Electric leakage detection system and polycrystalline silicon reduction furnace

A technology of leakage detection and reduction furnace, which is applied in the direction of measuring electricity, measuring devices, silicon compounds, etc., can solve problems such as economic loss, ground leakage, electrical system, reduction furnace influence, etc., and achieve the effect of reducing economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

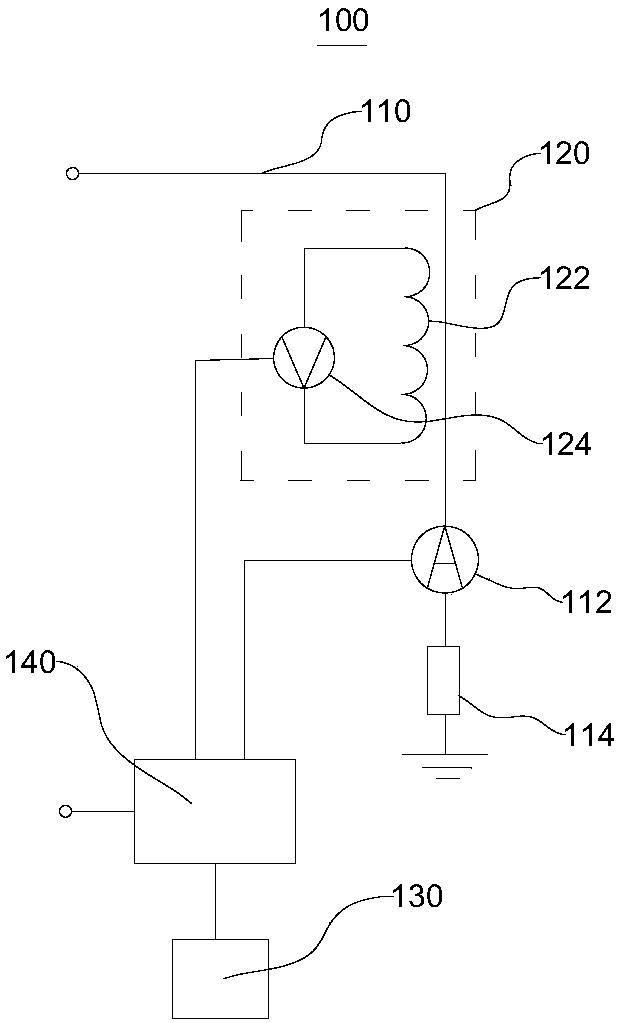

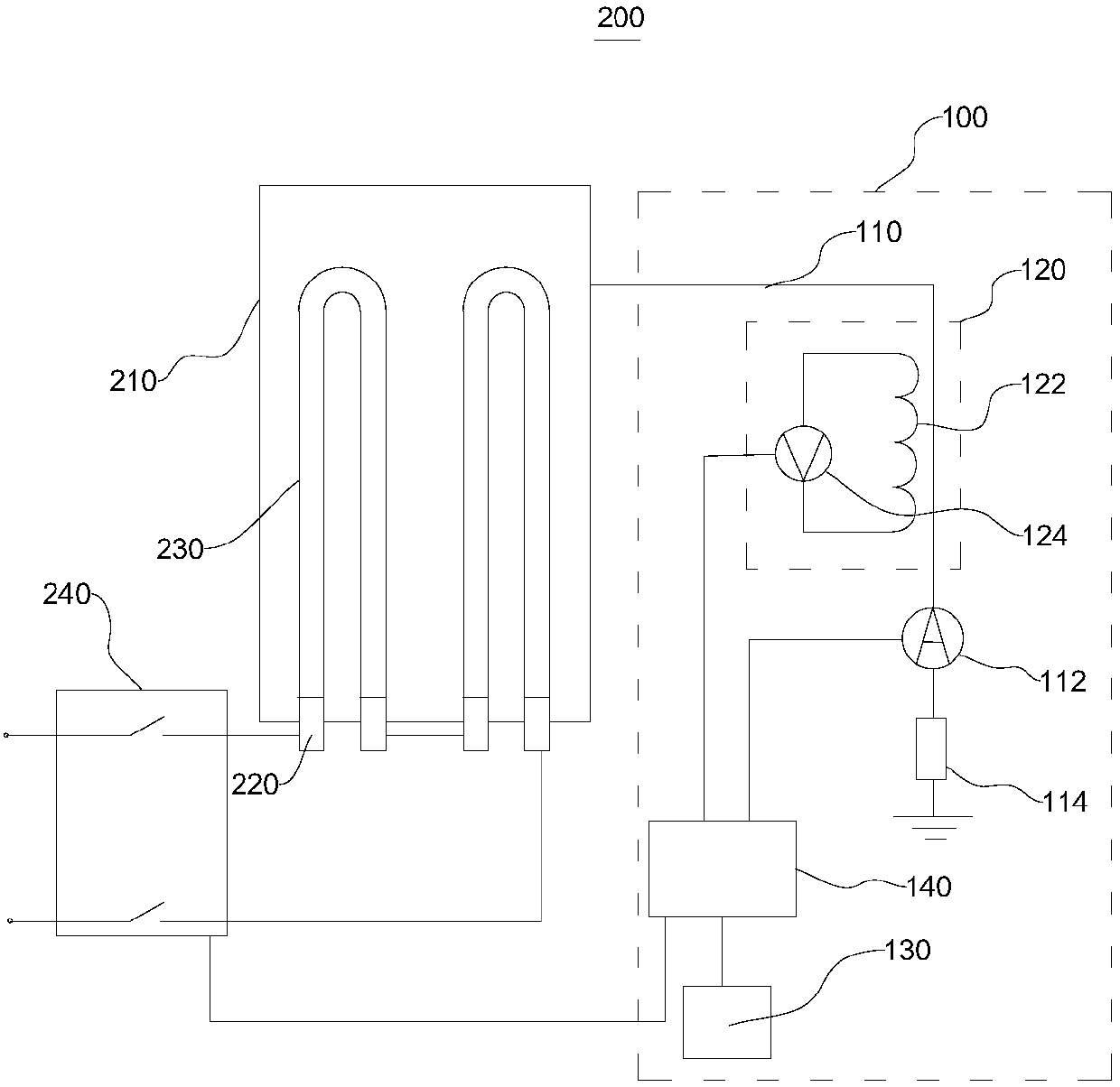

[0031] figure 1 It is a schematic diagram of the leakage detection system 100 in the embodiment of the present invention. Please refer to figure 1 , this embodiment provides a leakage detection system 100 for detecting a short circuit in a polysilicon reduction furnace. The leakage detection system 100 includes a ground current detection module and a current differential detection module 120 . The ground current detection module includes a ground wire 110 for connecting the furnace wall of the reduction furnace to the ground, and an ammeter 112 arranged on the ground wire. The current differential detection module 120 can detect the change rate of the current on the ground wire 110 over time, and can help technicians judge the type of short circuit in the reduction furnace through the current change rate on the ground wire 110 .

[0032] Generally speaking, the process of contacting the inverted silicon rod with the furnace wall of the reduction furnace to form a grounding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com