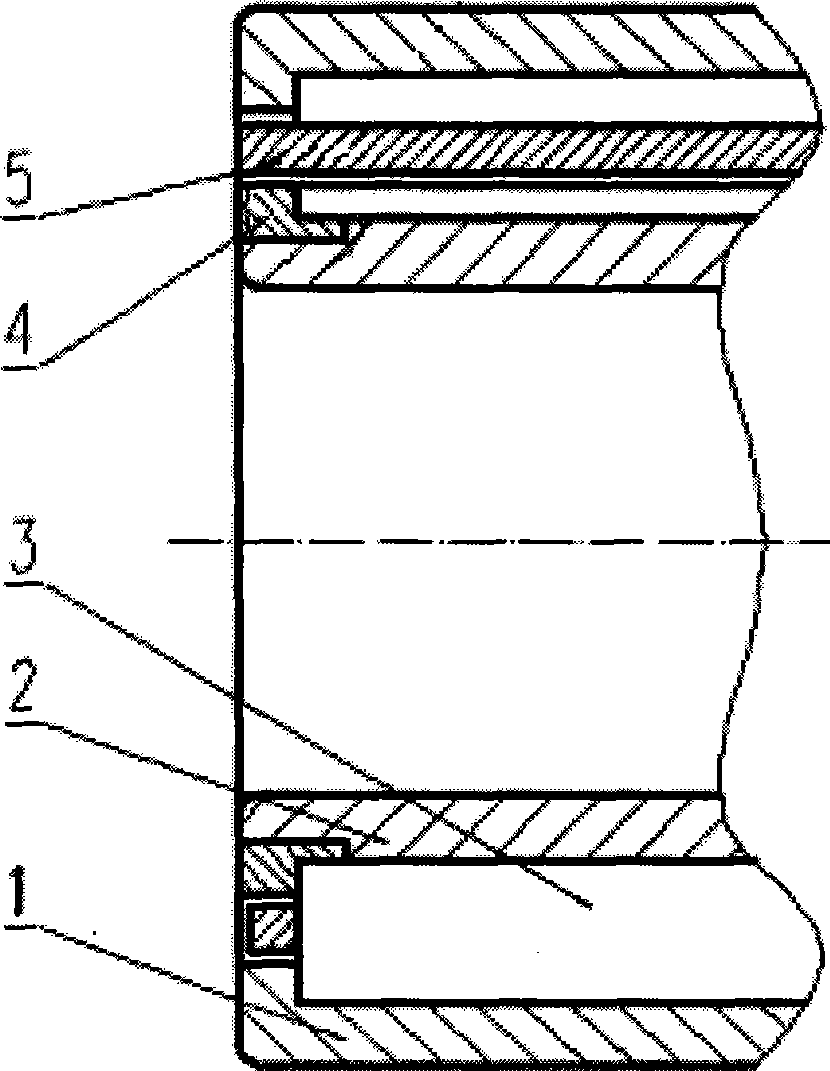

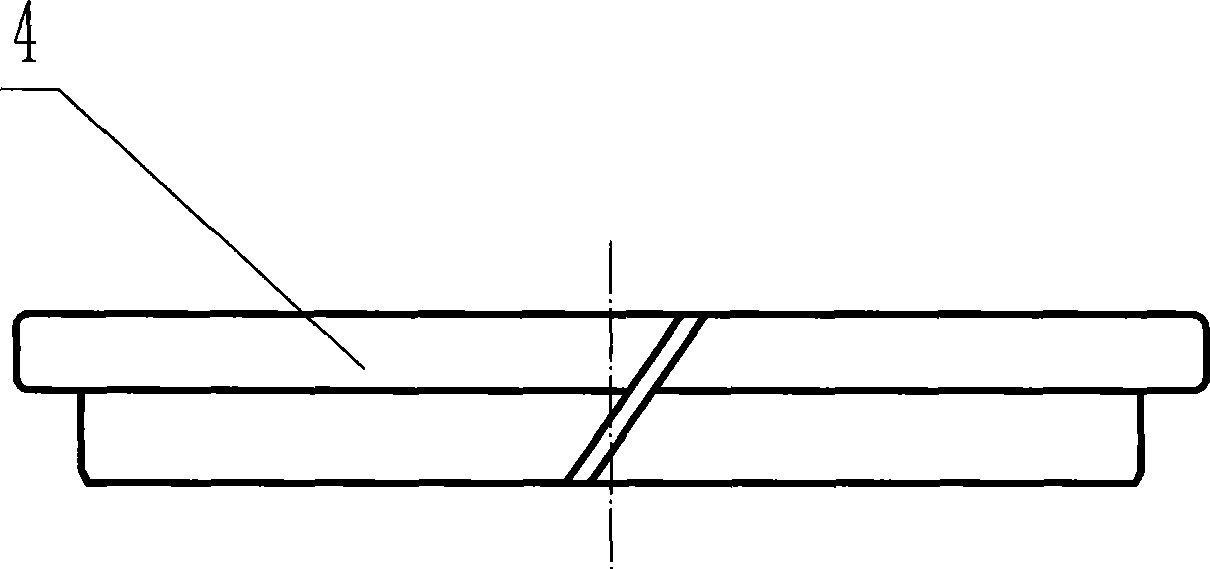

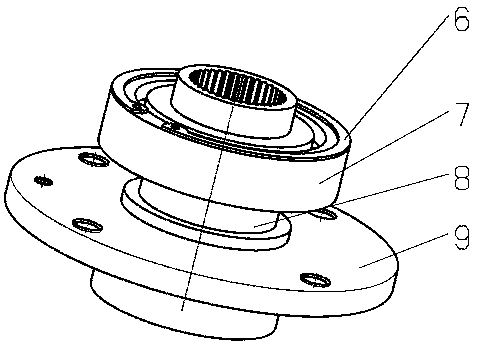

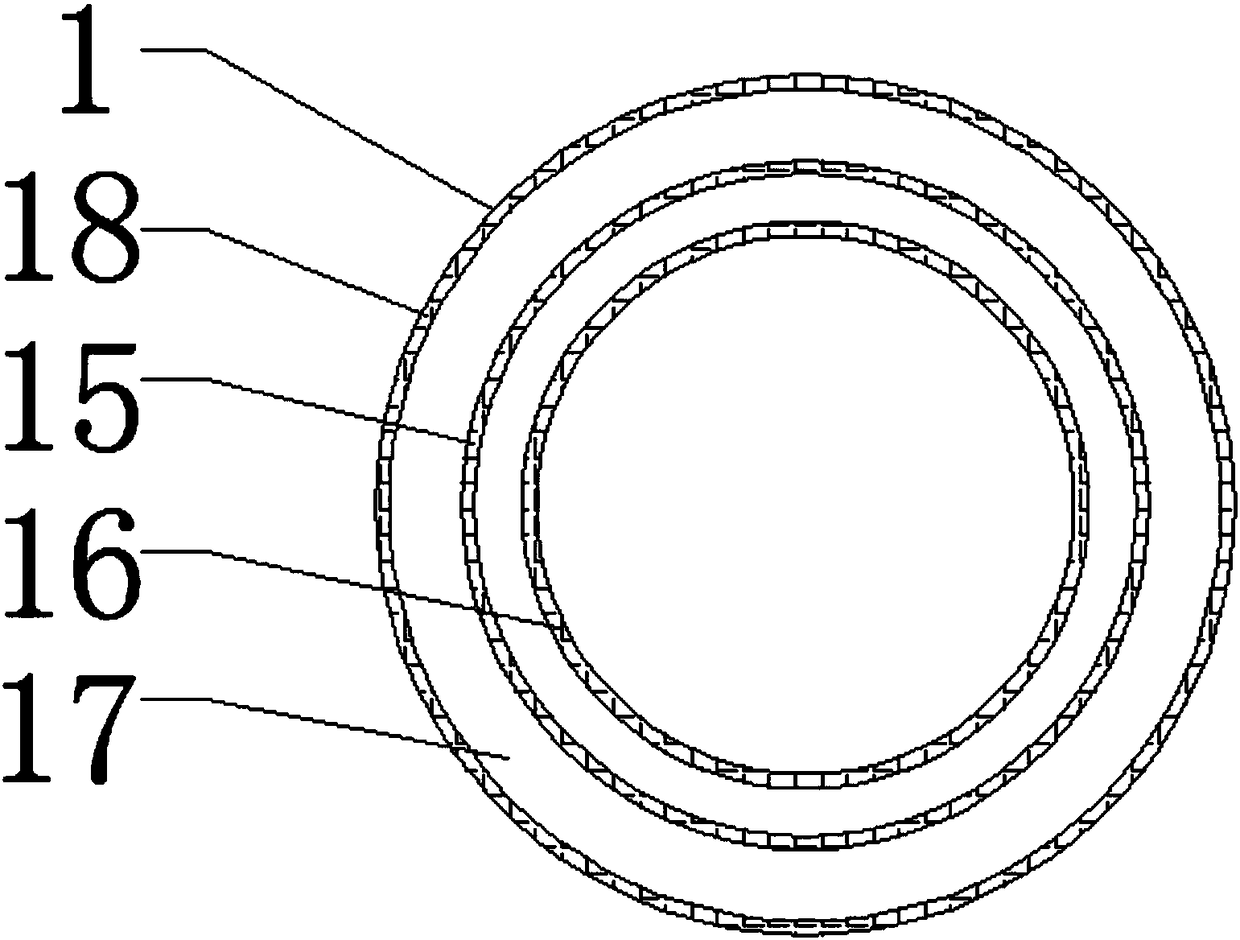

Radial pre-tightening method and pre-tightening ring of cylindrical roller bearing

The invention relates to a method for radially pretightening a column roller bearing, and a pretightening ring. The pretightening ring (4) comprises two step-shaped outer diameters of a pretightening ring (6) with different diameters, a rollerway nest circle of the pretightening ring (7), and a concentric or non-concentric inner diameter of the pretightening ring in a cylindrical annular structure, wherein no baffle is arranged on either end of the non-concentric outer diameter of the pretightening ring and is cut in the thinnest wall area from the outer diameter of the pretightening ring (6) to the outer diameter of the pretightening ring in the direction of 45 angle, so that the pretightening ring (4) has certain adjusting room and flexibility. The rollerway nest circle of the pretightenng ring (7) pushes a roller to an outer rollaway nest and generates mutual extrusion to prevent a rolling body from sliding on the surface of the rollaway nest. By adopting the method and the pretightening ring, the roller of a column roller bearing can be effectively prevented from skidding on the rollaway nest, and early invalidation of the bearing due to the skid of the bearing can be further prevented, so that the effective service life of the column roller bearing under special working conditions can be prolonged.

