Patents

Literature

44results about How to "Small loop resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

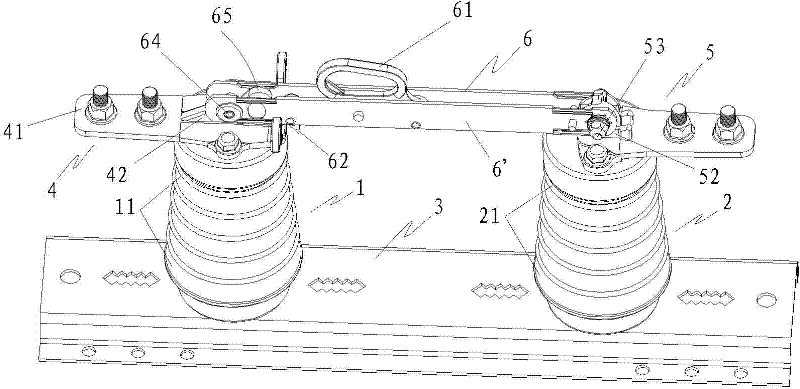

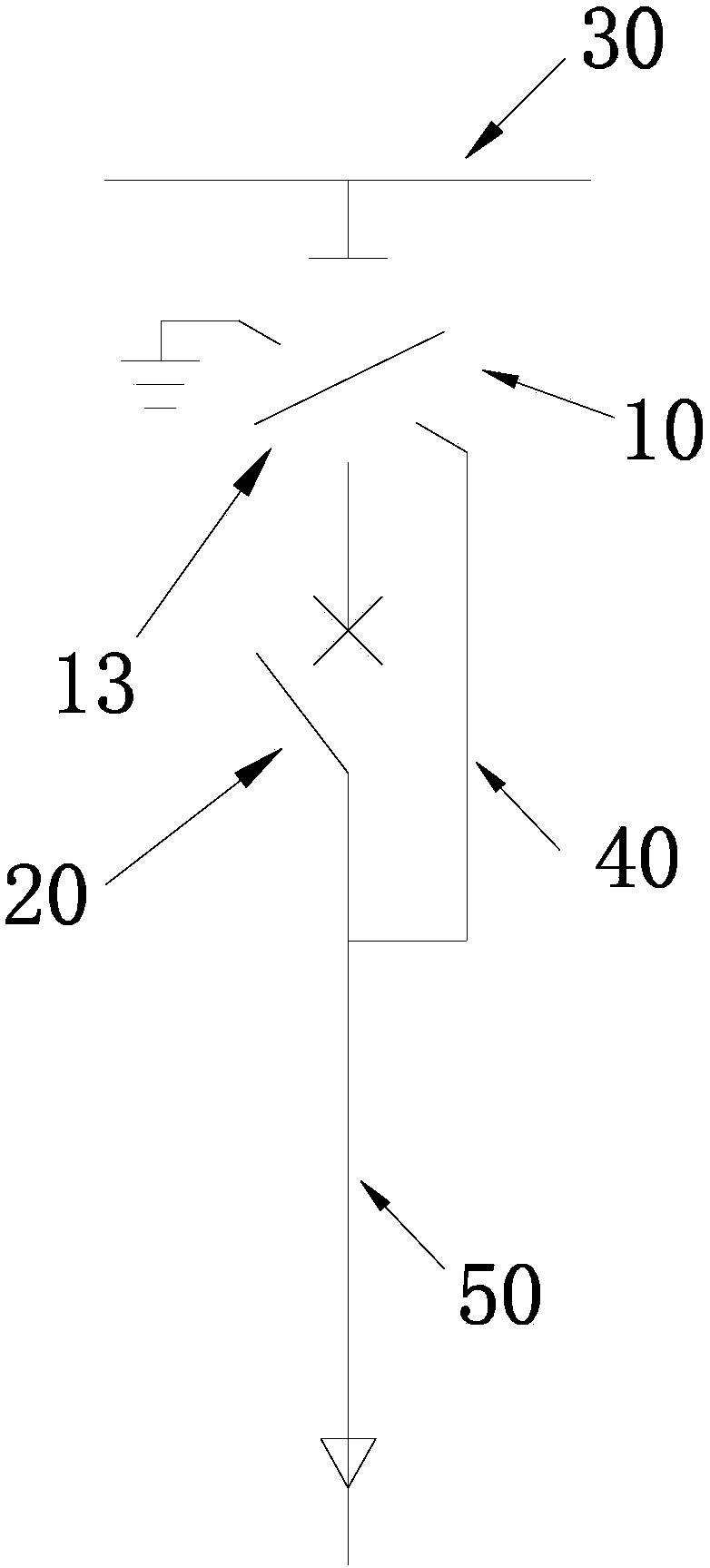

High voltage isolation switch

InactiveCN102394195AImprove conductivityLow costAir-break switch detailsContact electric connectionContact modeEngineering

The invention provides a high voltage isolation switch which comprises two insulation pillars which are vertically fixed on an installation plate. The two insulation pillars are fixed with a moving contact and a static contact respectively, the static contact is hinged with an isolator, and another end of the isolator is in overlapping joint with the moving contact, wherein the moving contact and a corresponding binding post are one-piece shaping, the static contact and a corresponding binding post are one-piece shaping, contact between the isolator and the moving contact is a surface to surface contact mode, and conductive connection is realized to reduce loop resistance of the whole isolation switch. Peripheral of the insulation pillar is provided with a parachute cluster which enlarges gradually from one end to another end of the insulation pillar, a screw is pivoted on the static contact, and the screw is sleeved with a disk spring set which presses against the isolator. Since employing the above structure, conduction performance of the high voltage isolation switch is improved, whole loop resistance is substantially reduced to 45-50 micro Omegas, and security and reliability in working are improved.

Owner:王漳泉 +2

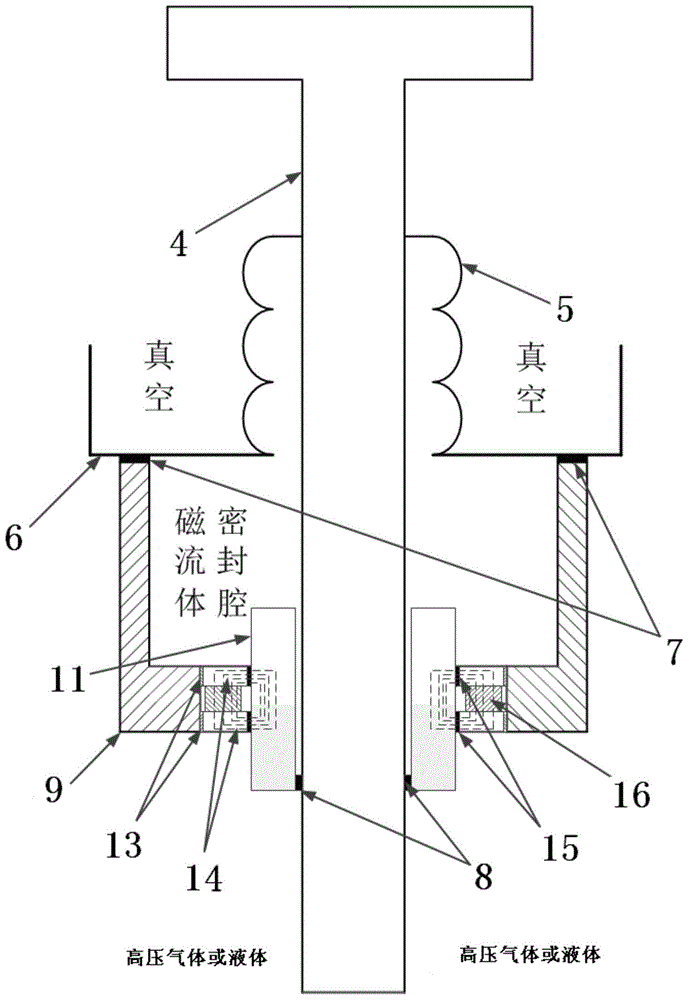

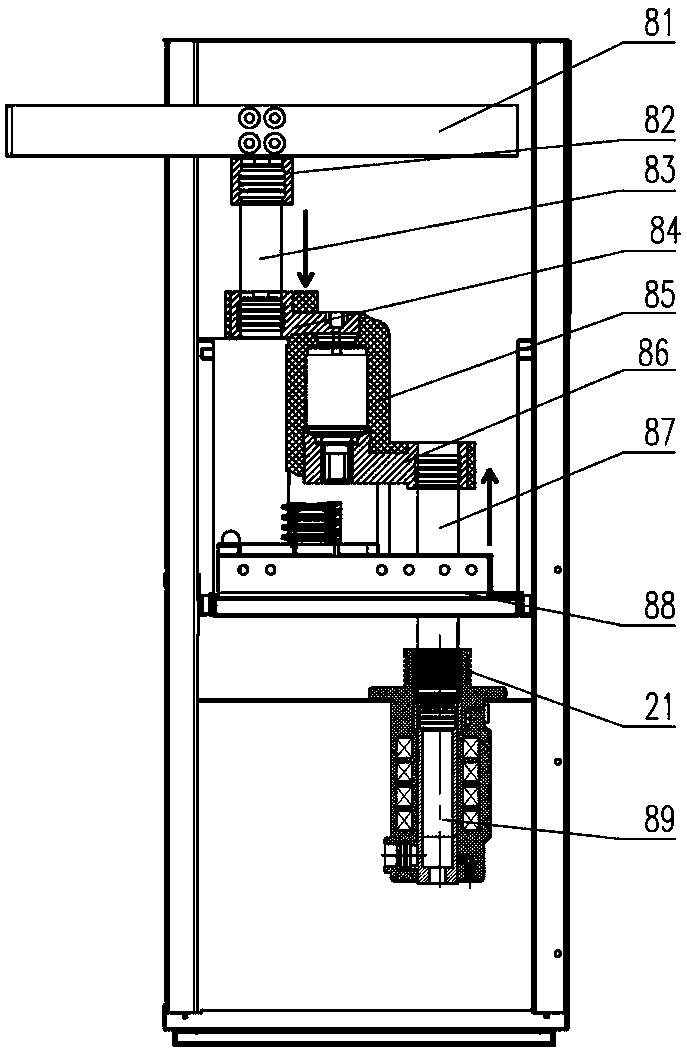

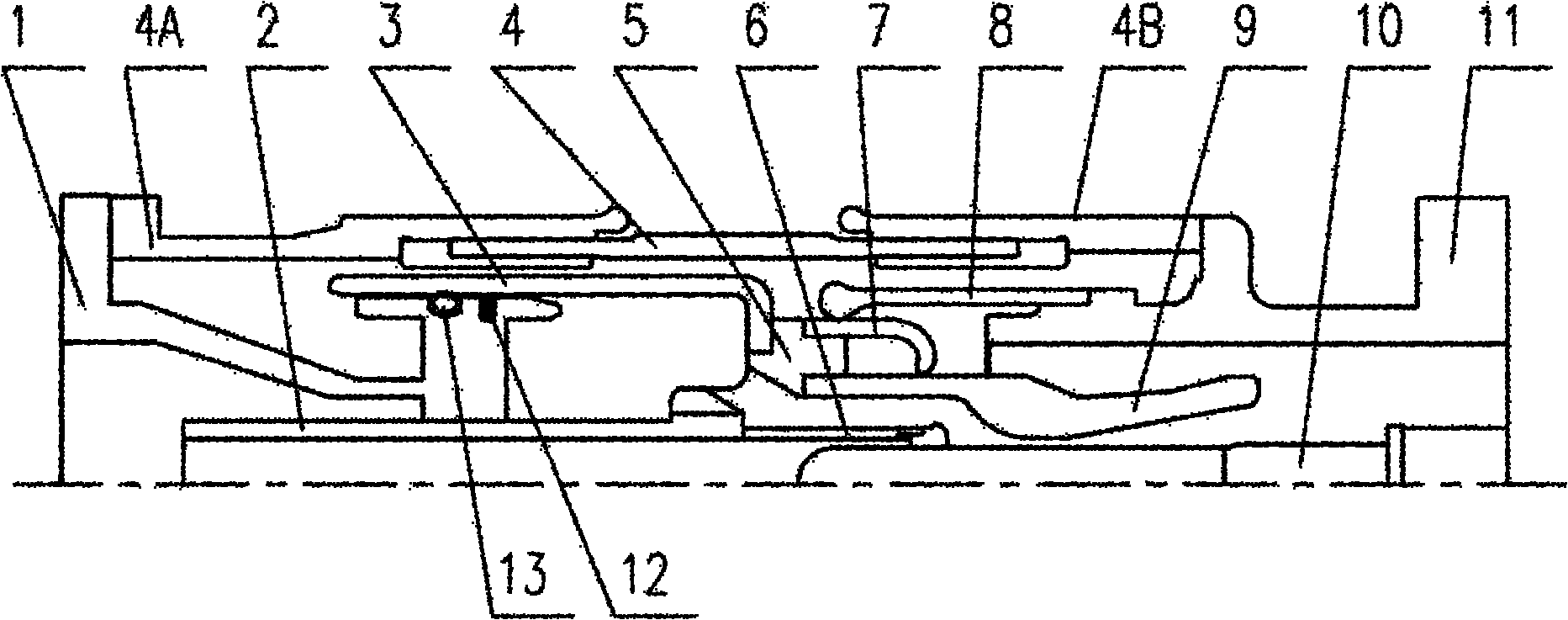

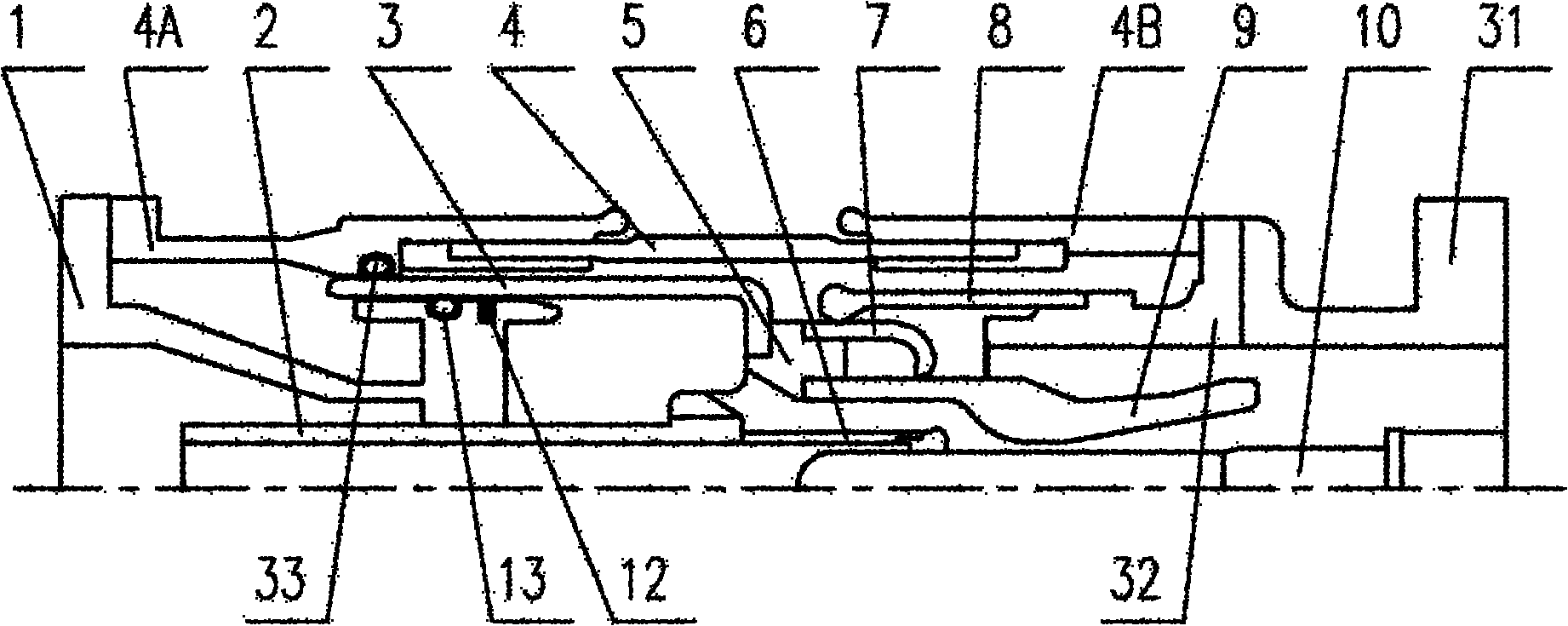

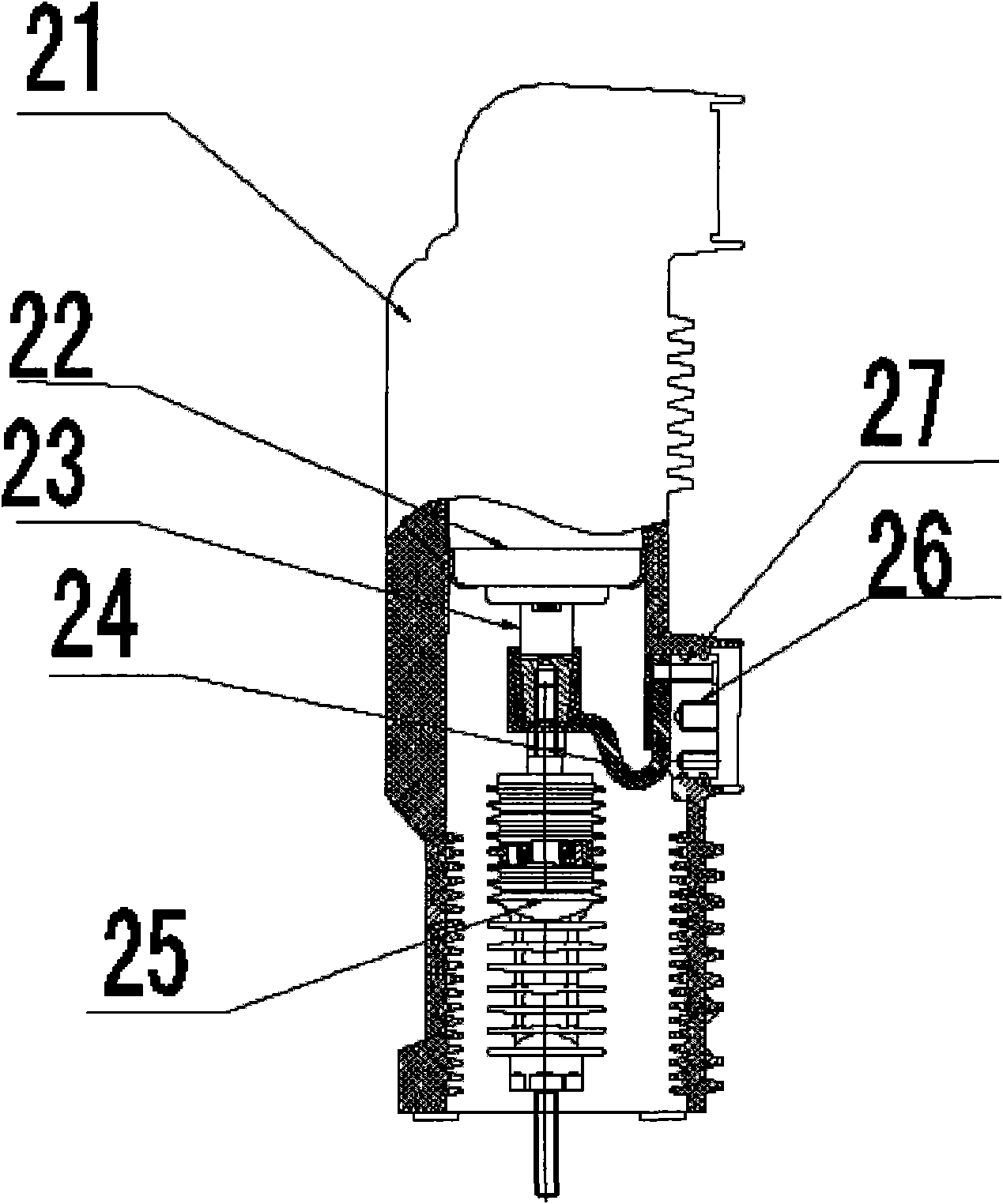

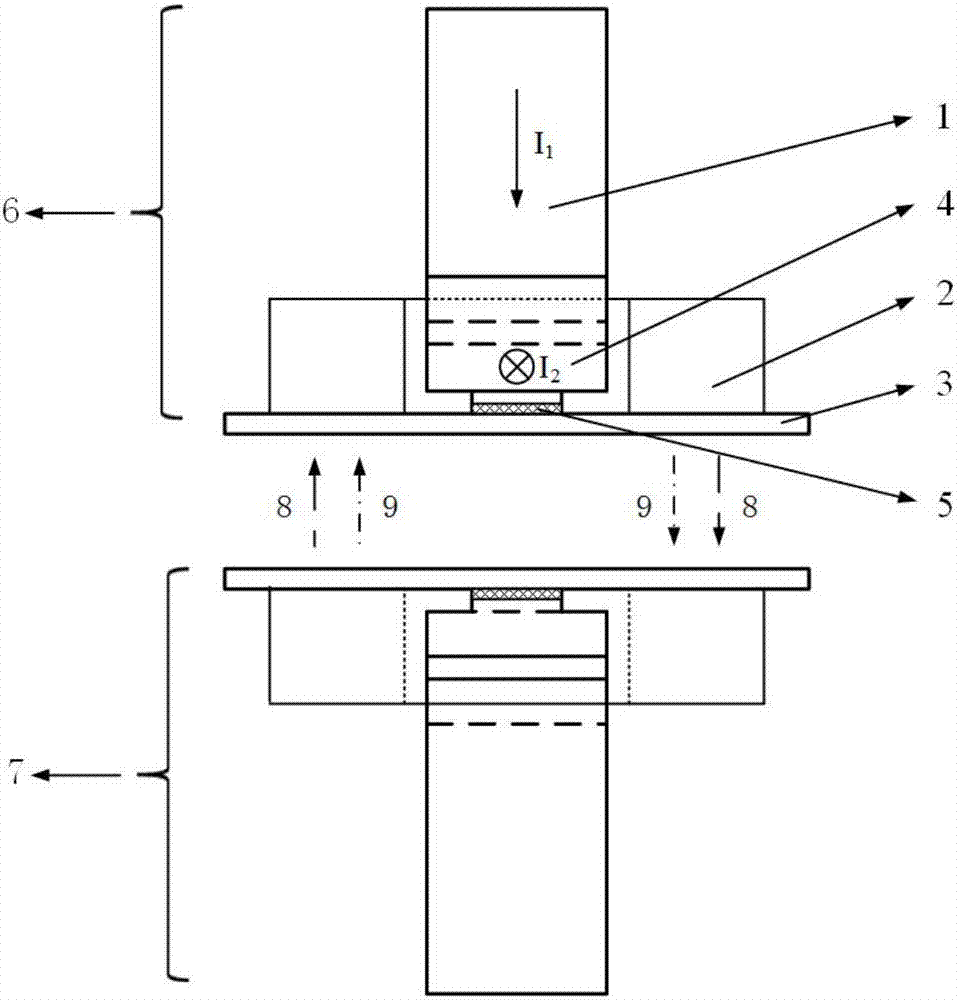

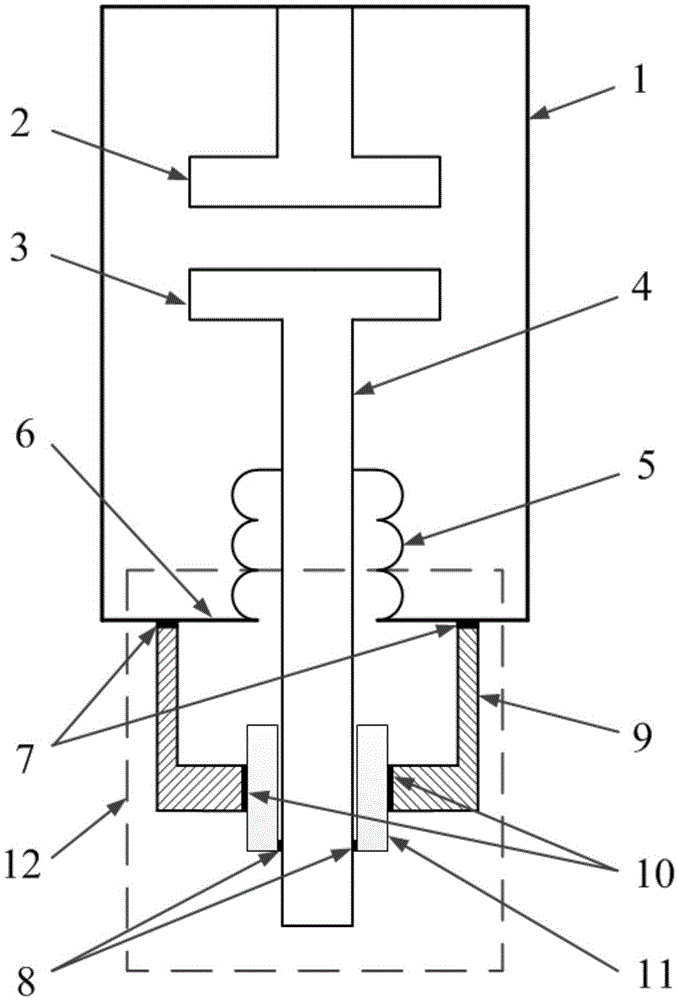

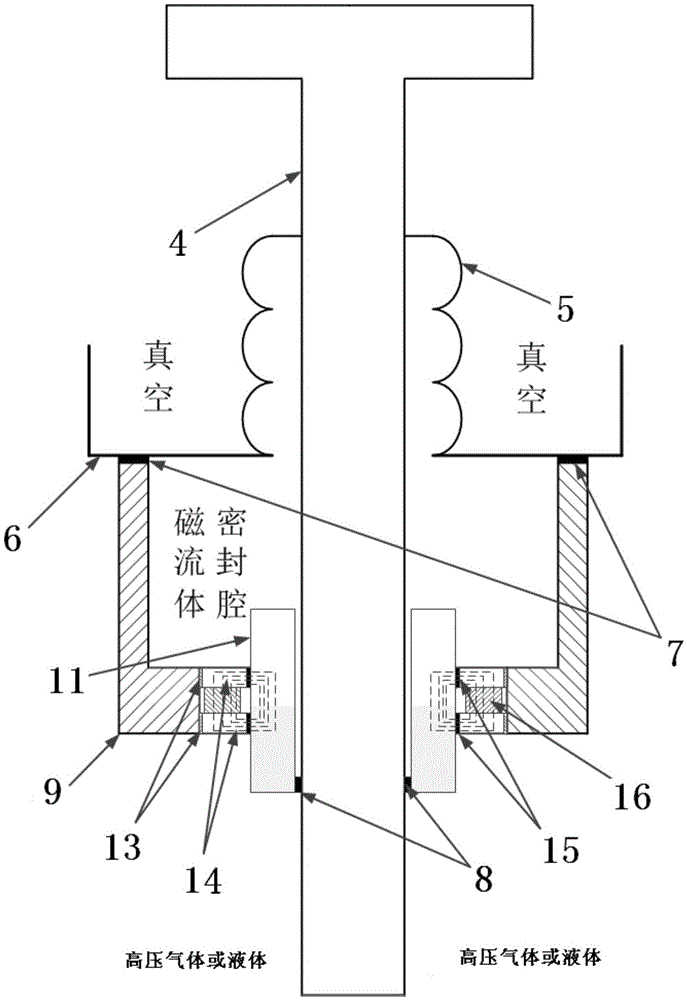

Protecting structure for vacuum air extinguish chamber corrugated pipe under high gas pressure and application

ActiveCN104810195AReduce the probability of fracture failureReduce pressure differenceHigh-tension/heavy-dress switchesAir-break switchesEngineeringHigh pressure

The invention discloses a protecting structure for a vacuum air extinguish chamber corrugated pipe under high gas pressure and application. The protecting structure comprises a hollow metal drum and a corrugated pipe outside sealing device, the hollow metal barrel is arranged at the end, positioned outside a vacuum arc extinguish chamber movable end cap, of a vacuum arc extinguish chamber movable electroconductive rod, one end of the corrugated pipe outside sealing device is arranged on the lower portion of the vacuum arc extinguish chamber movable end cap while the other end of the same is arranged outside the circumference of the hollow metal barrel, the hollow metal barrel and the vacuum arc extinguish chamber movable electroconductive rod are in welded sealing, the hollow metal barrel and the corrugated pipe outside sealing device are in direct-acting reciprocating sealing, and the corrugated pipe outside sealing device and the vacuum arc extinguish chamber movable end cap are in fixed gas sealing. By adopting magnetofluid direct-acting reciprocating sealing technology, a closed space can be formed among the inside of the vacuum arc extinguish chamber corrugated pipe, the lower portion of the vacuum arc extinguish chamber movable end cap and the movable electroconductive rod, and no high-pressure gas exists inside the closed space, so that difference of air pressure inside and outside the corrugated pipe is reduced, and breakage failure probability of the corrugated pipe can be lowered effectively.

