Large-core optical fiber end face processing device and processing method thereof

A technology of optical fiber end face processing and large core diameter, which is applied in the coupling of optical waveguides and other directions, can solve the problems that subsequent operations cannot be carried out smoothly, and achieve the effects of good end face grinding quality, low cost and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

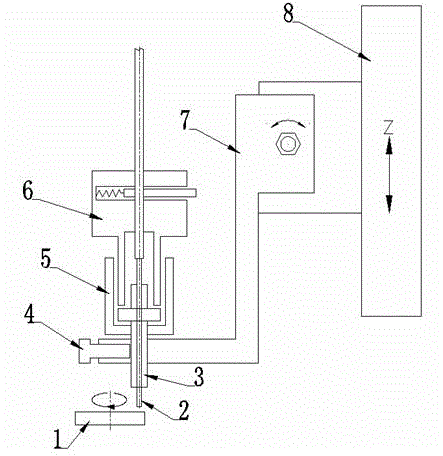

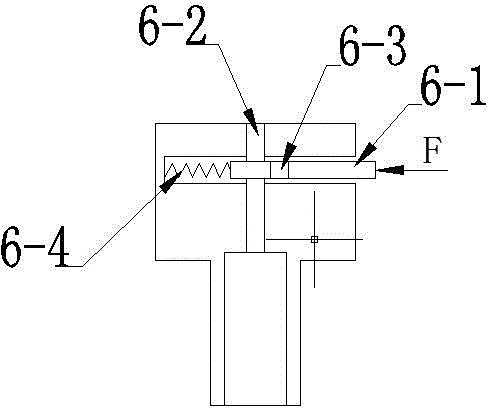

[0027] see Figure 1~3 , the present invention relates to a large-diameter optical fiber end face processing device and its processing method, the device includes a ferrule 3 pierced on the support mechanism 7, a grinding disc 1 is arranged under the ferrule 3, and the The ferrule 3 is a ceramic ferrule, and the ferrule 3 is inserted with a large core diameter optical fiber 2 stripped of the coating layer. The ferrule 3 is covered with a connecting mechanism 5 arranged in a "U" shape. The above ferrule The core 3 is plugged into the bottom of the "U"-shaped connection mechanism 5, a guide mechanism 6 is arranged on the connection mechanism 5, and the large-core-diameter optical fiber 2 with a coating layer is inserted on the guide mechanism 6;

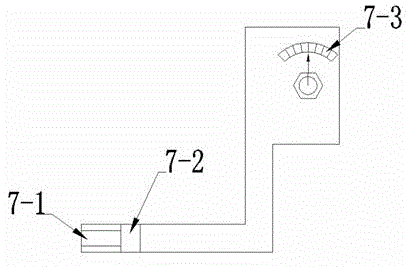

[0028] Specifically, the support mechanism 7 is vertically provided with a ferrule adapter hole 7-2 for the ferrule 3 to pass through, and the support mechanism 7 is horizontally provided with a bolt adapter hole 7-2 for the bolt 4 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com