Owner:中浙高铁轴承有限公司

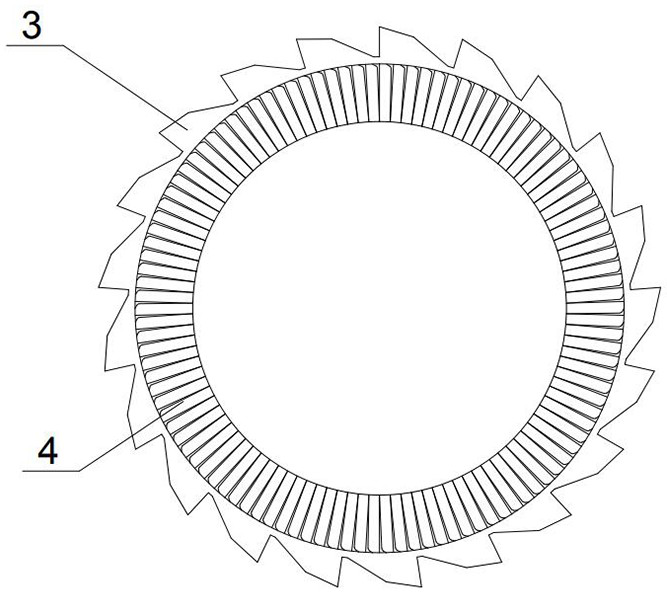

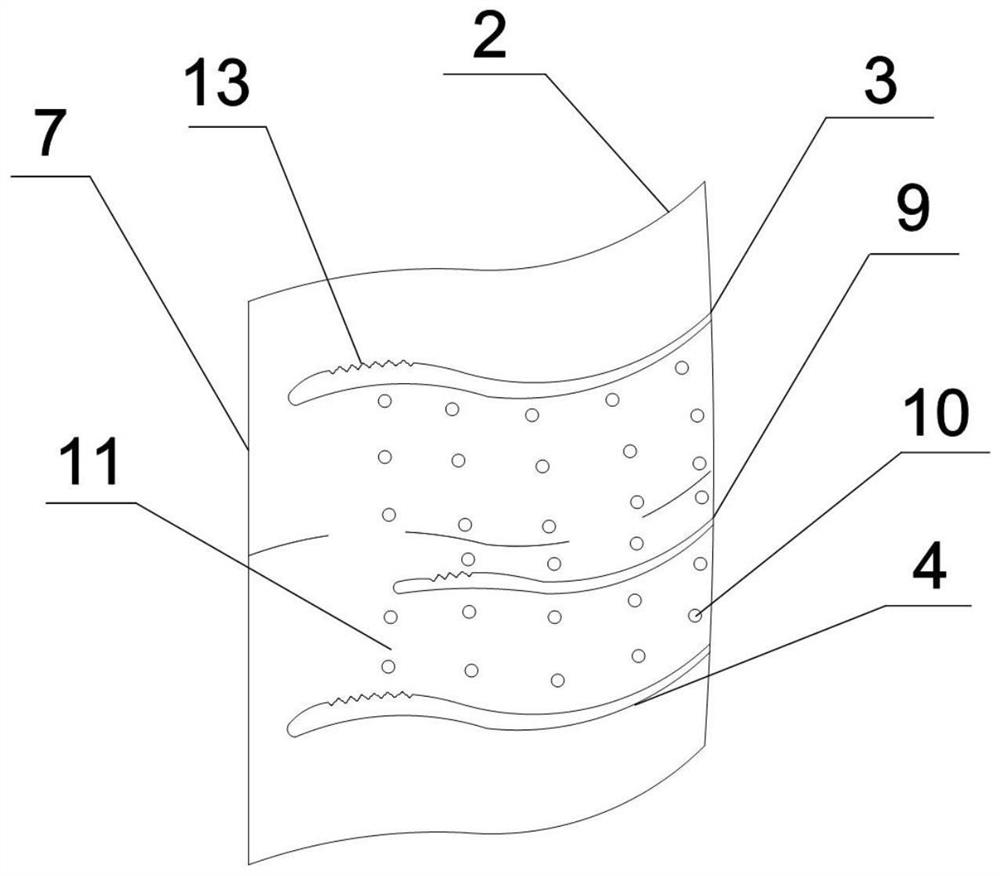

Circumferentially-biased high-speed centrifugal impeller for inhibiting separation of boundary layer

ActiveCN114109895AIncrease roughnessAvoid accumulationInternal combustion piston enginesPump componentsImpellerAviation

The circumferential offset high-speed centrifugal impeller capable of restraining boundary layer separation comprises a hub, a blade set is fixedly connected to the wall face of the hub, a groove structure is arranged at the front end of the blade set, and a sawtooth tail edge is arranged at the tail end of the blade set; an inlet of the blade group is arranged close to an inlet of the impeller, and a blade runner is arranged on the blade group and is arranged on the wall surface of the hub; a flow guide cover hood is arranged at the inlet position of the blade group; the hub face is provided with a flow stabilizing plane used for restraining accumulation of low-energy airflow on the suction face. When the high-speed centrifugal impeller operates, the adhesion capacity of the surfaces of the blades to airflow can be improved, the turbulence dissipation strength of the wall faces of the wing-shaped blades can be weakened, and the acting capacity of the impeller to gas can be improved; the invention has the advantages of simple structure, low processing difficulty and finer structure, and is particularly suitable for civil small and medium-sized aero-engines / gas turbine compressors and load ends of small and special motors for acting to compress working media.