Owner:XI AN JIAOTONG UNIV

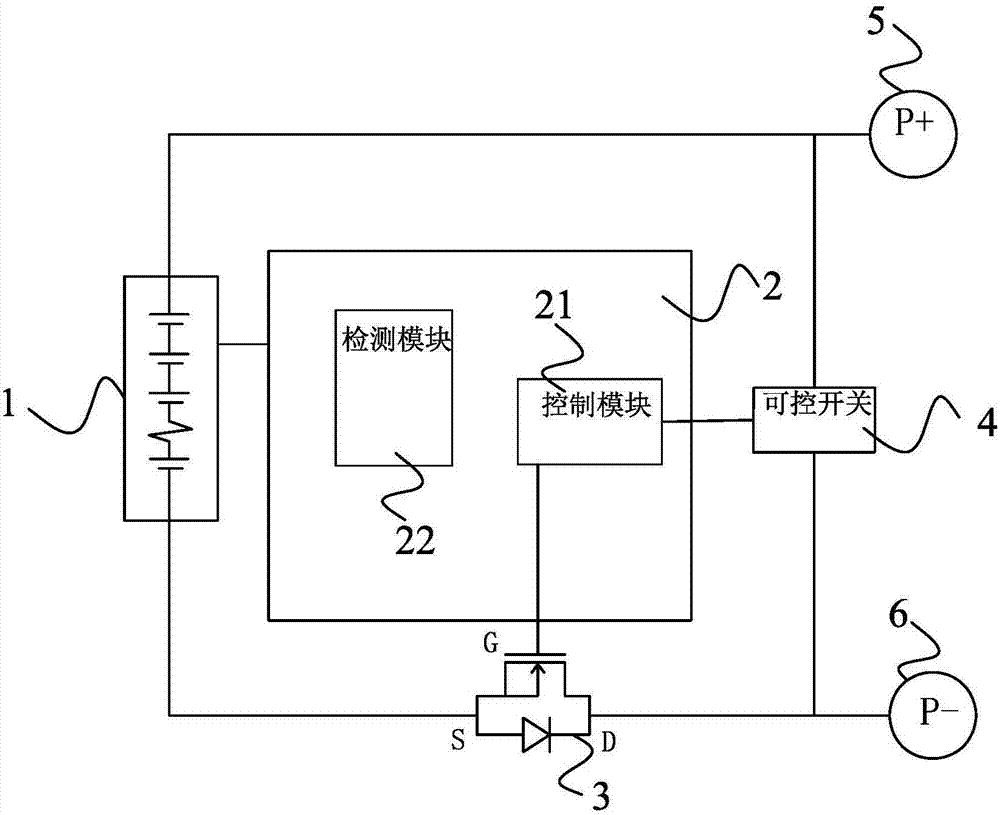

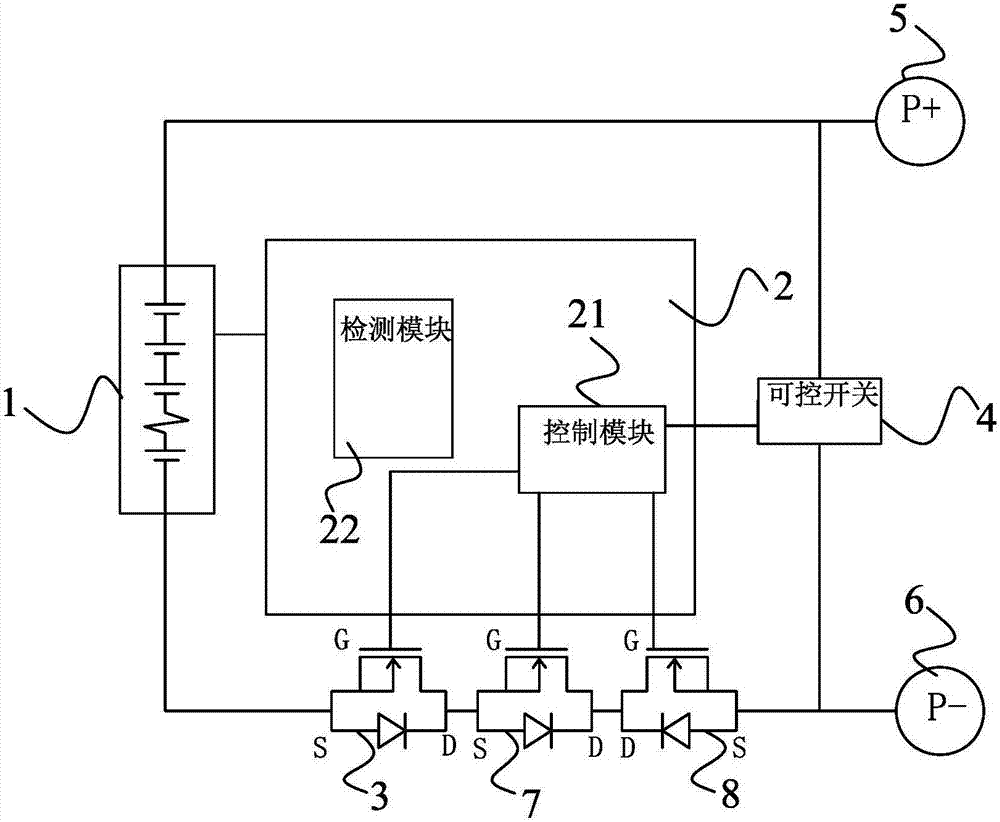

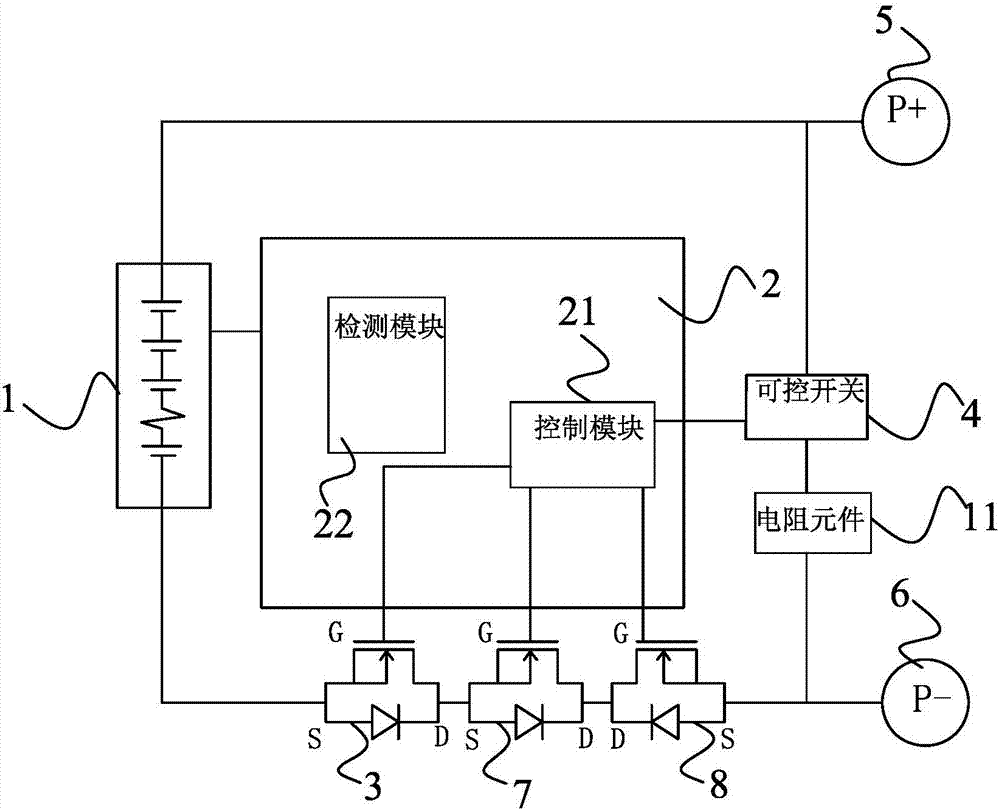

Battery protection circuit

InactiveCN107204638AAvoid short circuitReduce short circuitElectric powerBattery overcharge protectionElectrical batteryEngineering

The invention provides a battery protection circuit, and the circuit comprises a battery pack, a BMS main control unit, a first discharge MOS tube, a controllable switch, a positive end, and a negative end. The first discharge MOS tube and the battery pack are connected between the positive end and the negative end in a series manner, and the first discharge MOS tube is used for controlling the on / off of an output current of the battery pack. Two ends of the controllable switch are connected between the positive end and the negative end, and a series circuit which is formed by the battery pack and the first discharge MOS tube is connected with the controllable switch in a parallel manner. The BMS main control unit comprises a control module and a detection module, wherein the detection module is used for detecting the state information of the battery pack and transmitting the state information to the control module, and the control module is connected with the first discharge MOS tube and the controllable switch. The circuit provided by the invention aims at solving problems that a conventional battery protection circuit is large in loop resistance, is large in power consumption and is poor in reversibility of a secondary protection circuit.

Owner:BMTPOW LTD

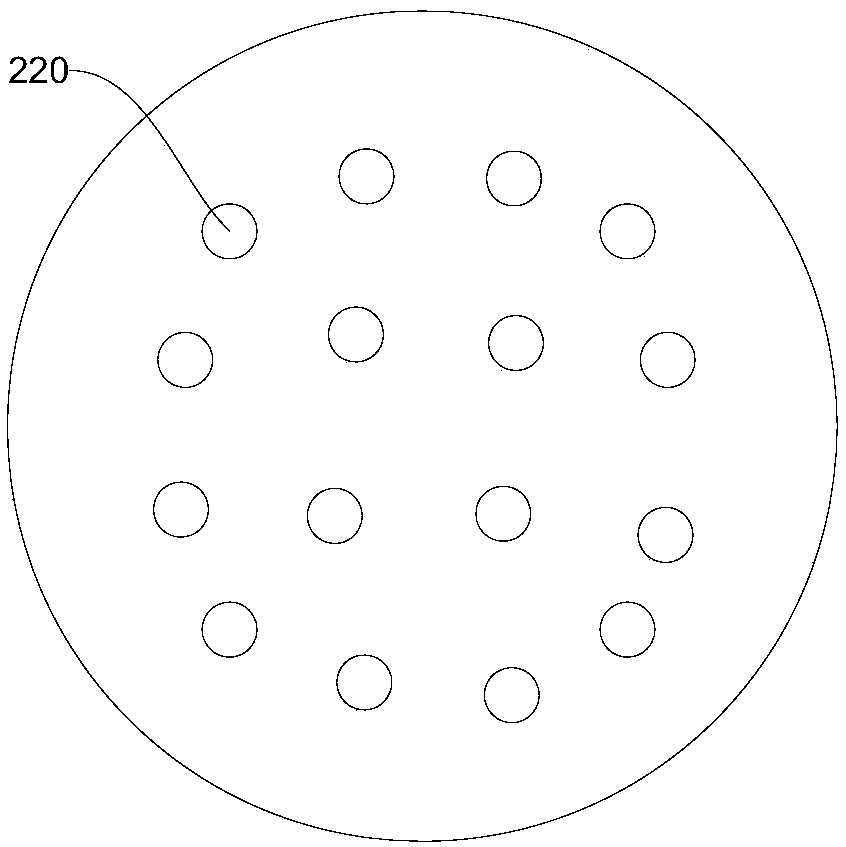

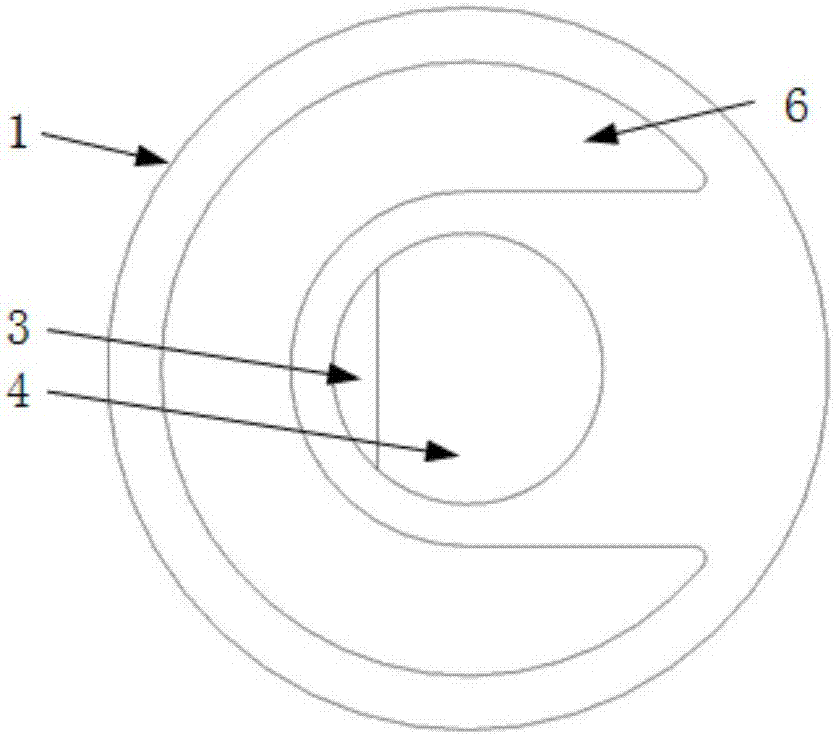

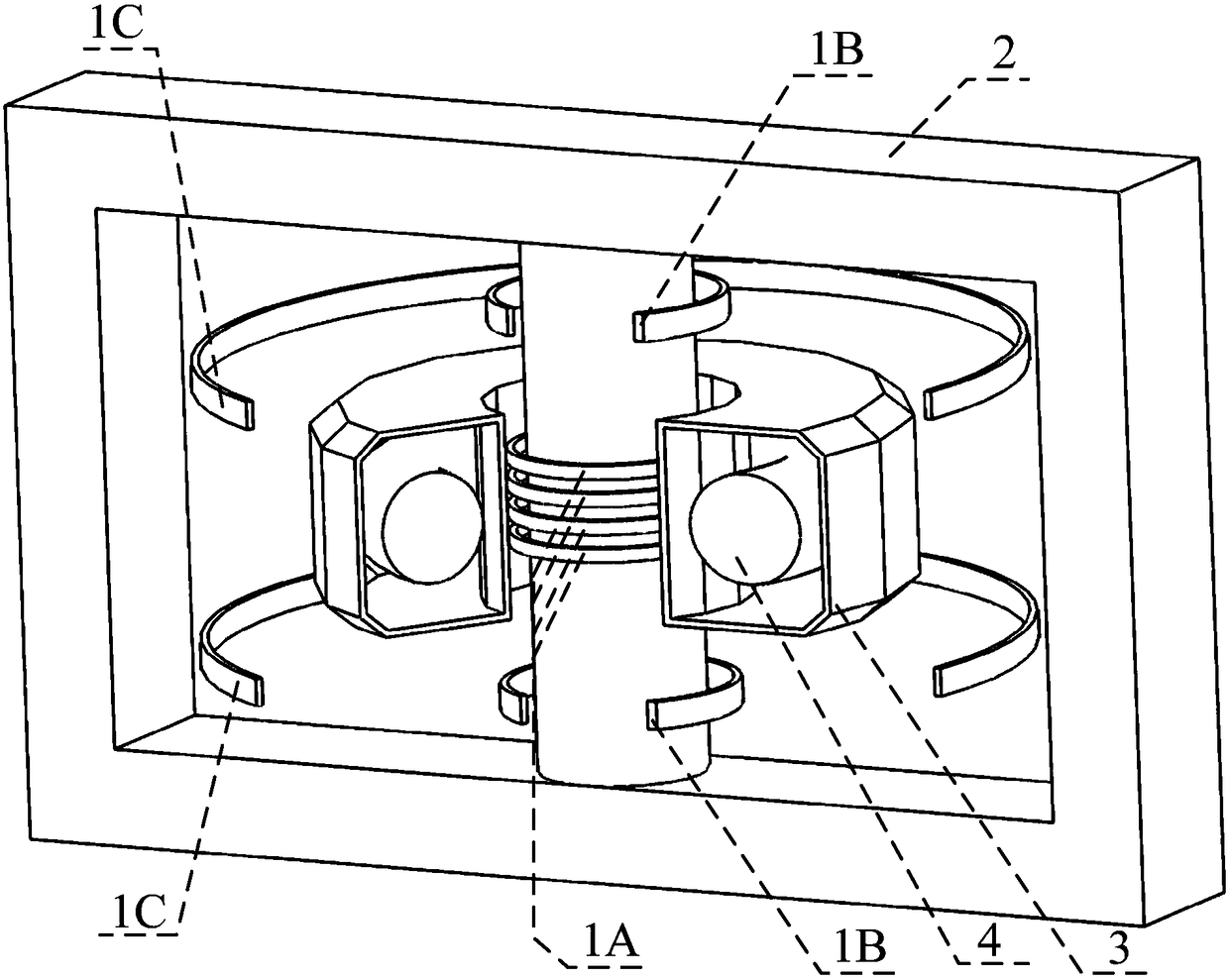

Vacuum switch tube for helical coil longitudinal magnetic field electrode

InactiveCN101425424AObvious superioritySignificant current pathHigh-tension/heavy-dress switchesAir-break switchesEngineeringVacuum switch

The invention provides a thread-coil type longitudinal magnetic field electrode vacuum switching tube which relates to the technical field of vacuum switches. The invention aims at providing a vacuum switching tube which has the arrangement disposal of the thread-coil type longitudinal magnetic field electrode so that the contradiction between the current conduction capacity and the short circuit current on-off capacity can be solved better. The vacuum switching tube comprises a moving conducting rod, a fixed conducting rod, a spiral coil, a spiral groove, a moving contact and a fixed contact which form a conducting loop. A coil of the vacuum switching tube takes the shape of a spiral body, and the turning direction of two thread coils arranged on a moving conductor and a fixed conductor is the same, and the moving contact and the fixed contact connected with the two thread coils are oppositely and longitudinally arranged. In the invention, the produced longitudinal magnetic field causes the vacuum arc produced between the contacts to keep in a non-aggregated state during the live cut-off; and the vacuum arc is extinguished when the current of an external circuit exceeds zero point, thereby the on-off of the circuit is finished.

Owner:湖北汉光科技股份有限公司

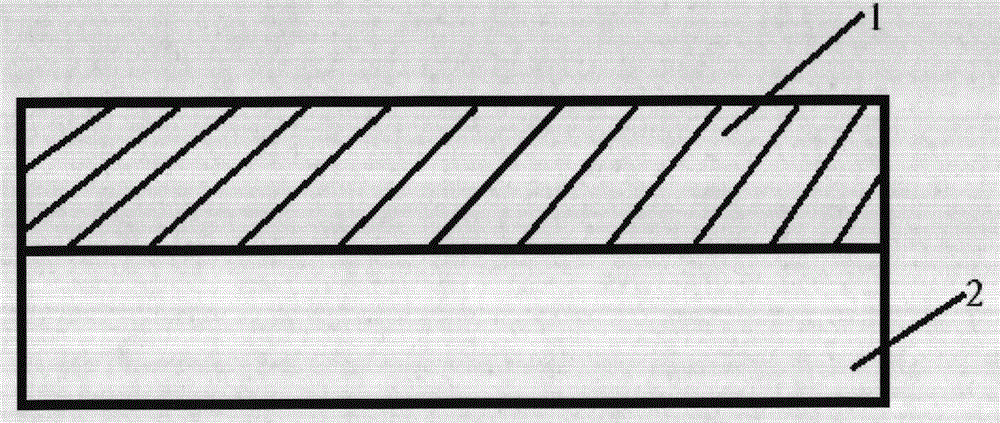

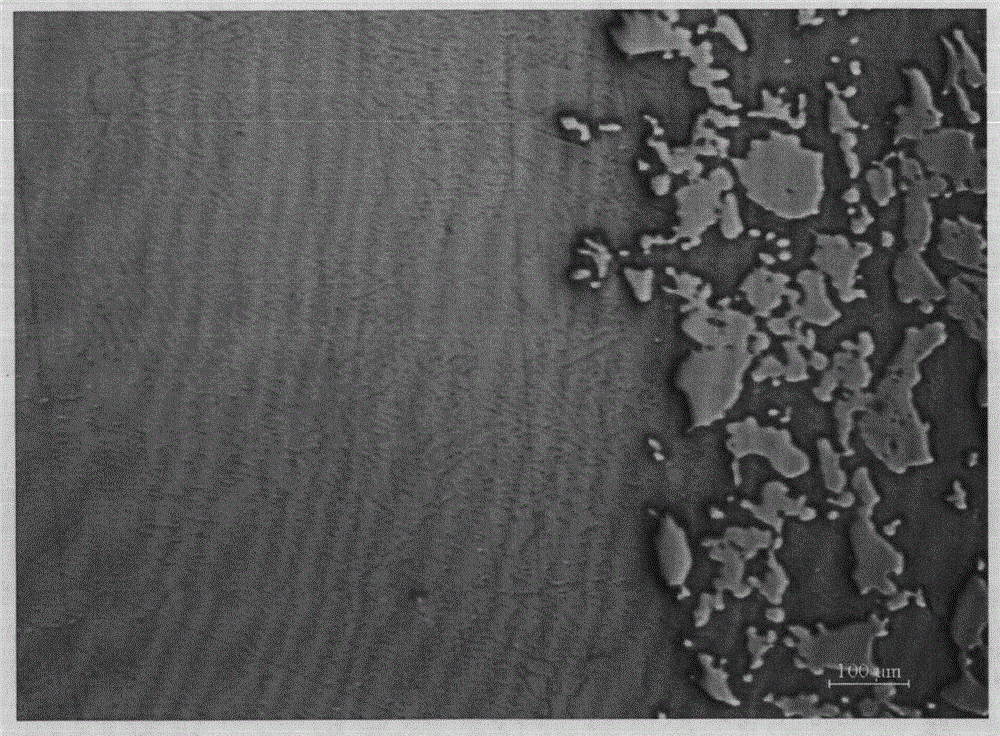

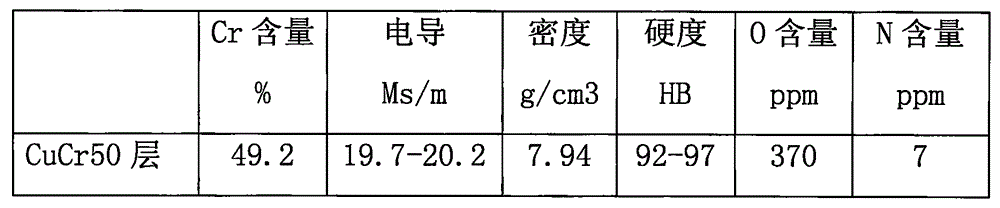

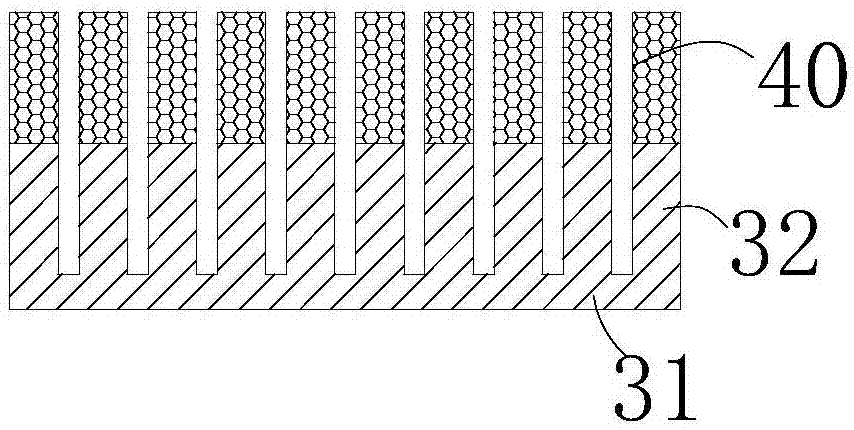

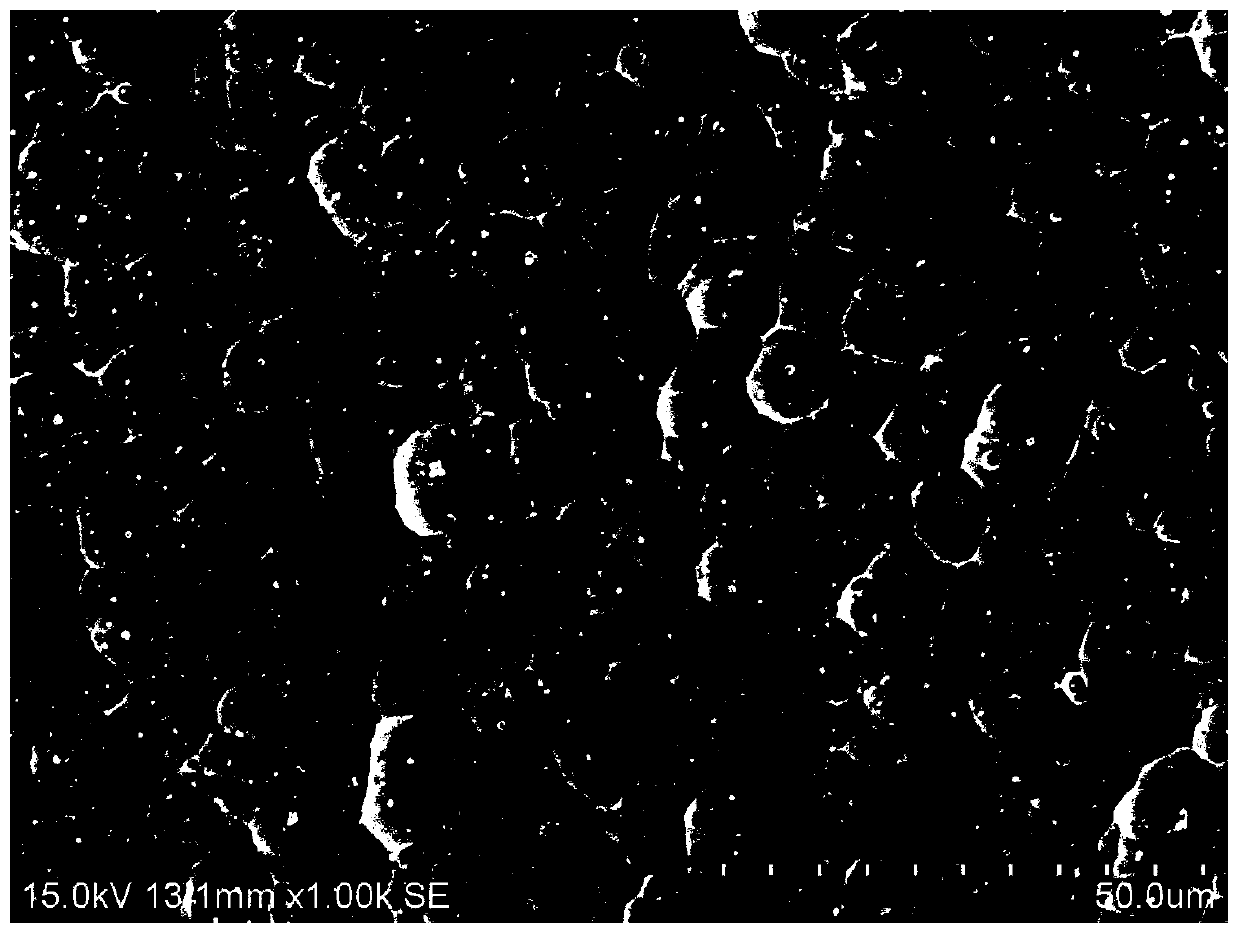

Gradient composite copper-chromium contact material and preparation method thereof

InactiveCN105206435ASave strategic metal CrSmall loop resistanceContact materialsTemperature curveCopper

The invention relates to a gradient composite copper-chromium contact material and a preparation method thereof. The gradient composite copper-chromium contact material is mainly composed of a CuCr50 layer and a CuCr1 layer. The CuCr50 layer comprises 45-55% of Cr with the balance being Cu by mass. The CuCr1 layer comprises 0.6-2.1% of Cr with balance being Cu by mass. The preparation method comprises the steps of raw material selection, powder mixing, compacting, infiltration and annealing. A product is improved based on the welding performance of a present copper-chromium contact material and the loop resistance. The infiltrated CuCr50 is prepared by a single-sheet infiltration technology, and the CuCr1 layer is formed by utilizing a designed temperature curve. An original contact composed of all CuCr50 is optimized into a contact composed of half CuCr50 and half of CuCr1, use of the strategic metal Cr is reduced, the loop resistance of the contact is reduced due to use of CuCr1, and the welding performance between the contact and a cup seat is improved.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Switch cabinet and incoming and outgoing line function module thereof

InactiveCN103683070AEfficient use ofReduce the overall heightSwitchgear with vertical withdrawalSwitchgear detailsElectricityElectrical conductor

The invention discloses a switch cabinet and an incoming and outgoing line function module thereof. The incoming and outgoing line function module comprises a conducting core with an axis extending linearly and a core-penetrating type mutual inductor sleeved on the periphery of the conducting core, the front end and the rear end of the conducting core are respectively provided with a first connection structure and a second connection structure which are serially connected on a main loop of the switch cabinet, the conducting core and the mutual inductor are solidified into a whole through an insulator casted on the outsides thereof, and the surface of the insulator is provided with adaptation holes which are corresponding to the first connection structure and second connection structure respectively and used for leading in an external conductor for conducting electricity and leading out an external conductor for conducting electricity. The core-penetrating type mutual inductor with the conducting core penetrating from the center is adopted in the incoming and outgoing line function module, and is casted into a whole through epoxy resin to form the incoming and outgoing line function module with a CT, space of a cabinet body is effectively utilized by the arrangement, and height of the cabinet body is decreased.

