Patents

Literature

34results about How to "Achieve precise guidance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

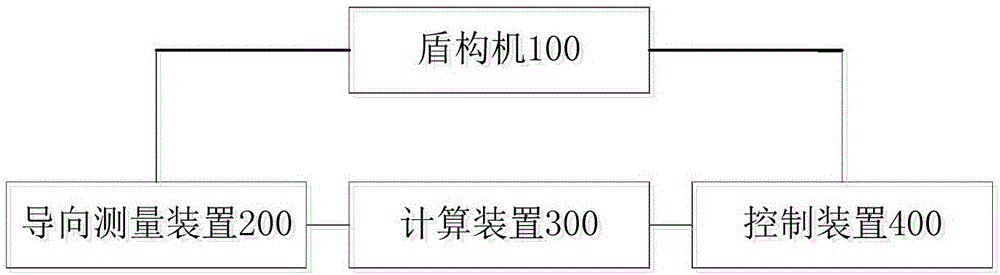

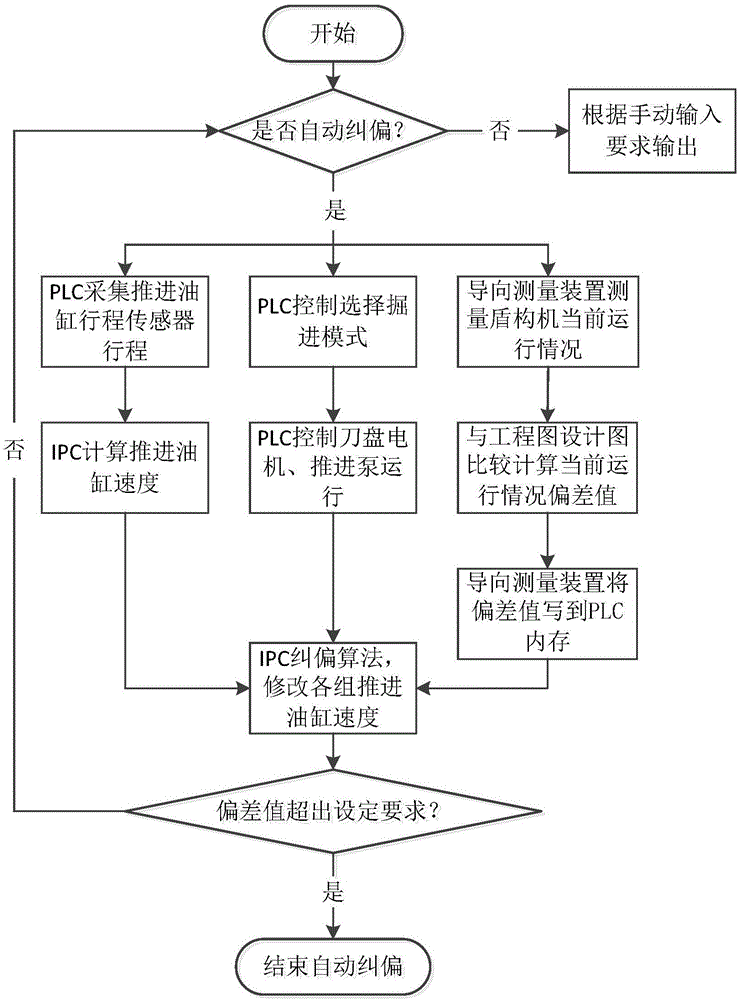

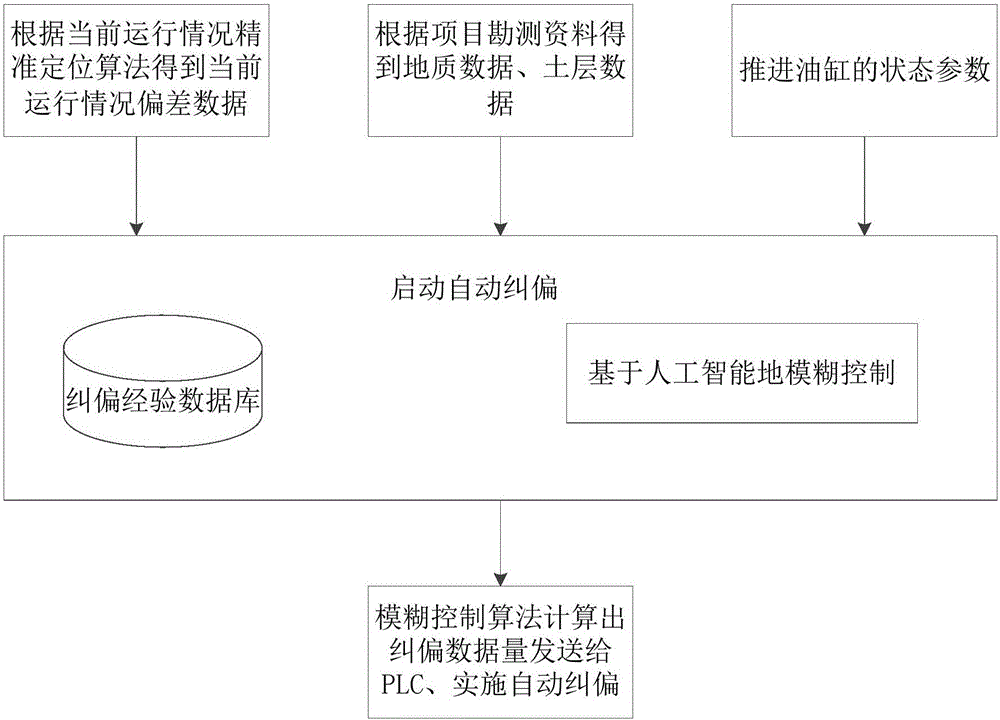

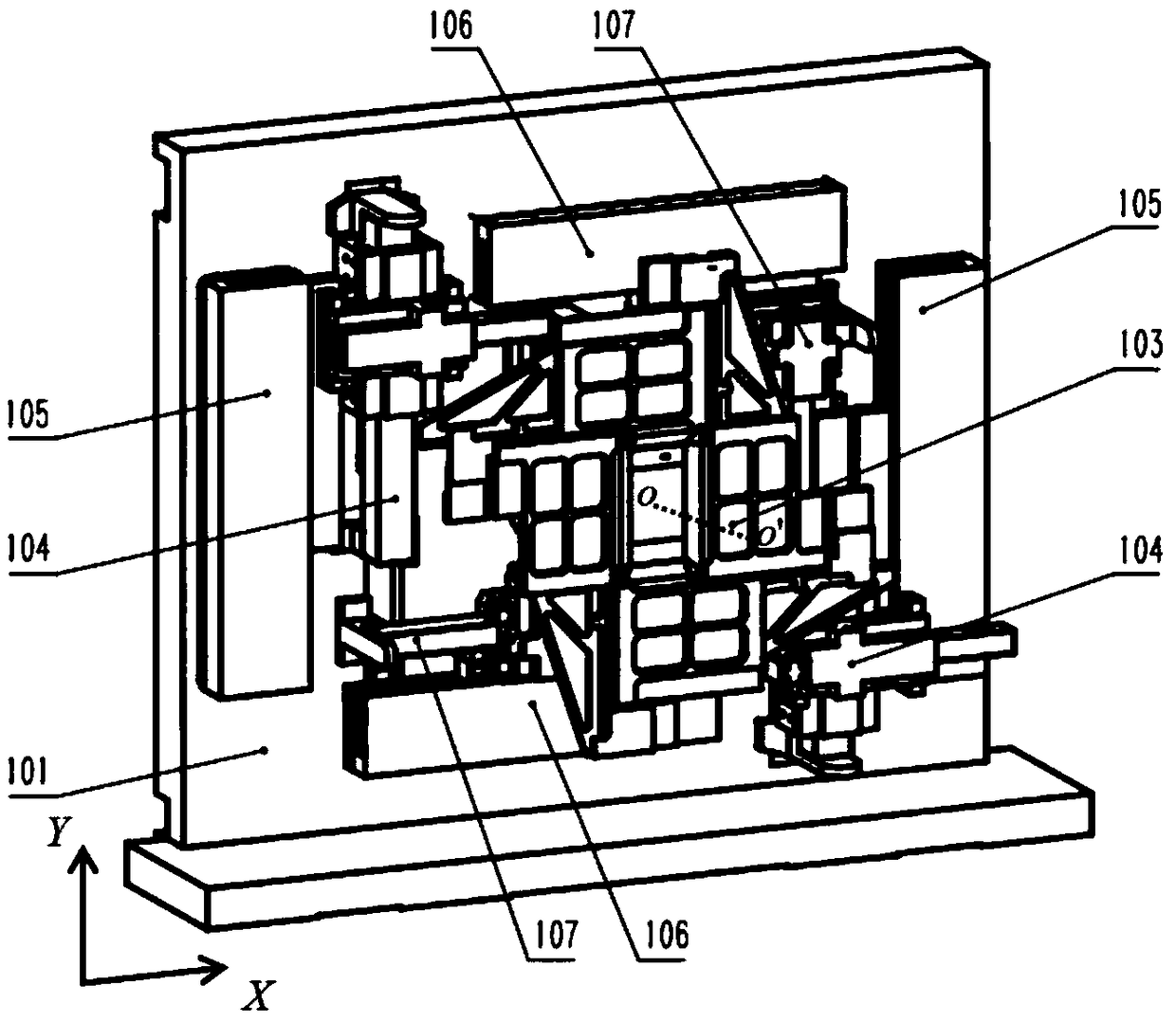

Deviation rectifying system of shield tunneling machine

InactiveCN106522973AAchieve precise guidanceRealize automatic deviation correctionTunnelsEngineeringShield tunneling

The invention provides a deviation rectifying system of a shield tunneling machine. The deviation rectifying system of the shield tunneling machine comprises the shield tunneling machine, a guide measuring device, a calculation device and a control device, wherein the guide measuring device is used for acquiring the current operating situation of the shield tunneling machine after the deviation rectifying system of the shield tunneling machine is started, and sending the current operating situation to the calculation device; the calculation device is used for receiving and saving the current operating situation; and the control device is used for reading the current operating situation from the calculation device, generating control instructions needed for controlling the shield tunneling machine according to the current operating situation, and rectifying deviation of the shield tunneling machine according to the control instructions. Through the deviation rectifying system of the shield tunneling machine, precise guiding and automatic deviation rectifying of the shield tunneling machine can be achieved, and the working efficiency of the shield tunneling machine is effectively improved.

