Capacitive touch screen functional chip, preparation method thereof, capacitive touch screen and electronic device

A capacitive touch screen and functional sheet technology, applied in the field of electronic devices and capacitive touch screen functional sheets, can solve the problems of inability to achieve arbitrary bending, complicated production process, high production cost, etc., and achieve good bonding strength, good conductivity, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

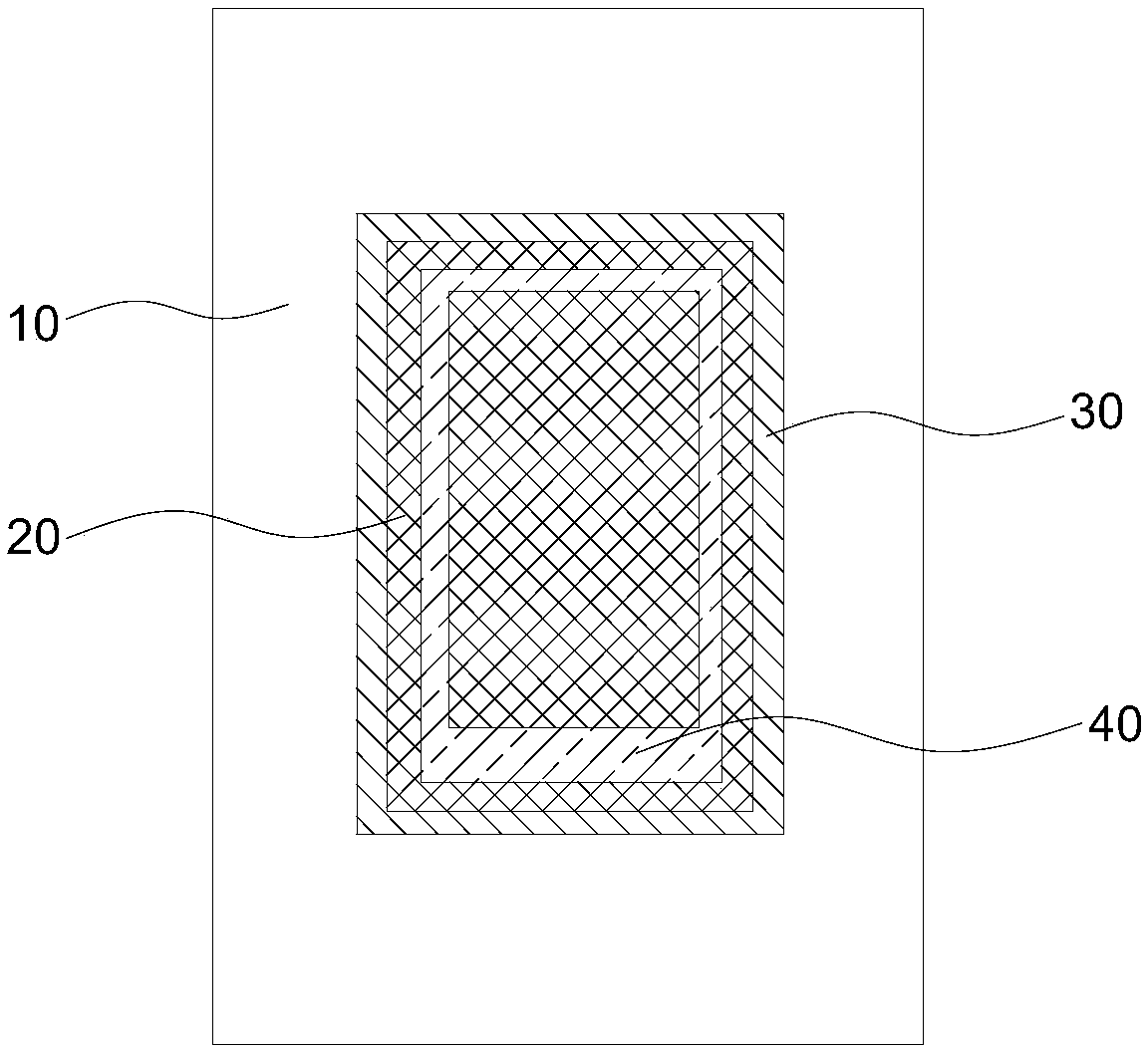

Image

Examples

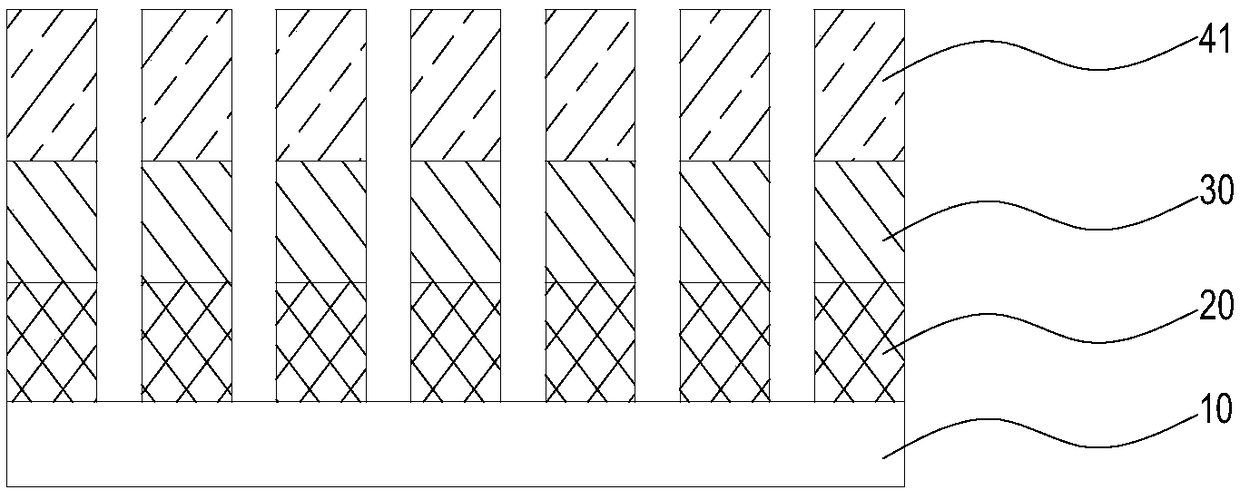

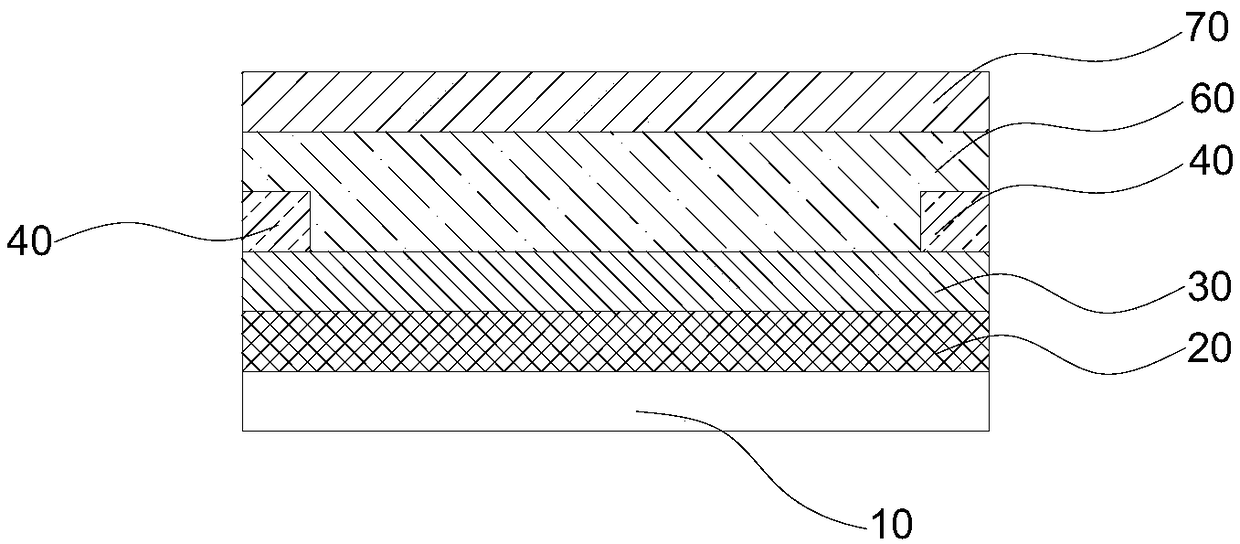

Embodiment 1

[0052] Printing step: by gravure printing method, on a 12 μm thick PET substrate (in this embodiment, the PET substrate is subjected to double-sided coating hardening treatment, so that the hardness of the printing surface is 1H, and the hardness of the non-printing surface is 3H). Roll printing of 30nm thick nano silver wire film layer, 10nm thick epoxy acrylic resin protective layer, 200nm thick nano silver particle conductive ink and 1μm thick graphene conductive ink, each printed layer needs to be dried and cured Only then can the next step of printing be carried out. Nano-silver particle conductive ink comprises a body layer and a lead layer extending outward from the body layer, the epoxy acrylic resin protective layer covers the nano-silver film layer, the body layer and the lead layer are all arranged on the epoxy acrylic resin protective layer, and the body The layer is located at the outer edge of the silver nanowire film layer, and the graphene conductive ink covers...

Embodiment 2

