Preparation process of waterproof enhancement sheet in modified polyvinylchloride

A polyvinyl chloride and waterproof sheet technology, which is applied in the field of preparation of modified polyvinyl chloride internally reinforced waterproof sheets, can solve the problems of uneven performance of waterproof sheets, waterproof, aging resistance and other performance indicators that cannot meet the requirements, Good and bad problems, etc., to achieve the effect of easy processing, low production cost, and improved waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation process of modified polyvinyl chloride interior reinforced waterproof sheet, the steps are as follows,

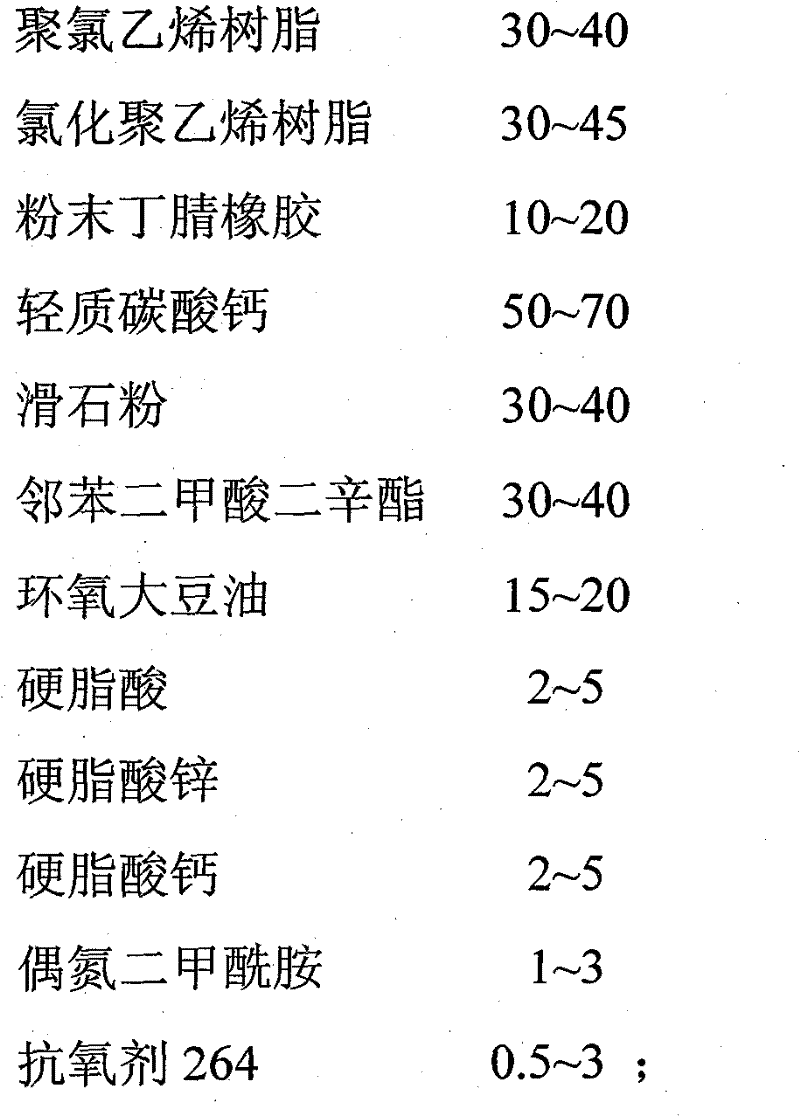

[0024] ①. Raw material preparation: prepare raw materials according to the following raw materials and parts by weight, wherein,

[0025]

[0026] ②. Thermal mixing: Put the polyvinyl chloride resin, chlorinated polyethylene resin, powdered nitrile rubber, light calcium carbonate, and talcum powder in the above-mentioned raw materials into a high-speed heating mixer with a volume of 300L for high-speed mixing, so that the temperature When it reaches 60±5°C, add stearic acid, zinc stearate, calcium stearate, antioxidant 264 and continue mixing at a high speed, and then slowly add dioctyl phthalate and cyclohexanol when the temperature reaches 70°C Oxygenated soybean oil continues to mix at a high speed, so that the temperature reaches 105°C to obtain a thermally mixed primary material;

[0027] ③. Cold mixing: Put the above-mentioned hot mixed prim...

Embodiment 2

[0031] The preparation process of modified polyvinyl chloride interior reinforced waterproof sheet, the steps are as follows,