Owner:XCMG KAIGONG HEAVY IND NANJING

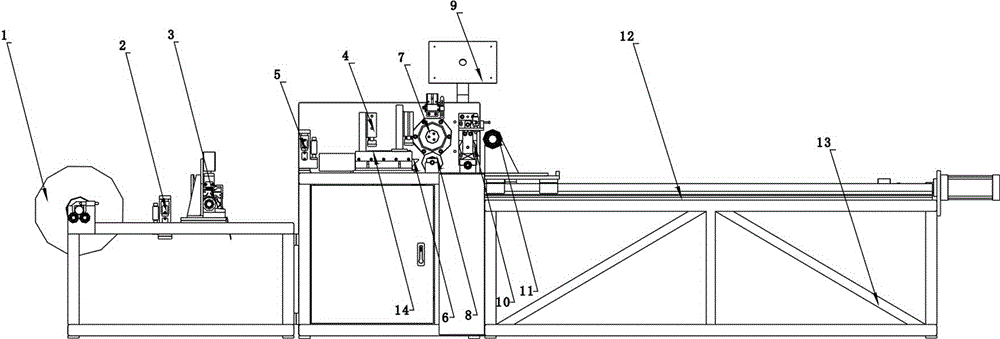

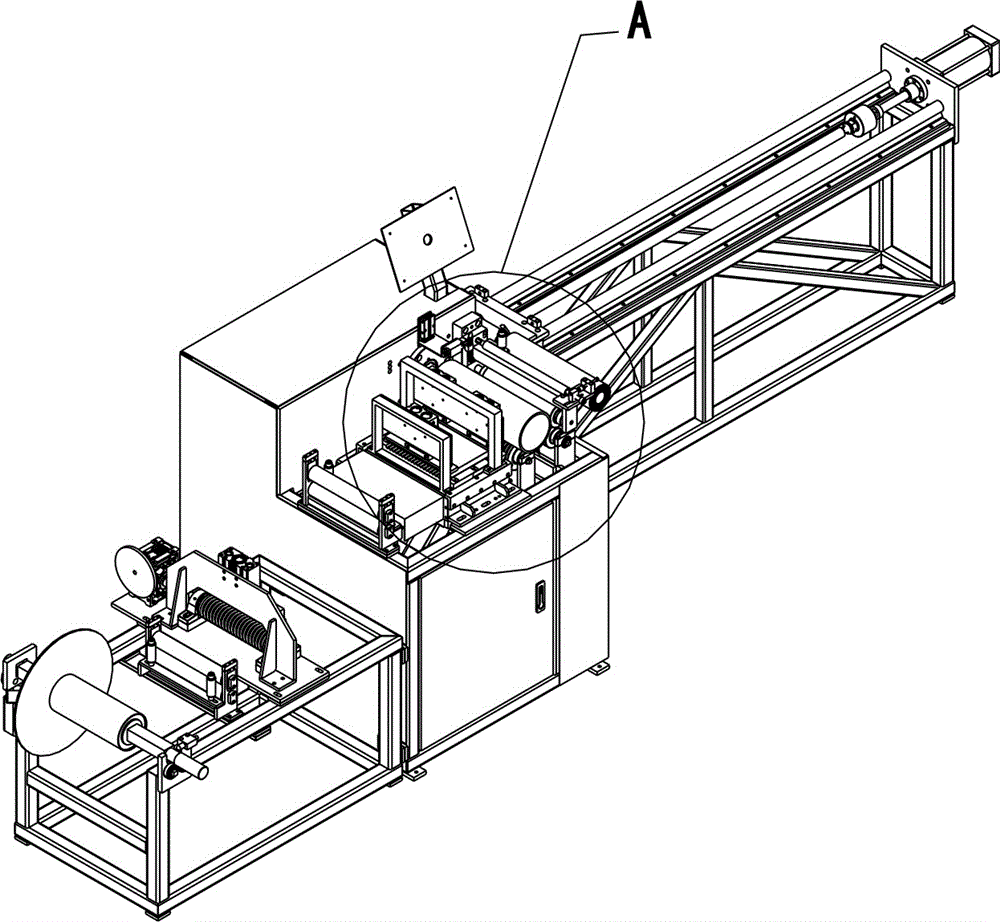

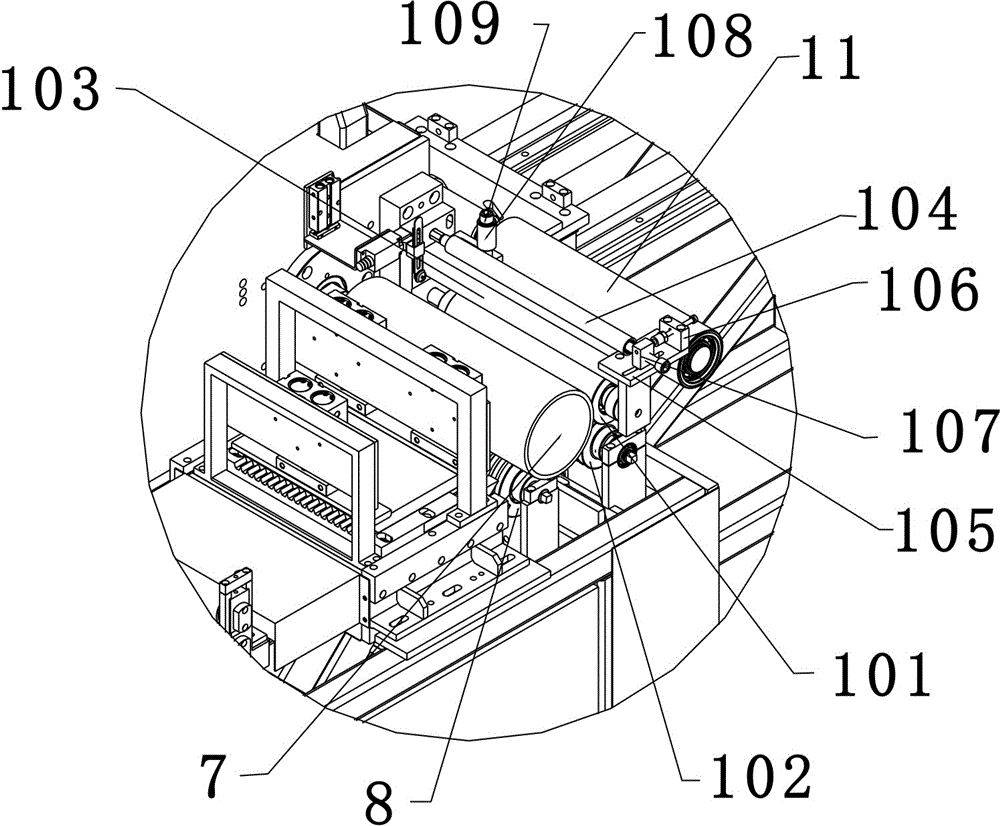

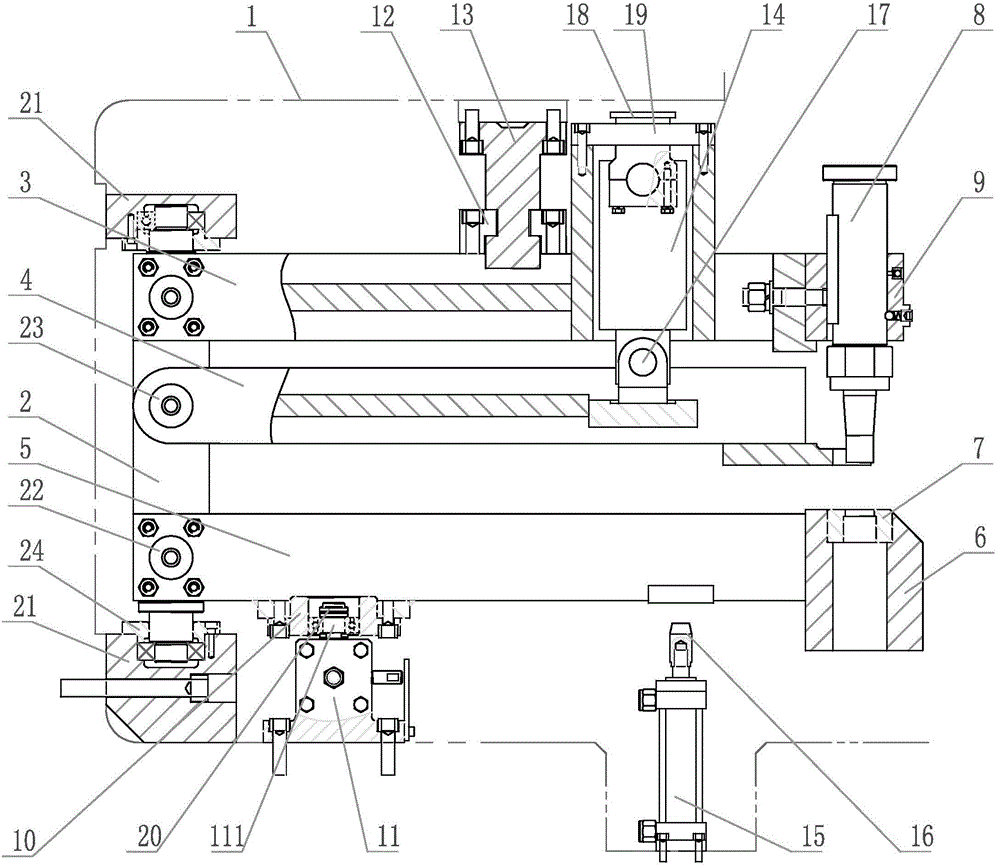

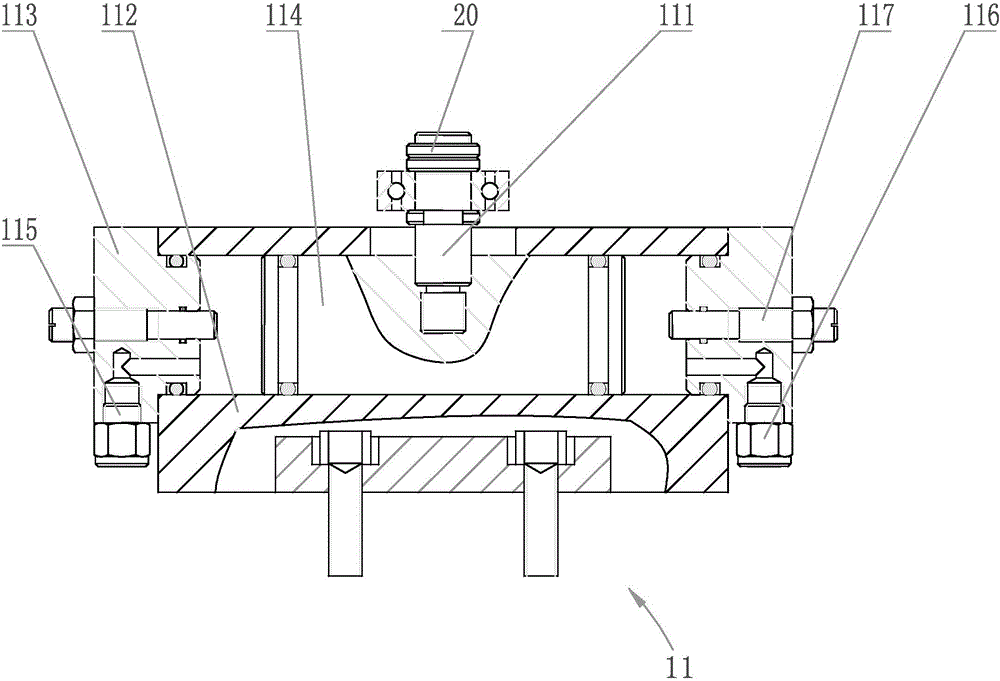

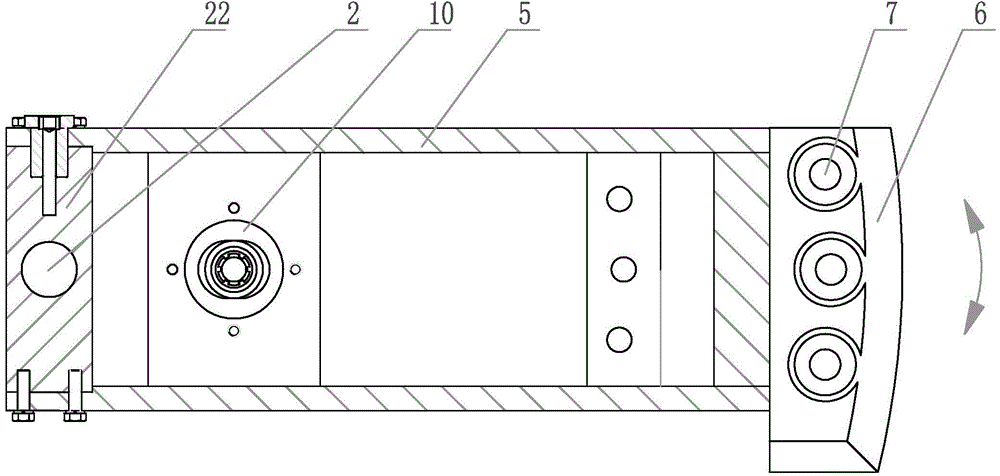

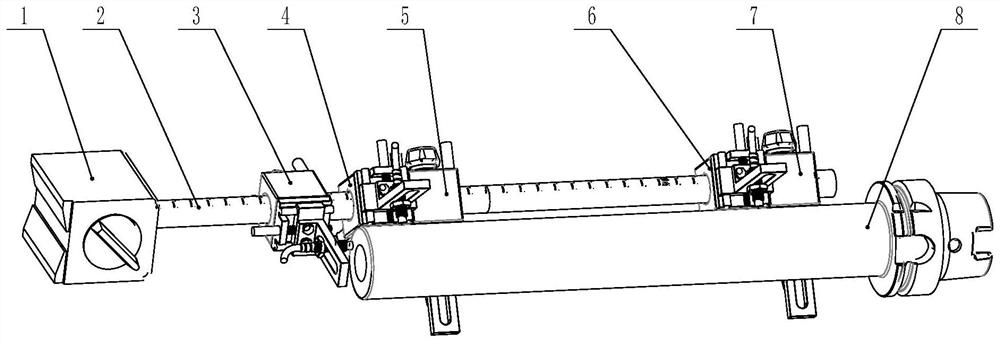

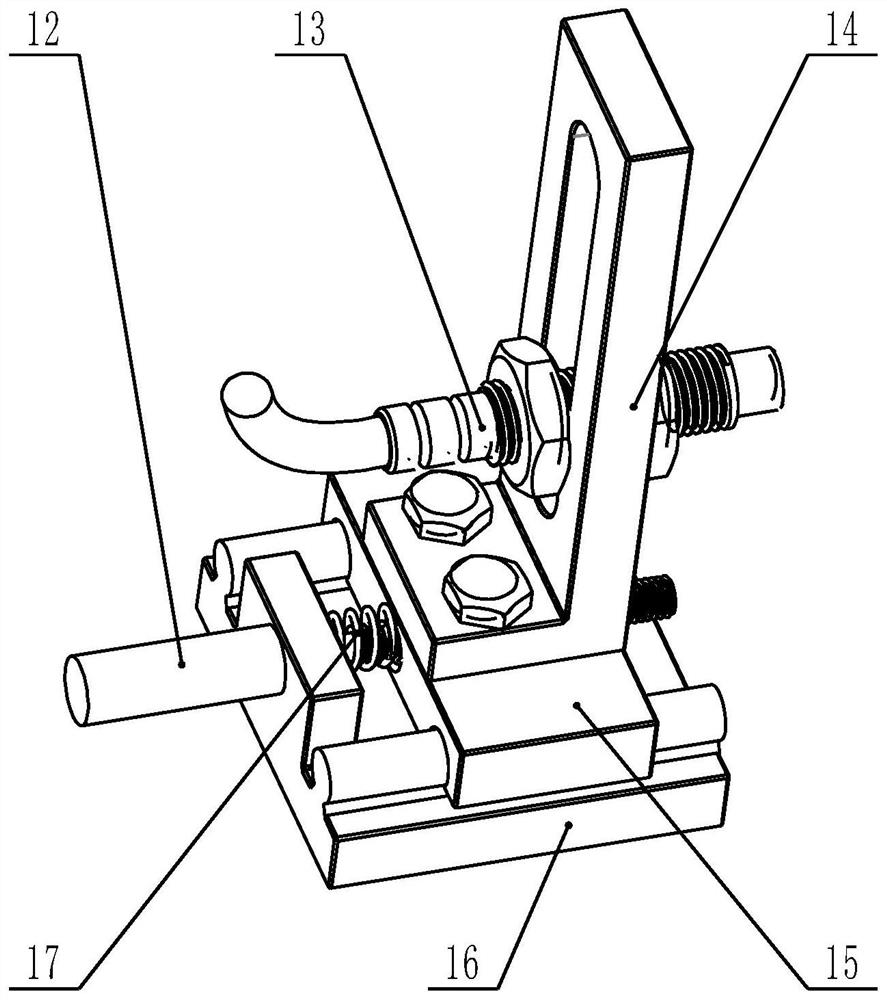

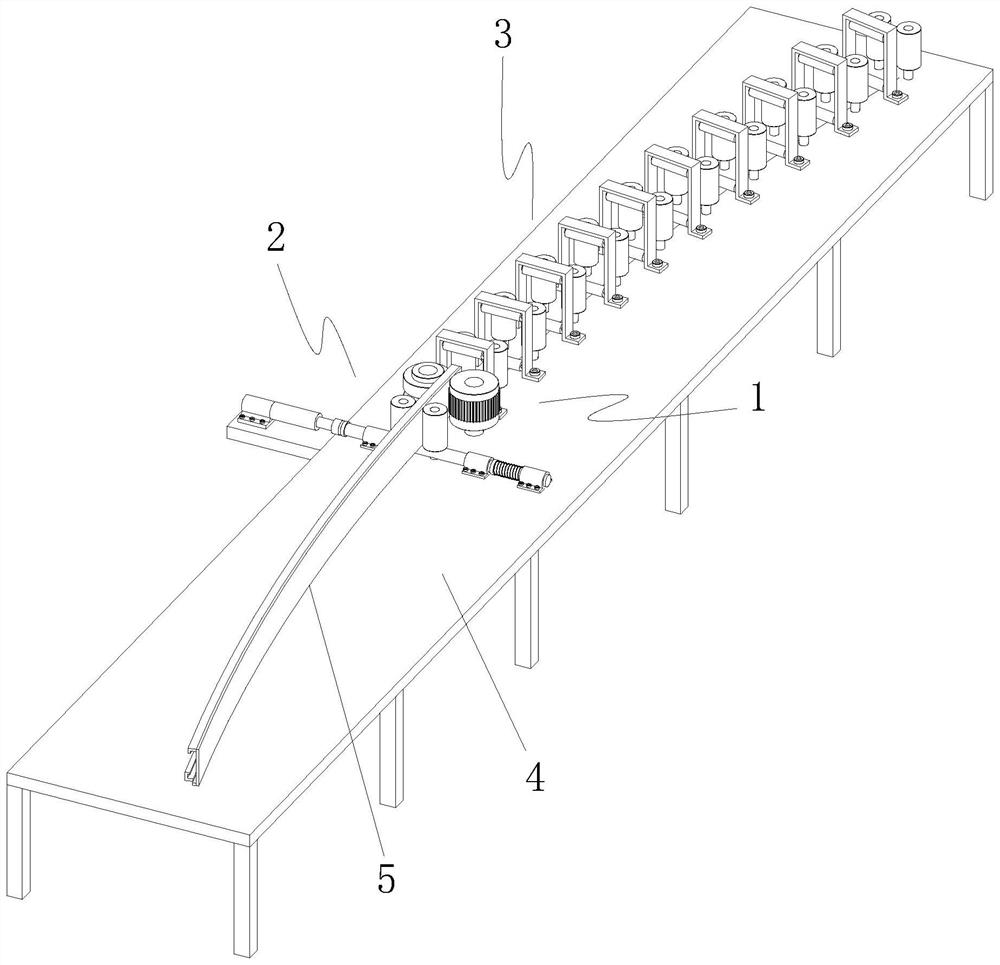

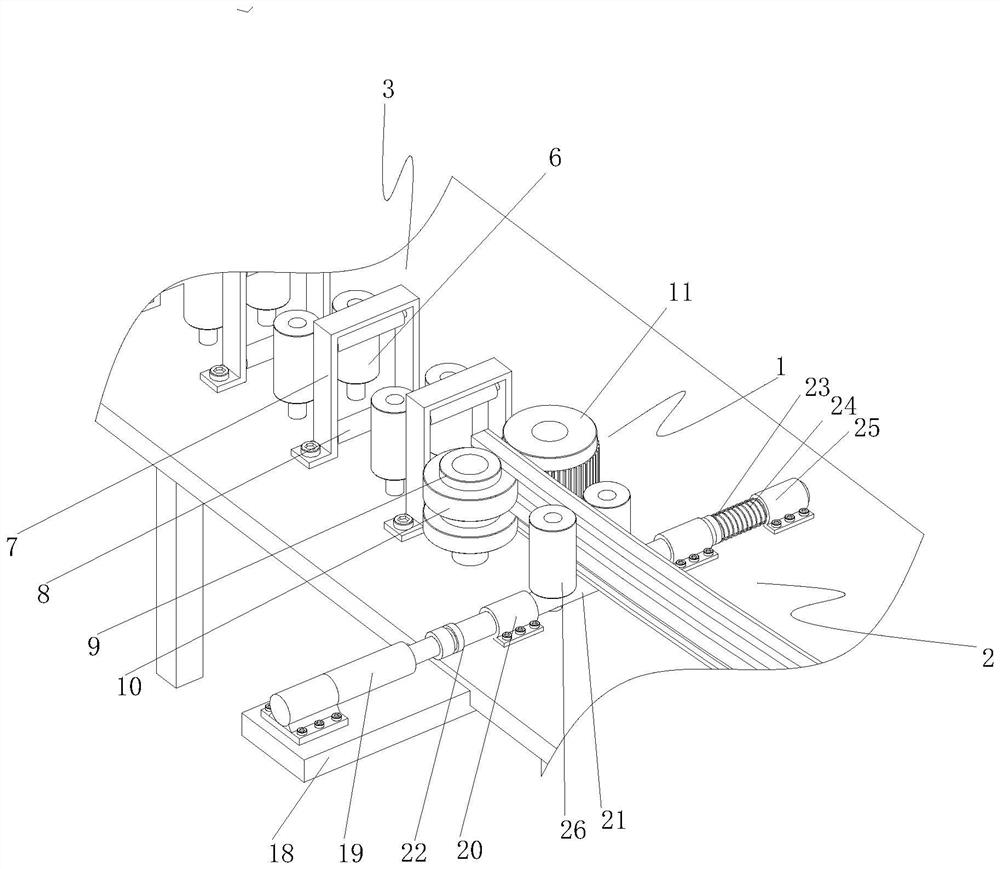

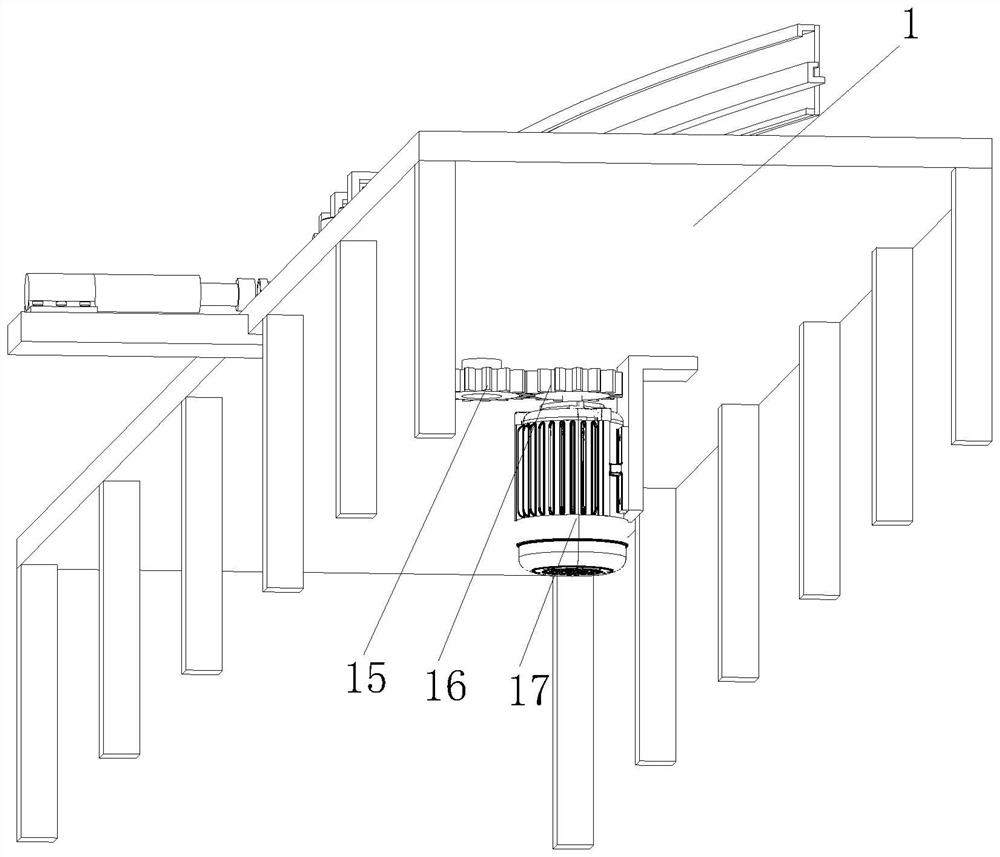

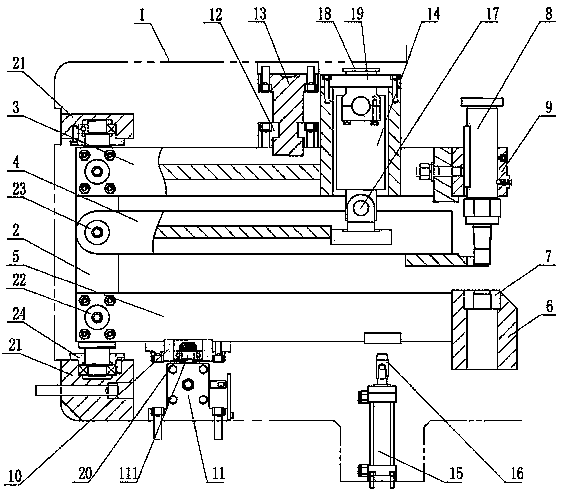

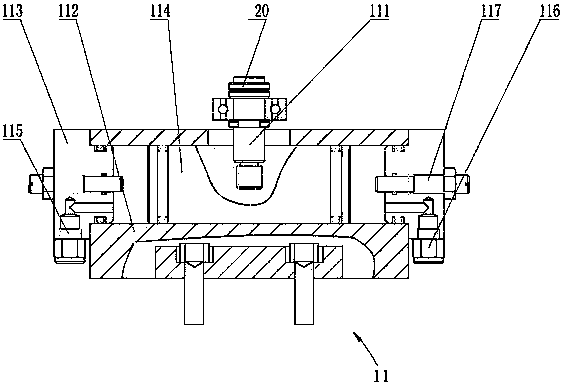

Rubber coating and cutting device for rubber v-belt wire billets

ActiveCN105619508ARealize mechanized cuttingReasonable designBeltsMetal working apparatusNumerical controlDrive shaft

The invention provides a rubber coating and cutting device for rubber v-belt wire billets. The cutting device is a numerical control group cutting device, and comprises a rack, a base rubber guiding device, a base rubber conveying device and a base rubber coating and cutting mechanism, wherein the base rubber guiding device, the base rubber conveying device and the base rubber coating and cutting mechanism are arranged on the rack in sequence; the base rubber coating and cutting mechanism comprises a driving shaft roller and a driven tensioning roller which are arranged on the rack, and also comprises a group cutting circular knife and an extrusion shaft roller, wherein the extrusion shaft roller is located between the driving shaft roller and the driven tensioning roller; and the upper part of the extrusion shaft roller is provided with the group cutting circular knife with a sliding mechanism. The cutting deviceprovided by the invention is simple in structure, high in cutting precision, labor efficiency and operation safety and convenient to install.