Owner:STATE GRID CORP OF CHINA +1

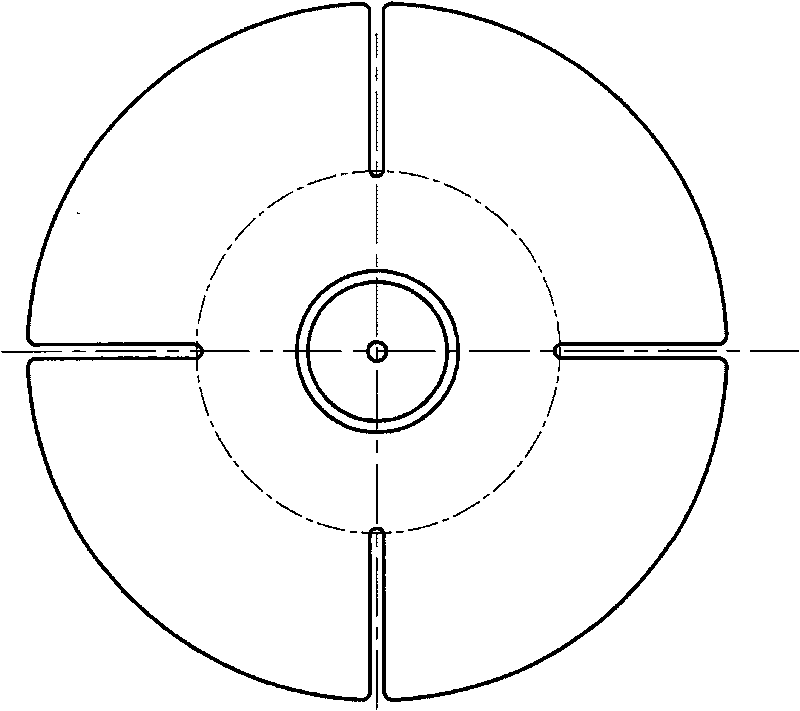

Contact of transverse magnetic field of novel vacuum arc-extinguishing chamber

InactiveCN104701068AIncrease the areaAvoid localized ablationHigh-tension/heavy-dress switchesAir-break switchesPre compressionTransverse magnetic field

The invention discloses a contact of a transverse magnetic field of a novel vacuum arc-extinguishing chamber. The contact comprises a first conducting rod, a first contact piece, a second contact piece and a second conducting rod, wherein one end of the first conducting rod is arranged at one end of a first contact end, the other end of the first conducting rod is a protruding end and is opposite to an opening direction of the first contact piece; one end of the second conducting rod is arranged at one end of a second contact end, the other end of the second conducting rod is a protruding end and is identical to an opening direction of the second contact piece; when the contact is closed, another end of the first contact end is in contact with another end of the second contact end and bears pre-compression when the contact is closed. The contact provided by the invention has the following advantages: 1, the area of the contact can be obviously improved at certain diameter of the contact, so as to improve the cut-off capacity of a breaker; 2, a radial outward opening distance of the contact can be controlled to be smaller under certain travel, so as to be beneficial for an expansion movement of an initial arc to be tend to be radially outward; 3, a tangent relative movement between movable and static contacts can be generated to prevent the contact from being partially ablated.

Owner:XI AN JIAOTONG UNIV

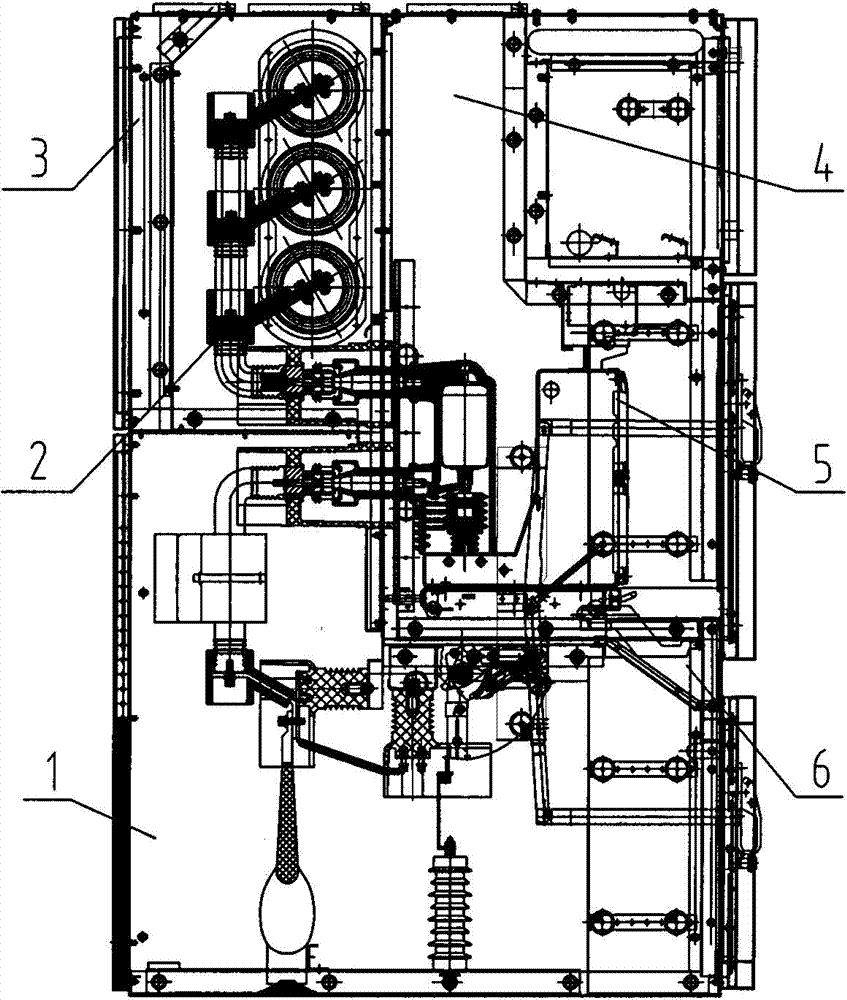

Modular movable-type solid insulated switchgear

InactiveCN103078263ACompact structureReasonable designSubstation/switching arrangement casingsSwitchgear earthing arrangementsBusbarModularity

The invention discloses modularized movable-type solid insulated switchgear and solves the problems of large size, poor power supply continuity and the like of existing switchgear. The technical key points are as follows: all electrified primary conductive elements and busbars in a power chamber module box body, a busbar chamber module box and a cable chamber module box are respectively wrapped and packaged into cabinet modules by adopting solid insulting medium, a power chamber module is connected with the cable chamber module and the busbar module through positioning parts to form an integral structure, and the modules are mutually separated by metal separators in a closed manner; the power chamber module is positioned above the front part of a cabinet body, the busbar chamber module is positioned above the rear part of the cabinet body, the cable chamber module is positioned on the lower part of the cabinet body, conductive or semi-conductive shielding layers are coated on the surfaces of the modules and can be directly and reliably grounded. The modularized movable-type solid insulated switchgear has the advantages that the structure is compact, the design is reasonable, the modularization of parts is realized, the insulation strength is high, the interchangeability is good, the on-site mounting and debugging are convenient, and the use is safe and reliable, and the purposes of on-site combination, mounting against a wall and maintenance in front of the cabinet are achieved.

Owner:淄博金龙电力设备股份有限公司 +1

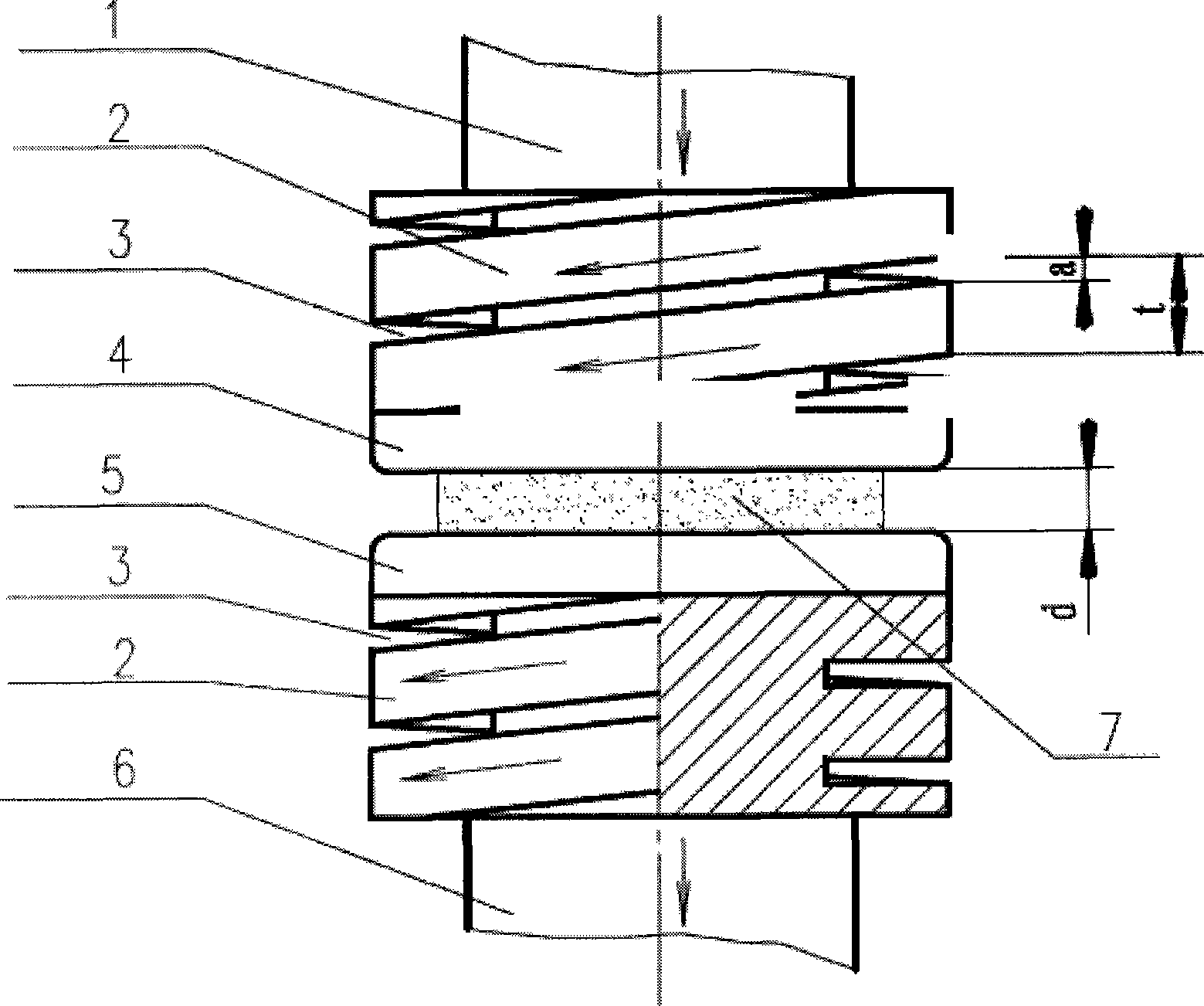

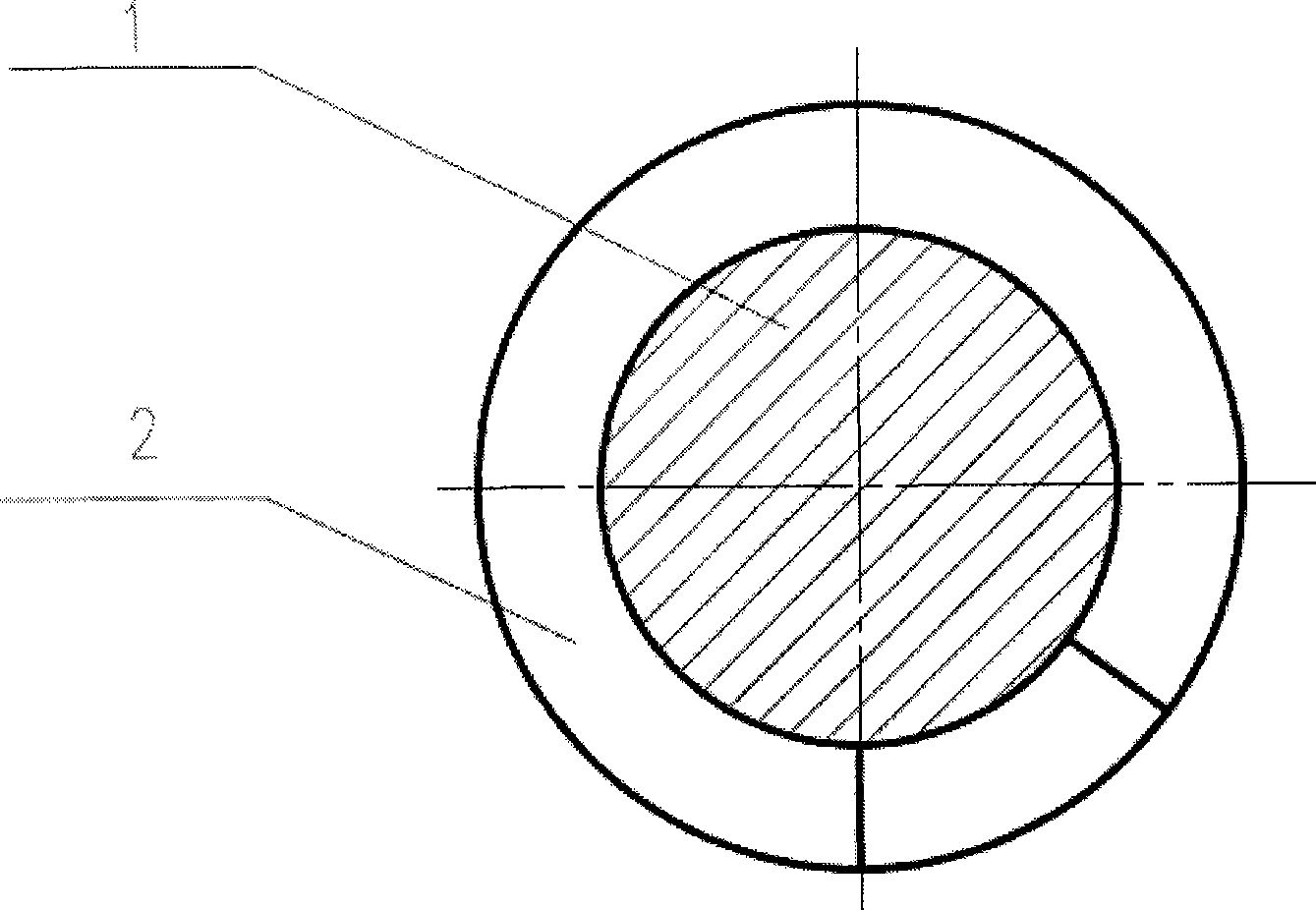

Arc extinguish chamber with high current-carrying capability for high-voltage switch equipment

ActiveCN101930871AOptimizationImprove cooling conditionsHigh-tension/heavy-dress switchesAir-break switchesEngineeringHigh pressure

The invention discloses an arc extinguish chamber with high current-carrying capability for high-voltage switch equipment. In the chamber, the outermost layer is an insulating support part with metal inserts at two ends, and comprises the metal inserts at two ends thereof; a movable contact system and a static contact system of the arc extinguish chamber are arranged inside the insulating support part, and are coaxial with the insulating support part; and the metal insert at the static end of the insulating support part is connected with the static contact system of the arc extinguish chamber, while the metal insert at the movable end is connected with the movable contact system of the arc extinguish chamber. The arc extinguish chamber adopts the metal inserts guiding current of a main loop to the insulating support part and the method for improving conductive part materials and structures in the main loop, so that the cross section of diversion can be increased, the loop resistance can be reduced, the radiating condition can be improved, and the whole through-flow capability of the arc extinguish chamber can be reinforced.

Owner:CHINA XD ELECTRIC CO LTD

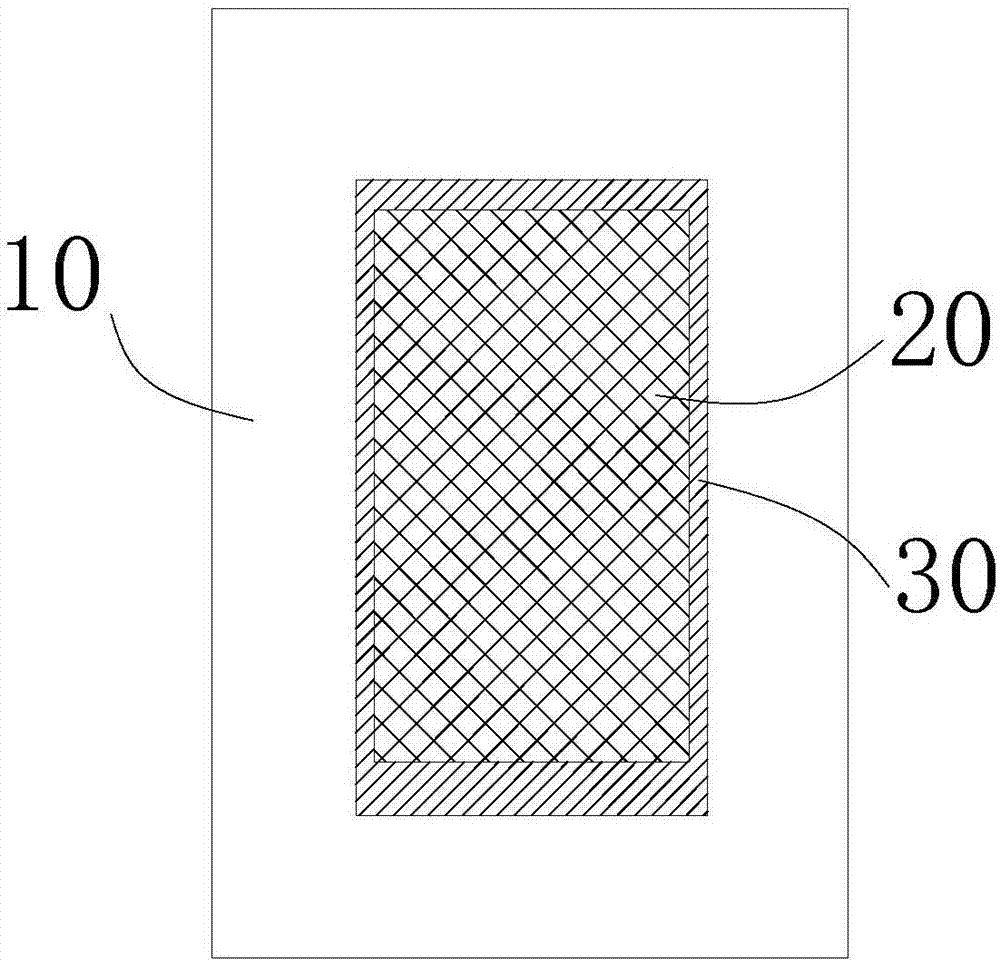

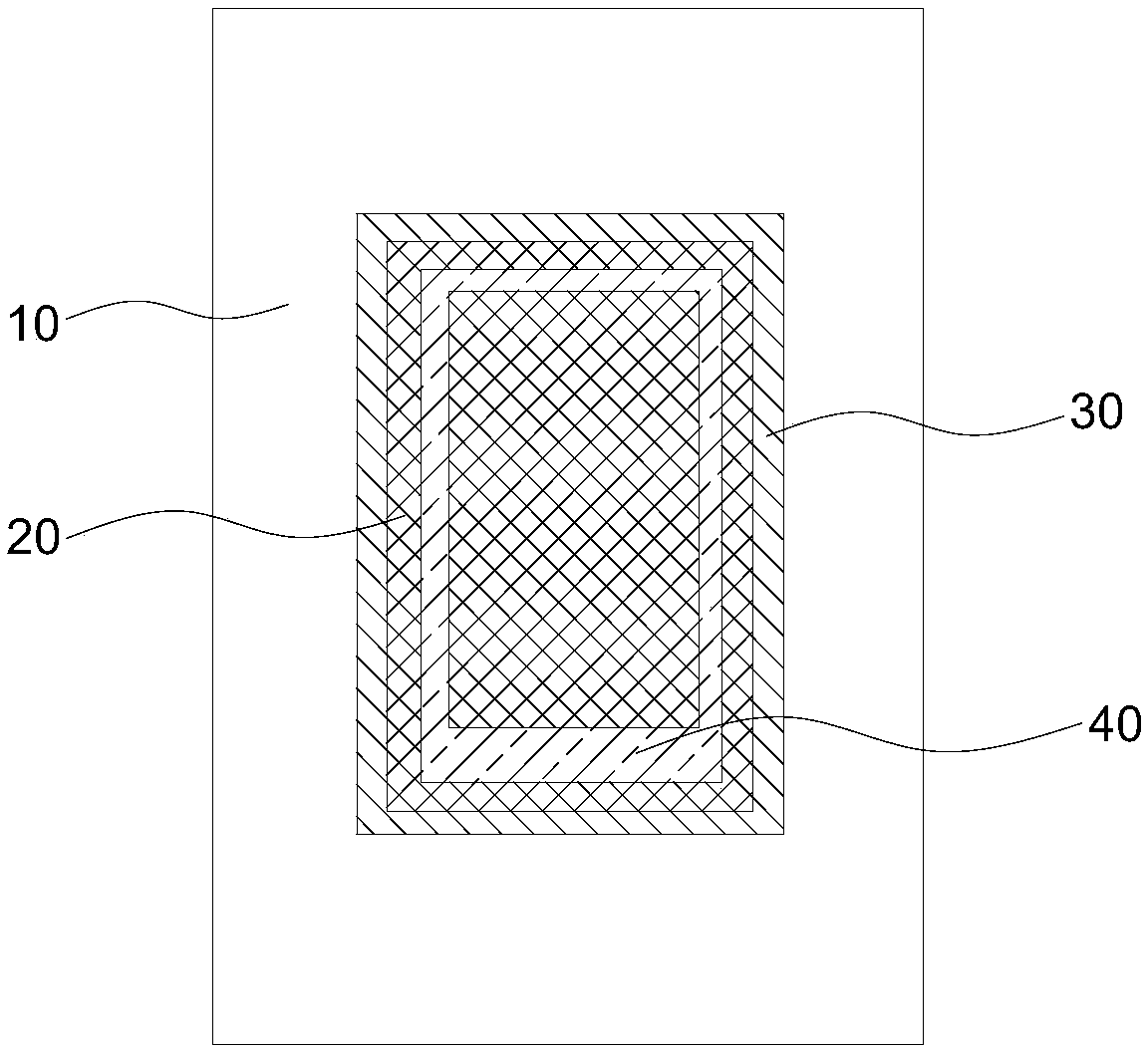

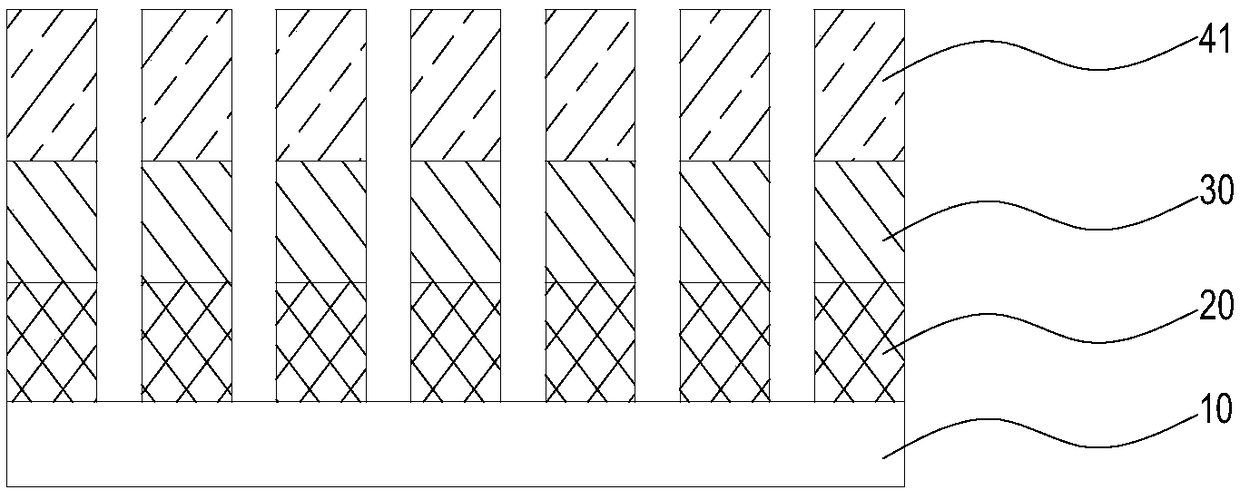

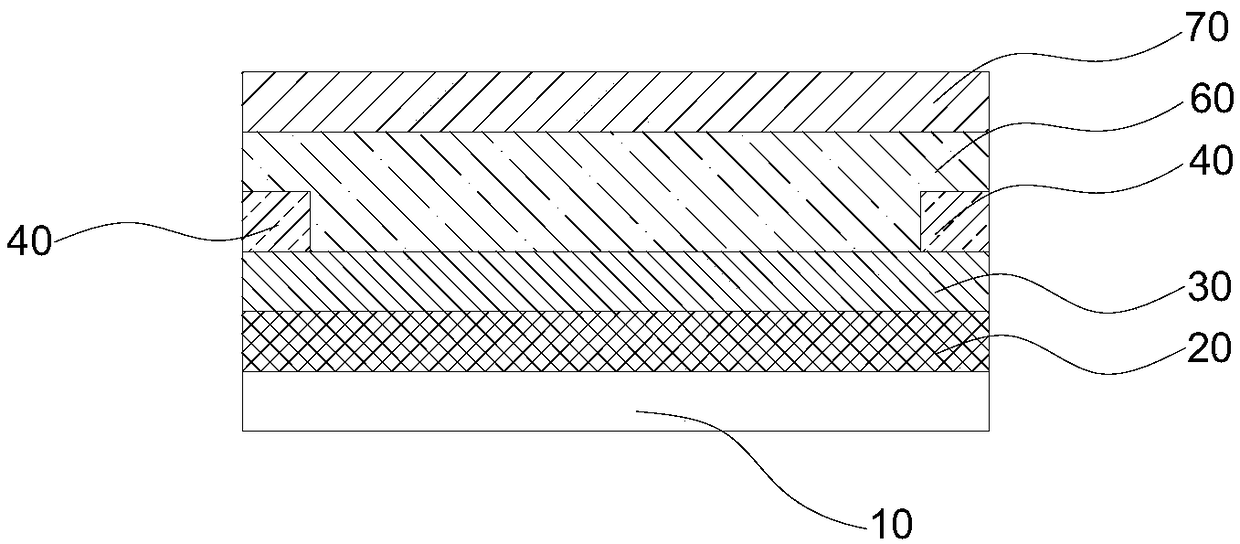

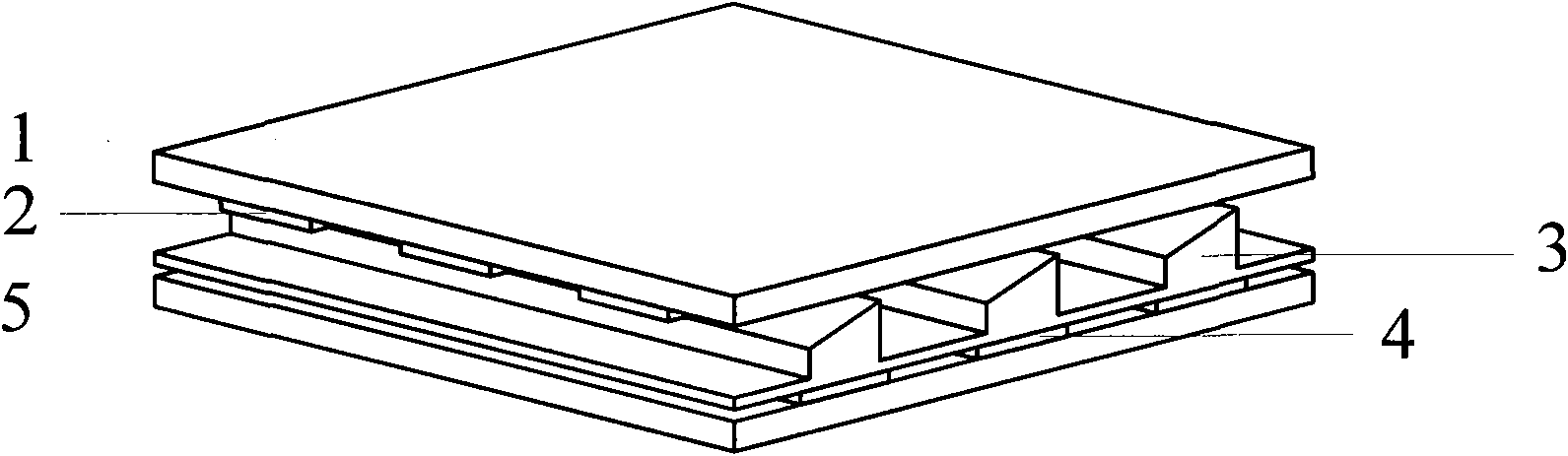

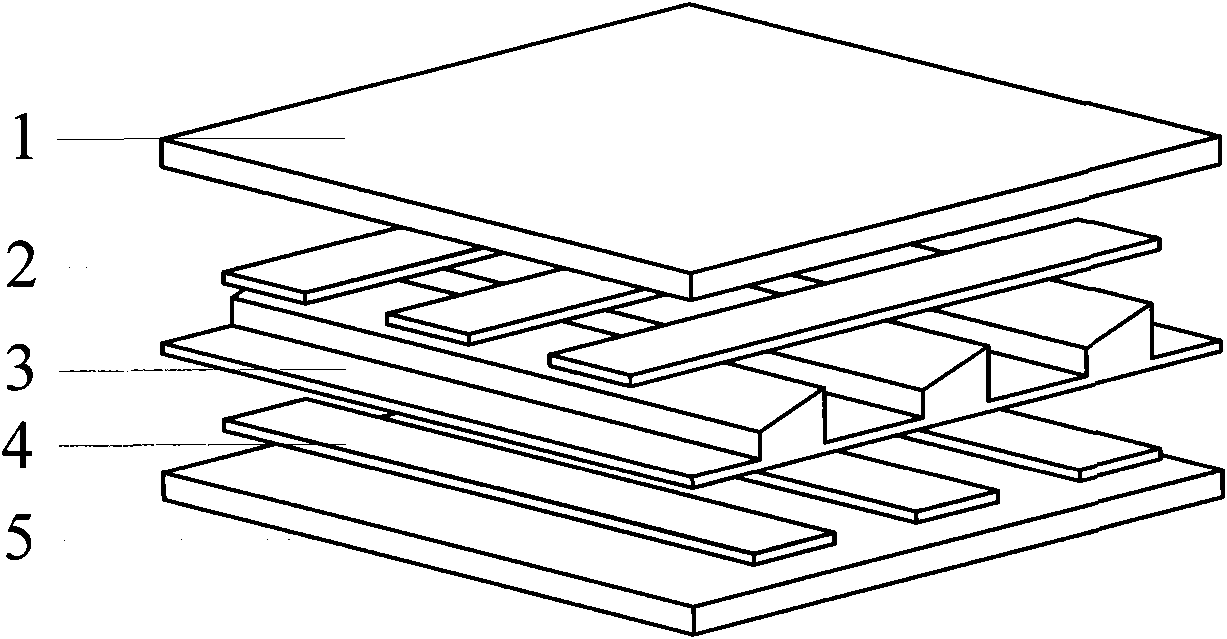

Roll-to-roll capacitive touch screen sensor and preparation method thereof

ActiveCN107577381AReduce visual contrastSmall loop resistanceInput/output processes for data processingEngineeringSurface cover

