Stainless steel matte finishing process

A treatment process, stainless steel technology, applied in the field of stainless steel matt treatment process, can solve the problems of toxic substances, low dissolution rate of environmental protection solution, low dissolution rate of stainless steel, etc., achieve good erosion effect, increase hardness, and fast dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

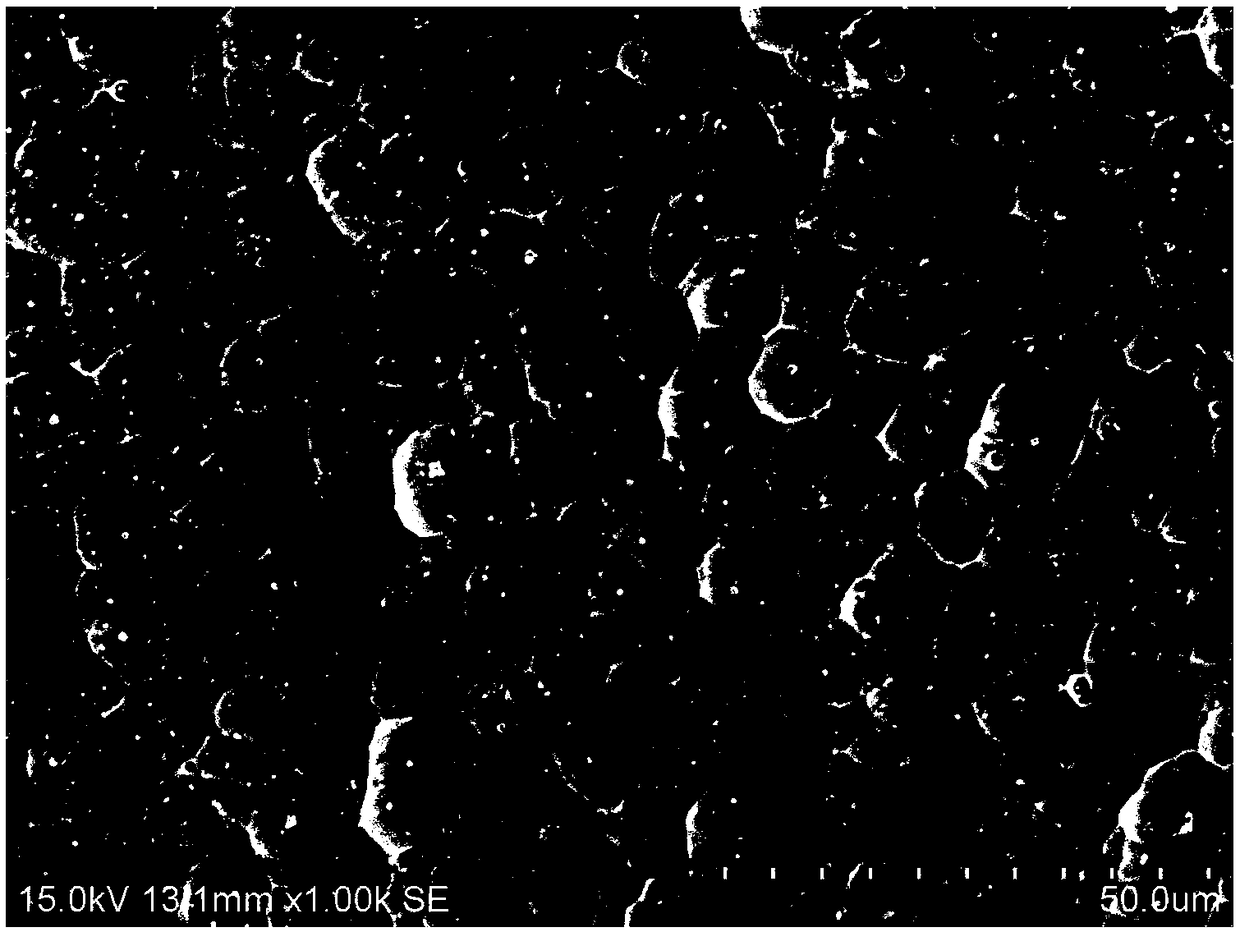

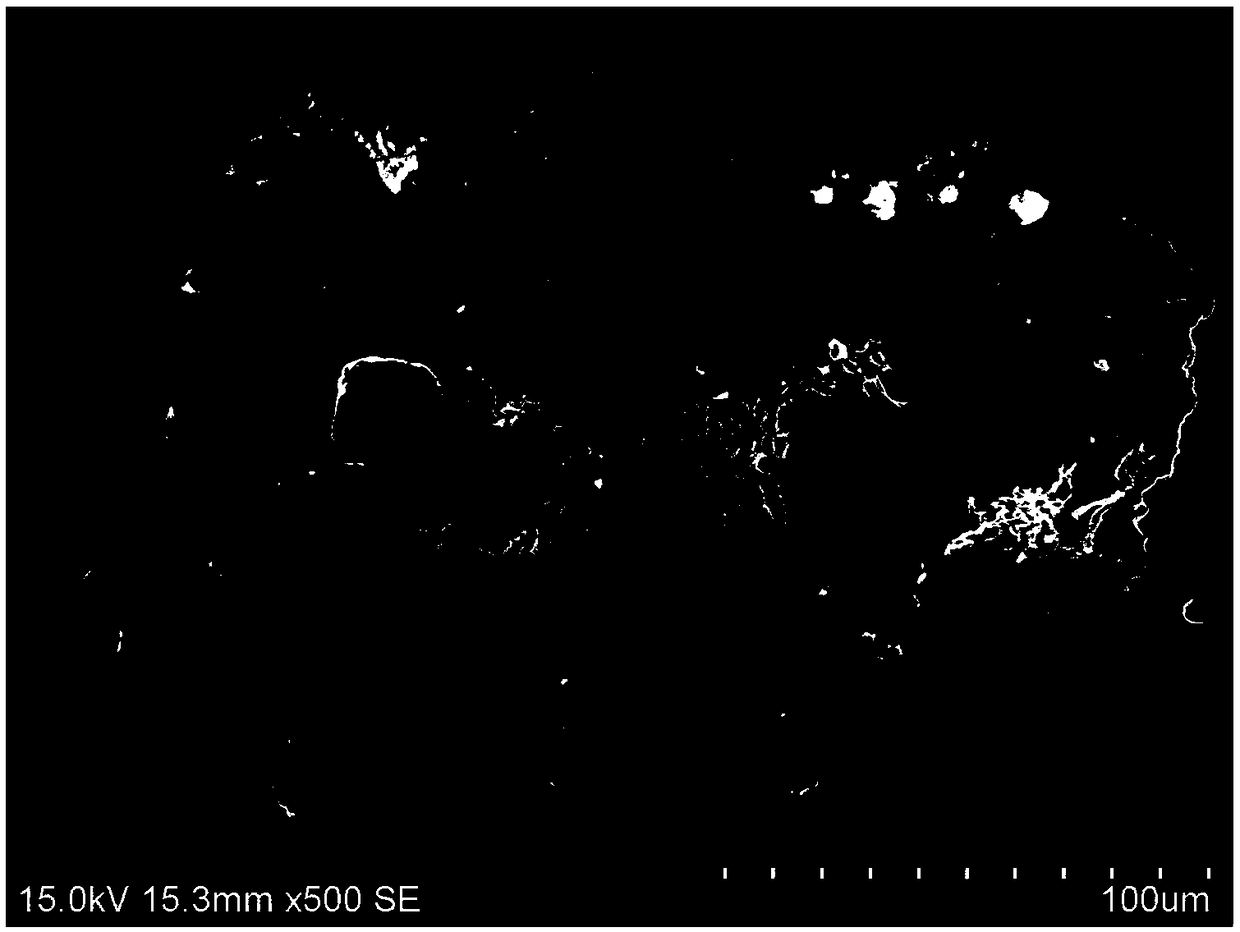

Image

Examples

Embodiment 1

[0032] A 304 stainless steel matt treatment process, comprising the following process steps:

[0033] (1), pre-processing:

[0034] A. Soak the 304 stainless steel workpiece in an alkaline solution at 70°C for 5 minutes to remove the oil on the surface of the 304 stainless steel workpiece. The alkaline solution is 64g / L NaOH, 20g / LNa 2CO 3 , 10g / L Na 2 SiO 3 and 50g / L Na 3 PO 4 One or more of them, the pH value of the alkaline solution is 9;

[0035] B. Place the 304 stainless steel workpiece after degreasing and decontamination in ultrasonic deionized water for 10 minutes, so that the dirt on the surface of the 304 stainless steel workpiece is thoroughly cleaned;

[0036] C, place the 304 stainless steel workpiece after ultrasonic treatment in absolute ethanol for 10 seconds and then dry it;

[0037] (2), matt anodizing treatment:

[0038] D. Connect the pre-treated 304 stainless steel workpiece to the positive pole of the power supply and place it in a container cont...

Embodiment 2

[0057] A 316L stainless steel matt treatment process, comprising the following process steps:

[0058] (1), pre-processing:

[0059] A. Soak the 316L stainless steel workpiece in an alkaline solution at 70°C for 5 minutes to remove the oil on the surface of the 316L stainless steel workpiece. The alkaline solution is 64g / LNaOH, 20g / LNa 2 CO 3 , 10g / LNa 2 SiO 3 and 50g / LNa 3 PO 4 One or more of them, the pH value of the alkaline solution is 8;

[0060] B. Place the 316L stainless steel workpiece after degreasing and decontamination in ultrasonic deionized water for 10 minutes, so that the dirt on the surface of the 316L stainless steel workpiece is completely cleaned;

[0061] C. Place the 316L stainless steel workpiece after ultrasonic treatment in absolute ethanol for 10 seconds and then dry it;

[0062] (2), matt anodizing treatment:

[0063] D. Connect the pre-treated 316L stainless steel workpiece to the positive pole of the power supply and place it in a container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com