Owner:SANLUX

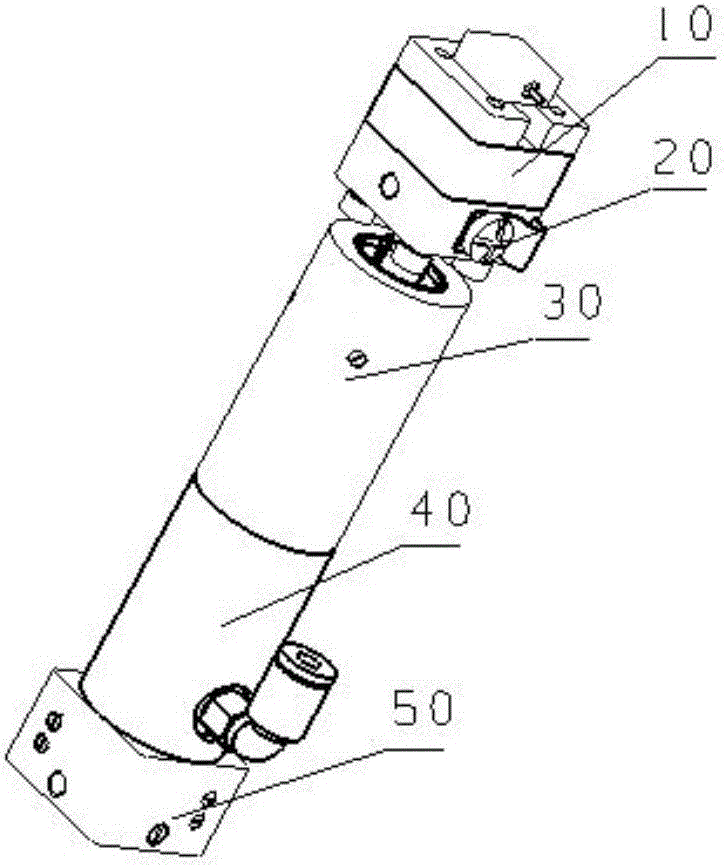

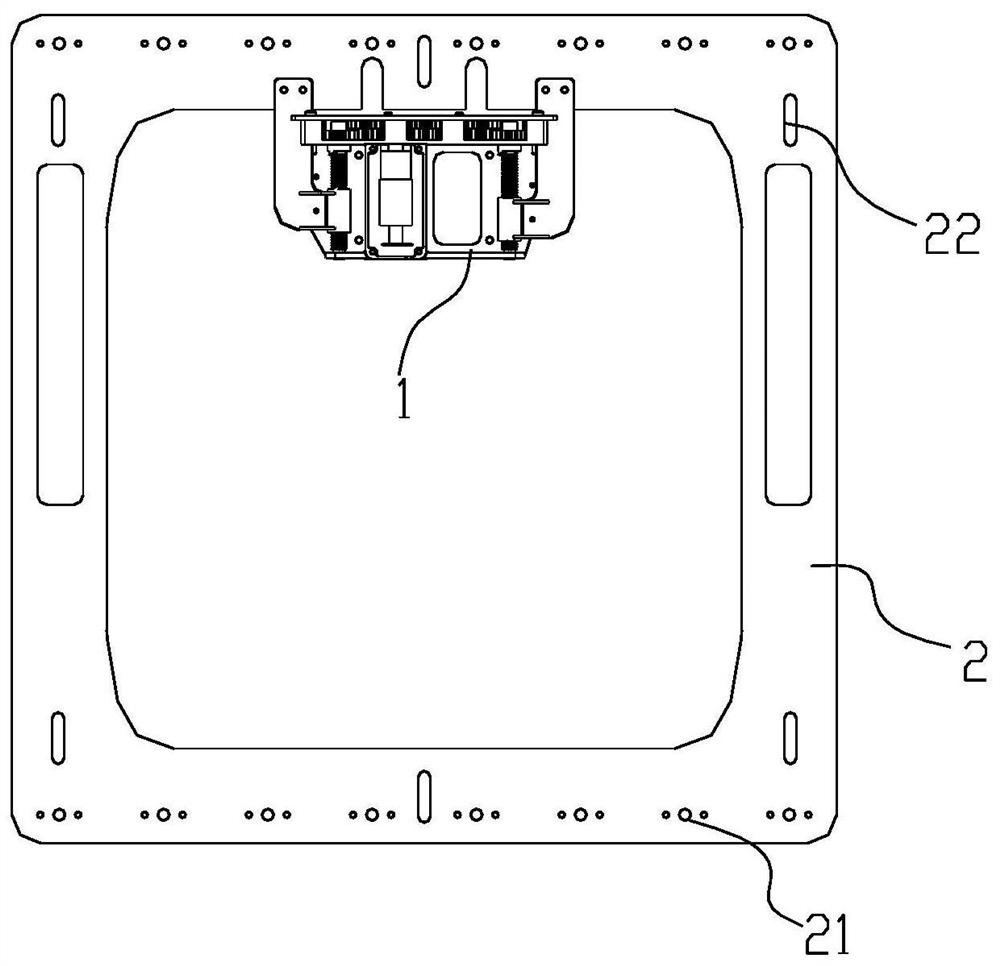

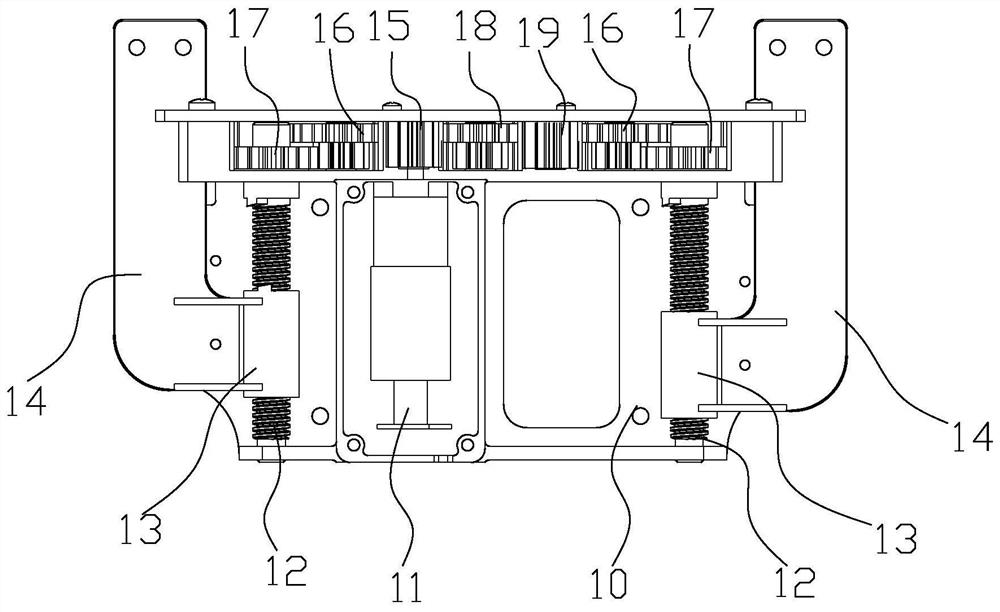

Hot-press heads and hot-press device

The invention discloses a hot-press device. The hot-press device comprises a hot-press head pair, a hot-press head pressure control system and a hot-press head temperature control system, wherein the hot-press head pair comprises an upper hot-press head and a lower hot-press head; the hot-press head pressure control system is connected with a power assembly of the lower hot-press head by an air pipe and is used for providing gas with stable pressure to the power assembly by closed loop feedback pressure control, and heating assemblies are driven to do reciprocating linear movement by the power assembly under the action of the pressure gas; and the hot-press head temperature control system is electrically connected with a first heating assembly of the upper hot-press head and a second heating assembly of the lower hot-press head, and is used for stabilizing the temperatures of the heating assemblies by closed loop feedback temperature control. According to the hot-press device, the power assemblies of the hot-press heads are connected into a control air path in parallel, and the same air pressure is provided by the pressure control system, so that the pressure output from a plurality of hot-press heads can be consistent. The temperatures of the multiple hot-press heads are stabilized by the closed loop feedback temperature control, so that the problems of an existing hot-press head that the pressure is inconvenient to adjust, and the stability and the consistency of the pressure and the temperature are difficult to ensure can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

