Roller row type omni-directional drilling rig whole step-by-step moving device

A technology of moving device and roller row, which is used in earth-moving drilling, supporting device, drilling equipment, etc., can solve the problems of limited moving direction and inability to achieve precise movement, so as to improve the utilization rate and improve the adaptability of the well site. , the effect of reducing the transfer error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

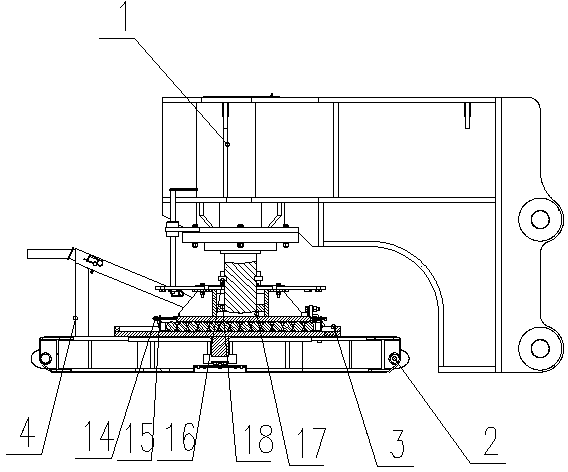

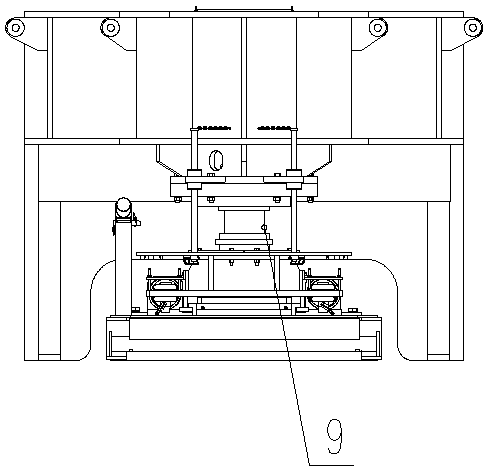

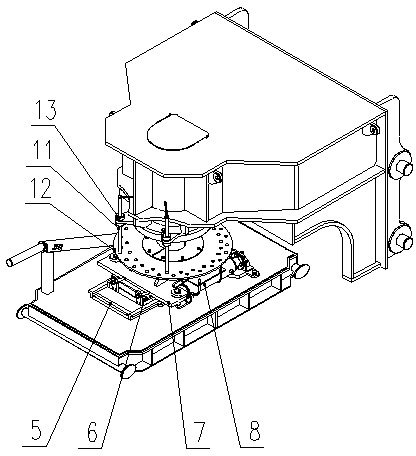

[0021] Attached below Figure 1-5 Specific embodiments of the present invention will be further described.

[0022] see Figure 1-5 : The bracket 1 is fixed to the base 19 of the cluster well drilling rig by connecting the pin shaft 21; the skid seat 2 is made of tailor-welded steel plates, which has a large grounding area and reduces the pressure on the ground; the reversing rotation mechanism 4 and the trolley 3 are installed on the skid seat 2 Top; the tray 5, the upper seat of the trolley 7, the roller row 6 and the translation cylinder 8 form the trolley 3; the roller row 6 is composed of 14 rollers installed on the frame, and the frame connects the rollers together; the translation cylinder 8 is a double cylinder , symmetrically arranged left and right, connected with the upper seat 7 of the trolley through the pin shaft, and the piston rod of the translation cylinder 8 is connected with the tray 5 through bolts; the tray 5 is welded by a steel plate and a right-ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com