Low-friction conveying channel and forming method thereof

A conveying channel and low-friction technology, applied in the field of conveying channel and its forming, can solve the problems of high relative molecular weight, difficult forming process, small flow rate, etc., achieve safety inspection, convenient maintenance and replacement, avoid R&D investment, and reduce cross-section Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

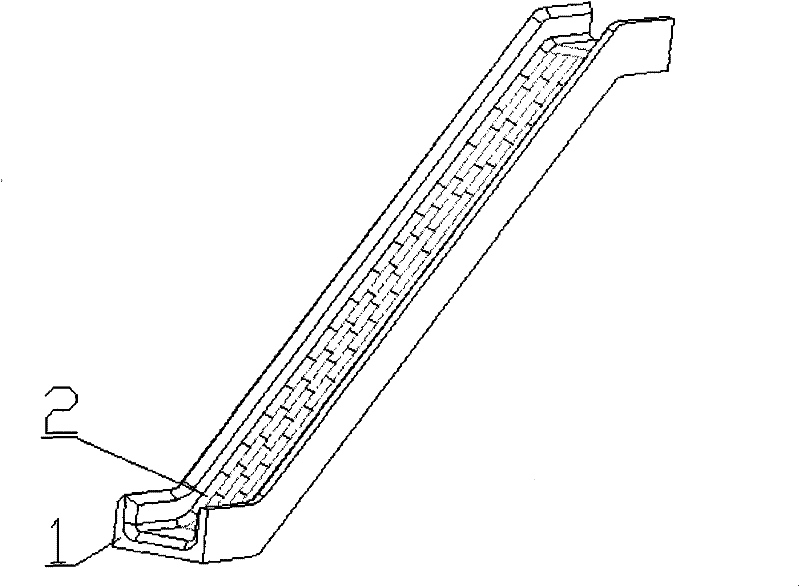

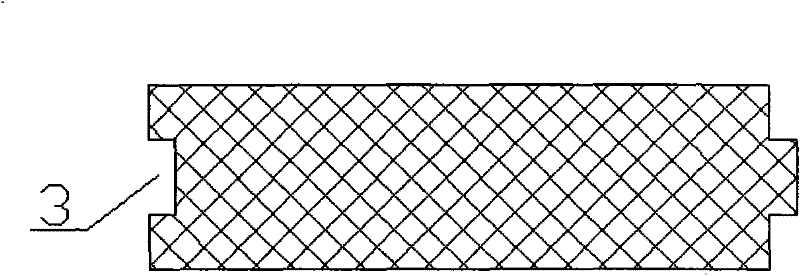

[0021] A low-friction conveying channel of the present invention is composed of two parts, a support base plate 1 and a face profile 2, such as figure 1 As shown; according to different materials and transportation requirements, the support base plate 1 can be made into different cross-sectional shapes. For example, when transporting liquids such as oil and mud, a closed channel should be used, and the support base plate 1 should be made into a circular pipe with a cross section; coal transport For large particles such as food, ore, a semi-closed channel should be used, and the supporting base 1 is made into a U-shaped structural channel; in order to improve the strength and rigidity of the supporting base 1, the supporting base 1 is generally made of metal materials, which can be It is formed by rolling or welding, or connected by screws or rivets; the support base plate 1 forms the support frame of the conveying channel along the conveying path, and the support base plate 1 i...

Embodiment 2

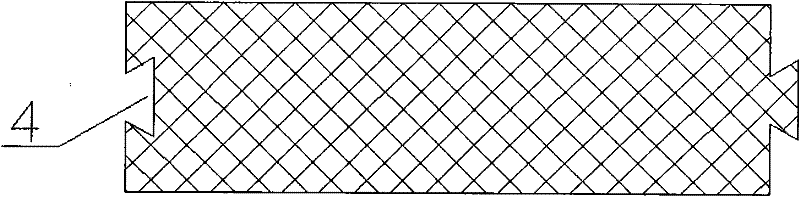

[0031] see Figure 4 , the structure, working principle and effect of this embodiment and embodiment 1 are basically the same. The difference is that the channel section adopts a closed section. The section shape of the face profile is fan-shaped, and the surface in contact with the material is arc-shaped. When the face profiles are spliced, the side is coated with adhesive, which is beneficial to form a closed structure after splicing, so as to transport liquids and other occasions that require a closed structure. This structure is not suitable for conveying fluid with high pressure, because the sealing is not easy to guarantee.

[0032] The low-friction conveying channel of the present invention can not only be used for conveying materials in various industries, but also can be used for slideways in playgrounds, kindergartens and the like.

[0033] The forming method of a low-friction conveying channel of the present invention is as follows: firstly, the supporting base pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com