Outgoing bus device

A busbar and outlet bushing technology, which is applied in the direction of semi-closed busbar devices, conductors, insulators, etc., can solve the problems of partial discharge, reduced insulation performance, uneven electric field distribution, etc., and achieve reliable conductor lapping, reduced loop resistance, The effect of uniform electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

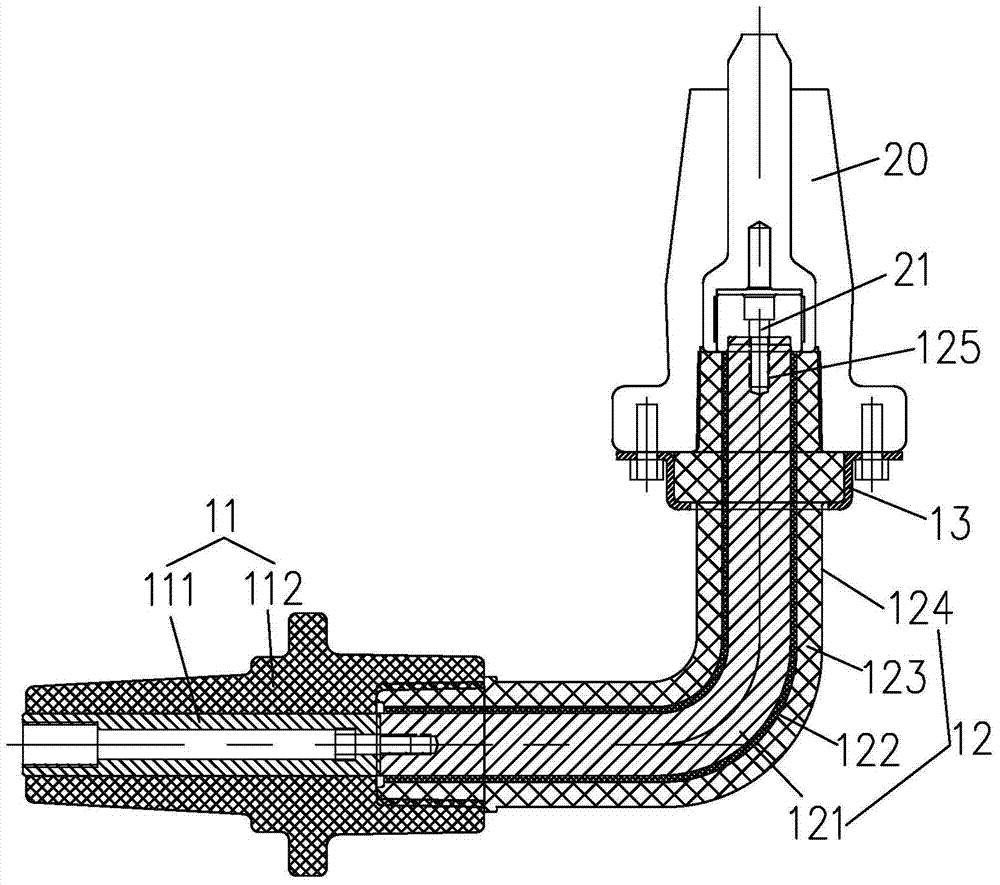

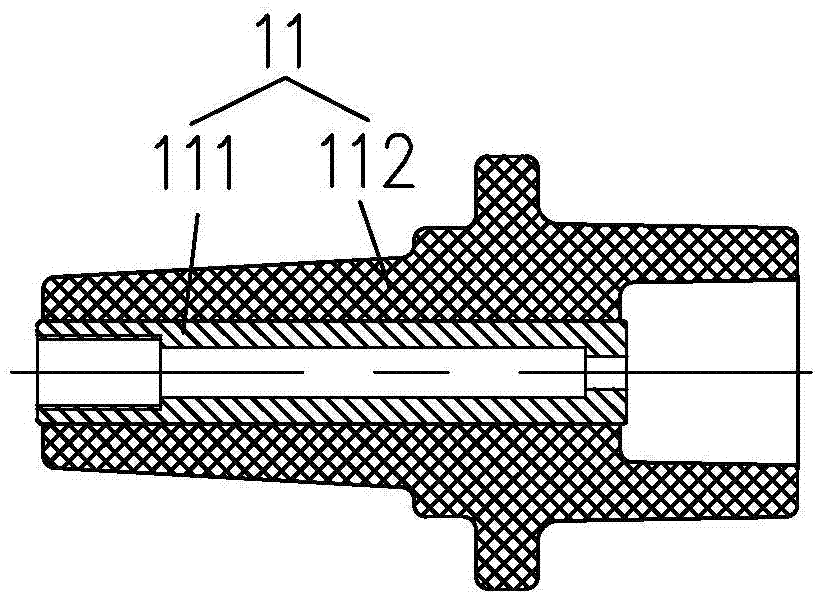

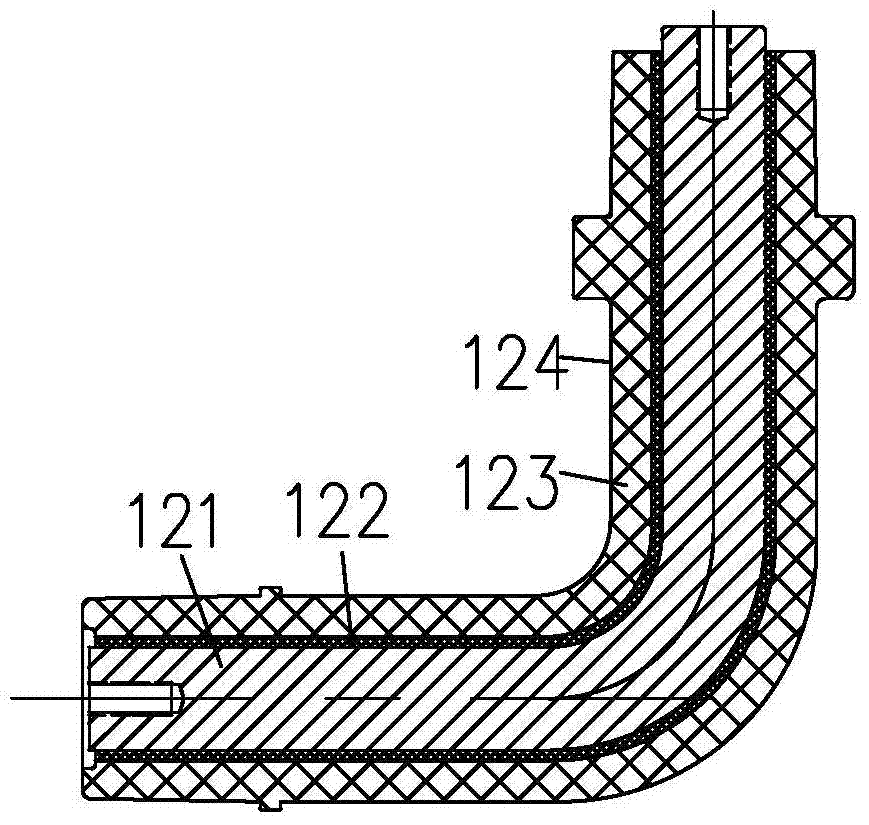

[0012] Such as figure 1 , 2 , 3, the outlet bus device of the present invention includes an outlet sleeve 11, a bus body 12, and a bus gland 13, the outlet sleeve 11 is connected to one end of the bus body 12, the bus gland 13 is connected to the other end of the bus body 12, and the bus The gland 13 is formed by laser cutting and stamping of sheet metal parts with a thickness of 3mm. The bus bar body 12 includes a conductive rod 121 and a conductive layer 122, a silicone rubber layer 123, and a semiconductor layer 124 arranged outside the conductive rod 121 in sequence. The two layers are bonded to each other. The conductive rod 121 is a copper rod with a diameter of 25 mm. The conductive layer 122 is formed by spraying and superimposing multiple layers of conductive glue. The copper rod and the silicone rubber layer 123 are bonded together through the conductive layer 122. , and the setting of the conductive layer 122 makes the electric field evenly distributed, improves an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com