The invention discloses a roll-to-roll capacitive touch screen sensor. The roll-to-roll capacitive touch screen sensor comprise a substrate, a first electrode, a second electrode, third electrodes, adisapparation protection layer and an OCA optical adhesive layer, wherein the first electrode is arranged at the middle part of the upper surface of the substrate; the second electrode is arranged onthe upper surface of the substrate and at the periphery of the first electrode; the second electrode comprises a second electrode body and second electrode leads; the third electrodes cover the secondelectrode leads; the disapparation protection layer covers the upper surface of the first electrode and the parts, except the surface covered by the third electrodes, of the second electrode; and theOCA optical adhesive layer covers the first electrode, the second electrode, the third electrodes and the disapparation protection layer. The invention furthermore discloses a preparation method of the roll-to-roll capacitive touch screen sensor. The touch screen sensor has the characteristics of being low in resistance, good in electric conductivity, low in production cost and excellent in buckling performance. The preparation method has the characteristics of being simple in process, high in production efficiency, good in product performance stability and high in yield.

Owner:珠海纳金科技有限公司

Stainless steel matte finishing process

The invention belongs to the technical field of surface treatment of medical equipment and relates to a stainless steel matte finishing process. The primary technical scheme is as follows: the stainless steel matte finishing process comprises the following steps: placing a deoiled stainless steel workpiece and the anode of a power supply connected in an anodizing matte finishing solution of a mixture containing 10-50 g / L H3PO4, 10-30 g / L C6H8O7, 100-300 g / L H2O2 and 0.4-1 g / L K2SO4; heating the solution to 60-80 DEG C and connecting a platinum and titanium net to the cathode of a direct current power supply, wherein the area ratio of the platinum and titanium net and the cathode of the direct current power supply is 1: 1; and keeping the distance between the cathode and the anode at 6.0 cm, carrying out anodizing for 30-60 min under the condition that the current density is 3.4-6.8 A / dm<2> and the working voltage is 9.4-10.5 V, wherein the surface of stainless steel workpiece is matteand has silver metal gloss, the hardness of the stainless steel is improved, and the pitting corrosion resistance is improved. The stainless steel matte finishing process provided by the invention notonly can solve the environmental problem that an existing stainless steel matte finishing solution contains harmful substances and strong acids, but also can solve the problem that the dissolving speed of the environment-friendly solution is low, thereby providing a new path for development of stainless steel matte technical treatment.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

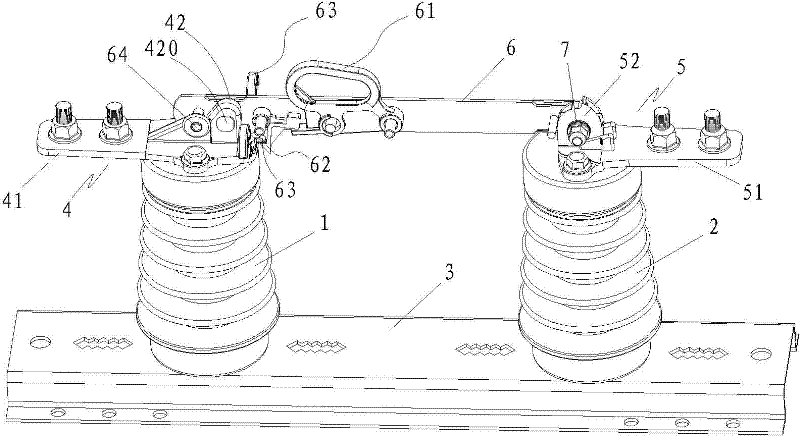

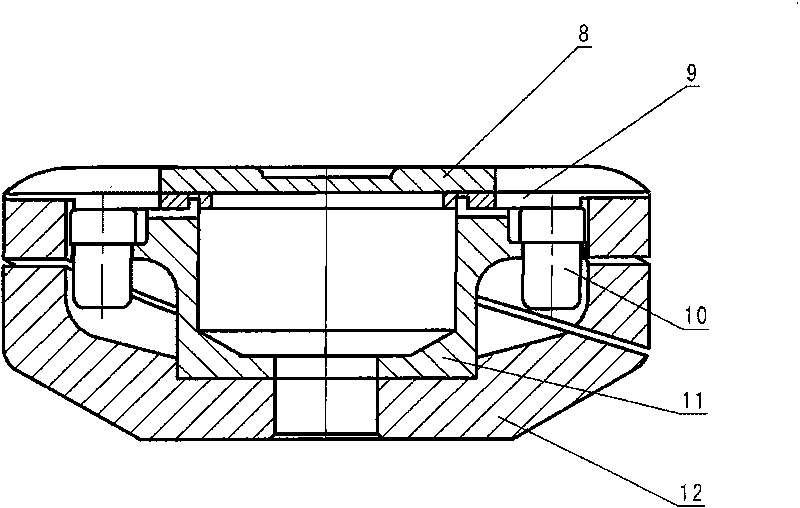

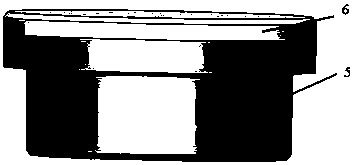

Fixedly-sealed polar column with anomalous soft connection

InactiveCN102376490AIncrease contact areaLarge flowHigh-tension/heavy-dress switchesAir-break switchesEngineering

The invention relates to a fixedly-sealed polar column with an anomalous soft connection. The fixedly-sealed polar column comprises a vacuum extinction chamber which is arranged inside the fixedly-sealed polar column; the upper end of a movable end is arranged inside the vacuum extinction chamber; the lower end of the movable end, which goes out of the vacuum extinction chamber, is connected with one end of the anomalous soft connection; the lower side of one end of the anomalous soft connection is connected with an insulating tension rod; the other end of the anomalous soft connection is integrally connected with a lower line outlet seat through a screw; the lower end of the movable end is in an external taper shape and the connection part of the anomalous soft connection with the lower end of the movable end is in the shape of a column with an internal taper; the connection part where the other end of the anomalous soft connection is connected with the lower line outlet seat through the screw is in the shape of a binding face; and a thread through hole is arranged on the binding face and the screw extends from a through hole of the lower line outlet seat to the thread through hole. The fixedly-sealed polar column provided by the invention has the beneficial effects that the contact area between the movable end of the extinction chamber and the soft connection is enlarged, the flow rate is increased, the loop resistance is easy to reduce, fewer parts are mounted and the design is simpler than that of sliding connection.

Owner:SHANGHAI ROX ELECTRIC

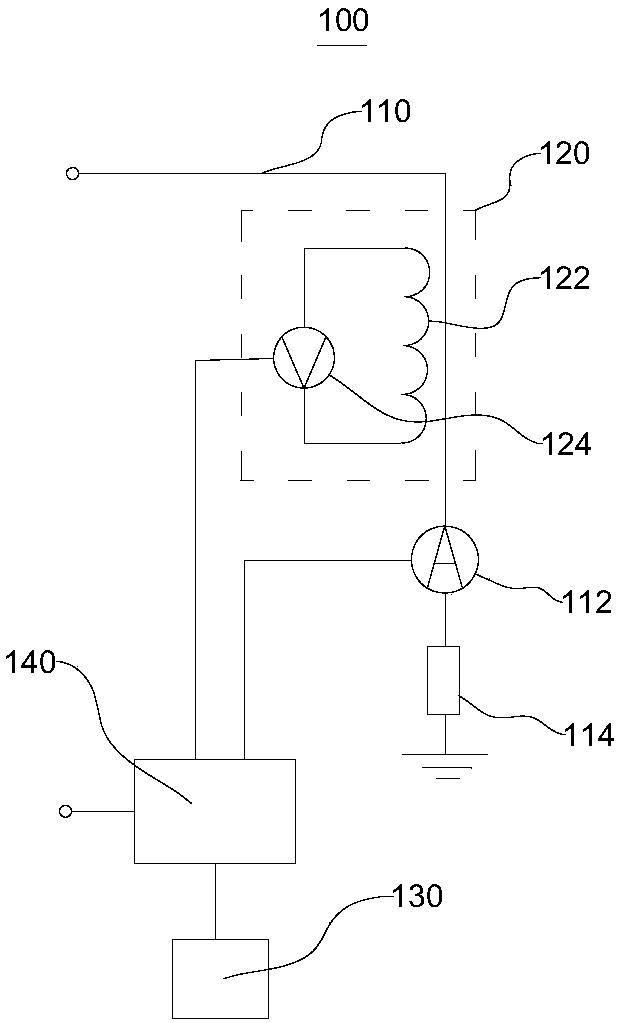

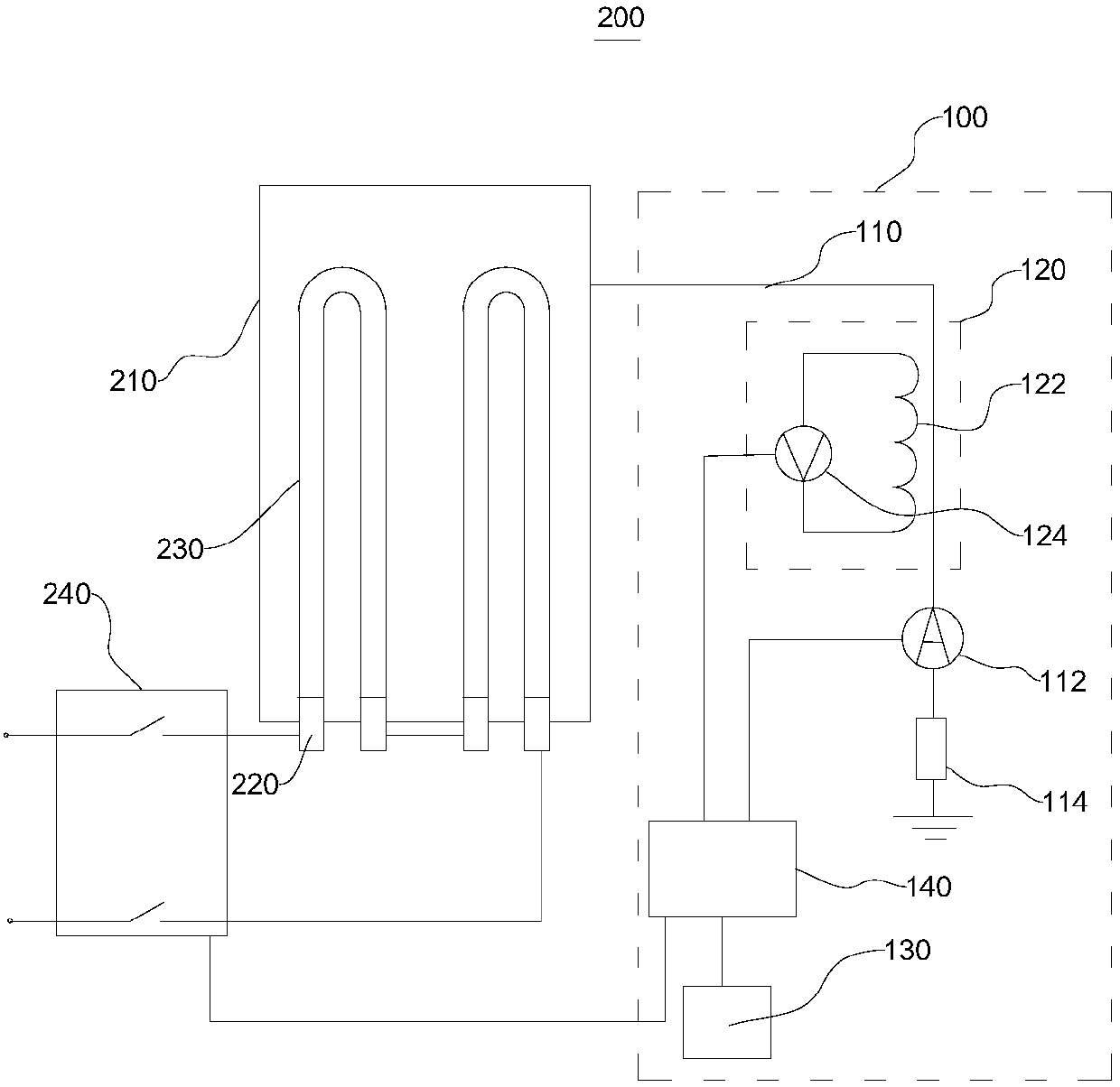

Electric leakage detection system and polycrystalline silicon reduction furnace

InactiveCN107748312AEasy to judgeReduce economic lossRate of change measurementElectrical testingEngineeringShort circuit fault

The invention relates to the field of polycrystalline silicon production equipment, and discloses an electric leakage detection system and a polycrystalline silicon reduction furnace. The electric leakage detection system comprises a grounding wire and a current differential detection module, wherein the current differential detection module can detect an amplitude change rate of leakage current in the grounding wire, so that whether the type of a grounding short-circuit fault in the reduction furnace belongs to a circuit short caused by dust accumulation or silicon junction at an electrode orfalling of silicon rods according to a detection result of the current differential detection module, thereby deciding whether to shut down the furnace to process or continue to operate according toactual conditions, and reducing the great economic loss caused by shutdown of the furnace due to misjudgment. The polycrystalline silicon reduction furnace disclosed by the invention is provided withthe electric leakage detection system, and the furnace wall of a furnace body of the polycrystalline silicon reduction furnace is grounded through the grounding wire, thereby being convenient for technicians to judge the short-circuit type in the reduction furnace.

Owner:ASIA SILICON QINGHAI

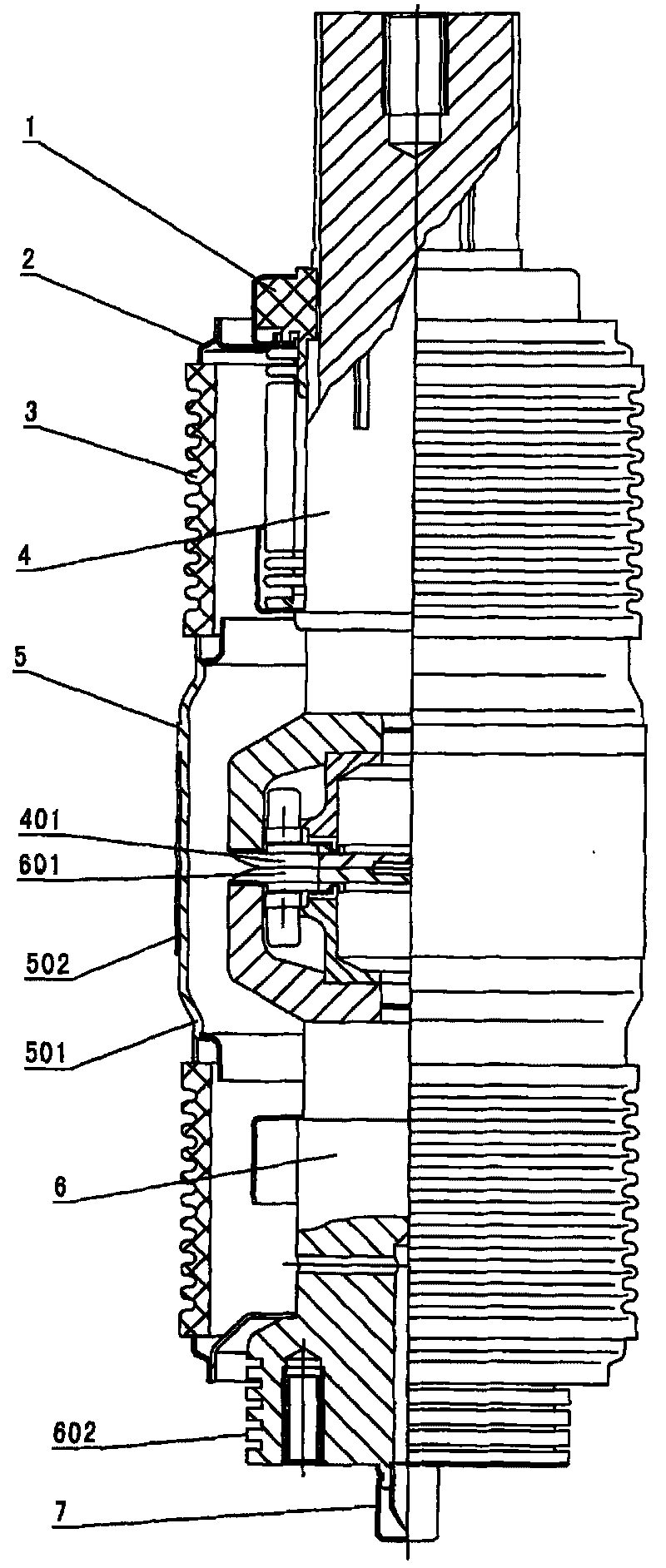

Vacuum switching tube for protective circuit breaker of generator outlet

InactiveCN101719432AMeet the needs of breakingImproved breaking current capabilityEmergency protective circuit arrangementsHigh-tension/heavy-dress switchesHigh surfaceEngineering

The invention relates to a vacuum switching tube for a protective circuit breaker of a generator outlet, solving the problem that the conventional vacuum switching tube has low surface utilization rate and small capacity and can not satisfy great current breaking requirement. The vacuum switching tube for a protective circuit breaker of a generator outlet comprises a guiding sleeve, ceramic insulated shells, a composite shielded sleeve, a movable end pipe core, a static end pipe core and a protective cap, wherein the ceramic insulated shell is respectively connected with the movable end pipe core and the static end pipe core by kovars; the composite shielded sleeve is connected with the ceramic insulated shells at both ends; and the contact combinations of the movable end pipe core and the static end pipe core are corresponding to each other. The vacuum switching tube for a protective circuit breaker of a generator outlet is characterized in that either contact combination is in arc-distributed electrode structure and respectively comprises a cup seat, a supporting disk, a magnetism-concentrating column, a contact body and an oxygen-free copper tray; the composite shielded sleeve comprises an arc absorption inner layer and a magnetic shielded outer layer; and the surface of a static conductive rod is provided with radiation grooves. The invention has the advantages of reasonable structure, strong current breaking and closing capabilities, small loop resistance, uniform electrode surface combustion, high surface utilization rate and strong radiation capability.

Owner:锦州华光开关管有限公司

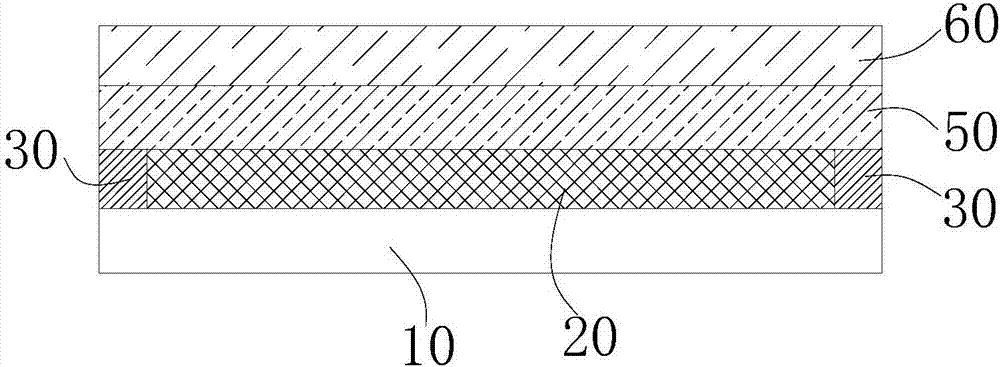

Capacitive touch screen functional chip, preparation method thereof, capacitive touch screen and electronic device

PendingCN108803954AImprove bending resistanceArbitrary distortionInput/output processes for data processingElectrical resistance and conductanceCapacitance

The invention discloses a capacitive touch screen functional chip, comprising a substrate, a capacitive sensing layer, a protection layer of the capacitive sensing layer, a conductive electrode layer,a wear-resistant conductive layer, a shadow elimination protection layer and an OCA optical adhesive layer, wherein the conductive electrode layer comprises a conductive electrode main body and a conductive electrode lead extending outward from the conductive electrode main body, and the capacitive sensing layer, the protection layer of the capacitive sensing layer, the shadow elimination protection layer and the OCA optical adhesive layer are transparent. The invention further discloses a preparation method of the capacitive touch screen functional chip, a capacitive touch screen and an electronic device. The capacitive touch screen functional chip disclosed by the invention has the advantages of good bending property, low resistance, good conductivity, high light transmittance, simple structure, etc.

