High voltage isolation switch

A high-voltage isolation switch, knife switch technology, applied in the direction of air switch parts, contact meshing, contact electrical connection, etc., can solve the problems of electrical conductivity, safety and reliability are not ideal, environmental adaptability and withstand voltage level It is not very high, the conduction effect of the high-voltage isolation switch is not very ideal, etc., to improve the anti-ultraviolet ability, improve the environmental adaptability and withstand voltage level, and avoid poor circuit conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

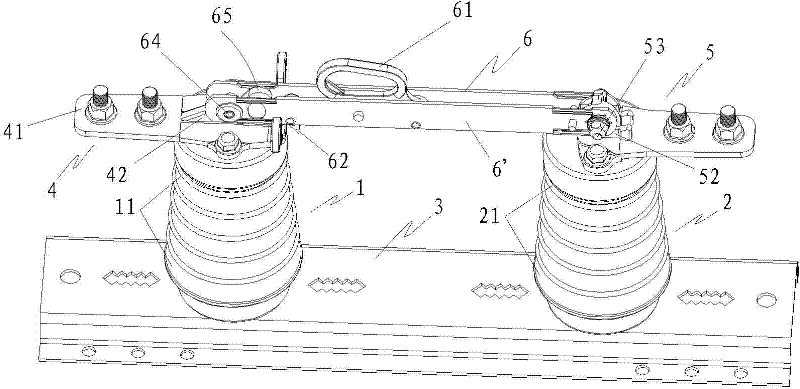

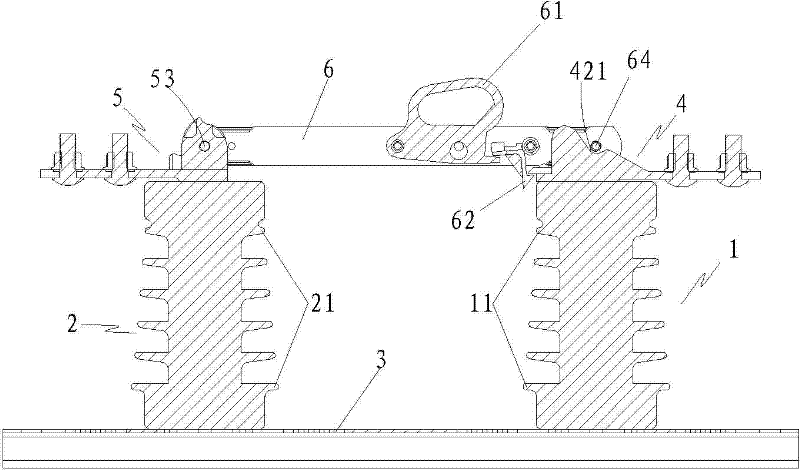

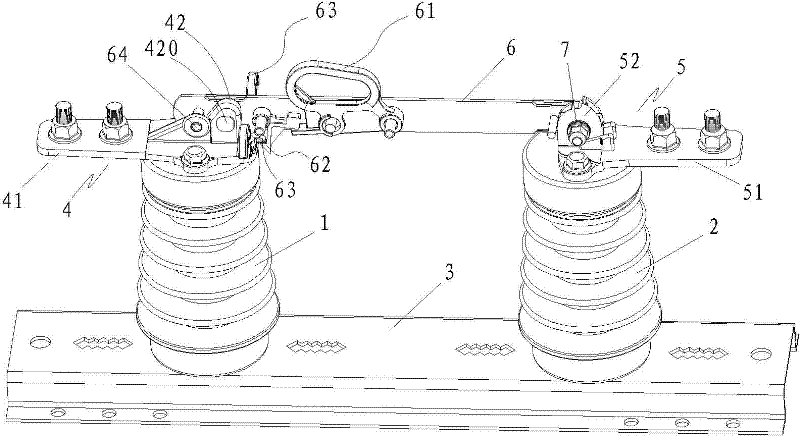

[0029] Examples such as Figures 1 to 4 Shown: a high-voltage isolating switch, including: a first insulating support 1 and a second insulating support 2 vertically fixed on a mounting plate 3, and a moving contact 4 and a static contact 5 are respectively fixed on the two insulating supports, and the static contact A knife switch is hinged on the head 5, and the other end of the knife switch is lapped on the moving contact 4, wherein the moving contact 4 and the static contact 5 are integrally formed with the corresponding terminal, and one end of the knife switch is the contact portion , the other end is the wiring part, that is, the moving contact part 42 and the first connecting terminal 41 are integrally formed, and the static contact part 52 and the second connecting terminal 51 are integrally formed. The knife switch includes a first knife sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com