Owner:BEIHANG UNIV

Oil pipe joint

InactiveCN101566261AScientific and reasonable designSimple structureFuel injection apparatusMachines/enginesDiesel engineProcessing cost

The invention discloses an oil pipe joint belonging to the technical field of diesel engine parts, namely a developed new-structure product aiming at the structure defects existing in the similar products. The oil pipe joint comprises a rail pipe, a joint, a fixed sleeve and a sealing ball, wherein the corresponding parts of the joint bottom and the rail pipe which are connected are respectively provided with conical sealing surfaces; a sealing ball with through holes is arranged between the two conical sealing surfaces, and the fixed sleeve sleeved on the rail pipe is provided with a thread which is matched with a thread arranged at the lower end of the joint. The invention has the advantages of scientific and reasonable design, simple structure, convenient maintenance, low processing difficulty of the sealing surface and the sealing ball, good sealing performance, no need of special equipment and low processing cost.

Owner:LIYANG SHENGJIE MACHINE

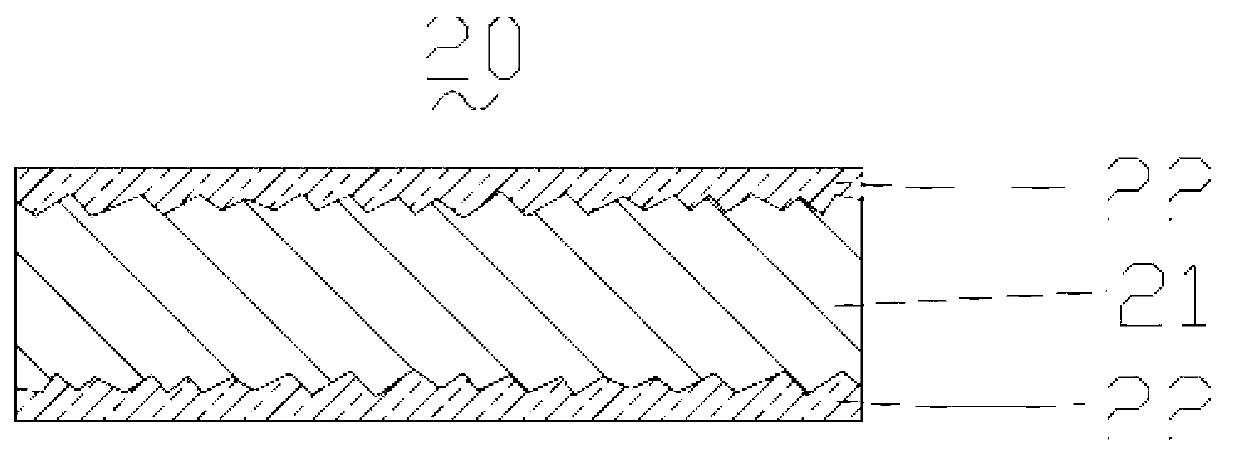

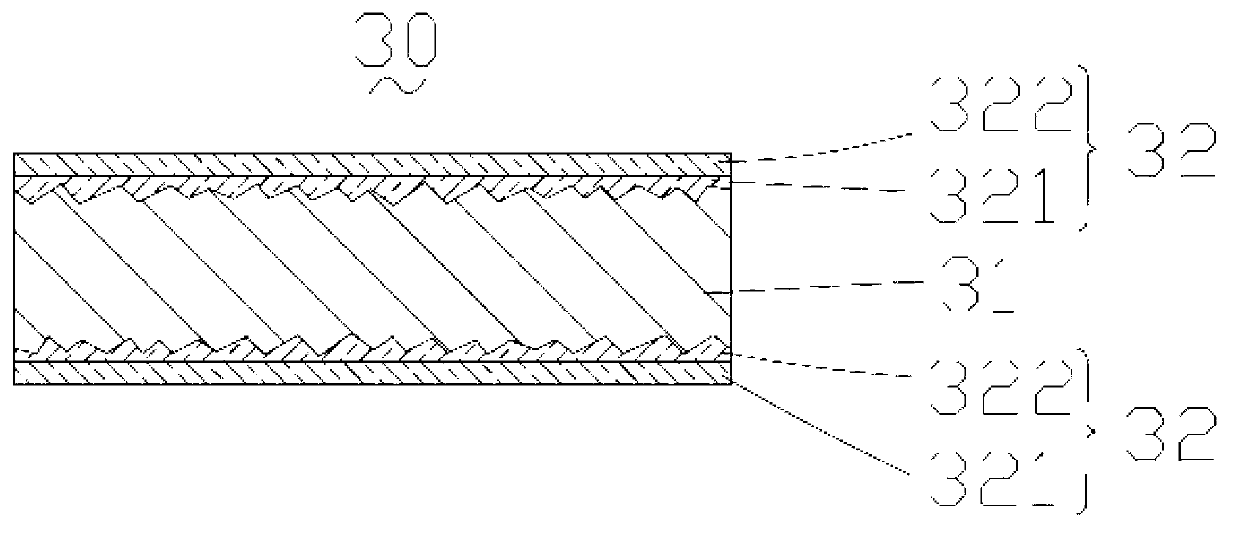

Multilayer printed circuit board and manufacturing method thereof

InactiveCN103002654AEasy to manufactureImprove insulation performanceCircuit susbtrate materialsMultilayer circuit manufacturePolymethyl methacrylateEngineering

The invention relates to a manufacturing method for a multilayer printed circuit board. The method comprises steps of providing at least two single-layer printed circuit boards which respectively comprise a substrate and a copper layer arranged on the surface of the substrate which is made of polymethyl methacrylate materials; providing at least one bonding layer and enabling the single-layer printed circuit boards and the bonding layer to be stacked in stagger; and conducting thermocompression bonding on a stack structure of the single-layer printed circuit boards and the bonding layer, enabling the two