Owner:珠海纳金科技有限公司

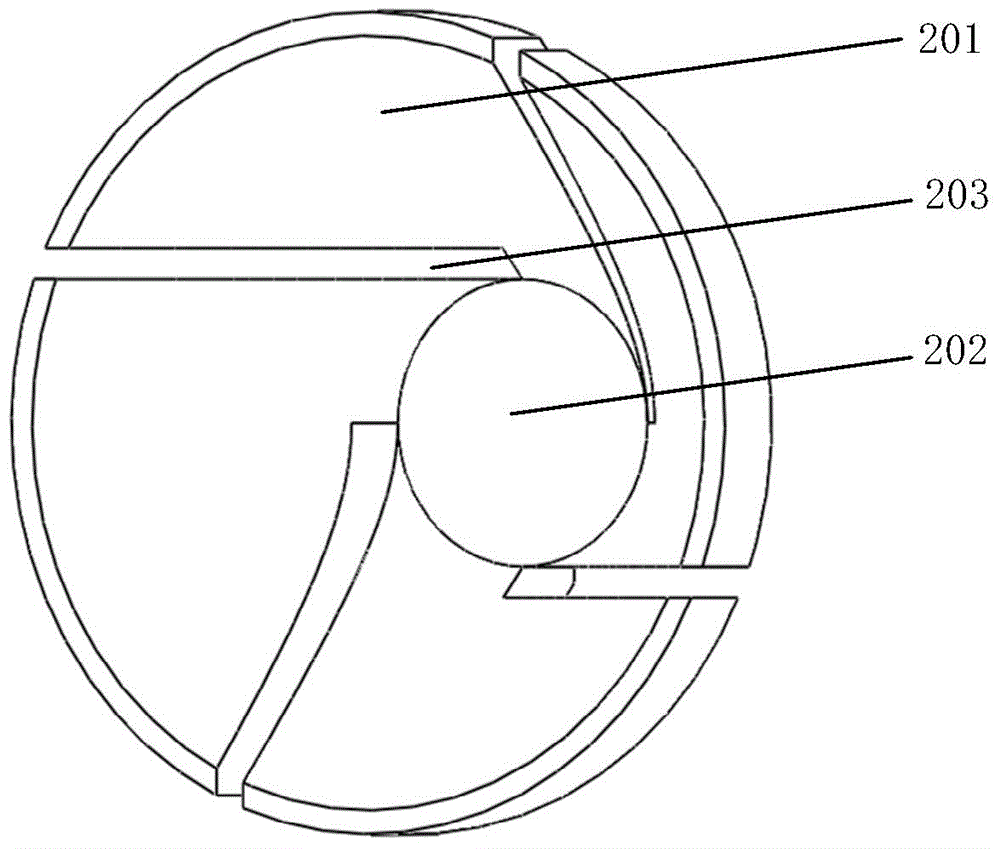

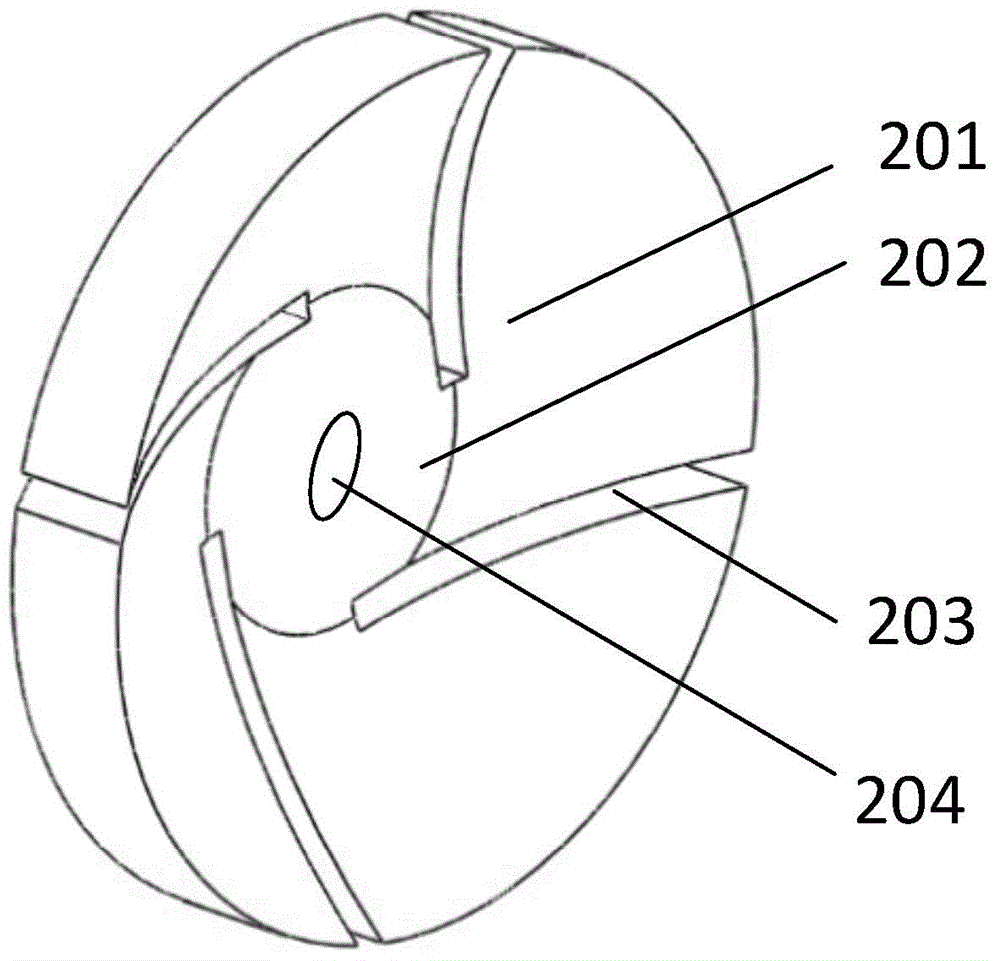

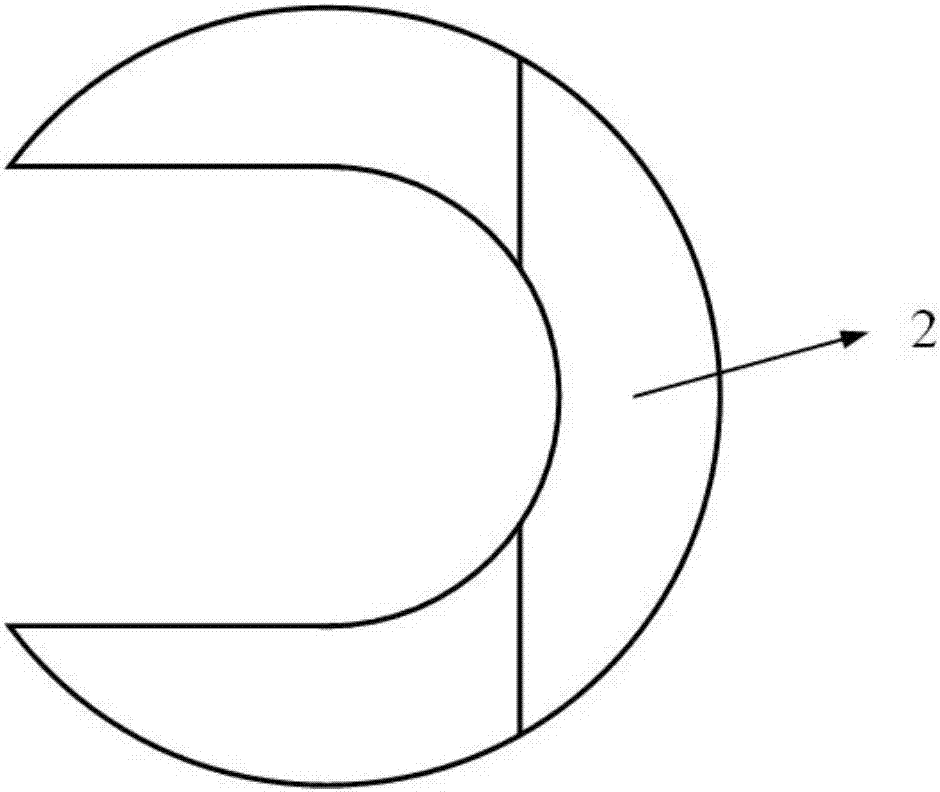

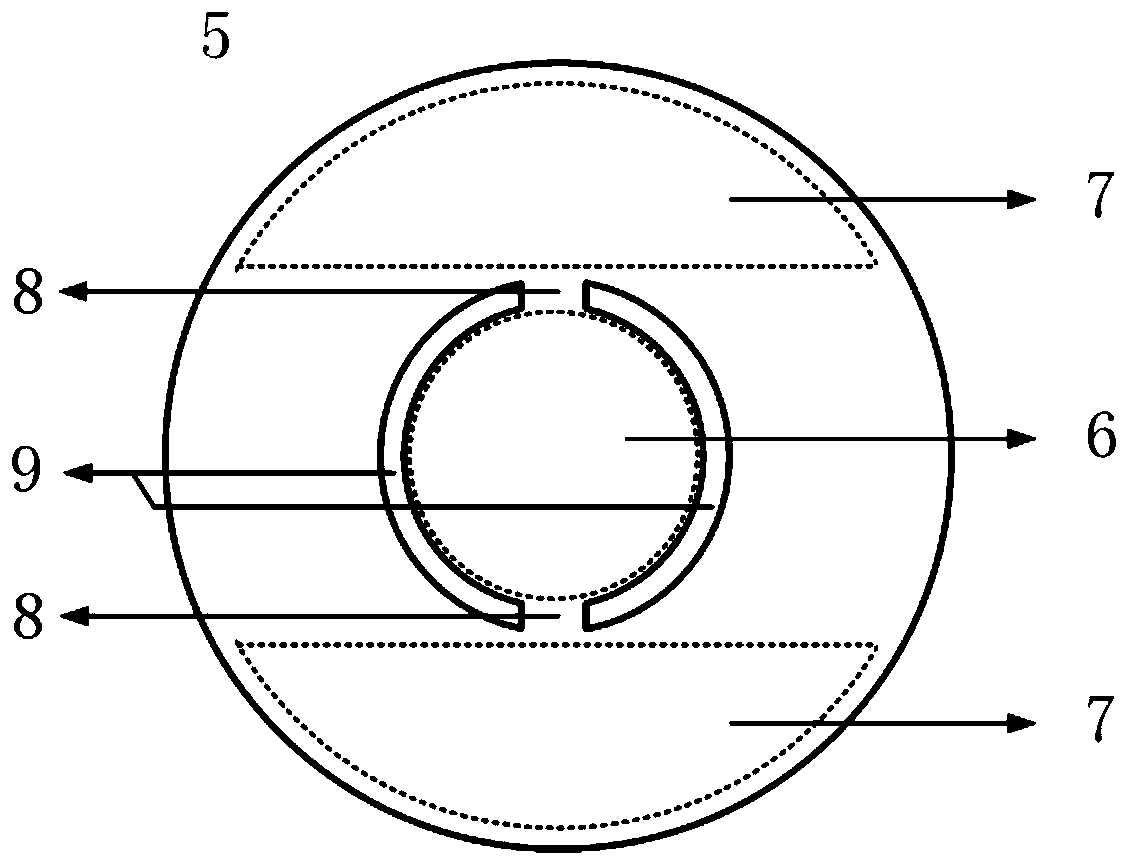

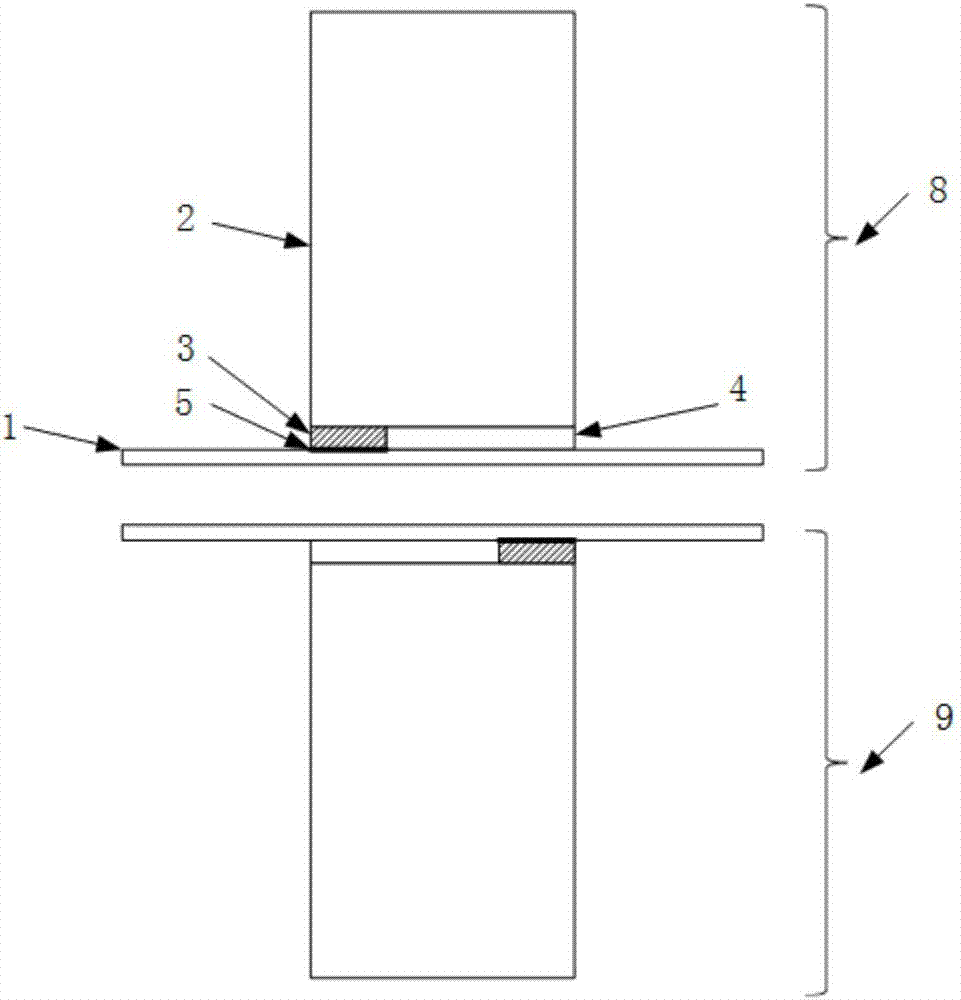

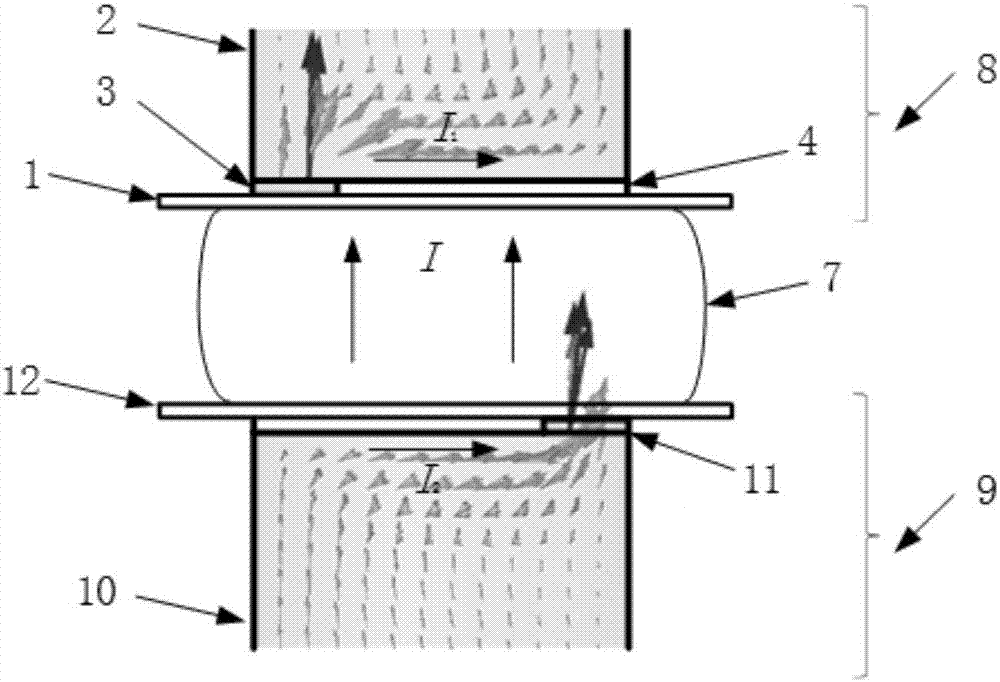

Vacuum interrupter bipolar compound longitudinal magnetic field contact structure

ActiveCN107123566AIncrease the strength of the longitudinal magnetic fieldIncrease the longest arcing distanceHigh-tension/heavy-dress switchesAir-break switchesUltimate tensile strengthContact system

The invention provides a vacuum interrupter bipolar compound longitudinal magnetic field contact structure. The structure comprises an anode contact system and a cathode contact system, wherein the anode contact system and the cathode contact system are arranged in a vacuum interrupter. The anode contact system comprises a contact sheet and a magnetic conductive structure which is arranged on the back of the contact sheet and is provided with an opening on the single side. A conductive rod is connected with the contact sheet through a diversion structure and passes through the opening of the magnetic conductive structure. The diversion structure, the magnetic conductive structure and the contact sheet are fixed by welding. The cathode contact system and the anode contact system share the same structure. The contact sheets are oppositely arranged, and the opening direction of the magnetic conductive structure is opposite. The conductive rod, the contact sheets and the diversion structure form a conductive circuit. The magnetic conductive structure forms a magnetic conductive circuit. According to the structure provided by the invention, the longitudinal magnetic field strength in the vacuum interrupter can be improved; a strong longitudinal magnetic field area is increased; the longitudinal magnetic field of the existing vacuum interrupter is increased; the maximum arcing distance of vacuum arc is effectively improved; and the vacuum interrupter circuit resistance is low.