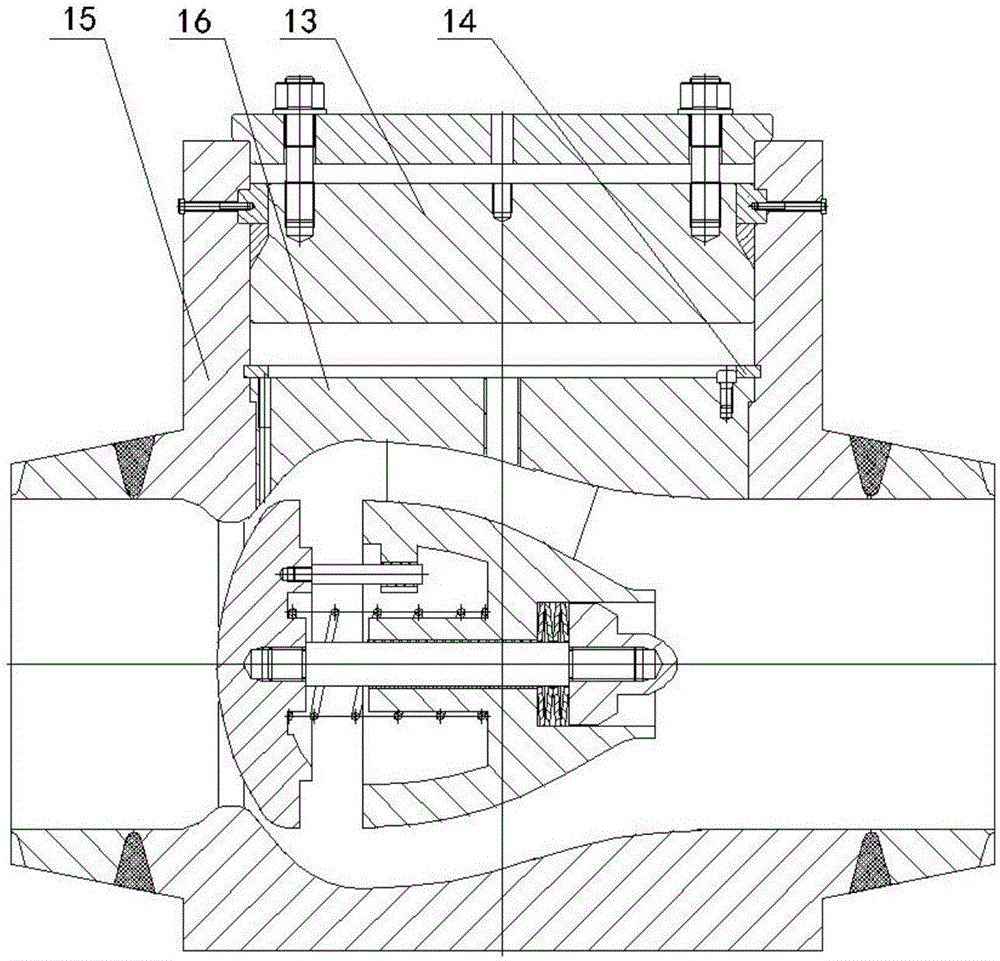

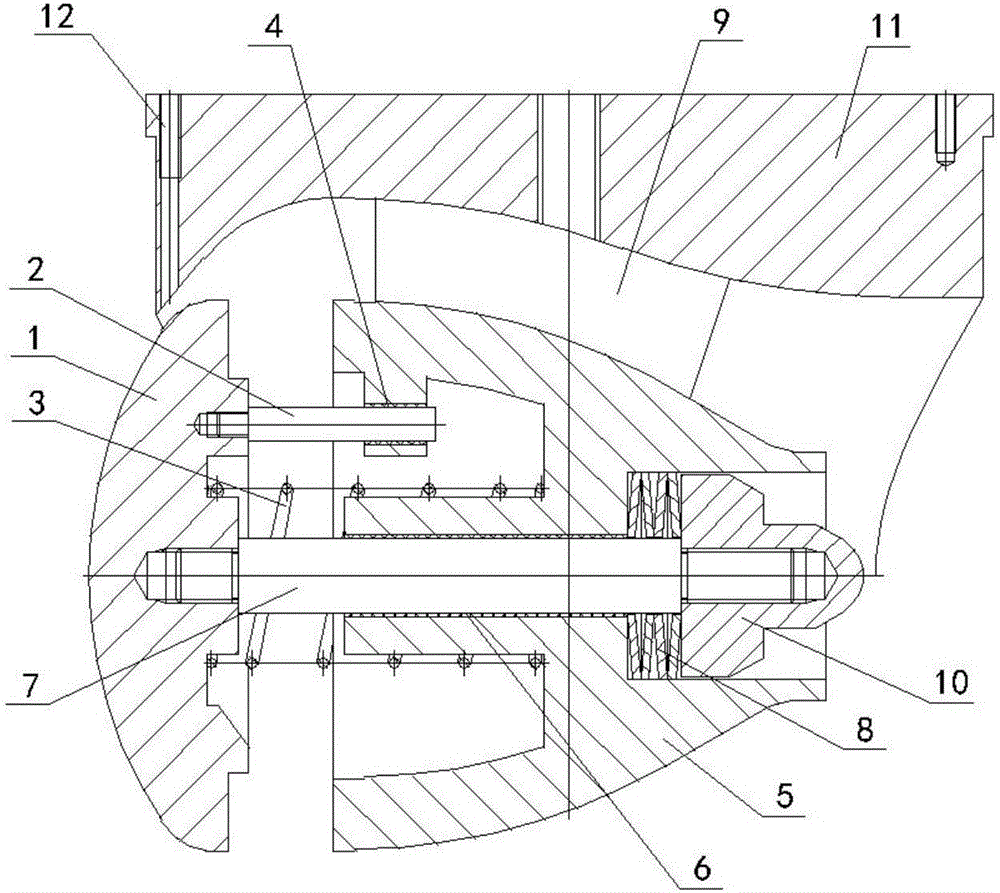

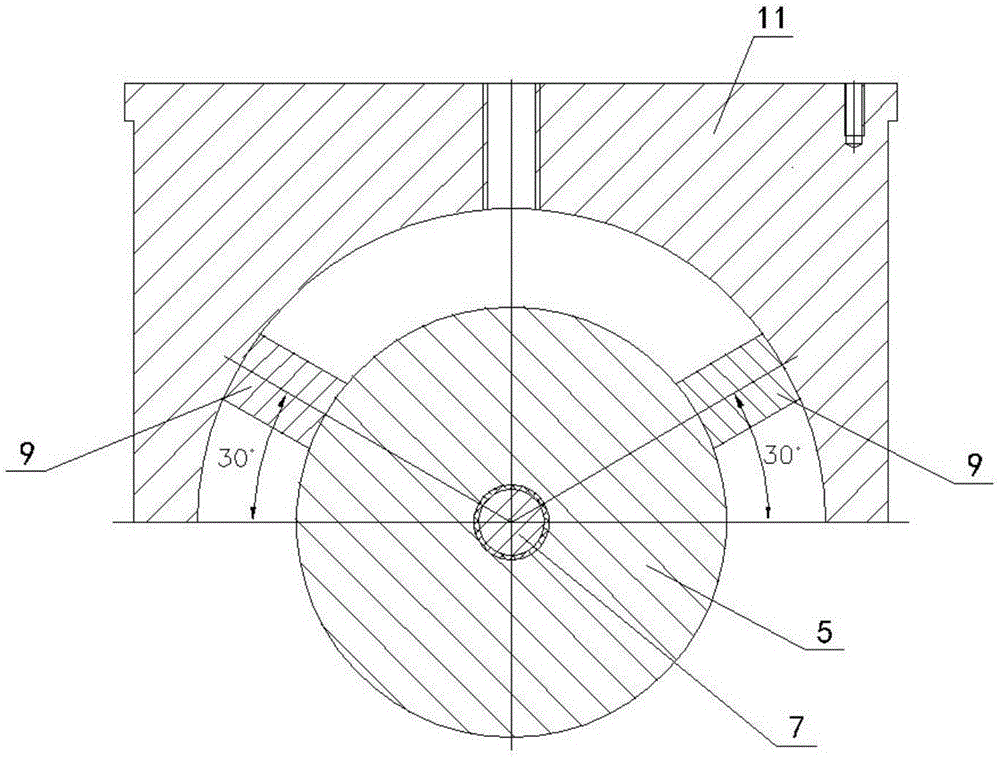

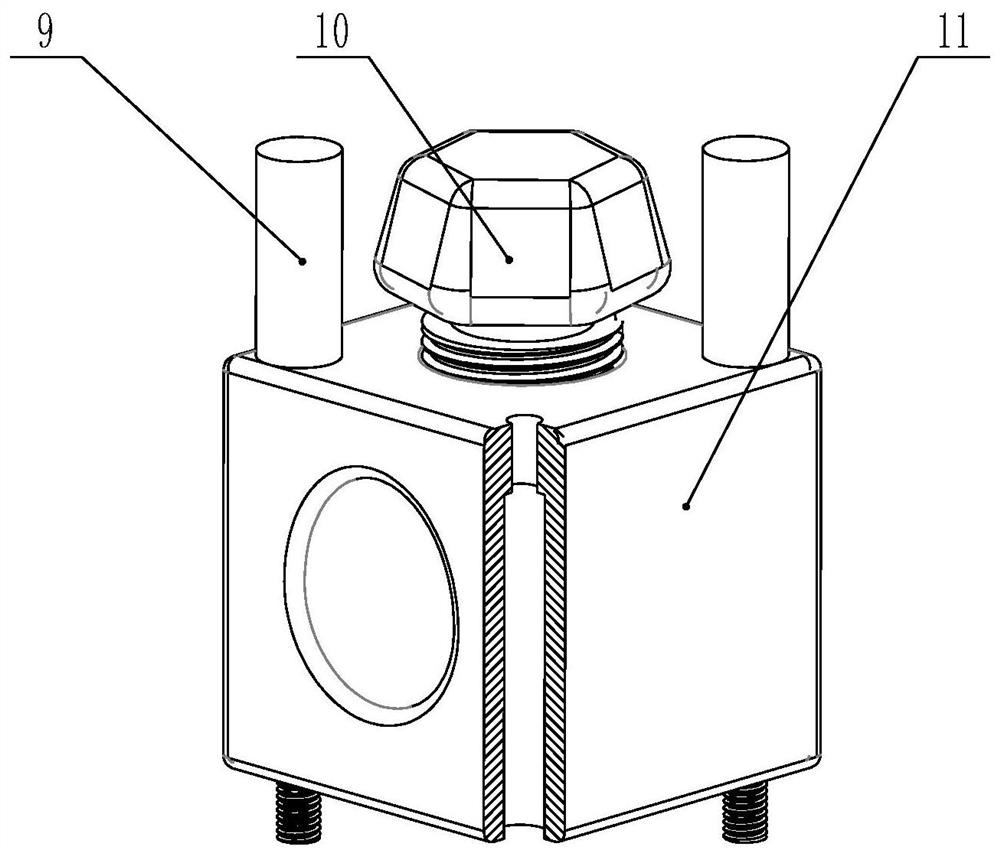

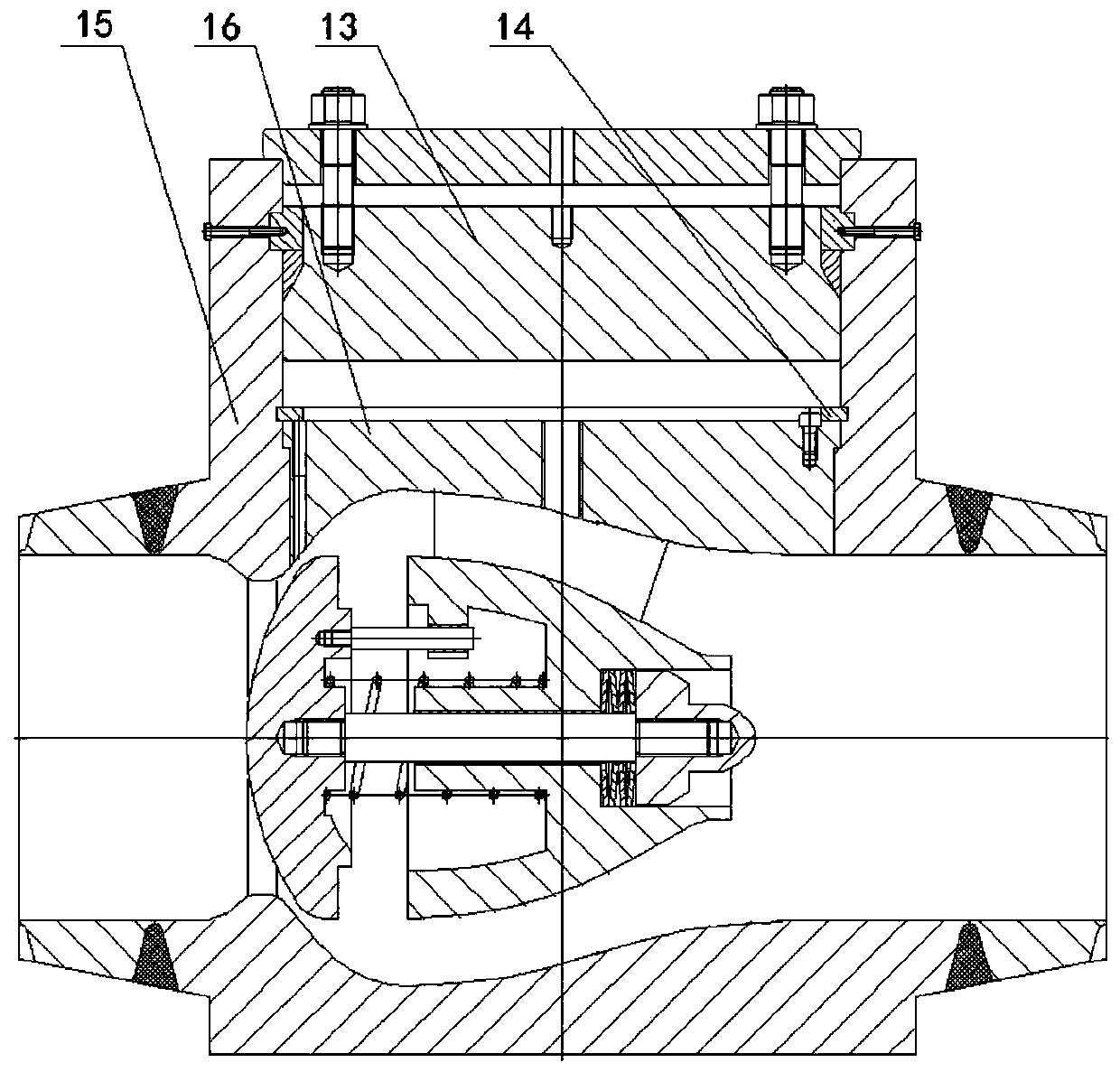

Online maintainable axial flow check valve

ActiveCN106838386ARemarkable resultsRealize online maintenanceCheck valvesValve members for absorbing fluid energyCheck valve

The invention discloses an online maintainable axial flow check valve which is characterized in that a top opening is formed in the top of a valve body, a valve spool component is placed into the valve body from the top opening, a valve cover is arranged at the top opening of the valve body to seal the valve body, a valve spool of the valve spool component is suspended on a valve spool support by a supporting rib, and the valve spool support is fixedly clamped at the top opening of the valve body by the aid of a valve spool fixing clamp ring. The online maintainable axial flow check valve is low in flow resistance and noise, and can realize online maintenance.

