Novel conductor connector

A conductor and a new type of technology, applied in the direction of multi-conductor connectors, conductive connections, connections, etc., can solve problems such as high cost, many parts, and poor versatility of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

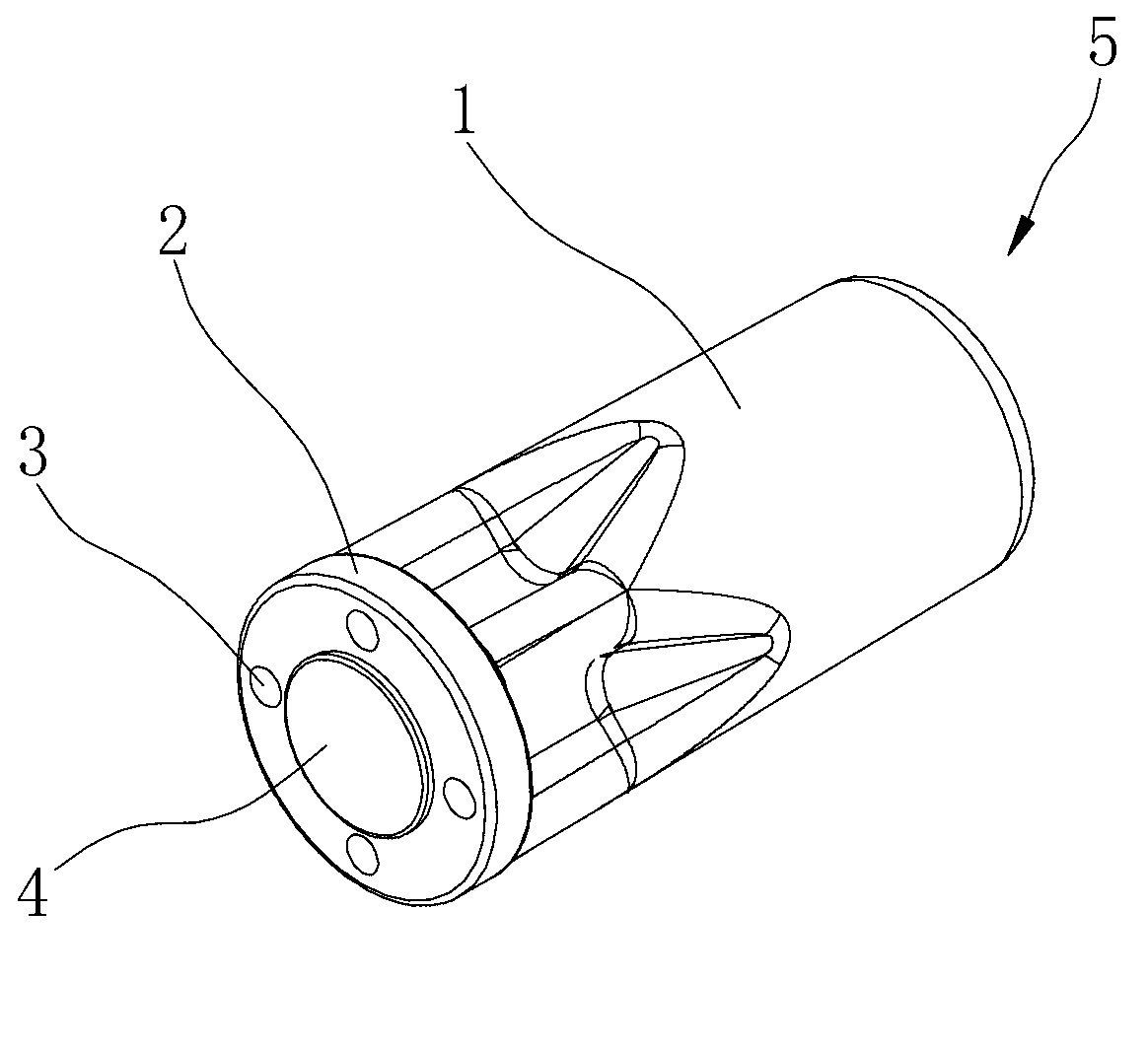

[0019] to combine figure 1 and Figure 4 , a new type of conductor joint, including a straight conductor 1, one end of the straight conductor 1 is a connecting flange 2, there are four mounting holes 3 on the connecting flange 2, and a circular protrusion is provided in the middle of the outer end of the connecting flange 2 Surface 4, a section from the middle of the straight conductor 1 to the connecting flange 2 has a quincunx-shaped section. The other end of the straight conductor 1 is a single-ended connector 5 .

[0020] This type of conductor joint is used for straight-through connection of gas-insulated metal-enclosed switchgear.