Owner:XI AN JIAOTONG UNIV

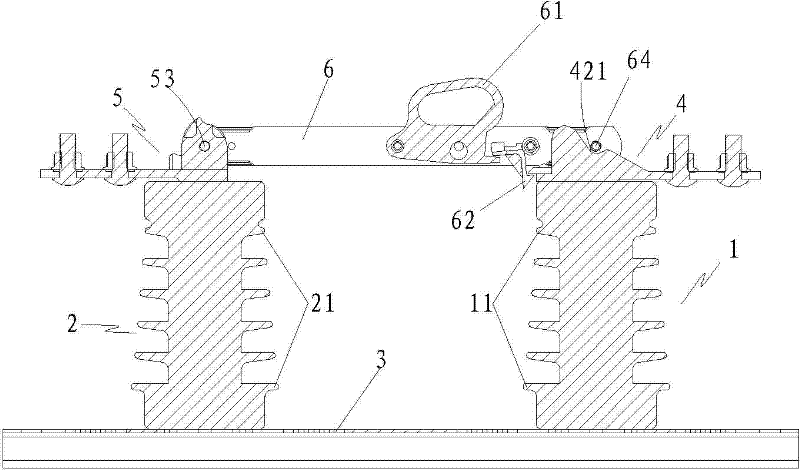

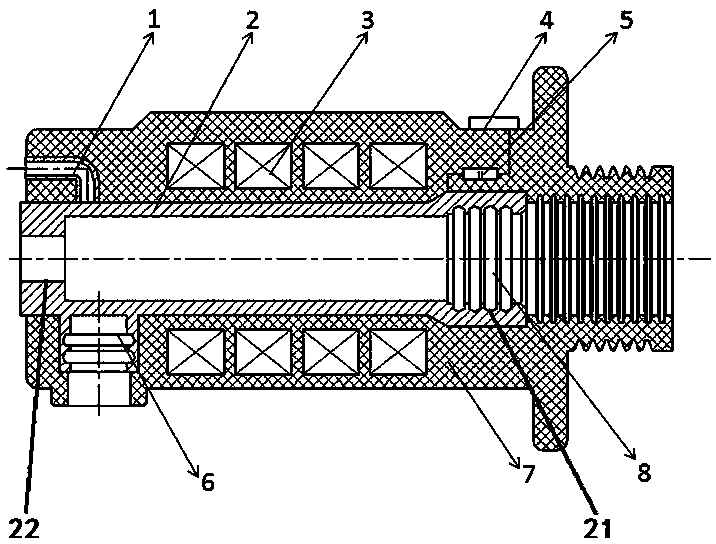

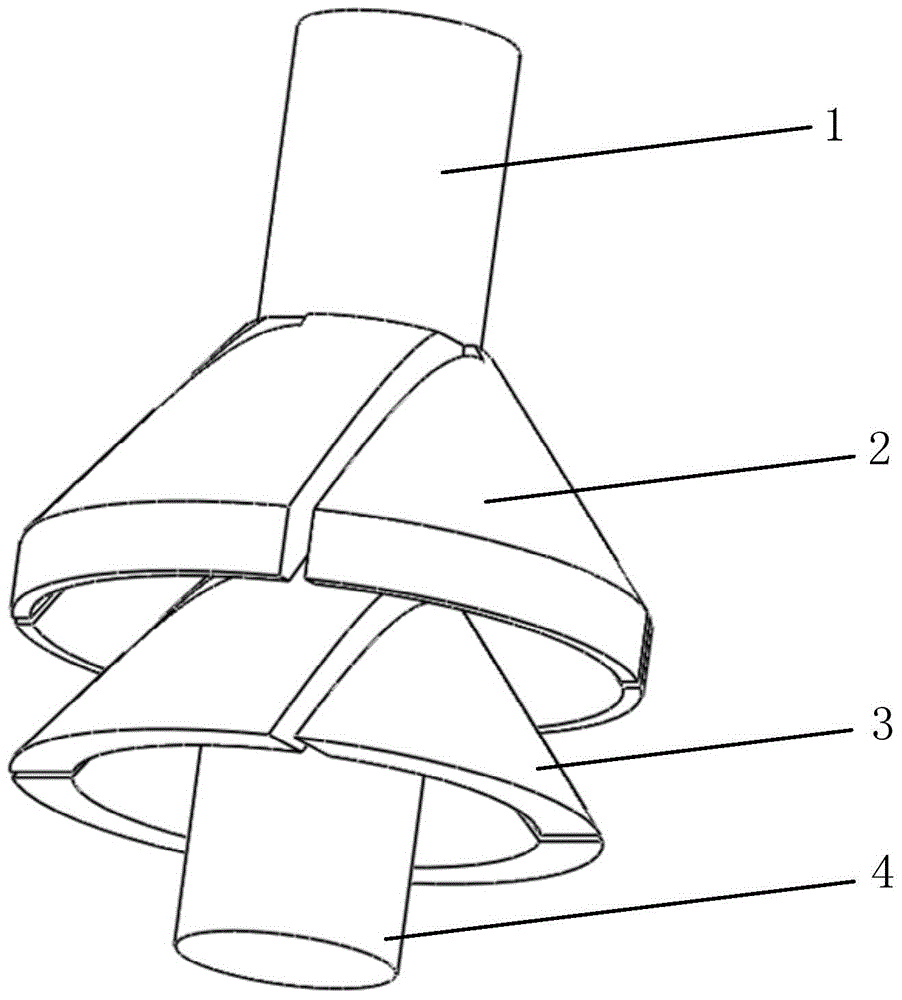

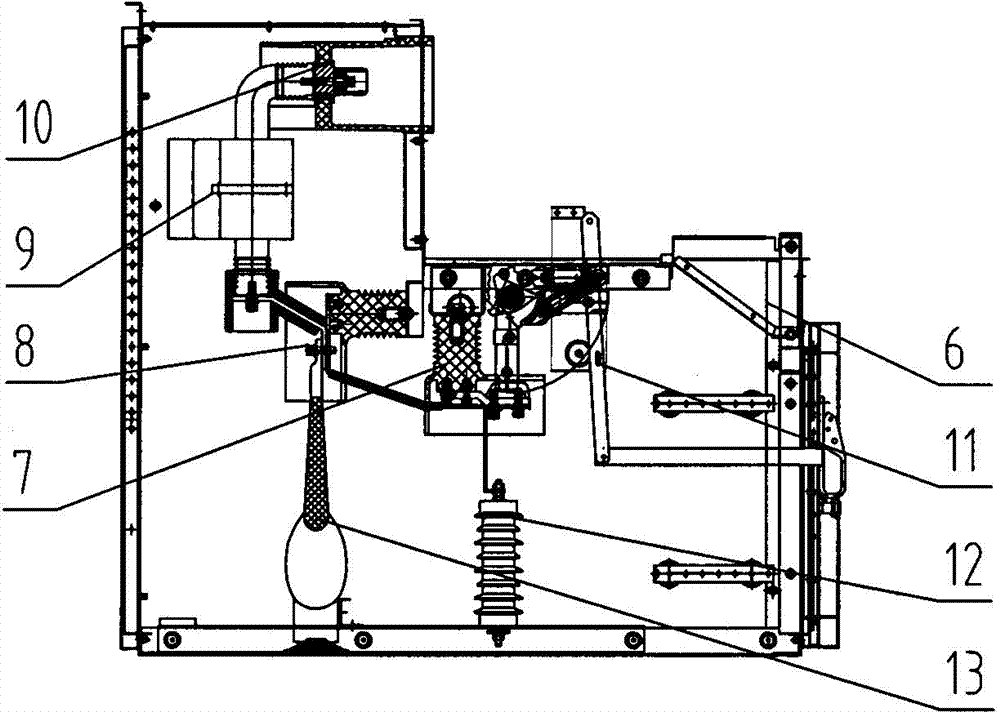

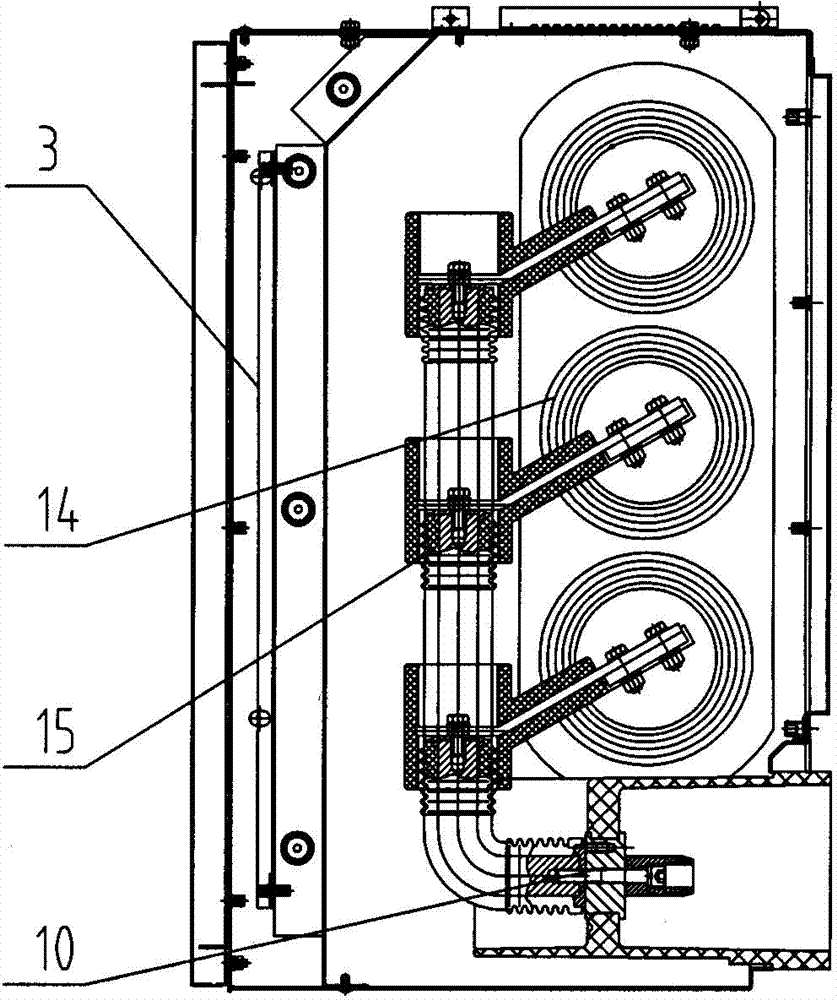

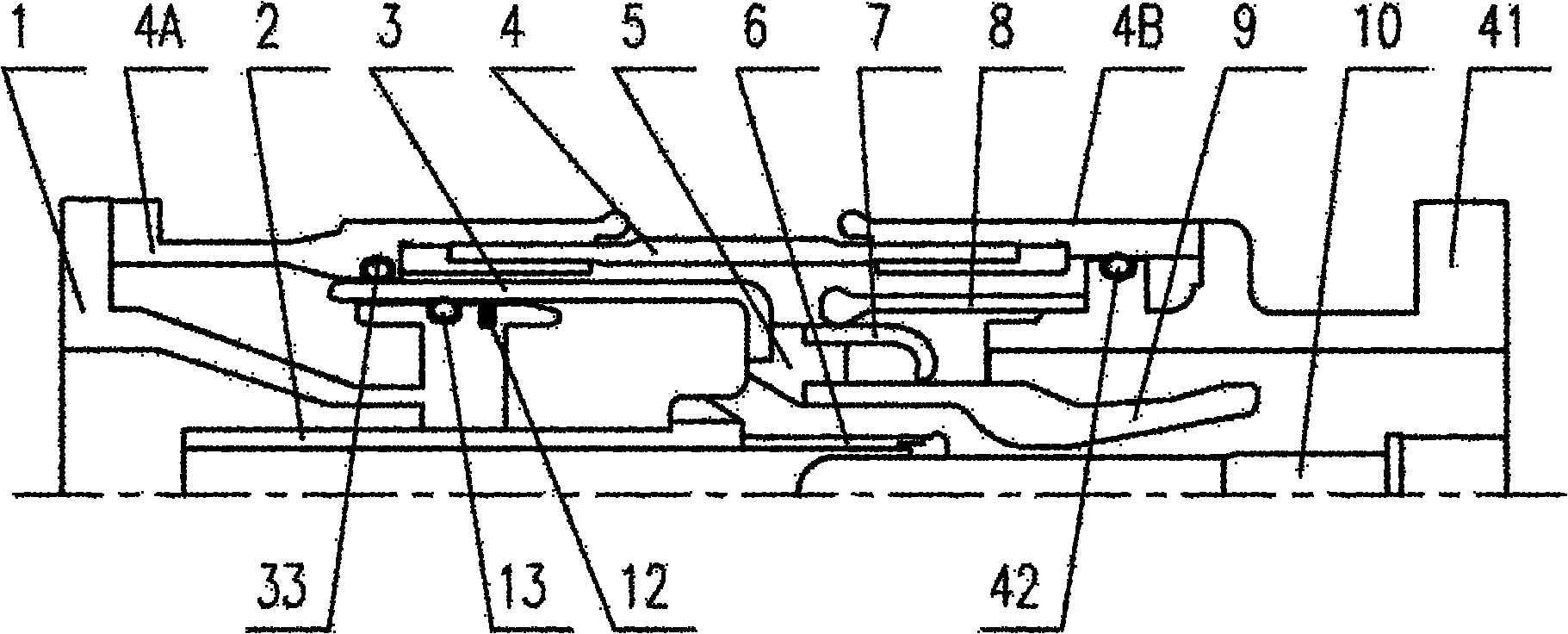

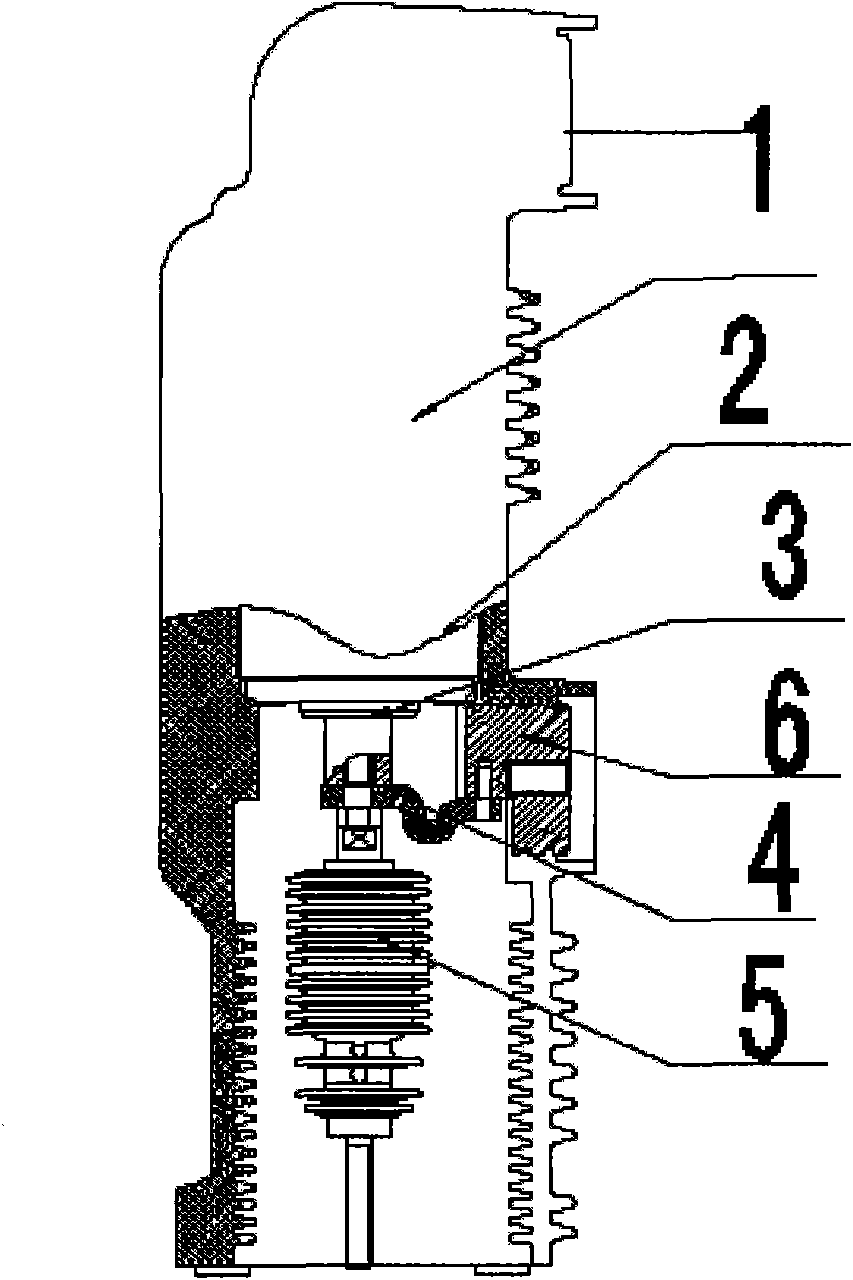

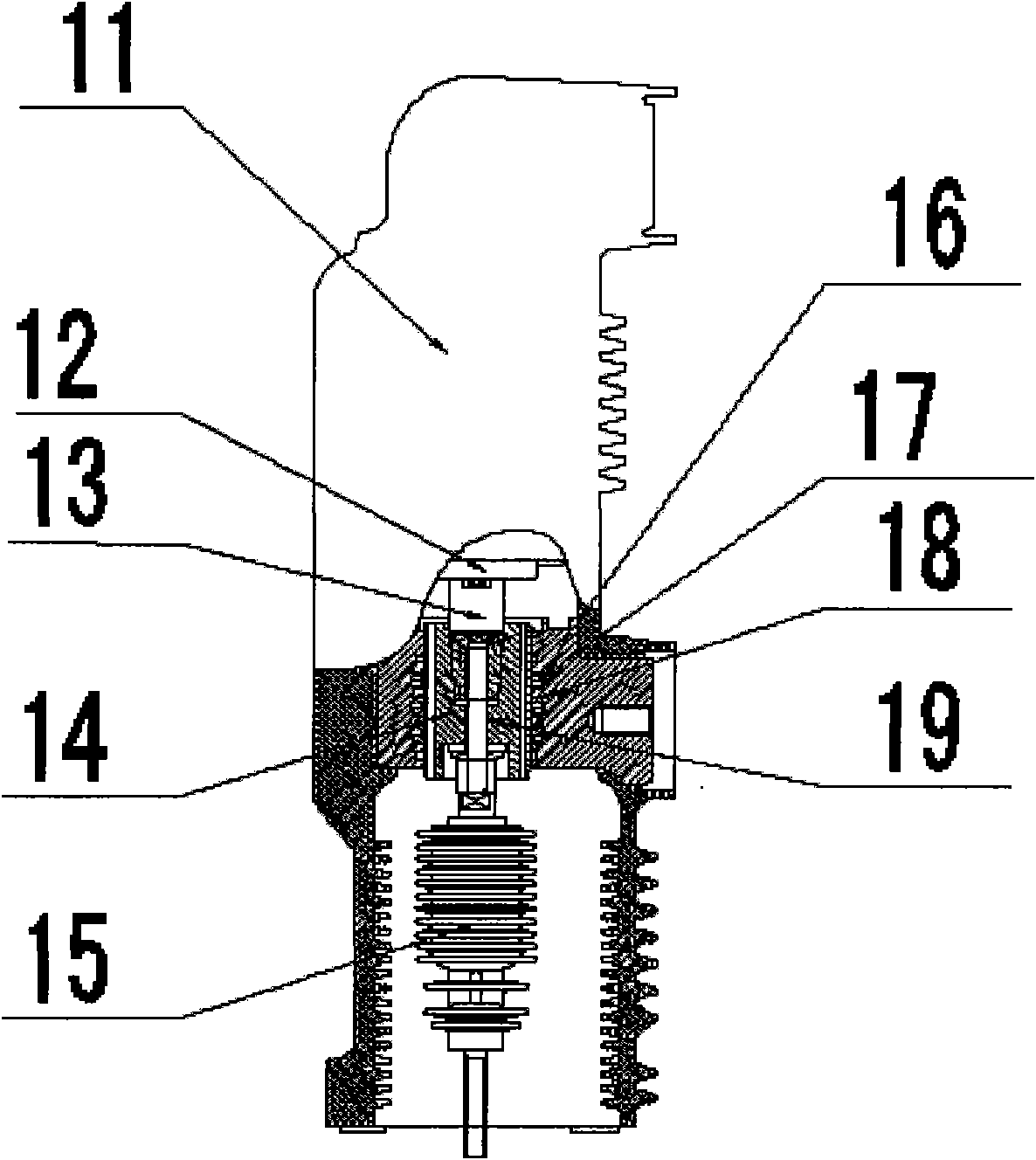

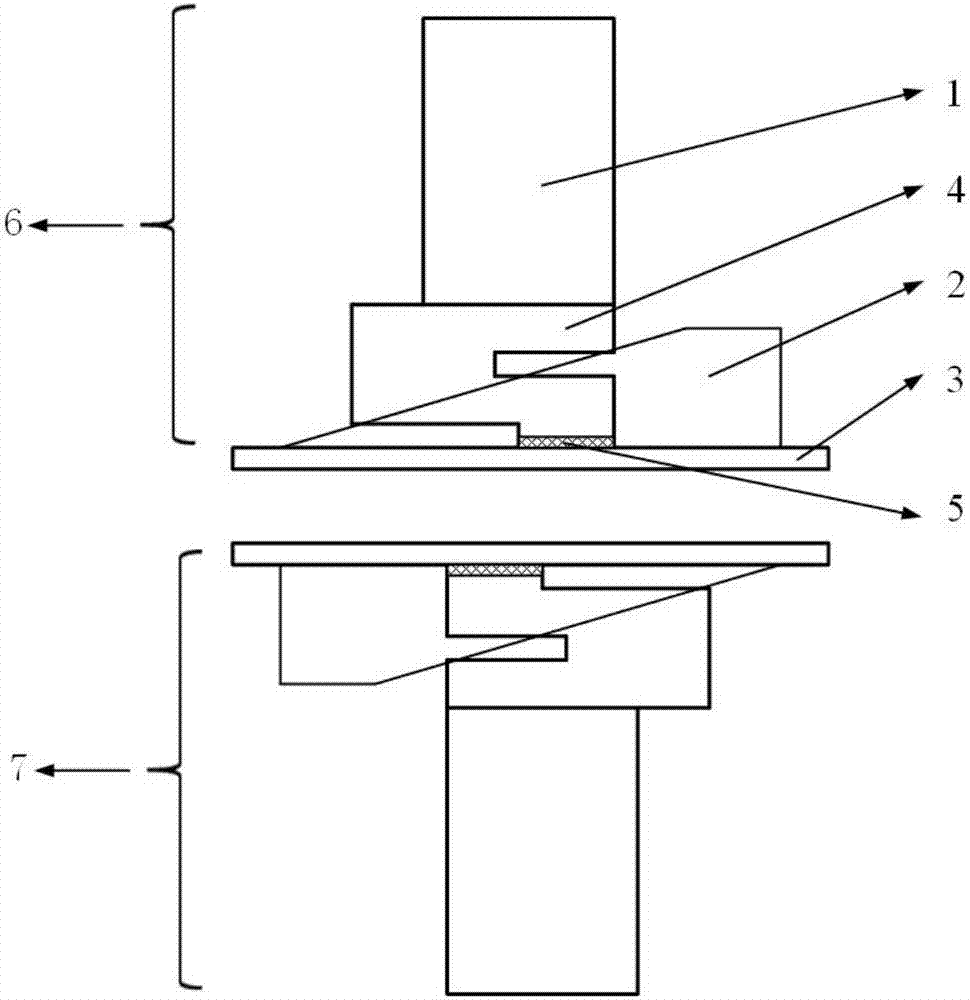

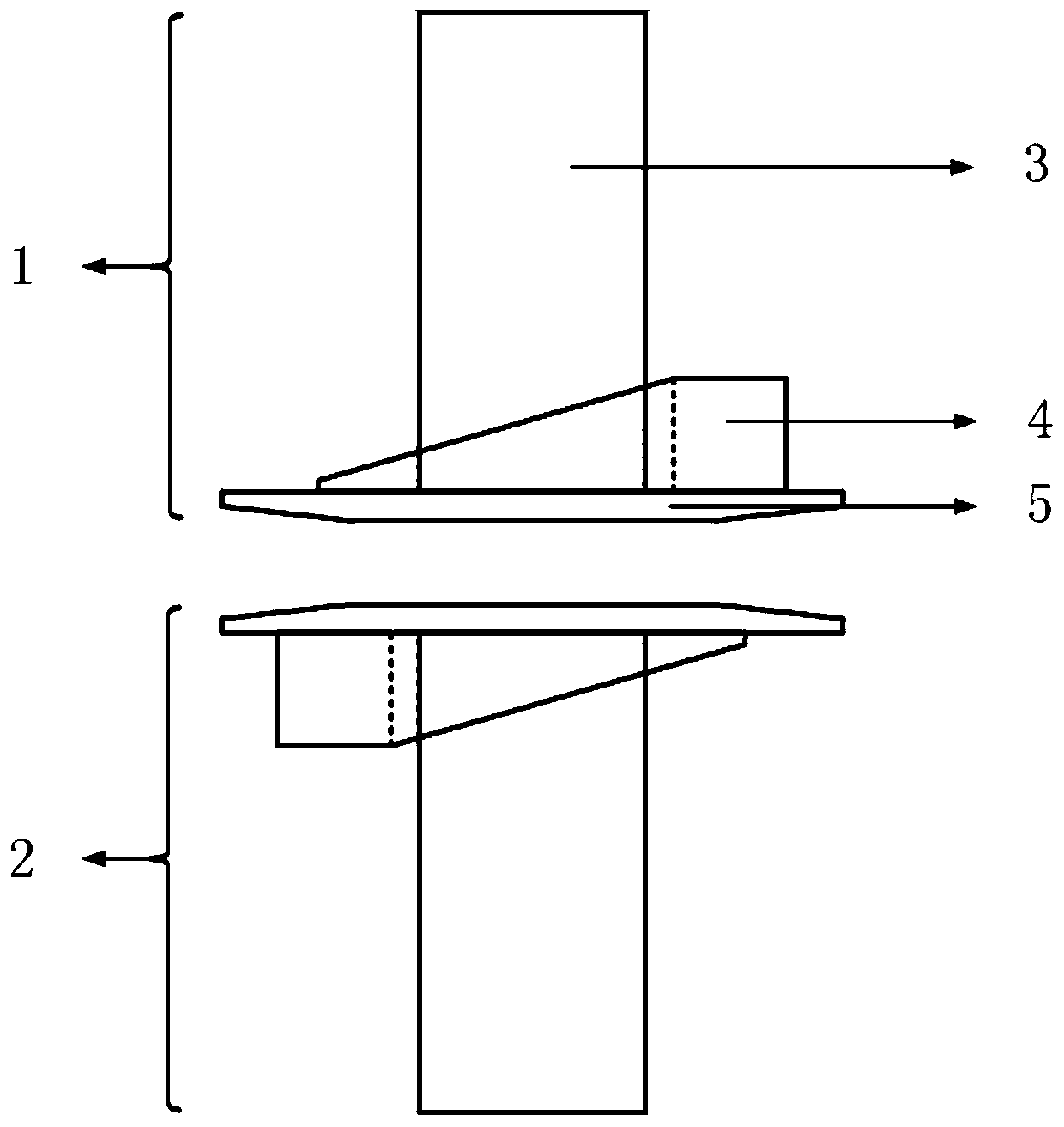

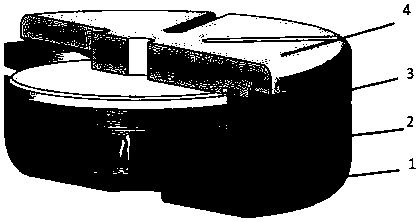

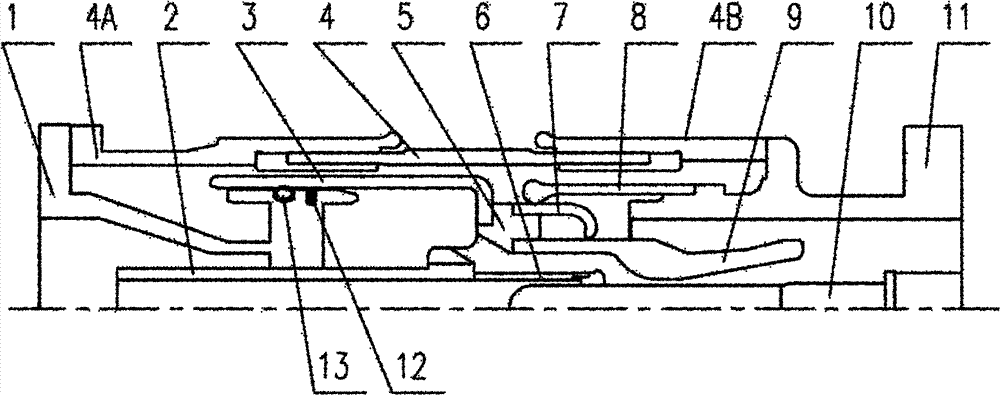

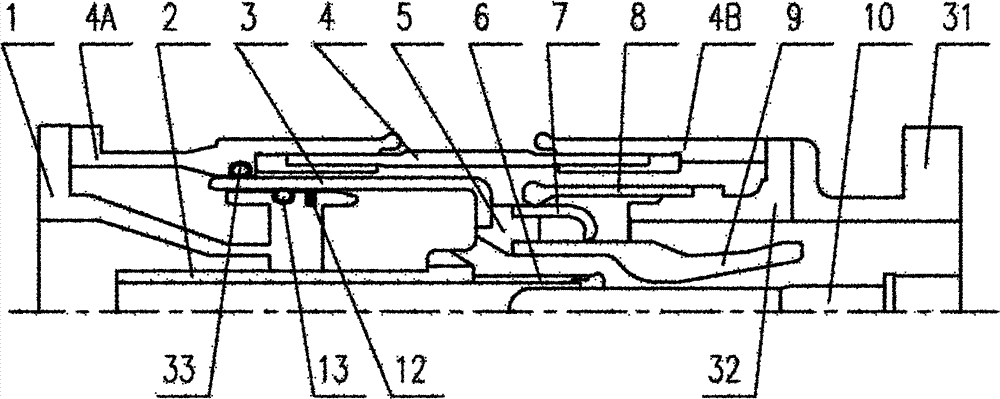

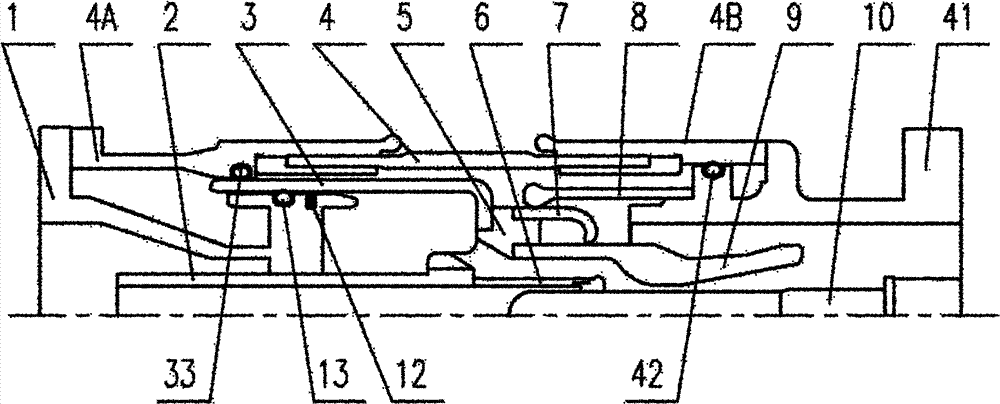

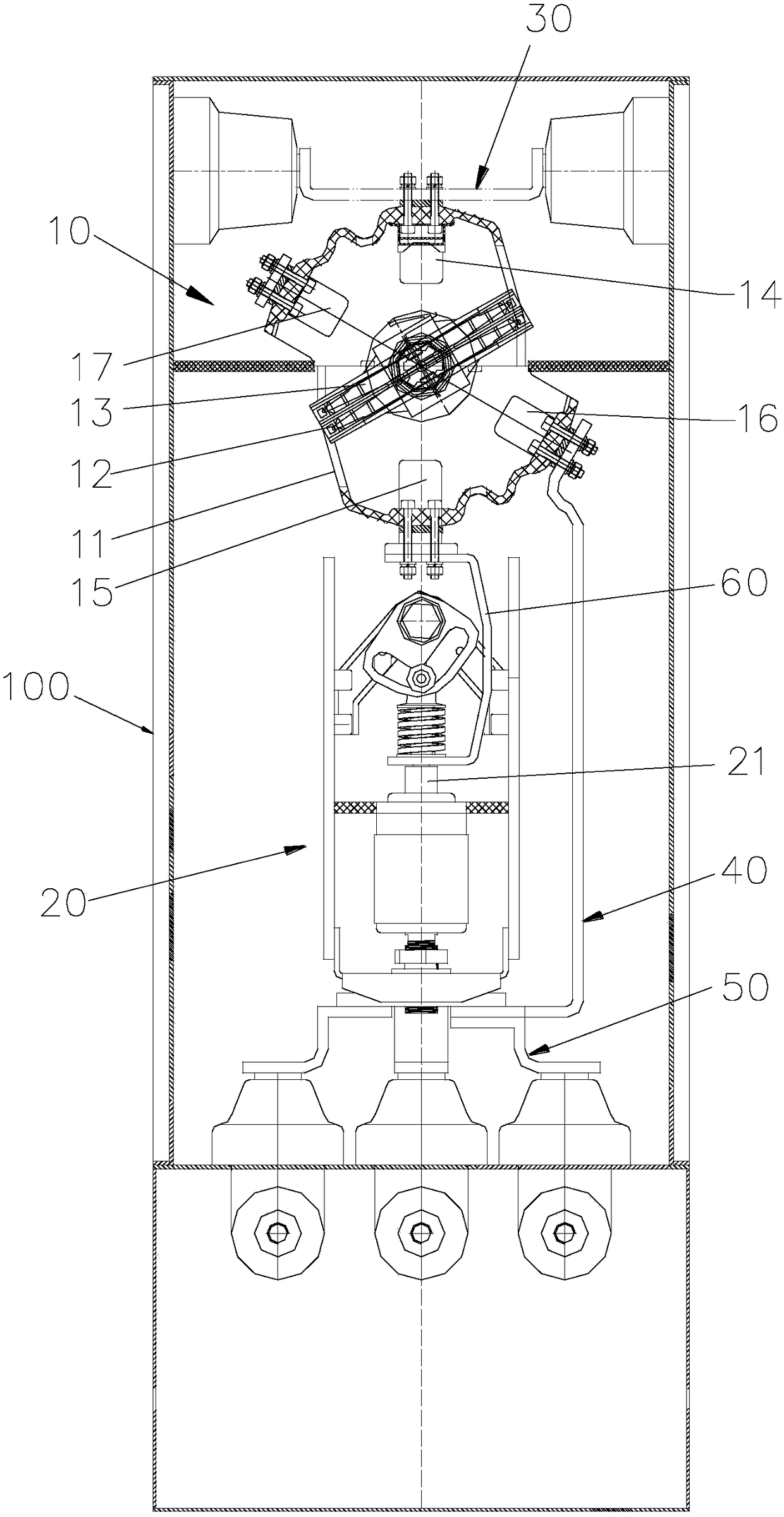

Novel vacuum circuit breaker with fixedly encapsulated pole

InactiveCN102969194AReduce oxidationSmall loop resistanceHigh-tension/heavy-dress switchesAir-break switchesPower stationMoisture

The invention relates to a novel vacuum circuit breaker with a fixedly encapsulated pole. The vacuum circuit breaker comprises a vacuum arc-extinguishing chamber (1), an upper contact arm (2) and a lower contact arm (3) and is characterized in that the vacuum arc-extinguishing chamber and the upper contact arm (2) are fixedly encapsulated. The novel vacuum circuit breaker with the fixedly encapsulated pole adopts a high performance epoxy resin material, utilizes the automatic pressure gel (APG) process to fixedly encapsulate the vacuum arc-extinguishment chamber, the upper contact arm and the lower contact arm, is suitable for working environment with large sand, dryness, plateau highness and coldness, moisture, foul, underground and power stations, simultaneously reduces oxidation of conductive parts of the circuit breaker, reduces circuit resistance and improves main circuit connection reliability. Experiments prove that mechanical service life can reach 30000 times.

Owner:远大中联控股集团有限公司

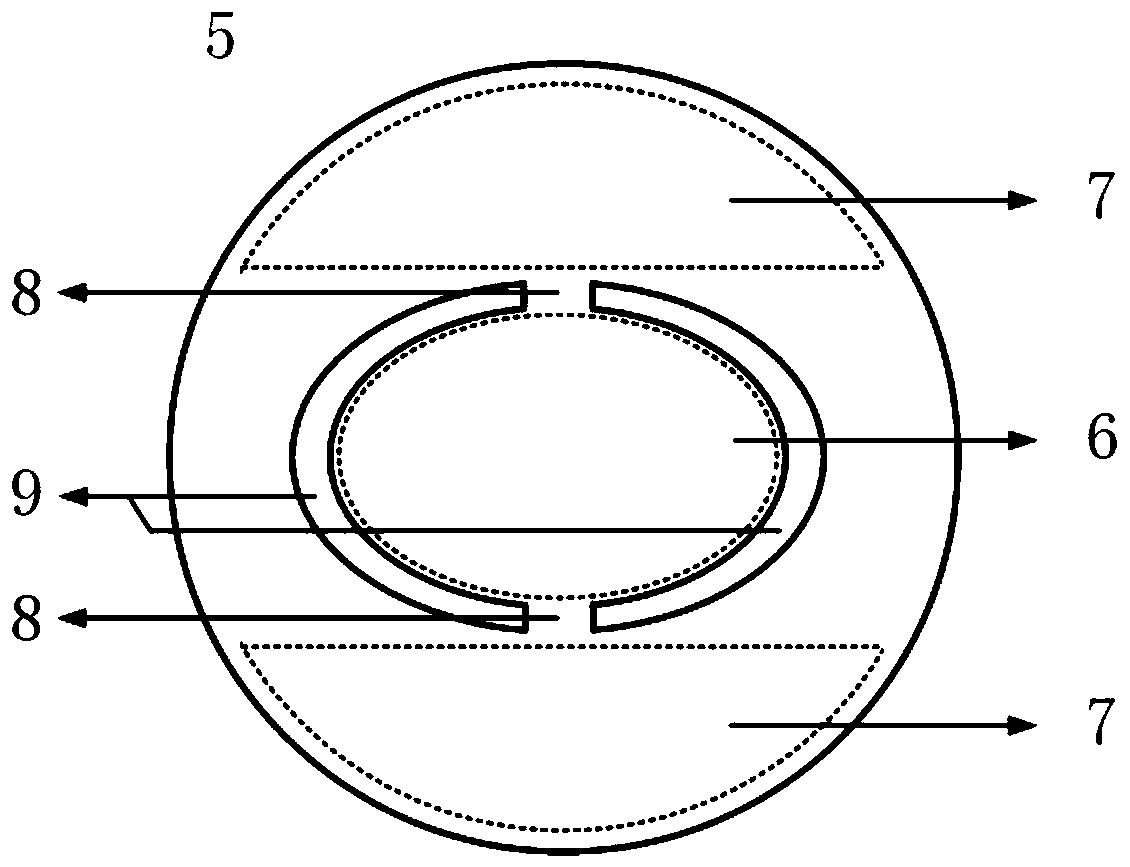

A High Rated Current Longitudinal Magnetic Field Vacuum Interrupter Contact Structure

ActiveCN107093535BSmall loop resistanceStrong rated flow capacityHigh-tension/heavy-dress switchesAir-break switchesElectrical resistance and conductanceElectrical connection

Owner:XI AN JIAOTONG UNIV

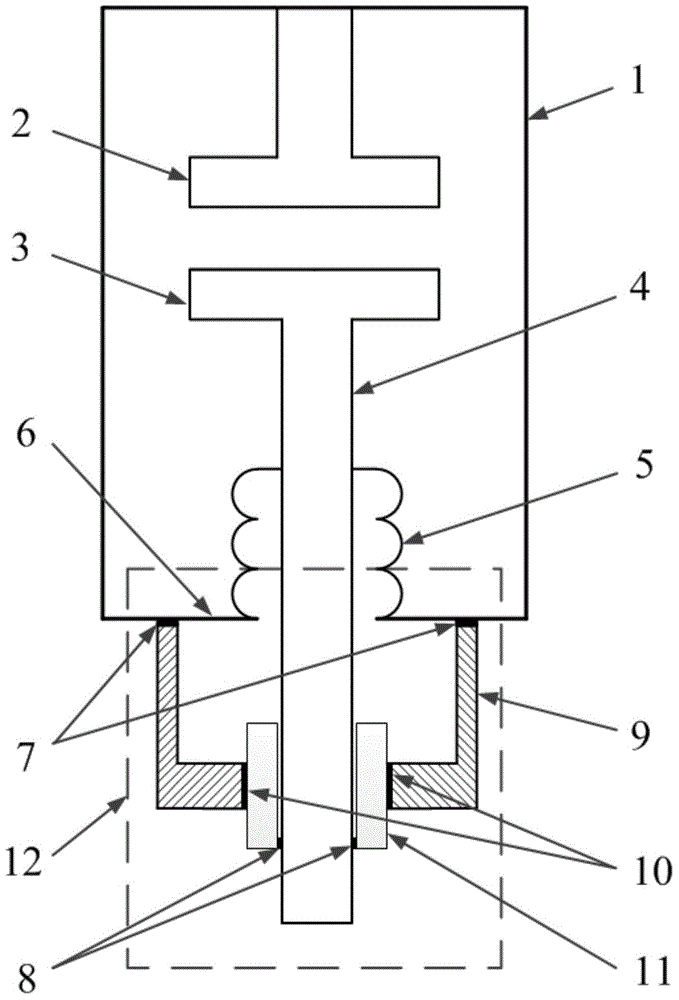

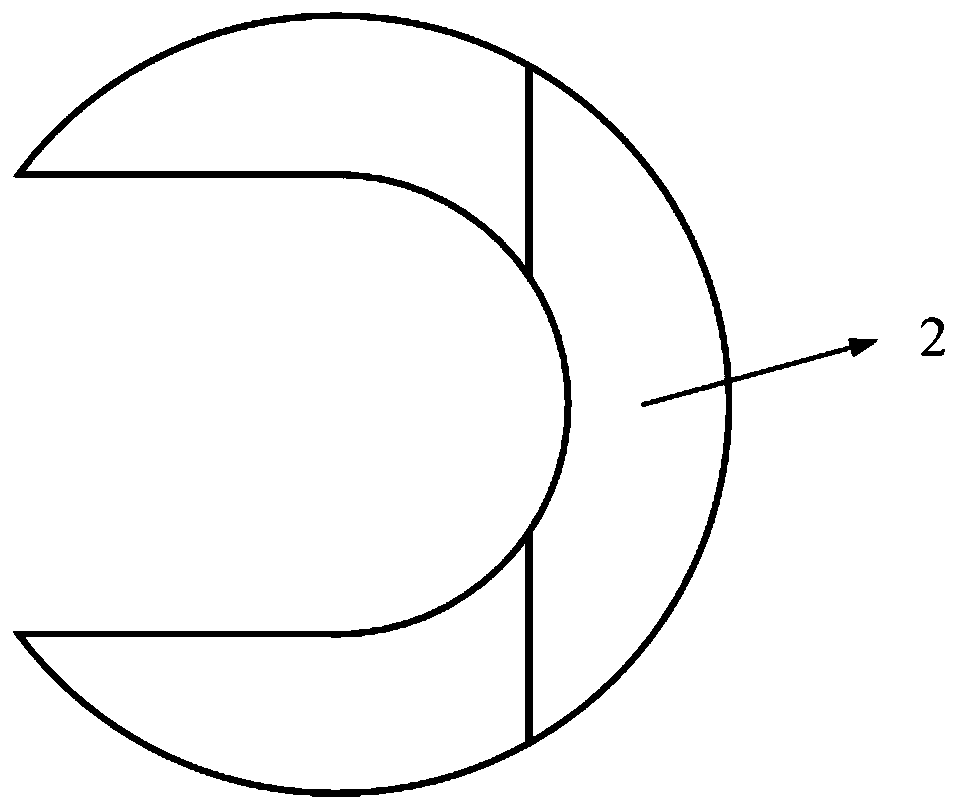

Contact system structure of vacuum arc extinguishing chamber

PendingCN108511262AHigh strengthHigh hardnessHigh-tension/heavy-dress switchesAir-break switchesEngineeringContact system

The invention discloses a contact system structure of a vacuum arc extinguishing chamber. The contact system structure comprises a contact system (1), wherein an inner contact (2) is arranged in the contact system (1), and a main contact (4) is arranged above the contact system (1); and the lower part of the main contact (4) is connected with a hook ring (3), and the inner contact (2) is connectedwith the main contact (4) through the hook ring (3). According to the scheme of the invention, the loop resistance of the vacuum arc extinguishing chamber can be reduced, and thus the temperature rise can be reduced, and the purpose of increasing the rated current can be achieved; and meanwhile, since a coil of a contact base does not bear the temperature rise part of the rated current, a 1 / 2 turn or longer coil can be used to improve the short-circuit breaking current capability, and thus the purpose of reducing bounce can also be achieved.

