Component prism-based phase diversity wavefront sensor

A wavefront sensor and phase difference technology, used in instruments, scientific instruments, measuring devices, etc., can solve the problems of easy mutual interference of first-order diffracted beams, difficult grating processing, and high requirements, so as to improve the detection ability and increase the processing difficulty. , The effect of processing is not difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

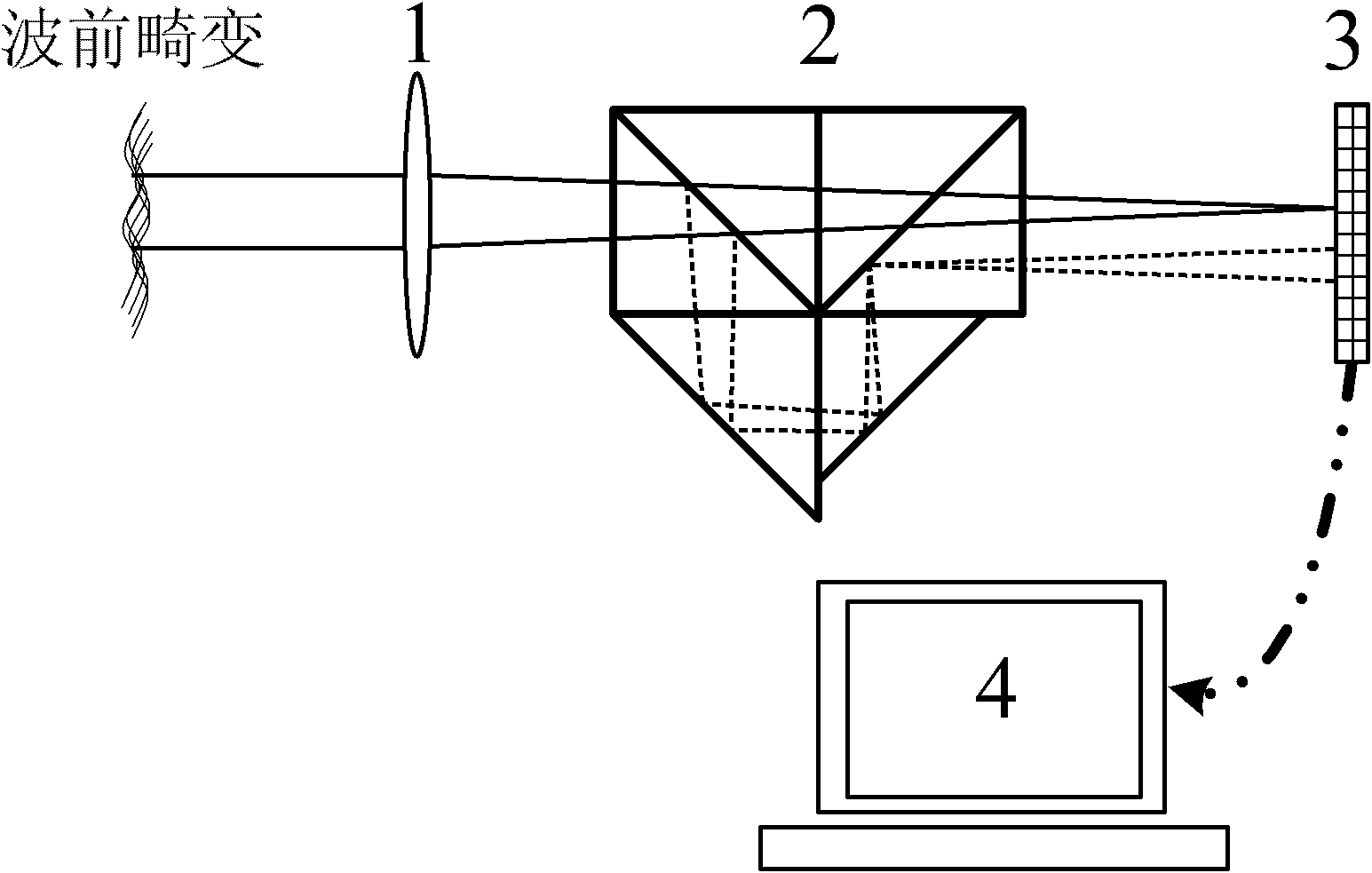

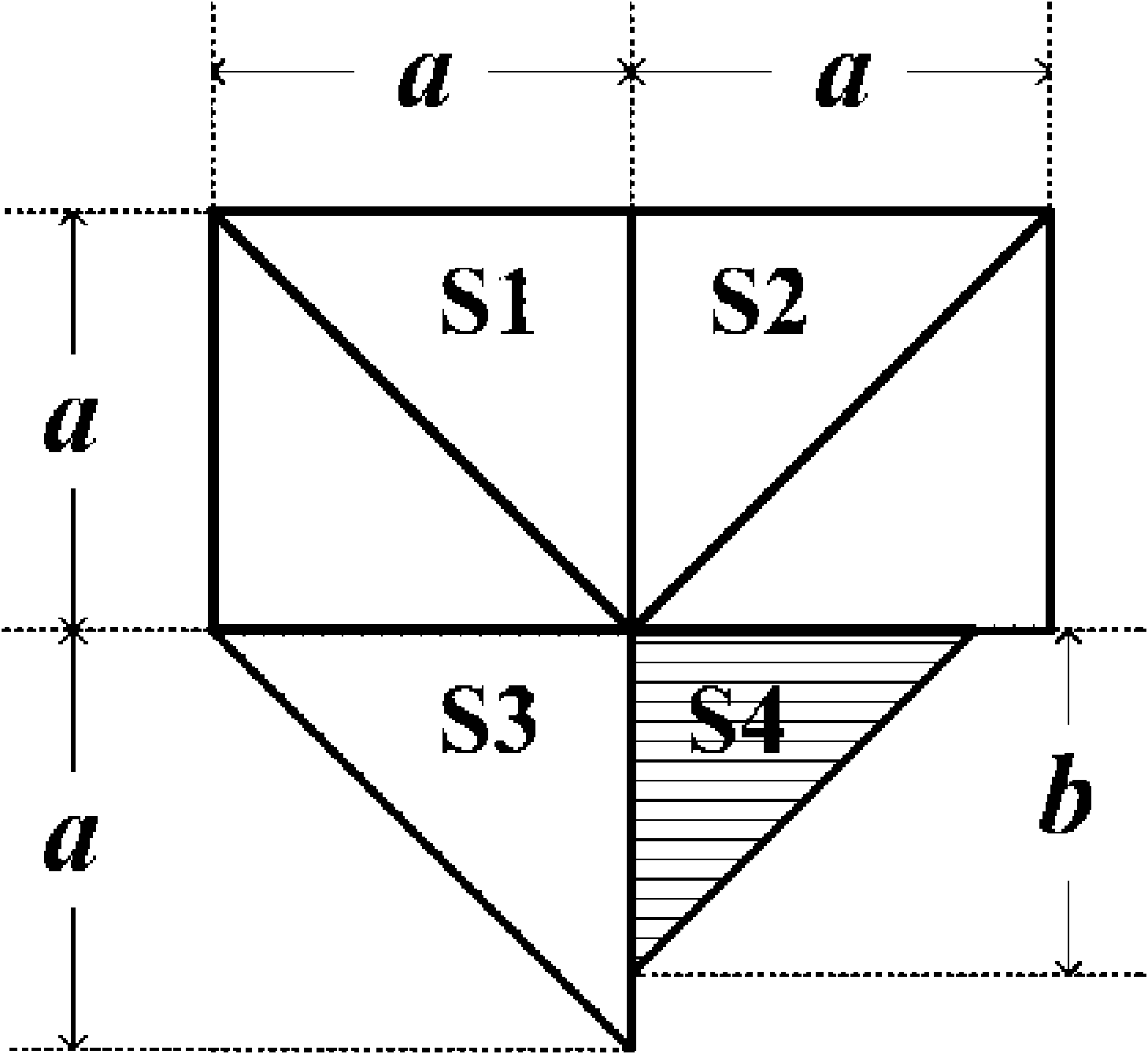

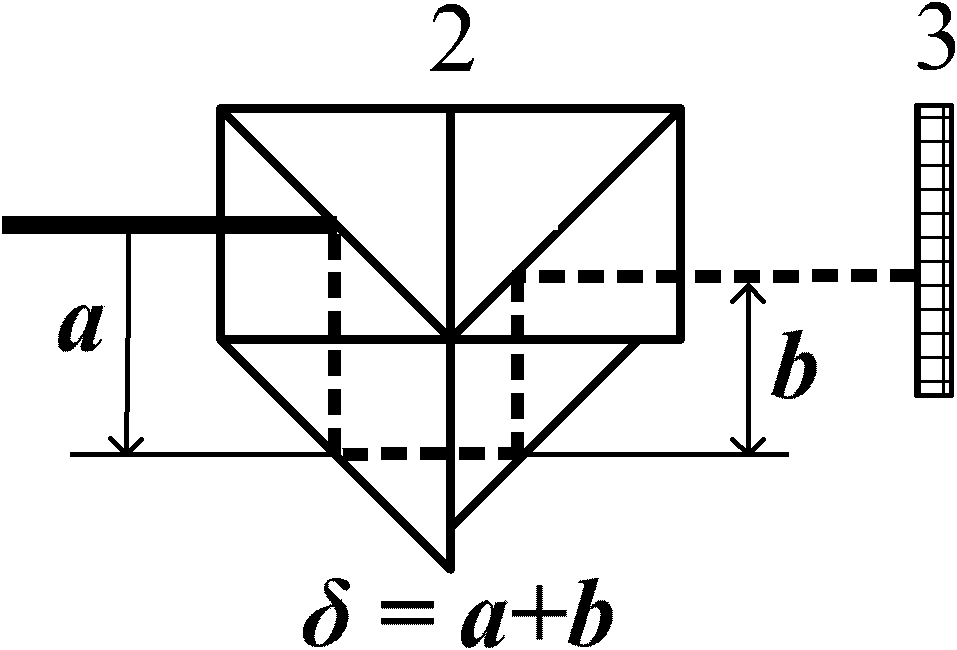

[0023] Such as figure 1 , 2As shown, the combined prism-based phase difference wavefront sensor of the present invention includes: a lens 1 , a combined prism 2 , an imaging detector CCD 3 and a computer 4 . The combined prism 2 is composed of the first dichroic prism S1 and the second dichroic prism S2, the first right-angle triangular reflector S3 and the second right-angle triangular reflector S4; first, the parallel light beam containing the distorted wavefront is irradiated vertically on the surface of the lens 1, After being focused by the lens 1, the parallel light beam becomes a converging light beam, and the converging light beam is vertically incident on the front surface of the first dichroic prism S1 in the combination prism 2, and the incident light beam is divided into two beams by the first dichroic prism S1, and the transmitted light beam is in accordance with the original The direction continues to propagate, and after the second beam splitting prism S2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com