Embodiment 2

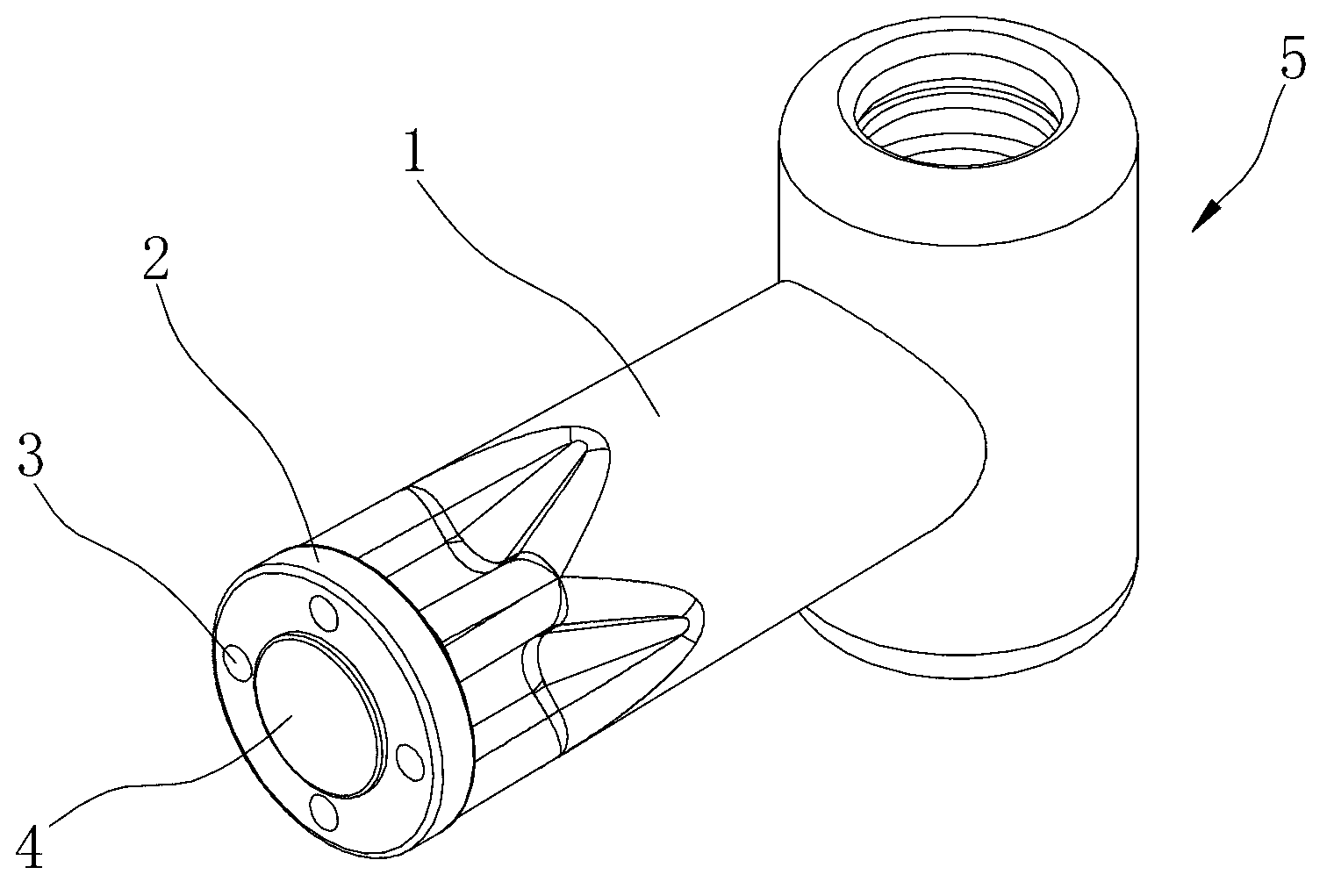

[0022] to combine figure 2 and Figure 4 , a new type of conductor joint, including a straight conductor 1, one end of the straight conductor 1 is a connecting flange 2, there are four mounting holes 3 on the connecting flange 2, and a circular protrusion is provided in the middle of the outer end of the connecting flange 2 Surface 4, a section from the middle of the straight conductor 1 to the connecting flange 2 has a quincunx-shaped section. The other end of the straight conductor 1 is a double-ended joint 5 , and the two joints are arranged in a T-shape with the straight conductor 1 .

[0023] This conductor joint is a three-way connection for gas-insulated metal-enclosed switchgear.