[0057] Printing process: by silk screen method, on the 2000μm thick polyvinyl chloride substrate (in this embodiment, the non-printing surface is subjected to single-side coating hardening treatment, so that its hardness is 3H) and sequentially print 2000nm thick nano Silver wire film layer, 300nm thick alkyd resin protective layer, 20000nm thick graphene conductive ink and 20μm thick silver copper powder conductive ink, each printed layer needs to be dried and cured before the next step of printing. The graphene conductive ink includes a body layer and a lead layer extending outward from the body layer. The alkyd resin protective layer covers the nano-silver film layer. Both the body layer and the lead layer are arranged on the alkyd resin protective layer, and the body layer is located At the outer edge of the silver wire film layer, silver-copper powder conductive ink covers the lead wire layer to obtain a printed board.

Embodiment 3

[0062]Printing process: by jet printing method, on the 50μm thick polyimide substrate, roll-to-roll printed 80nm thick nano-silver wire film layer, 100nm thick phenolic resin protective layer, 5000nm thick silver powder-copper powder conductive ink And 5μm thick nano-titanium dioxide particle conductive ink, each printed layer needs to be dried and cured before the next step of printing. The silver powder-copper powder conductive ink includes a body layer and a lead layer extending outward from the body layer. The phenolic resin protective layer covers the nano silver wire film layer. The body layer and the lead layer are both arranged on the phenolic resin protective layer, and the body layer is located on the At the outer edge of the nano-silver wire film layer, the conductive ink of nano-titanium dioxide particles covers the lead layer to obtain a printing plate.

[0063] Etching step: laser etching out the capacitive sensing layer 20 on the nano-silver wire film layer, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com