single-layer printed circuit boards to be tightly bonded through the bonding layer and forming the multilayer printed circuit board. The invention further provides the multilayer printed circuit board manufactured by using the manufacturing method for the multilayer printed circuit board. The multilayer printed circuit board and the manufacturing method have the advantages of being excellent in electric and mechanical performance, wide in applicable scope, low in cost and simple in manufacture method.

Owner:SHENZHEN WUZHU TECH

Floating caliper disc brake

PendingCN108488265ADidn't change size drasticallyReduce eccentric wearAxially engaging brakesBrake actuating mechanismsRubber ringReciprocating motion

The invention discloses a floating caliper disc brake. The floating caliper disc brake is composed of a brake block, a brake piston, a piston sealing ring, a brake caliper body, a caliper body support, a brake disc and the like. The floating caliper disc brake is characterized in that the brake disc is arranged at one end of a disc seat and is fixed by an M10 bolt, the caliper body support is fixed to a frame through an M12 bolt, the brake caliper body is connected with the caliper body support through a shaft pin and a shaft pin bolt, the brake piston is installed in a piston cavity of the brake caliper body and can do reciprocating motion, the piston sealing ring is installed in a groove of the brake piston, the cross section of the brake piston is a shape similar to an oval, and the oval-like section is composed of two semicircles and a rectangle, and an oval-like rubber ring is arranged so as to be matched with the oval-like piston sealing ring and the oval-like piston cavity in the brake caliper body. The contact size of the brake piston and the brake block in the tangential direction relative to the brake disc is increased, so that the thrust borne by the brake block in the braking process is more uniform, and the braking performance of the brake is not influenced while the eccentric wear of the brake block is reduced.

