Vacuum switch tube for helical coil longitudinal magnetic field electrode

A vacuum switch tube and longitudinal magnetic field technology, applied in electrical switches, high voltage/high current switches, circuits, etc., can solve the problems of not being too short in length, affecting deionization, and restricting size, etc., achieving simple electrode structure and no difficulty in processing. Large, the effect of reducing heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

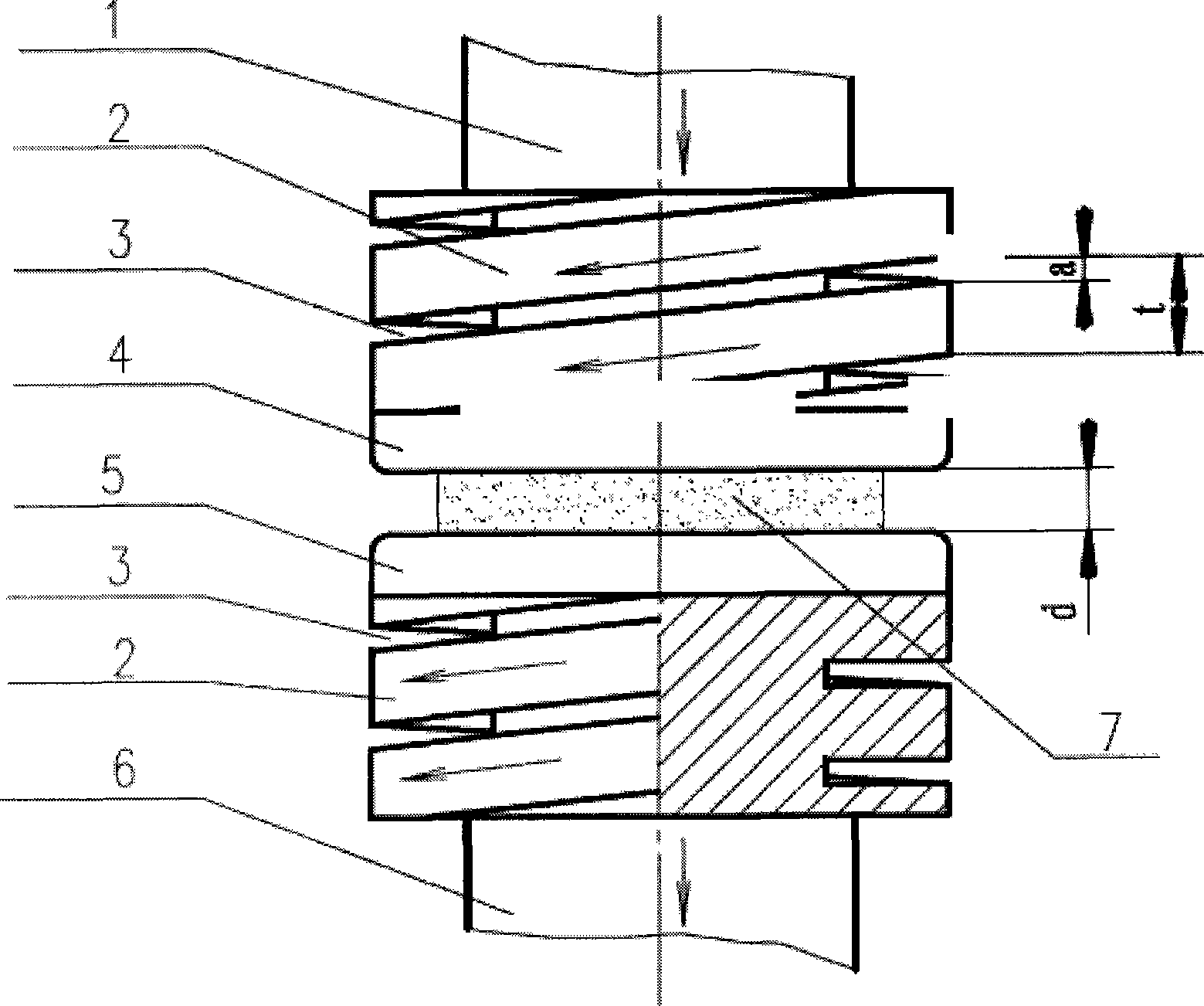

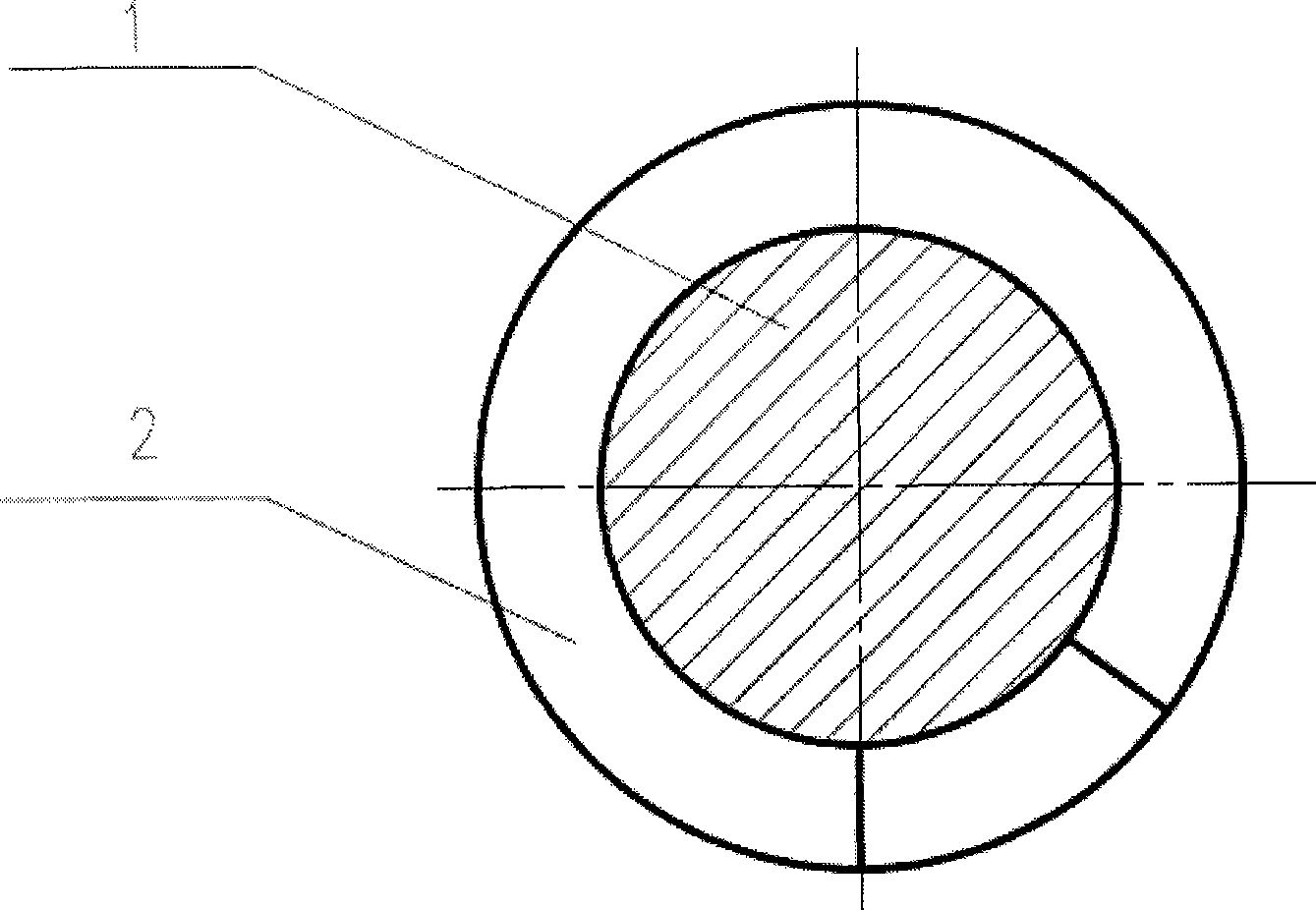

[0021] The vacuum switch tube with a rated voltage of 12KV and a breaking current of 100kA is designed with 2 turns of the helical coil, the groove width is 4mm, the pitch is 14mm, the depth of the groove is 30% of the outer diameter of the threaded part, and the distance between the dynamic and static contacts It is 12mm, the outer diameter of the threaded part is 100mm, and the length is 28mm.

Embodiment 2

[0023] The vacuum switch tube with a rated voltage of 35KV and a breaking current of 63kA is designed with 3 turns of the spiral coil, the groove width is 2mm, the pitch is 12mm, the depth of the groove is 35% of the outer diameter of the threaded part, and the distance between the dynamic and static contacts It is 24mm, the outer diameter of the threaded part is 100mm, and the length is 36mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com