Valveless micropump suction cup driven by laminated radial hybrid compliant structure

A flexible structure and laminated technology, applied in the field of micro-adsorption devices and valveless micro-pump suction cups, can solve the problems of large operating noise, large volume, and high energy consumption, and achieve the effects of light weight, small volume, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following Example.

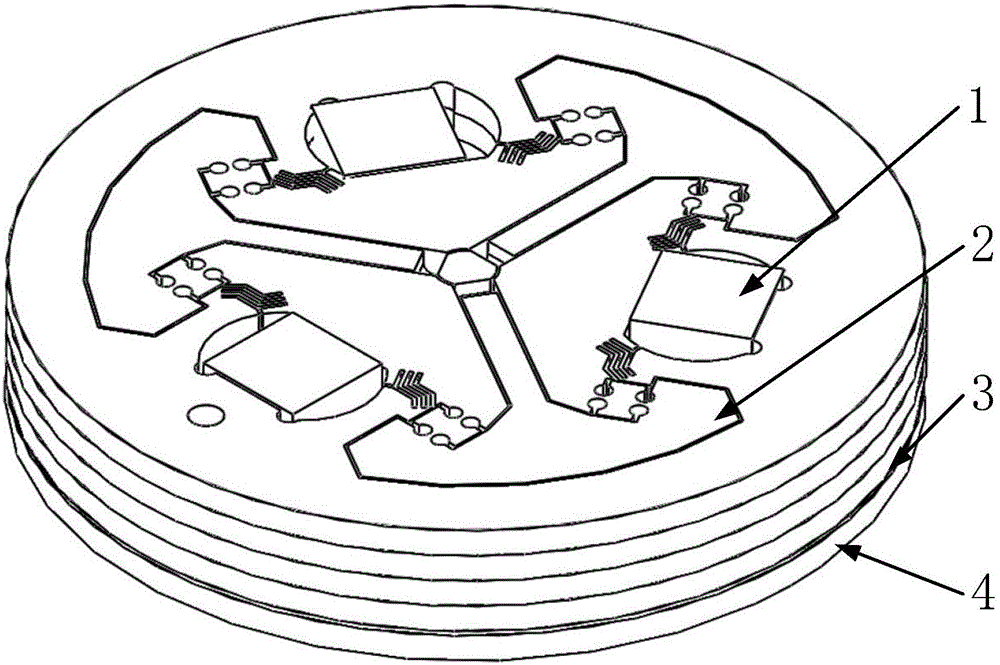

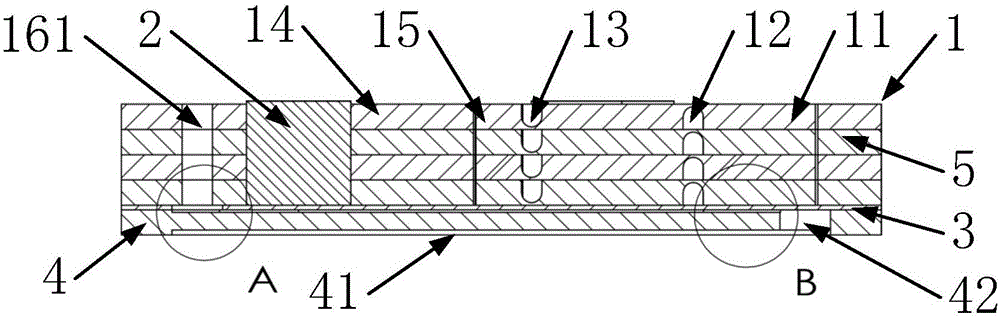

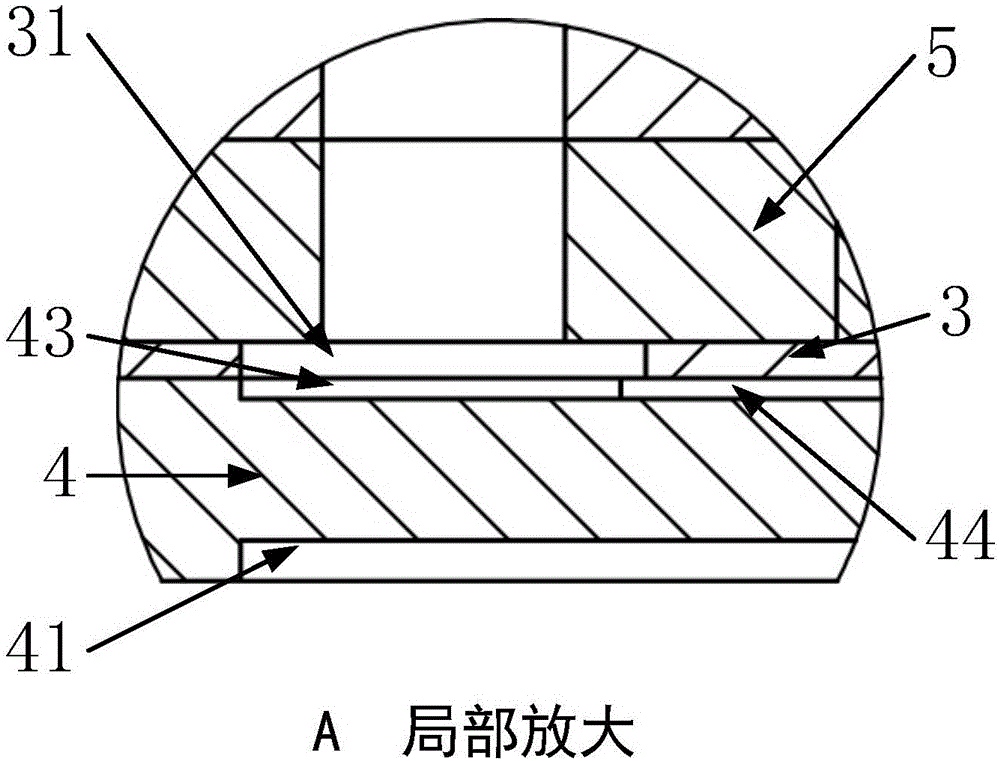

[0037] Please refer to figure 1 with figure 2 , shows a valveless micropump suction cup driven by a laminated radial hybrid compliant structure, which includes a laminated hybrid compliant amplifying mechanism 1, stacked piezoelectric ceramic sheets 2 and a thin-film micropump. The laminated hybrid compliant amplifying mechanism 1 can convert radial input displacement into axial output displacement. In this embodiment, the laminated hybrid compliant amplifying mechanism 1 is disc-shaped, and its internal functional structure is centrally radiating Type symmetry, it adopts singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com