A Protection Structure and Application of Bellows of Vacuum Interrupter under High Gas Pressure

A vacuum interrupter, gas pressure technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc. liters, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

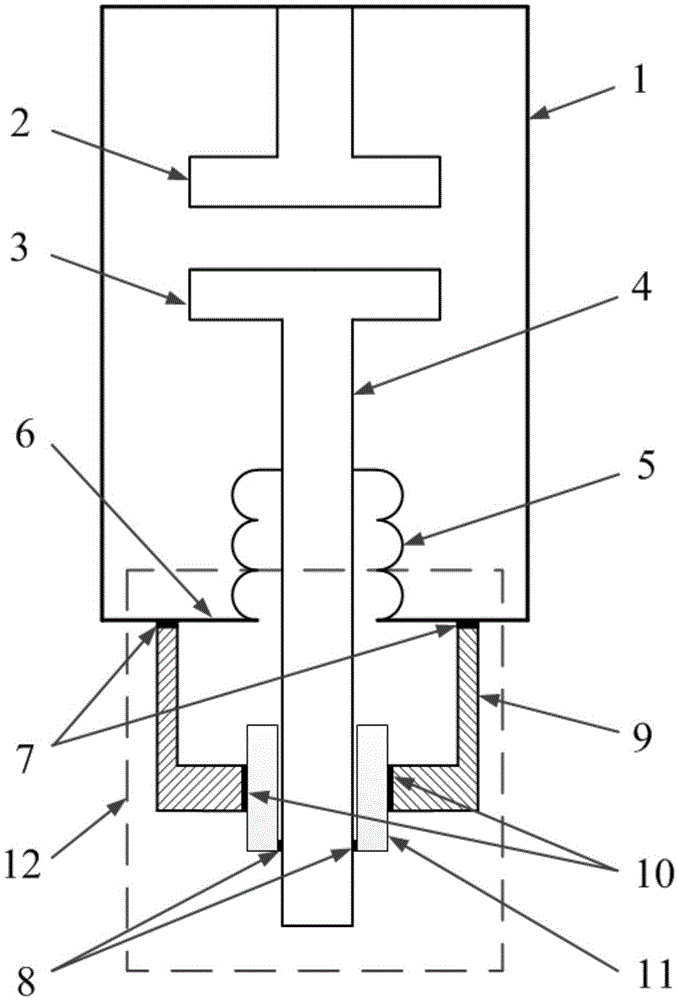

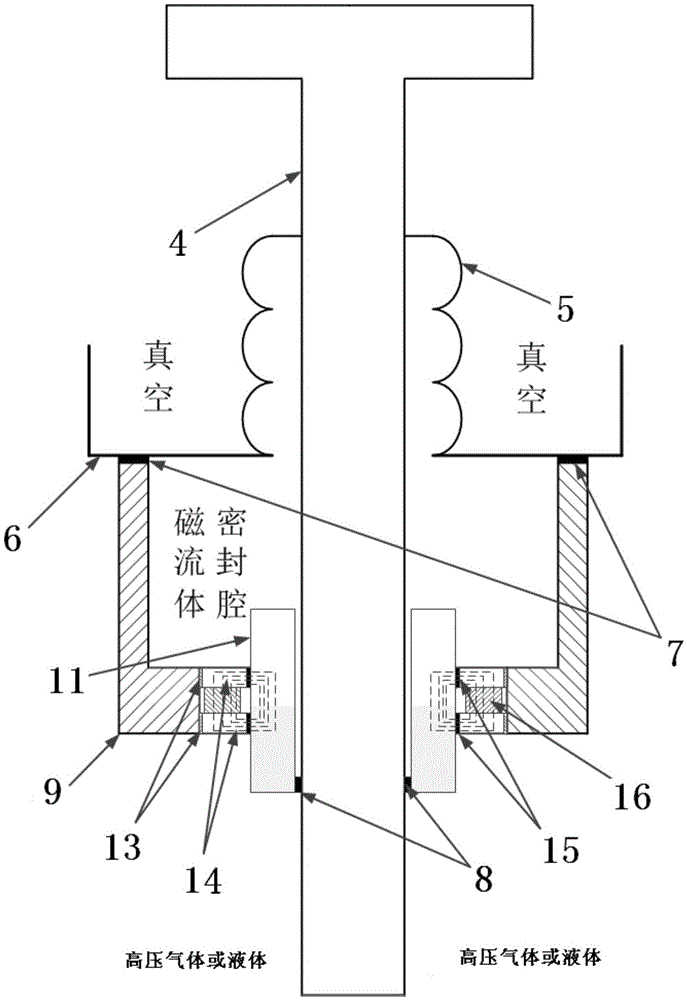

[0016] Such as figure 1 As shown, the vacuum interrupter 1 is in a vacuum environment, the static contact 2 is fixedly connected to the vacuum interrupter 1, one end of the bellows 5 is welded to the movable conductive rod 4, and the other end is welded to the movable end cover of the vacuum interrupter 6 . When the vacuum circuit breaker performs opening and closing operations, the bellows 5 is compressed or restored, which plays a sealing role. The protective structure of the bellows of the vacuum interrupter under high gas pressure of the present invention is figure 1 The fluid direct-movement reciprocating sealing area 12 shown by the dotted line in the middle includes a hollow metal cylinder 11 arranged at the end of the movable conductive rod 4 of the vacuum interrupter at the outside of the movable end cover 6 of the vacuum interrupter, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com