Owner:中国振华电子集团宇光电工有限公司(国营第七七一厂)

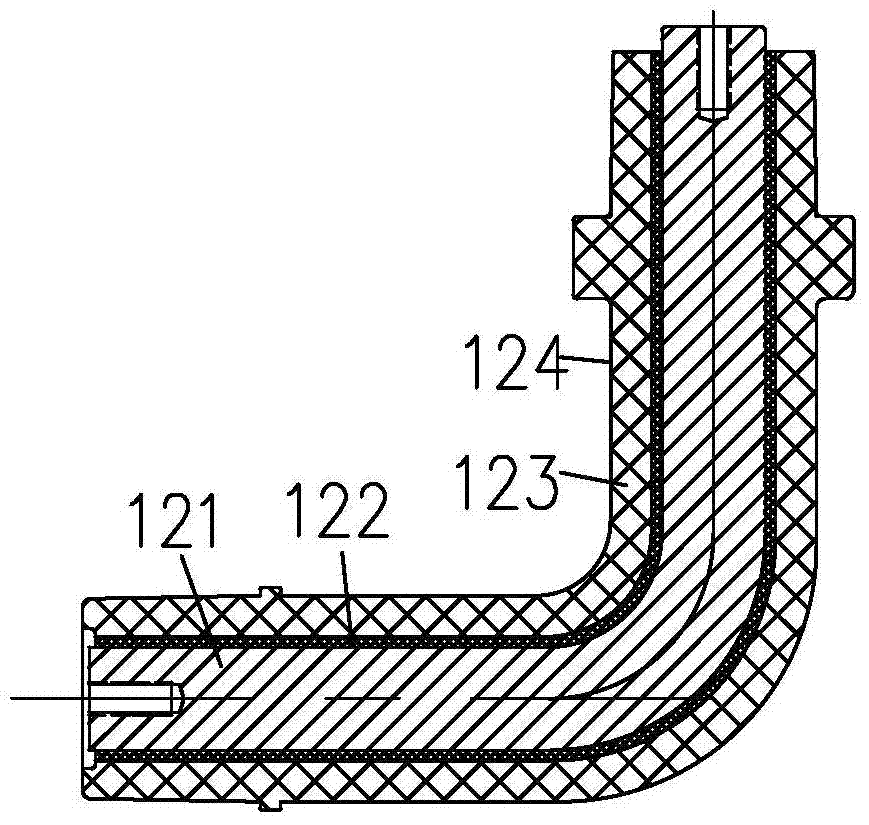

U-shaped longitudinal magnetic contact conductive structure of high-voltage vacuum arc-extinguishing chamber

InactiveCN107086149AImproved conductive structureImprove controlHigh-tension/heavy-dress switchesAir-break switchesElectrical resistance and conductanceEngineering

Disclosed is a U-shaped longitudinal magnetic contact conductive structure of a high-voltage vacuum arc-extinguishing chamber. The U-shaped longitudinal magnetic contact conductive structure comprises a movable contact conductive structure and a static contact conductive structure arranged in the vacuum arc-extinguishing chamber; the movable contact conductive structure comprises a contact piece and a conductive rod arranged on the back part of the contact piece; a current converging block and a supporting base are mounted at one end, close to the contact piece, of the conductive rod; the other end of the current converging block is welded with the contact piece; a U-shaped iron sheet group is arranged on the contact piece; the current converging block is arranged in a position far from the slot opening of the U-shaped iron sheet group; the length of the current converging block in the direction of the slot opening of the U-shaped iron sheet group is smaller than 1 / 2 of the diameter of the conductive rod; and the static contact conductive structure and the movable contact conductive structure are the same in structure, and the contact pieces thereof are arranged oppositely and are coaxially mounted in central symmetry. By virtue of the structure, the relatively low loop resistance of the high-voltage vacuum arc-extinguishing chamber can be ensured while the longitudinal magnetic field of the U-shaped longitudinal magnetic contacts in a large opening range can be effective reinforced, so that the effective area of the longitudinal magnetic field is enlarged, and the short-current-circuit disconnecting capability of the U-shaped longitudinal magnetic contacts of the high-voltage vacuum arc-extinguishing chamber in the large opening range is improved.

Owner:XI AN JIAOTONG UNIV

A Protection Structure and Application of Bellows of Vacuum Interrupter under High Gas Pressure

ActiveCN104810195BReduce the probability of fracture failureReduce pressure differenceHigh-tension/heavy-dress switchesAir-break switchesEngineeringHigh pressure

The invention discloses a protecting structure for a vacuum air extinguish chamber corrugated pipe under high gas pressure and application. The protecting structure comprises a hollow metal drum and a corrugated pipe outside sealing device, the hollow metal barrel is arranged at the end, positioned outside a vacuum arc extinguish chamber movable end cap, of a vacuum arc extinguish chamber movable electroconductive rod, one end of the corrugated pipe outside sealing device is arranged on the lower portion of the vacuum arc extinguish chamber movable end cap while the other end of the same is arranged outside the circumference of the hollow metal barrel, the hollow metal barrel and the vacuum arc extinguish chamber movable electroconductive rod are in welded sealing, the hollow metal barrel and the corrugated pipe outside sealing device are in direct-acting reciprocating sealing, and the corrugated pipe outside sealing device and the vacuum arc extinguish chamber movable end cap are in fixed gas sealing. By adopting magnetofluid direct-acting reciprocating sealing technology, a closed space can be formed among the inside of the vacuum arc extinguish chamber corrugated pipe, the lower portion of the vacuum arc extinguish chamber movable end cap and the movable electroconductive rod, and no high-pressure gas exists inside the closed space, so that difference of air pressure inside and outside the corrugated pipe is reduced, and breakage failure probability of the corrugated pipe can be lowered effectively.

Owner:XI AN JIAOTONG UNIV

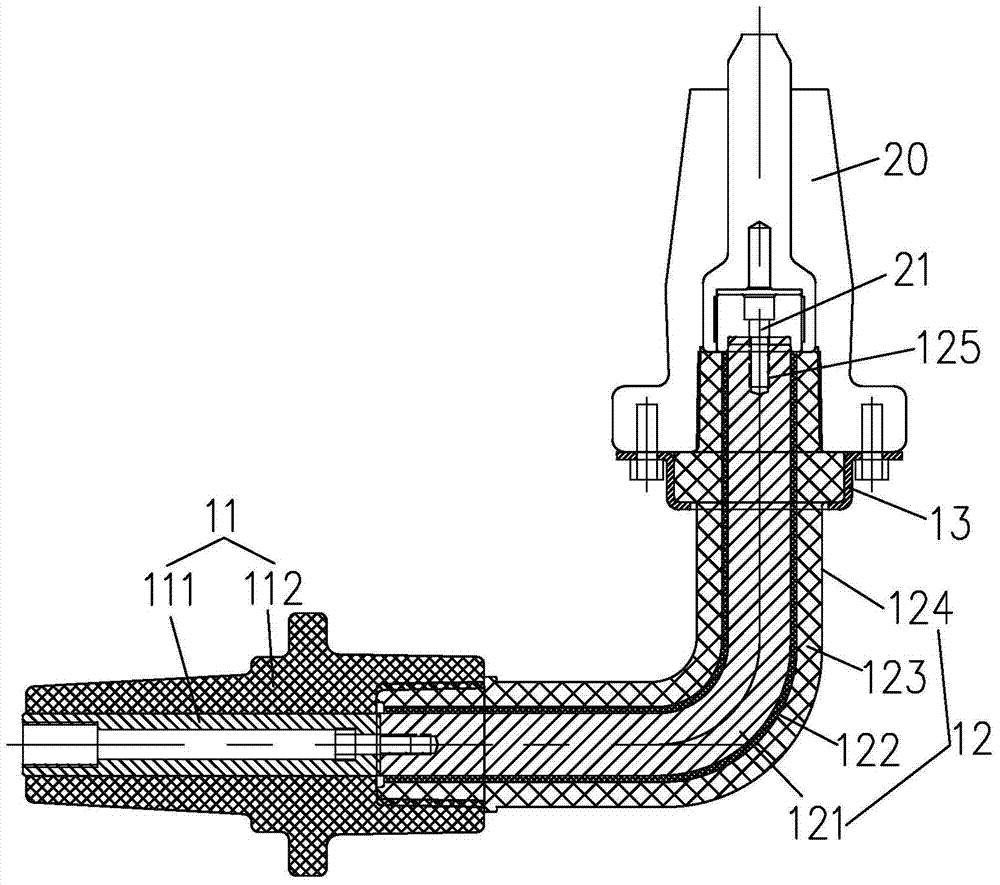

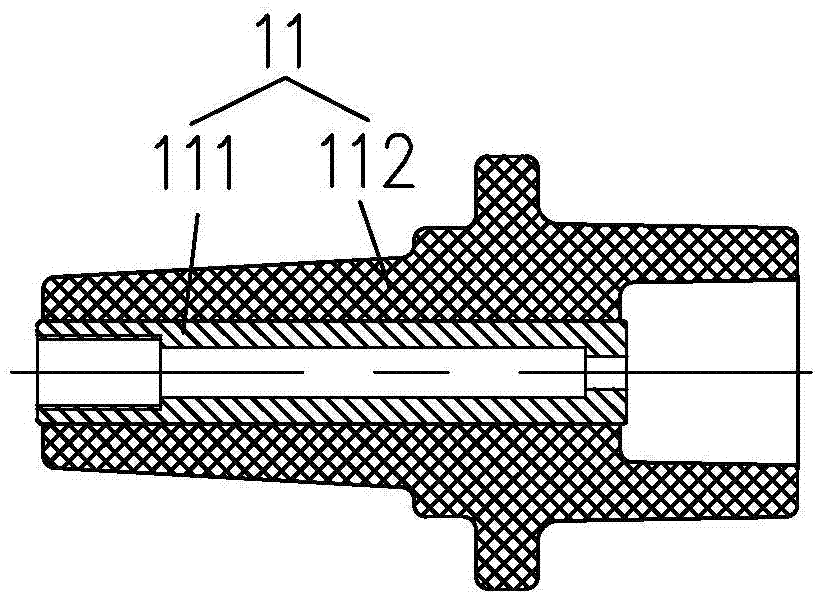

Outgoing bus device

ActiveCN105391014BGood flexibilityAvoid crackingInsulated cablesPartially enclosed bus-bar installationsEngineeringElectric field

The invention discloses an outlet bus bar device which comprises an outlet casing pipe, a bus bar body and a bus bar gland, wherein the outlet casing pipe is connected to one end of the bus bar body, the bus bar gland is connected to the other end of the bus bar body, the bus bar body comprises a conductive rod as well as a conductive layer, a silicone rubber layer and a semi-conductor layer which are sequentially arranged outside the conductive rod, and every two adjacent layers are mutually bond. The outlet bus bar device provided by the invention is not liable to crack, and is safe and reliable in a using process; the electric field distribution is more uniform, local discharge can be prevented, the assembly is simple and convenient, preassembly can be performed in advance to realize modular assembly, and the production efficiency is improved.

Owner:北京合锐清合电气有限公司

A stainless steel matt treatment process

The invention belongs to the technical field of surface treatment of medical equipment and relates to a stainless steel matte finishing process. The primary technical scheme is as follows: the stainless steel matte finishing process comprises the following steps: placing a deoiled stainless steel workpiece and the anode of a power supply connected in an anodizing matte finishing solution of a mixture containing 10-50 g / L H3PO4, 10-30 g / L C6H8O7, 100-300 g / L H2O2 and 0.4-1 g / L K2SO4; heating the solution to 60-80 DEG C and connecting a platinum and titanium net to the cathode of a direct current power supply, wherein the area ratio of the platinum and titanium net and the cathode of the direct current power supply is 1: 1; and keeping the distance between the cathode and the anode at 6.0 cm, carrying out anodizing for 30-60 min under the condition that the current density is 3.4-6.8 A / dm<2> and the working voltage is 9.4-10.5 V, wherein the surface of stainless steel workpiece is matteand has silver metal gloss, the hardness of the stainless steel is improved, and the pitting corrosion resistance is improved. The stainless steel matte finishing process provided by the invention notonly can solve the environmental problem that an existing stainless steel matte finishing solution contains harmful substances and strong acids, but also can solve the problem that the dissolving speed of the environment-friendly solution is low, thereby providing a new path for development of stainless steel matte technical treatment.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

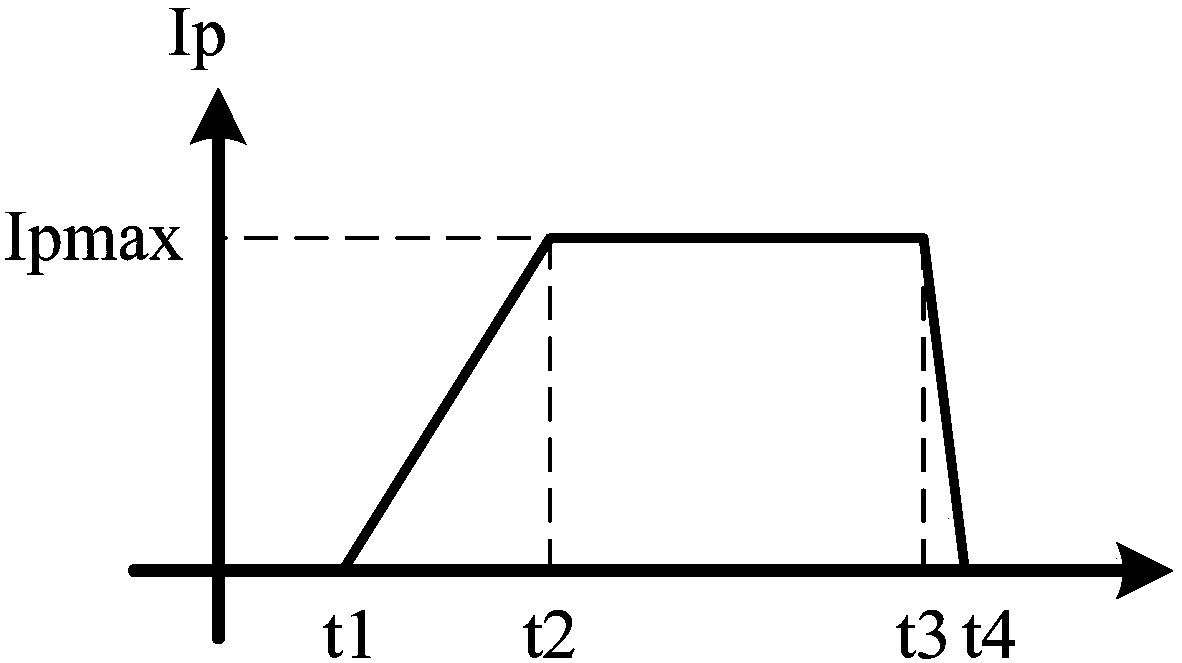

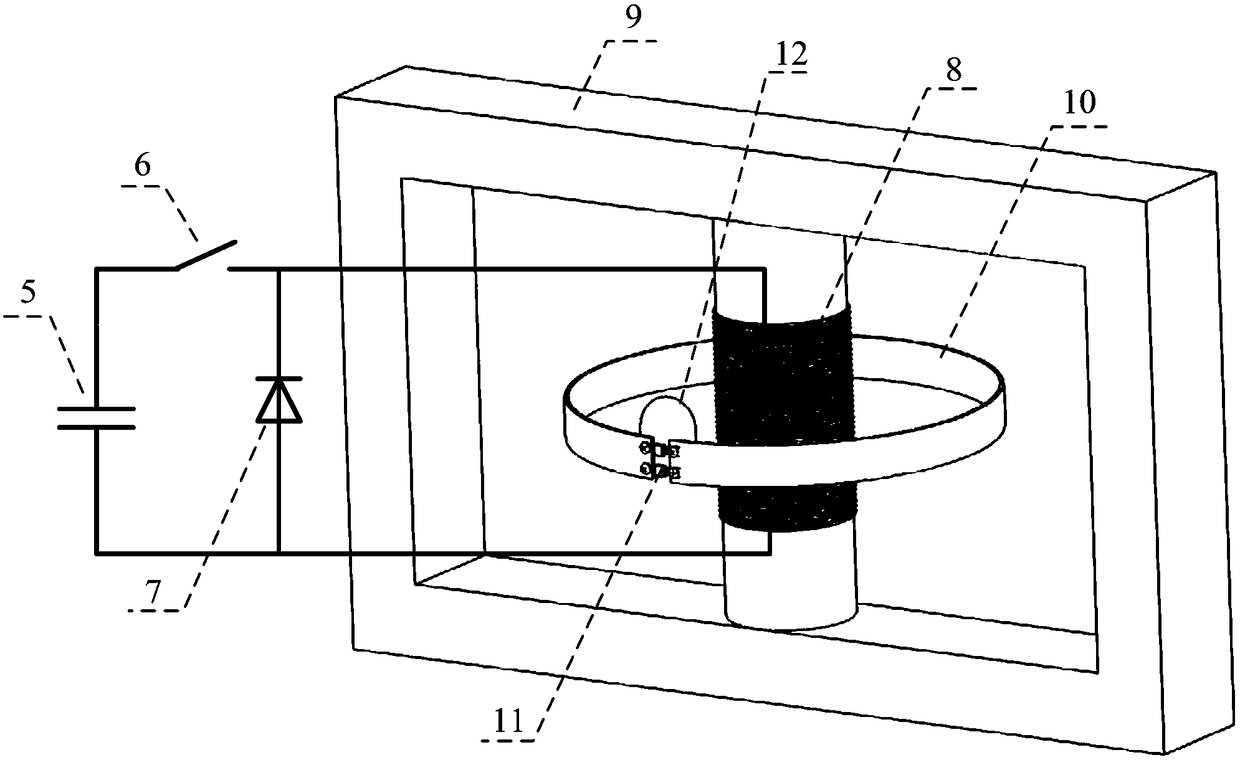

A tokamak plasma rupture simulation device and simulation method

The invention discloses a Tokamak plasma disruption simulation system and a simulation method. The device comprises a power supply capacitor, a discharge switch, a freewheeling diode, an ohmic coil, a core, a plasma coil, a disruption simulation switch, a disruption simulation resistor, and a trigger control unit. The power supply capacitor is used for supplying power to the ohmic coil and inductively generating a current in the plasma coil. When the discharge switch is switched on, the power supply capacitor discharges electricity to subsequent circuits. When the discharge switch is switched off, the power supply capacitor does not discharge electricity, and the voltage of the power supply capacitor remains unchanged. The freewheeling diode is used for constituting a loop with the ohmic coil after the discharge switch is switched off, and providing after flow for the current of the ohmic coil. The ohmic coil is used for simulating an ohmic field coil of a Tokamak device, supplying power to the ohmic field coil through the power supply capacitor, and inductively generating and controlling and maintaining a plasma coil current in a secondary plasma coil. The plasma coil is used for simulating a plasma current loop of the Tokamak device, and the current in the coil is used to simulate a plasma current.

Owner:HUAZHONG UNIV OF SCI & TECH

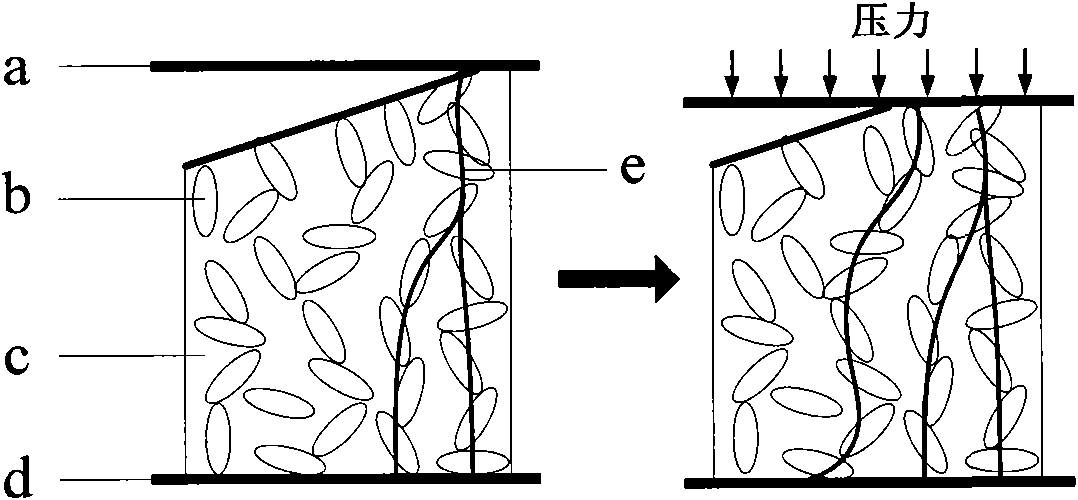

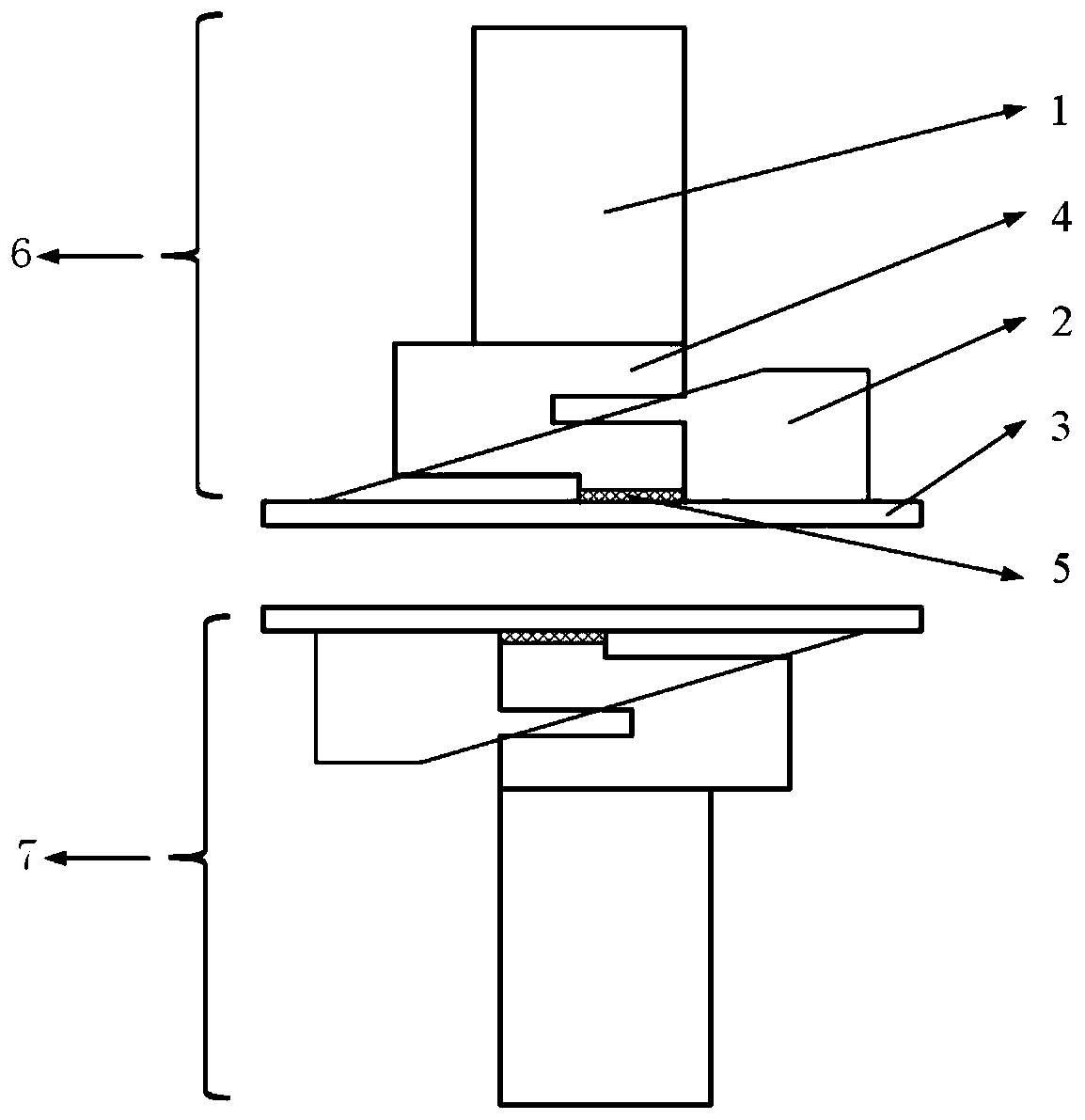

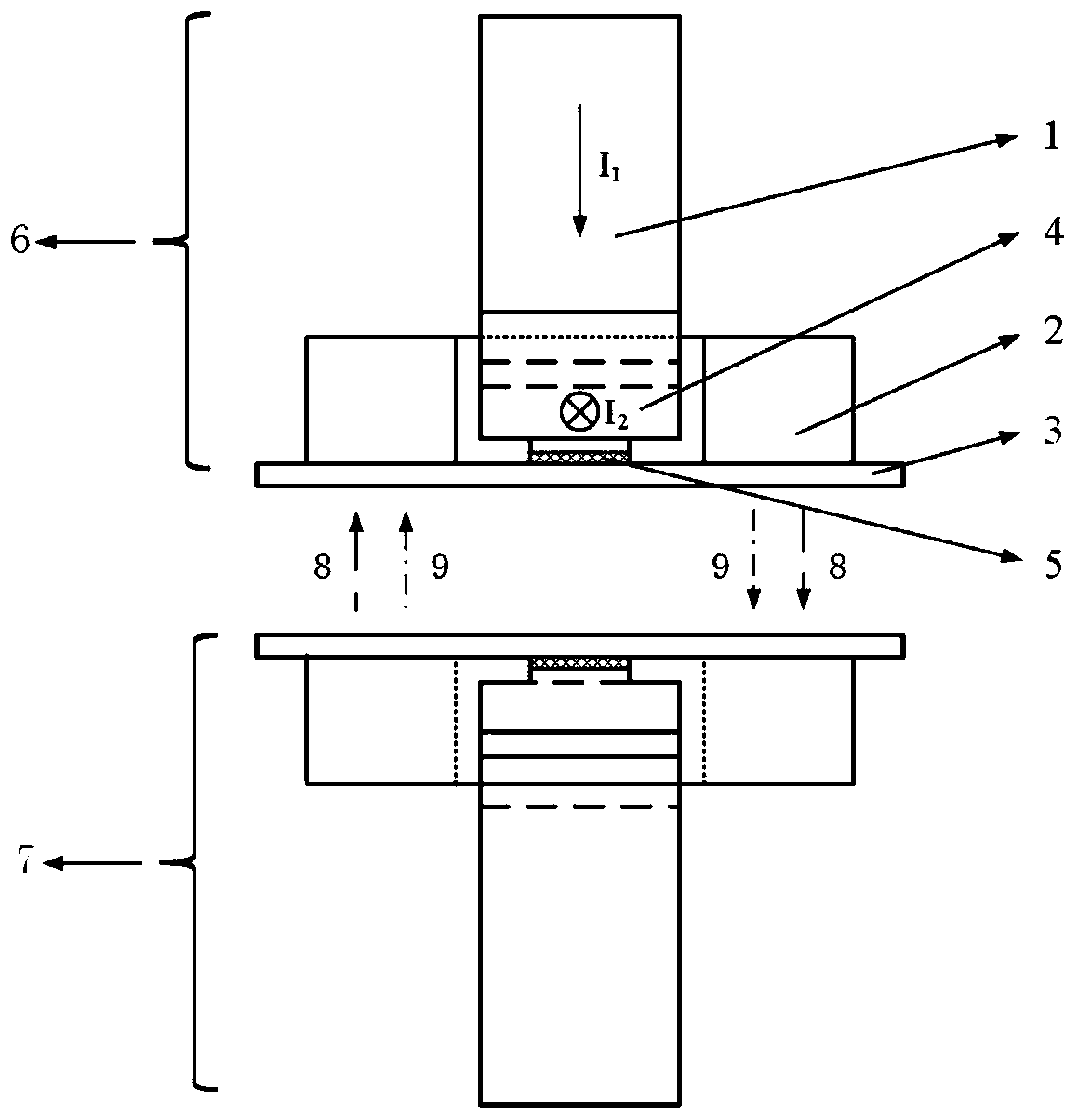

Array type flexible force sensor

InactiveCN102374911BHigh sensitivity factorSolution to short lifeForce measurement using piezo-resistive materialsEngineeringForce sensor

The invention relates to an array type flexible force sensor, which comprises an upper insulation protecting layer, a parallel metal row electrode graphically arranged on the lower surface of the upper insulation protecting layer, a lower insulation protecting layer, a parallel metal column electrode graphically arranged on the upper surface of the lower insulation protecting layer, and a first sensitive membrane layer positioned between the row electrode and the column electrode, wherein the first sensitive membrane layer consists of a filling type sensitive material layer and a filling typesensitive material convex strip or convex block adhered onto the upper surface of the filling type sensitive material layer, and the longitudinal section of the convex strip or convex block is in a wedge, conical or serrated shape; the convex strip or convex block is vertically aligned with the column electrode, and the row electrode and the column electrode are distributed in a spatial vertical intersection way; a spatial vertical intersection part and the first sensitive membrane layer contained in the spatial vertical intersection part form a force sensing unit, and the filling type sensitive material is a conductive composite material that conductive particles are uniformly dispersed in a flexible insulation matrix material. The array type flexible force sensor has the advantages of high sensitivity, stable performances, long service life and the like.

