Floating caliper disc brake

A disc brake and floating caliper technology, applied in the direction of brake type, axial brake, brake components, etc., can solve problems such as eccentric wear, uneven friction between the front and rear ends of the inner brake block, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

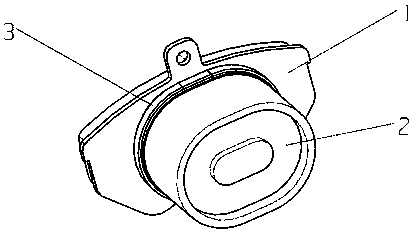

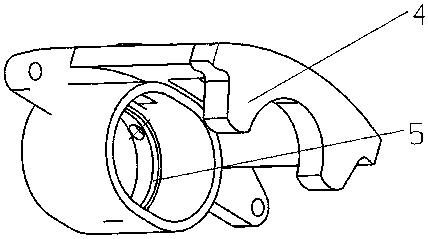

[0026] Such as figure 1 As shown, the cross-section of the brake piston 2 of a floating caliper disc brake is designed to be a kind of ellipse, and the cross-sectional shape is similar to a standard racing track, consisting of two semicircles on both sides and a rectangle in the middle. The radius of the semicircle outer edge on both sides of the section of the brake piston 2 is 28 mm, and the length of the two sides is 15 mm. The height of the brake piston 2 is 60mm. There is a brake piston (2) inner cavity with a depth of 55mm inside the brake piston 2. The radius of the semicircle on both sides of the inner cavity section of the brake piston (2) is 23mm. The brake piston (2) The inner cavity faces the side of the brake block (1). In the 2mm wide groove at 7mm from the bottom of the brake piston 2, a piston sealing ring 3 of rubber material is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com