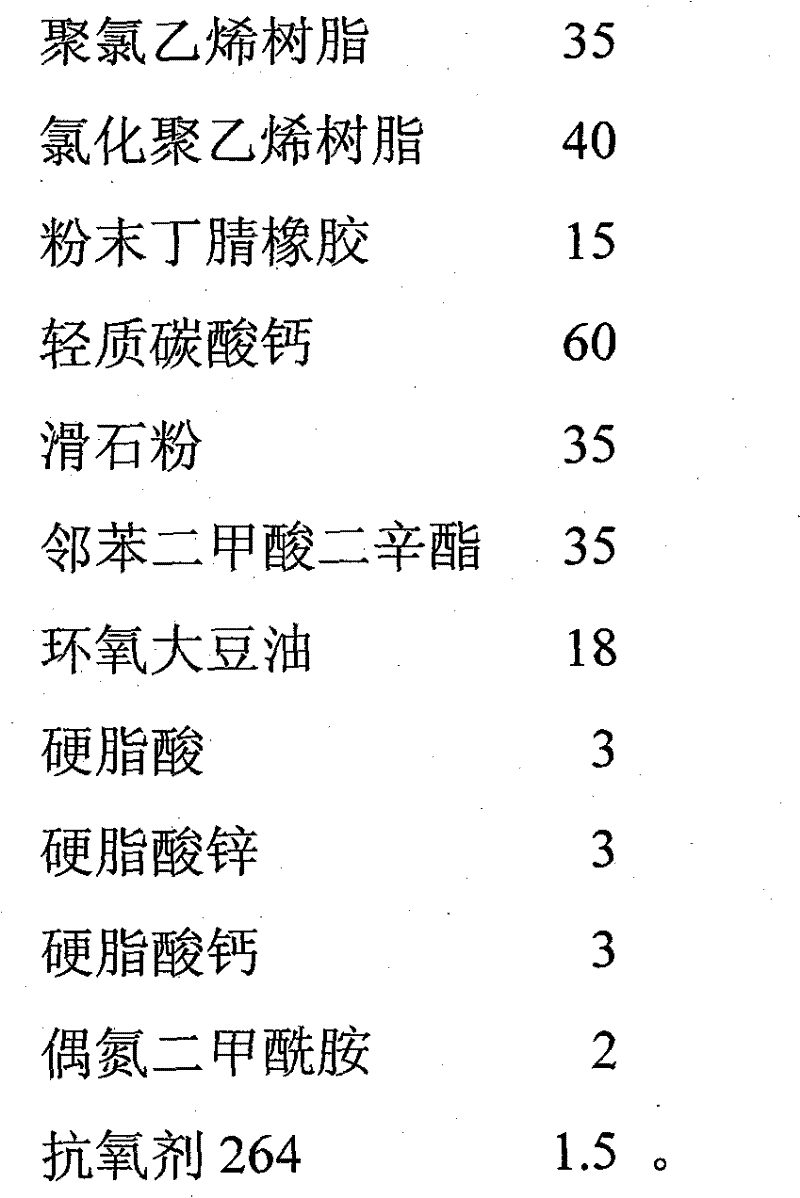

[0032] ①. Raw material preparation: prepare raw materials according to the following raw materials and parts by weight, wherein,

[0033]

[0034] ②. Thermal mixing: Put the polyvinyl chloride resin, chlorinated polyethylene resin, powdered nitrile rubber, light calcium carbonate, and talcum powder in the above-mentioned raw materials into a high-speed heating mixer with a volume of 300L for high-speed mixing, so that the temperature When it reaches 60±5°C, add stearic acid, zinc stearate, calcium stearate, antioxidant 264 and continue mixing at a high speed, and then slowly add dioctyl phthalate and cyclohexanol when the temperature reaches 70°C Oxygenated soybean oil continues to mix at a high speed, so that the temperature reaches 105°C to obtain a thermally mixed primary material;

[0035] ③. Cold mixing: Put the above-mentioned hot mixed prim...

Embodiment 3

[0039] The preparation process of modified polyvinyl chloride interior reinforced waterproof sheet, the steps are as follows,

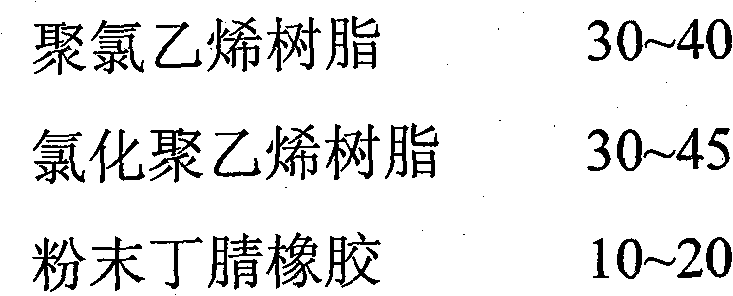

[0040] ①. Raw material preparation: prepare raw materials according to the following raw materials and parts by weight, wherein,

[0041]

[0042]

[0043]②. Thermal mixing: Put the polyvinyl chloride resin, chlorinated polyethylene resin, powdered nitrile rubber, light calcium carbonate, and talcum powder in the above-mentioned raw materials into a high-speed heating mixer with a volume of 300L for high-speed mixing, so that the temperature When it reaches 60±5°C, add stearic acid, zinc stearate, calcium stearate, antioxidant 264 and continue mixing at a high speed, and then slowly add dioctyl phthalate and cyclohexanol when the temperature reaches 70°C Oxygenated soybean oil continues to mix at a high speed, so that the temperature reaches 105°C to obtain a thermally mixed primary material;

[0044] ③. Cold mixing: Put the above-mentioned hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com