Owner:TSINGHUA UNIV

A Bipolar Composite Longitudinal Magnetic Field Contact Structure for Vacuum Interrupter

ActiveCN107123566BIncrease the strength of the longitudinal magnetic fieldIncrease the longest arcing distanceHigh-tension/heavy-dress switchesAir-break switchesEngineeringSystem structure

The invention provides a vacuum interrupter bipolar compound longitudinal magnetic field contact structure. The structure comprises an anode contact system and a cathode contact system, wherein the anode contact system and the cathode contact system are arranged in a vacuum interrupter. The anode contact system comprises a contact sheet and a magnetic conductive structure which is arranged on the back of the contact sheet and is provided with an opening on the single side. A conductive rod is connected with the contact sheet through a diversion structure and passes through the opening of the magnetic conductive structure. The diversion structure, the magnetic conductive structure and the contact sheet are fixed by welding. The cathode contact system and the anode contact system share the same structure. The contact sheets are oppositely arranged, and the opening direction of the magnetic conductive structure is opposite. The conductive rod, the contact sheets and the diversion structure form a conductive circuit. The magnetic conductive structure forms a magnetic conductive circuit. According to the structure provided by the invention, the longitudinal magnetic field strength in the vacuum interrupter can be improved; a strong longitudinal magnetic field area is increased; the longitudinal magnetic field of the existing vacuum interrupter is increased; the maximum arcing distance of vacuum arc is effectively improved; and the vacuum interrupter circuit resistance is low.

Owner:XI AN JIAOTONG UNIV

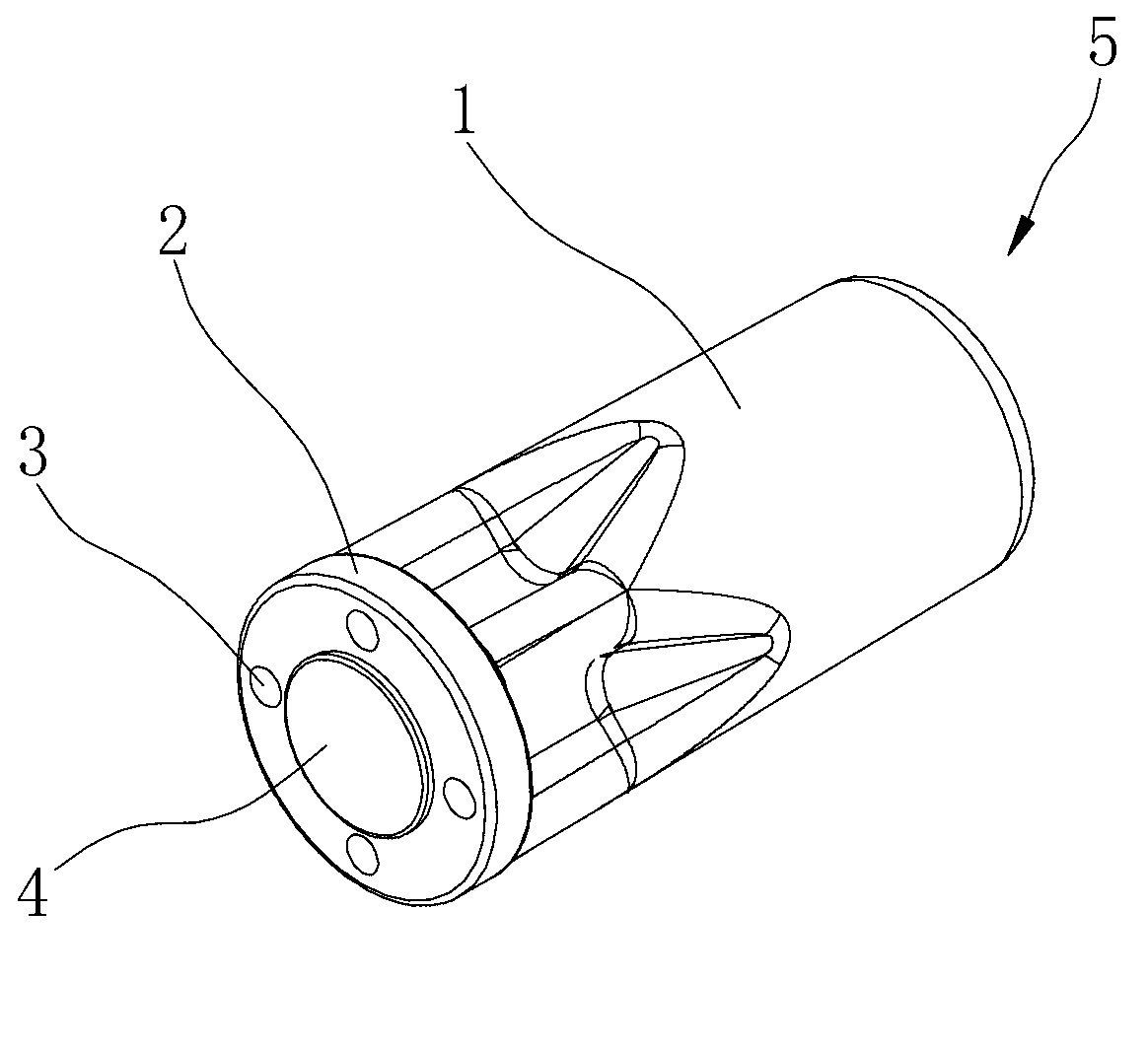

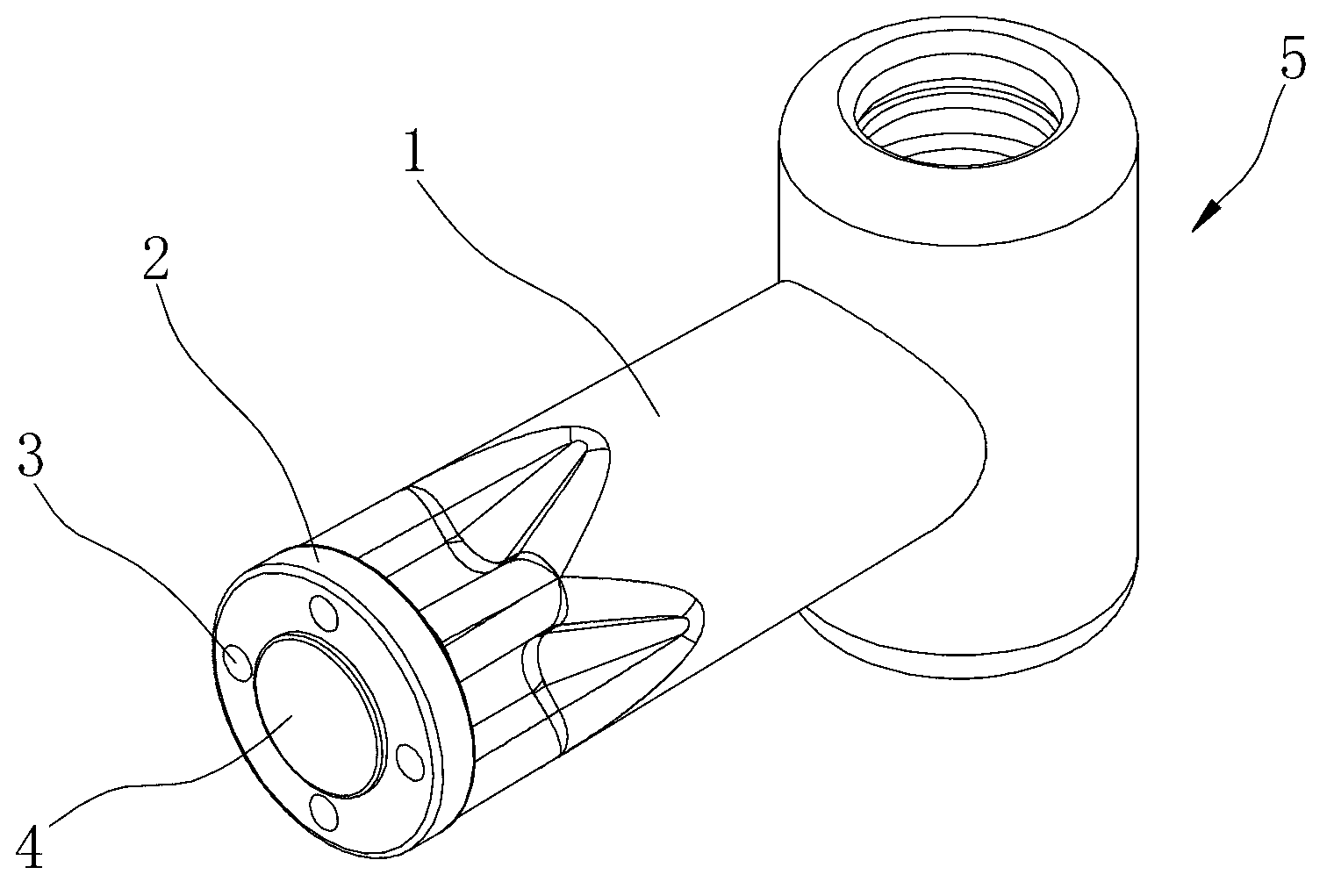

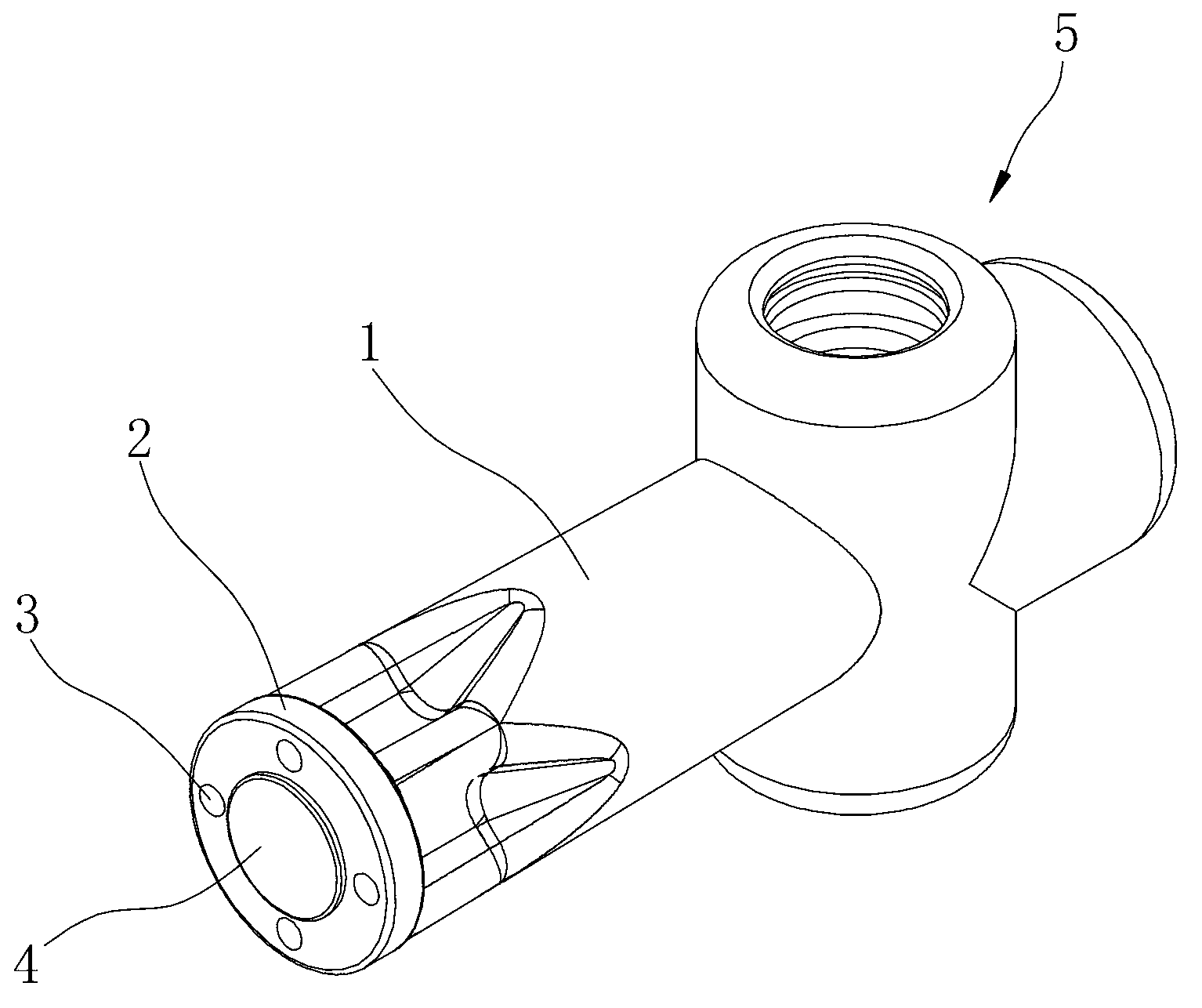

Novel conductor connector

ActiveCN103022742ASimple structureEasy to processSwitchgear arrangementsMultiple conductors connectorElectrical conductorEngineering

The invention discloses a novel conductor connector which comprises a straight conductor. One end of the straight conductor is provided with a connecting flange, four installing holes are arranged on the connecting flange, a circular protrusion face is arranged in the middle of the outer end of the connecting flange, the section of a section from the middle of the straight conductor to the connecting flange is quincunx-shaped, and a single-end connector, a double-end connector or a three-end connector are arranged at the other end of the straight conductor. The novel conductor connector is connected with an insulation piece through a bolt directly through the connecting flange, a quincunx-shaped structure has a shielding effect, and shielding covers are reduced. Only one contact face is arranged in connection, and return circuit resistance is reduced. In addition, the conductor connector is simple in structure, easy to machine and manufacture and low in manufacture cost.

Owner:YIHE ELECTRIC GRP

Arc extinguish chamber with high current-carrying capability for high-voltage switch equipment

ActiveCN101930871BOptimizationImprove cooling conditionsHigh-tension/heavy-dress switchesAir-break switchesElectrical resistance and conductanceHigh pressure

The invention discloses an arc extinguish chamber with high current-carrying capability for high-voltage switch equipment. In the chamber, the outermost layer is an insulating support part with metal inserts at two ends, and comprises the metal inserts at two ends thereof; a movable contact system and a static contact system of the arc extinguish chamber are arranged inside the insulating supportpart, and are coaxial with the insulating support part; and the metal insert at the static end of the insulating support part is connected with the static contact system of the arc extinguish chamber, while the metal insert at the movable end is connected with the movable contact system of the arc extinguish chamber. The arc extinguish chamber adopts the metal inserts guiding current of a main loop to the insulating support part and the method for improving conductive part materials and structures in the main loop, so that the cross section of diversion can be increased, the loop resistance can be reduced, the radiating condition can be improved, and the whole through-flow capability of the arc extinguish chamber can be reinforced.

Owner:CHINA XD ELECTRIC CO LTD

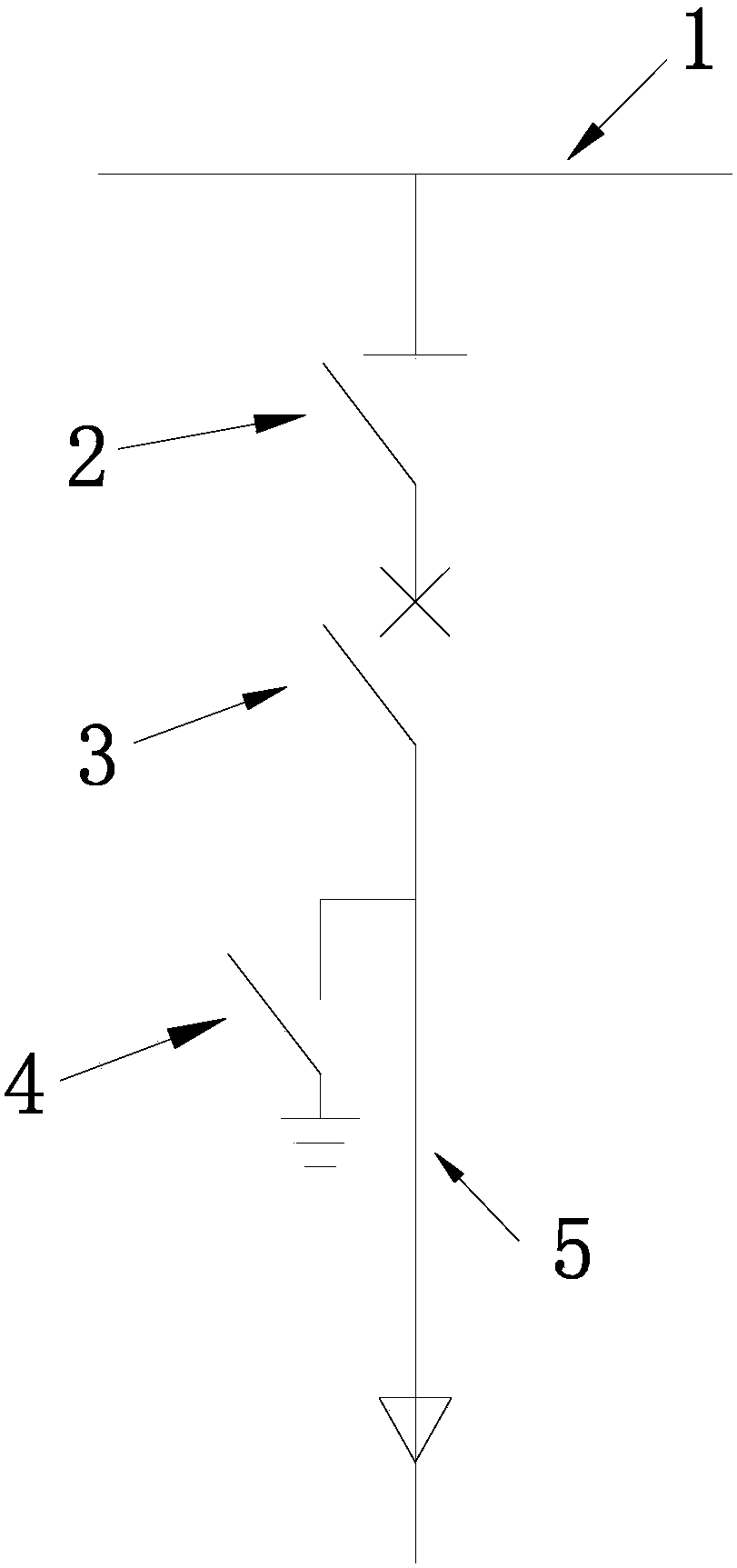

High voltage AC switchgear

ActiveCN106099656BReduce volumeImprove reliabilityBus-bar/wiring layoutsSubstation/switching arrangement casingsElectricityEngineering

The invention relates to a high-voltage alternating current switch cabinet. The high-voltage alternating current switch cabinet comprises a vacuum switch and an integrated switch, wherein the integrated switch is placed among a main bus, the vacuum switch and a pre-ground bus; the vacuum switch is electrically connected with a branched main bus; the branched main bus is electrically connected with the pre-ground bus; the integrated switch can connect the vacuum switch with the main bus or enables the pre-ground bus to be connected to the ground; when the integrated switch connects the vacuum switch with the main bus, the integrated switch, the vacuum switch and the branched main bus form a main loop; and when the integrated switch enables the pre-ground bus to be connected to the ground, the vacuum switch and the main bus are isolated, and the integrated switch and the pre-ground bus form a ground loop. According to the high-voltage alternating current switch cabinet, only two switch elements of the vacuum switch and the integrated switch are included, thus the number of the switch elements is decreased, a circuit structure is simplified, the overall volume of the high-voltage alternating current cabinet is reduced, and the reliability of the high-voltage alternating current cabinet is improved; and meanwhile an interlocking device is not needed for use, and thus the problems of faults of failure and misoperation of the interlocking device are avoided.

Owner:TOP DIRECTION LTD

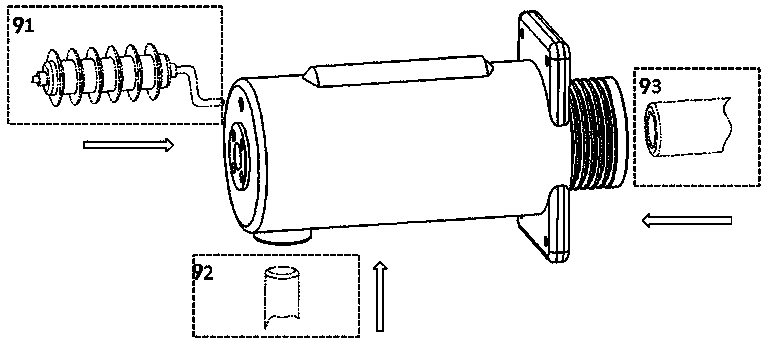

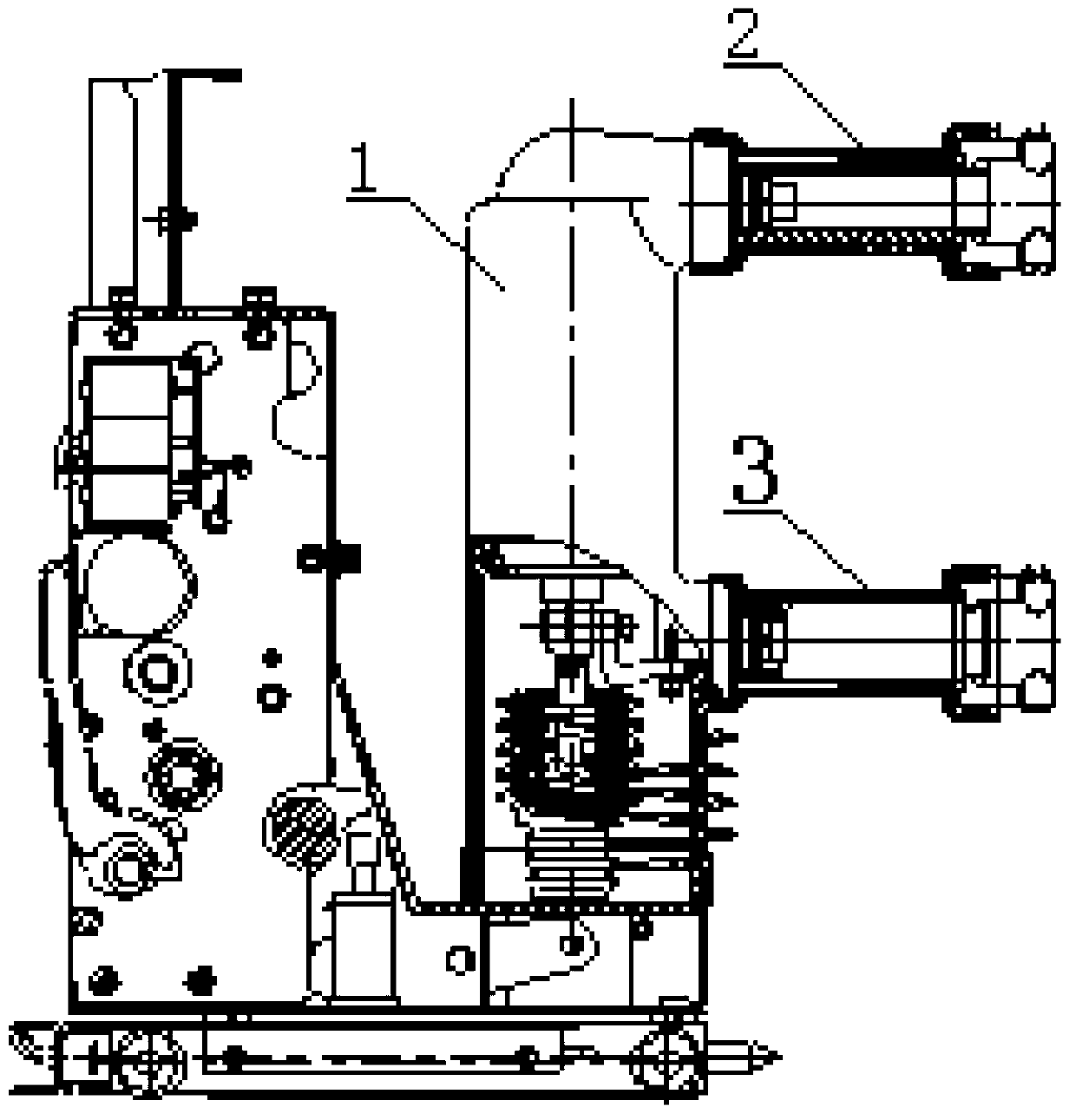

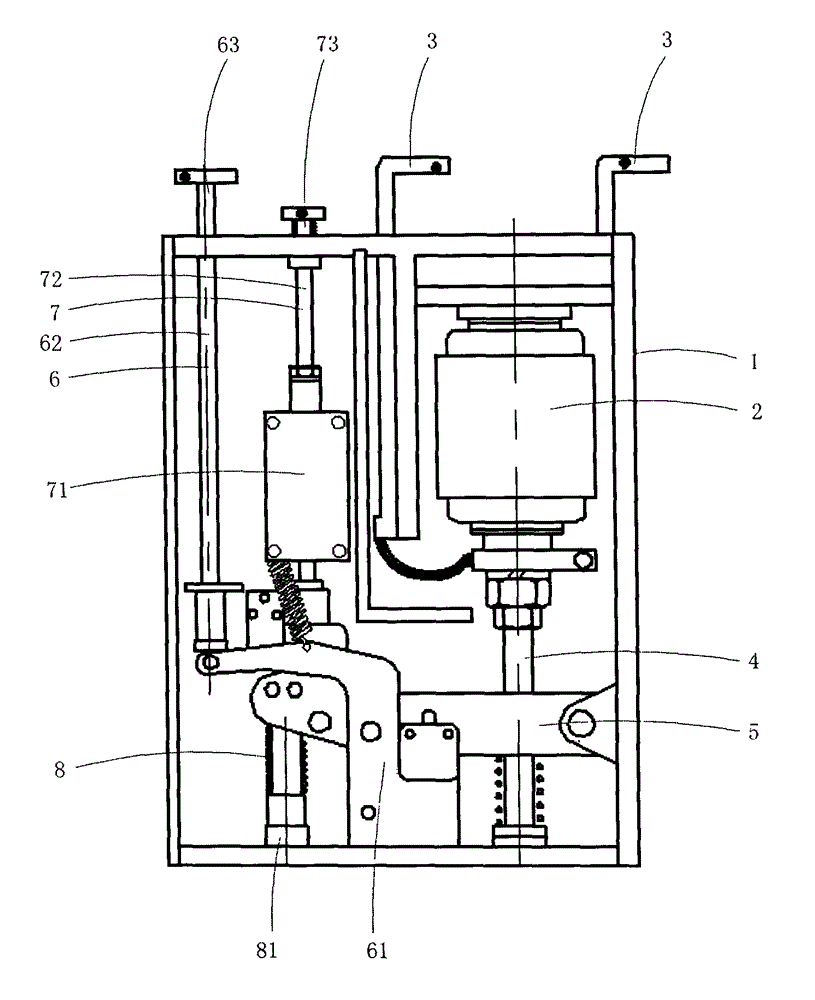

Rapid box type single-pole vacuum contactor

ActiveCN104576171AClosing speed is fastIncrease the itineraryHigh-tension/heavy-dress switchesAir-break switchesElectricityVacuum switch

The invention discloses a rapid box type single-pole vacuum contactor which comprises an insulation shell, a vacuum switching tube, two electric connection terminals, an insulation pull rod, a lever, an opening mechanism and a closing mechanism, wherein the vacuum switching tube is arranged in the shell, the two electric connection terminals are arranged on the shell and connected with two electrodes of the vacuum switching tube respectively, the insulation pull rod is arranged in the shell and connected with a moving contact of the vacuum switching tube, the lever is used for driving the insulation pull rod to perform opening and closing actions, the opening mechanism is used for driving the lever to perform the opening action, and the closing mechanism is used for driving the lever to perform the closing action. The closing mechanism comprises a driving lever and a closing driving rod, wherein the driving lever is rotatably arranged in the shell and used for driving the lever to rotate, the closing driving rod is used for driving the driving lever to rotate, and the end, far away from the driving lever, of the closing driving rod extends out of the shell to be served as a manual closing button; the opening mechanism comprises an electromagnetic tripping mechanism and an opening driving rod, wherein the electromagnetic tripping mechanism is arranged in the shell and used for driving the lever to rotate, the opening driving rod is used for triggering the electromagnetic tripping mechanism to work, and the outer side end of the opening driving rod extends out of the shell to be served as a manual opening button. The rapid box type single-pole vacuum contactor is high in closing speed and capable of meeting the requirements of grid-connected power generation of novel electricity equipment.

Owner:ANHUI YUTENG VACUUM ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com