Embodiment 3

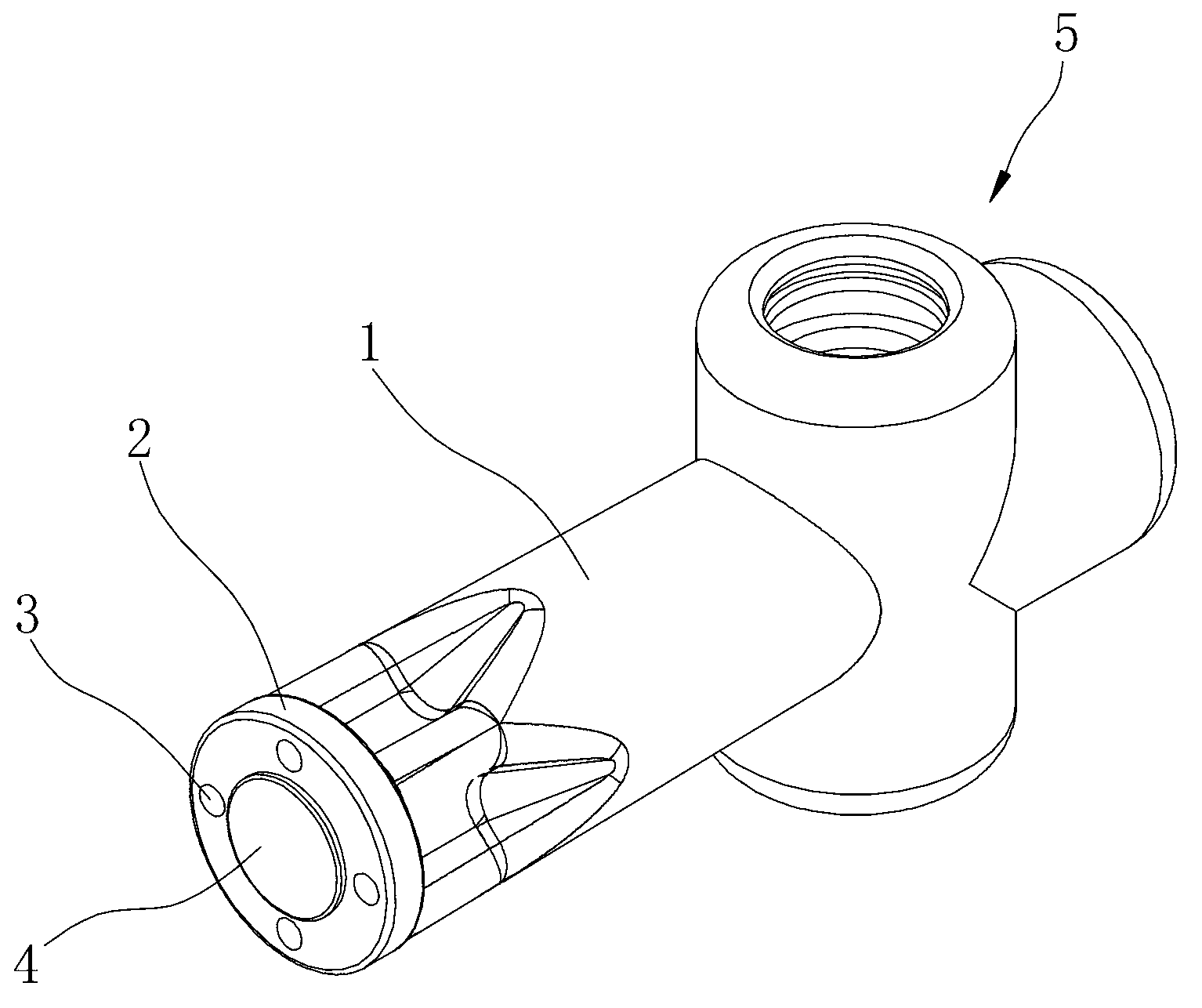

[0025] to combine image 3 and Figure 4 , a new type of conductor joint, including a straight conductor 1, one end of the straight conductor 1 is a connecting flange 2, there are four mounting holes 3 on the connecting flange 2, and a circular protrusion is provided in the middle of the outer end of the connecting flange 2 Surface 4, a section from the middle of the straight conductor 1 to the connecting flange 2 has a quincunx-shaped section. The other end of the straight conductor 1 is a three-head joint 5, and the three joints and the straight conductor 1 are arranged in a cross shape.

[0026] This type of conductor joint is used for four-way connection of gas-insulated metal-enclosed switchgear.

[0027] The new body joint introduced in the above embodiments is directly connected to the insulator by bolts through the connecting flange, and the quincunx structure has the function of shielding, which reduces the use of shielding covers. There is only one contact surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com