Pipeline detaching device for technology services

A technology for dismantling devices and technical services, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve problems such as unusable pipes, bursting pipes, and increased processing costs, so as to facilitate handling, loading and unloading, The structure of the equipment is simple and the processing is not difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

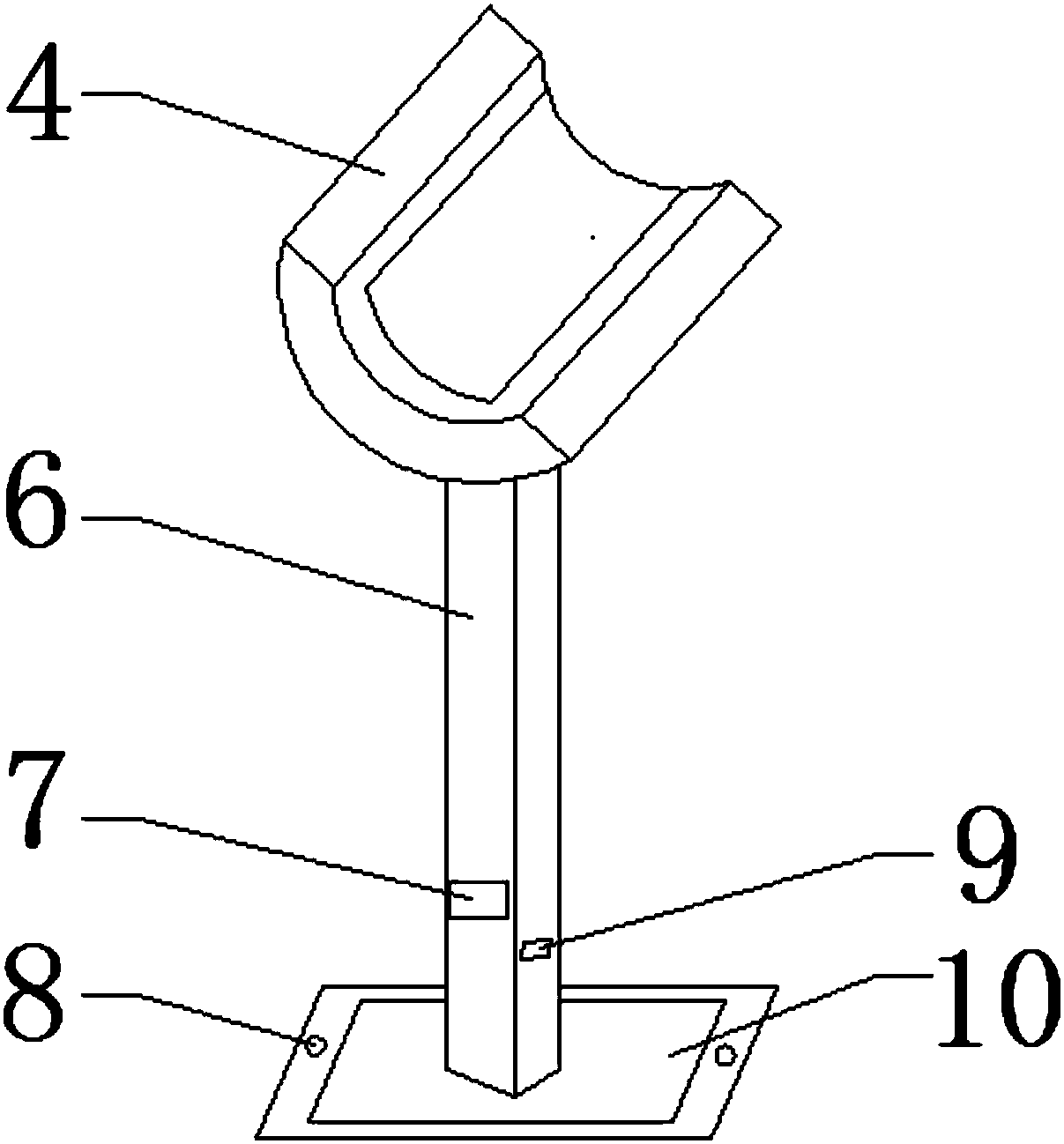

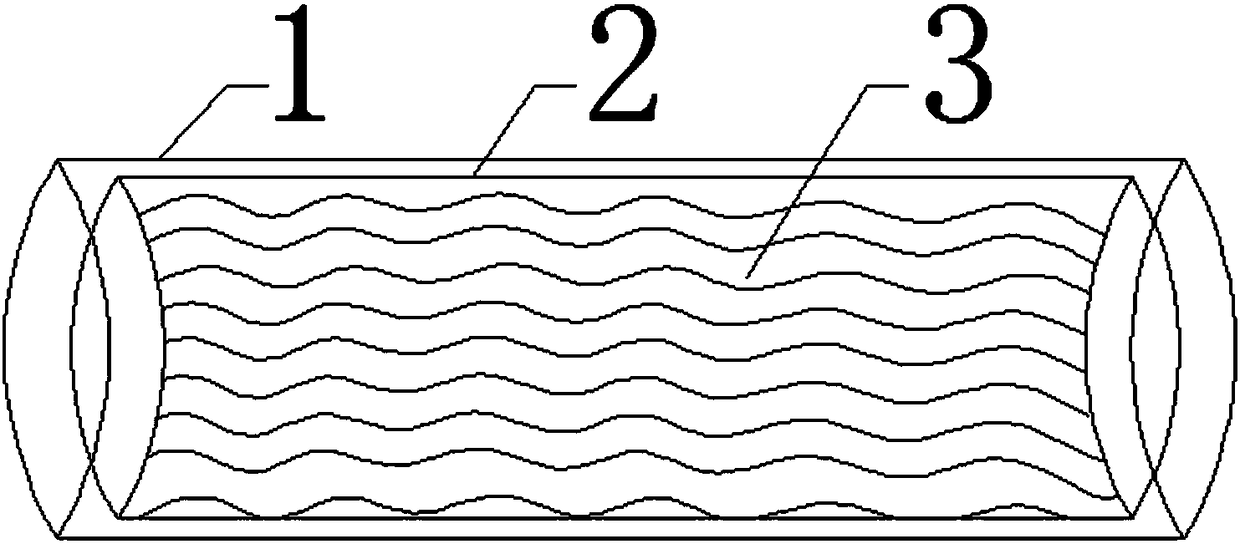

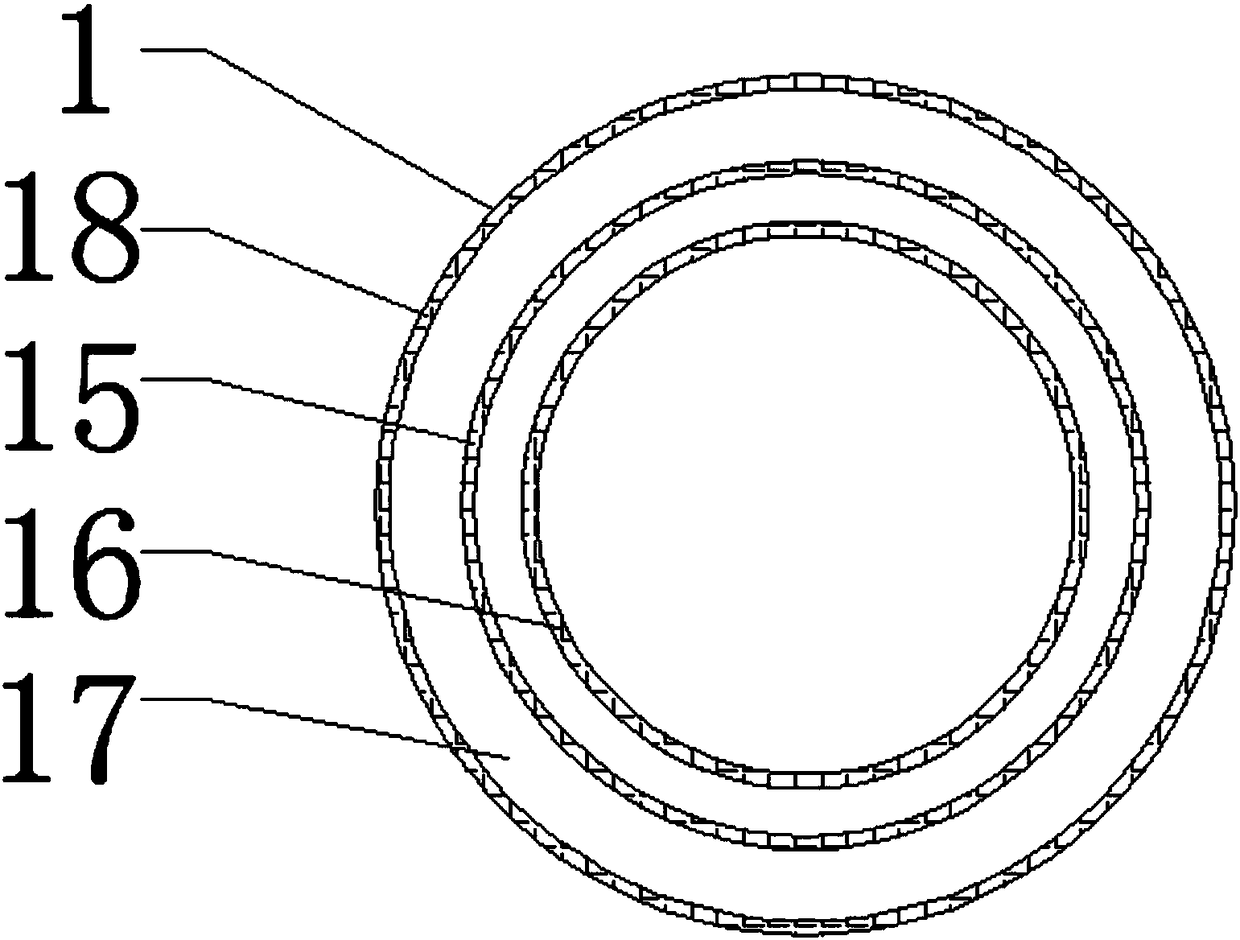

[0023] Specific implementation method: assemble the equipment during use, install the bracket 4 on the rotating shaft 5, fix the strong support base 6 on the base 10, fix the equipment on the ground through the fixing hole 8 of the base 10, and place the bracket 4 Under the housing 1, use a tape measure 12 to clamp in the connection port to measure the length of the pipe 2 to be replaced, use the vise 11 and the saw 13 in the tool box 7 to cut the pipe 2, replace the damaged pipe 2 and replace it with a new one Pipeline 2, and wrap the insulation layer 16, heating layer 15 and anti-corrosion layer 18 on the outside of the pipeline 2, and a sponge 17 is arranged in the middle of the anti-corrosion layer 18 and the heating layer 15, which can alleviate the damage to the pipeline 2 when there are falling objects , and the characteristics of the sponge 17 itself can keep out the cold, heat insulation, and prevent the pipe 2 from bursting when the temperature is too low in winter. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com