Owner:SHANDONG UNIV OF TECH

Pipeline detaching device for technology services

The invention provides a pipeline detaching device for technology services. The pipeline detaching device comprises a shell and a base. A pipeline is arranged inside the shell and internally providedwith petroleum; a supporting base is mounted on the upper portion of the base; a rotating shaft is mounted on the top of the supporting base, and a bracket is mounted on the upper portion of the rotating shaft; a corrosion-resistant layer, a heating layer and a heat-preservation layer are mounted on the inner side of the shell, the corrosion-resistant layer is located on the outer layer of the heating layer, and the heating layer is located on the outer side of the heat-preservation layer; a vice, a measuring tape, a saw and a screw driver are arranged inside a toolkit, the vice is located onthe left side of the measuring tape, the measuring tape is located above the saw, and the saw is located on the left side of the screw driver; and a plurality of heavy iron blocks are arranged in thebase. The pipeline detaching device is simple in structure, convenient to use, low in manufacturing cost, low in machining difficulty and good in corrosion-resistant effect, the service life of the pipeline is prolonged, the pipeline detaching device is suitable for being commonly applied, heating and heat preservation can be achieved, parts of the device can be detached mutually, and carrying anddetaching are facilitated.

Owner:天津欧津汇溢市场调查有限公司

A fast positioning method for grouting holes in tunnel curtains

ActiveCN108386208BSimple mechanical structureProcessing is not difficultUnderground chambersTunnel liningProtractorEffective length

The invention relates to a quick positioning method for a tunnel curtain grouting hole. Before using the positioning device, the effective length of a telescopic rod is adjusted according to the construction sequence of the 'first an outer ring and then an inner ring', and then an extension angle is drilled according to the design of each grouting hole position on the outer ring to adjust the inclination of a positioning steel ring; after the positioning device is adjusted, a hoop is nested on an orifice tube; at this time, the positioning steel ring is aligned with the highest position of thegrouting hole in the outer ring, and a circle is drawn along the inner edge of the steel ring to quickly position for a drill pipe to drill; similarly, the telescopic rod is rotated several times andall grouting holes in the outer ring can be sequentially and quickly drawn according to the same included angle; the mode is repeated and the effective length of the telescopic rod is adjusted so that other grouting hole positions can be quickly positioned, the construction radius can be adjusted by changing the length of the telescopic rod, while a plane angle disc and an extension protractor can change the angle of the positioning steel ring. After the length of the telescopic rod and the angle of the extension protractor are determined, the same ring of grouting holes can be quickly positioned, and the construction efficiency is high.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

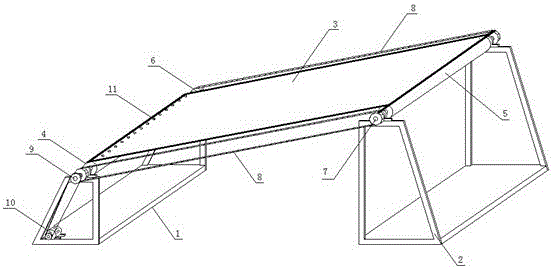

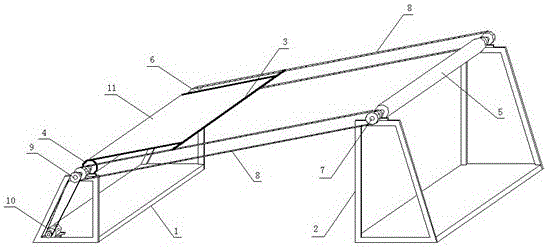

An automatic retractable water diversion device

ActiveCN104100112BSolve problemsSolve the leakBuilding roofsIndustrial buildingsDrive wheelEngineering

The invention provides an automatic collection and release water distribution device, which relates to a mechanical automation device. The automatic collection and release water distribution device consists of a front-end support, a tail-end support and a cord fabric, wherein the front-end support is connected with a rotating roller I through a bearing, the tail-end support is connected with a rotating roller II through a bearing, the rotating roller I and the rotating roller II are positioned on the same plane and are mutually parallel, driving wheels I and driving wheels II at the same sides of the rotating roller I and the rotating roller II are in transmission connected by chains, one side of the rotating roller I is provided with a driven wheel which is in transmission connection with a motor fixed on the front-end support, one end of the cord fabric is fixedly arranged on the surface of the rotating roller I through more than two rivets axially and uniformly, and the two sides of the other end of the cord fabric are hinged to the chains at the two sides.

Owner:浙江旺能生态科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com