Owner:HEFEI GENERAL MACHINERY RES INST

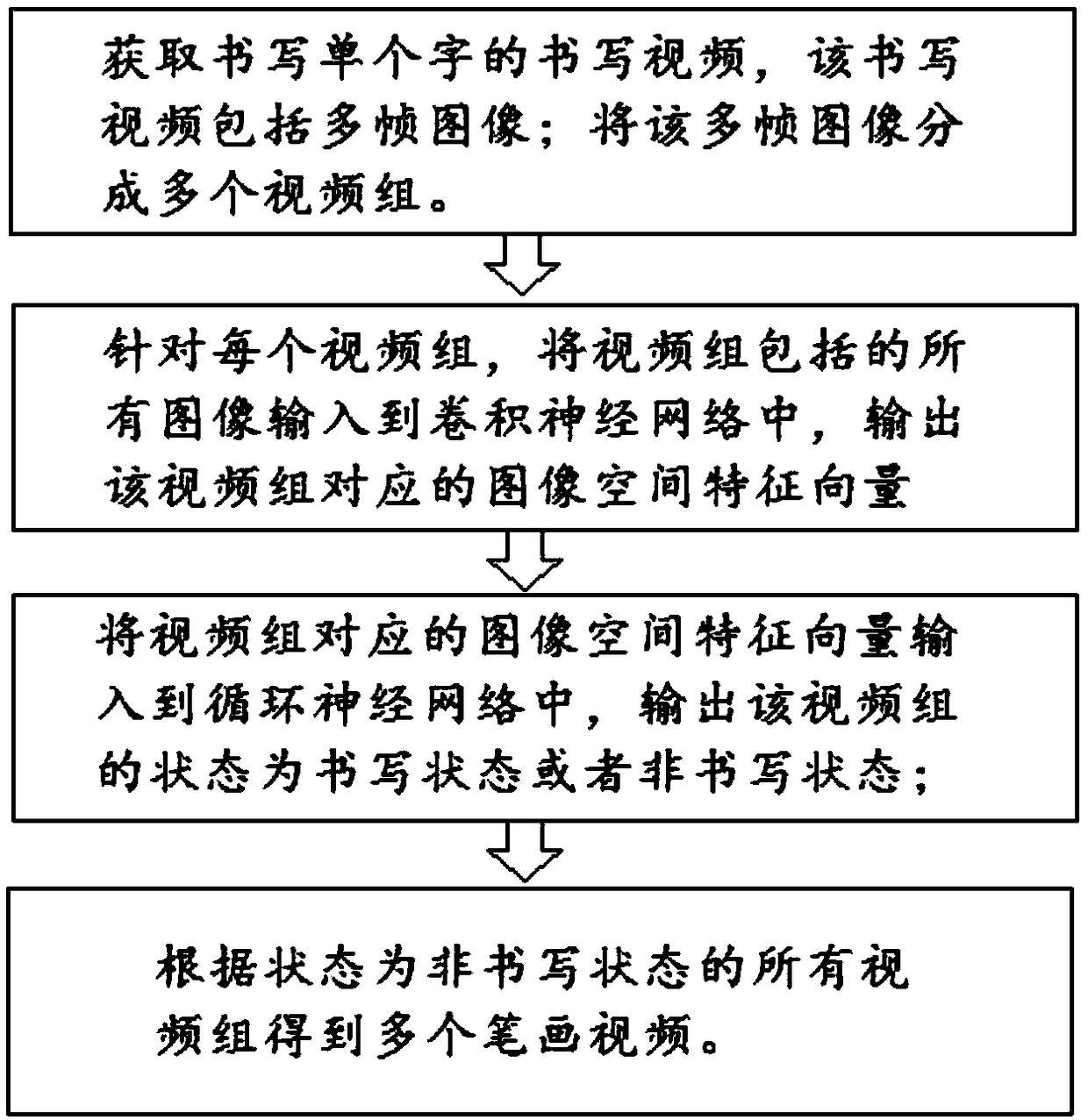

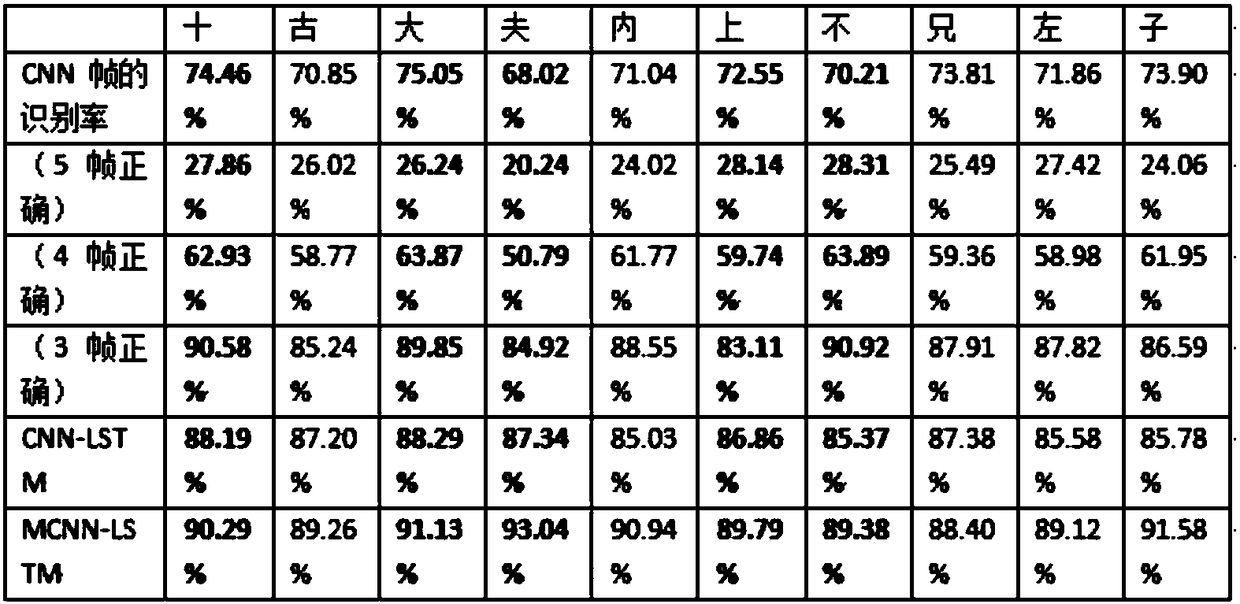

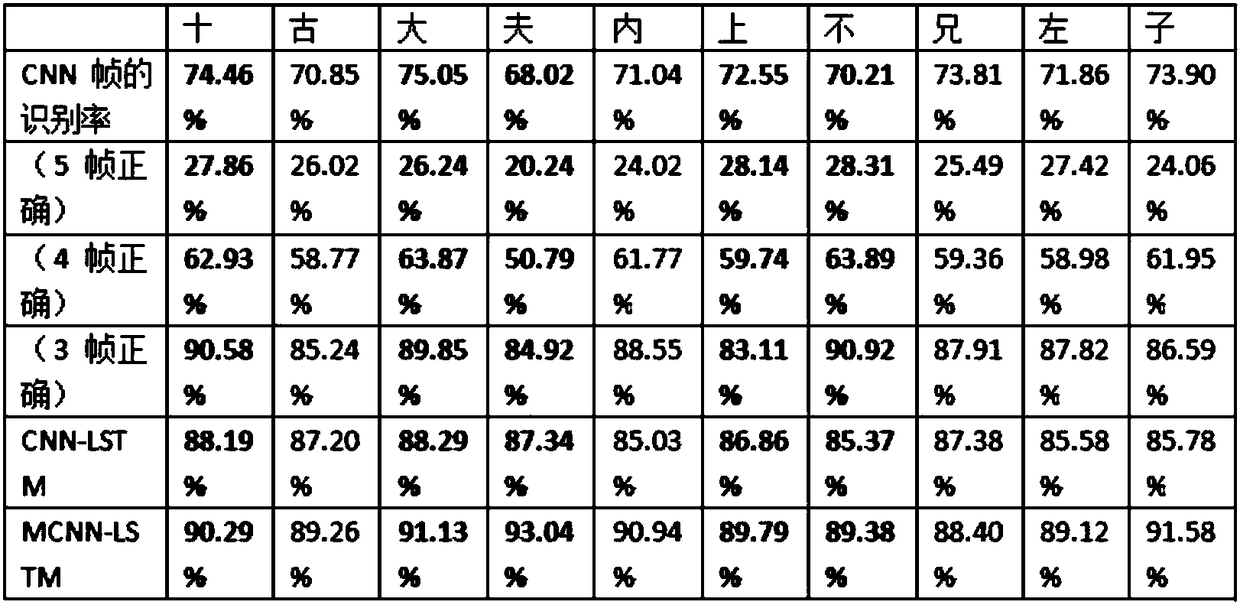

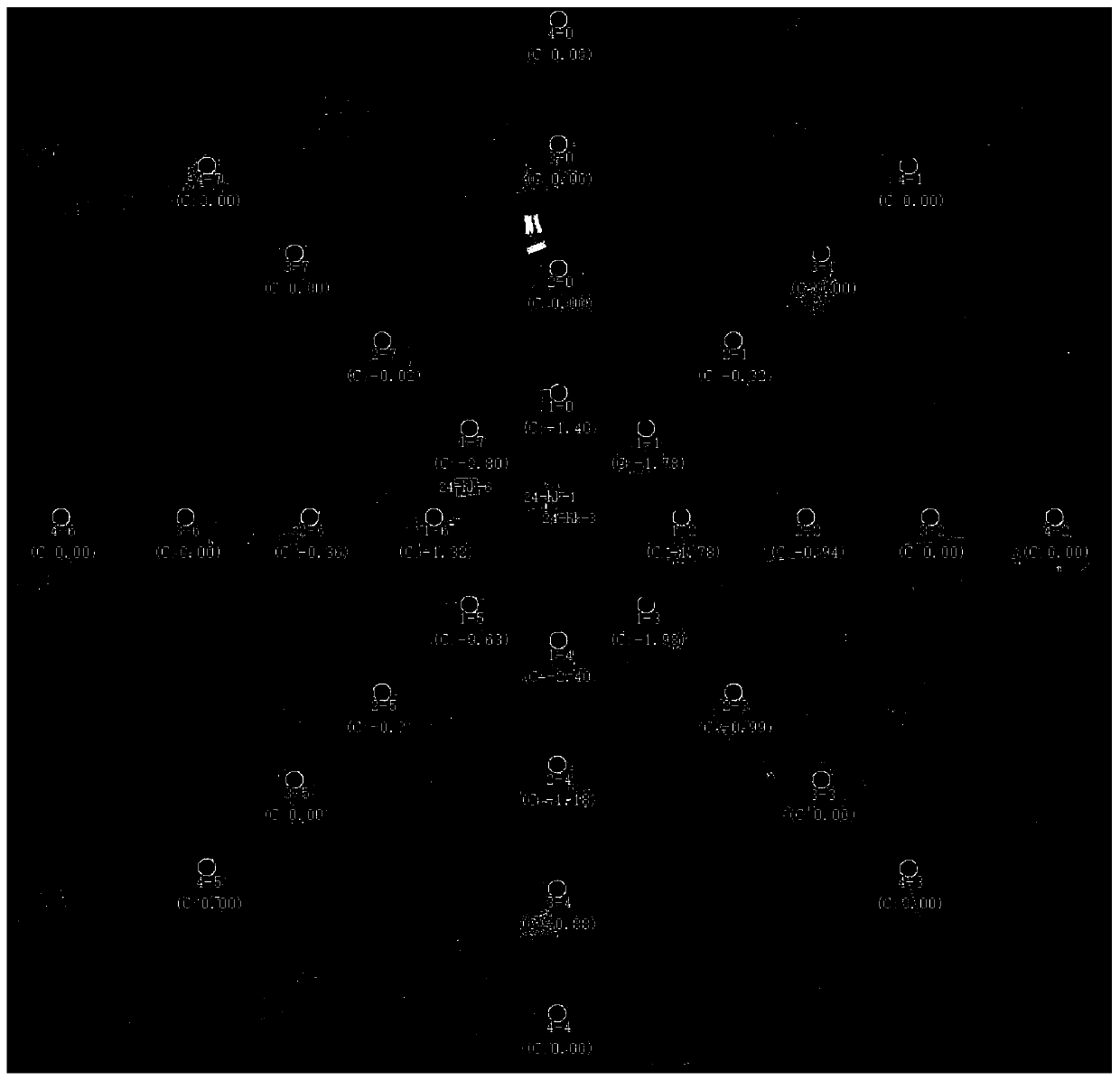

Stroke segmentation method based on writing video and calligraphy copying guiding method

InactiveCN108764070AFew parametersEnhance expressive abilityCharacter and pattern recognitionNeural architecturesTime domainComputer graphics (images)

The invention discloses a stroke segmentation method based on a writing video and a calligraphy copying guiding method. According to the stroke segmentation method based on the writing video, a convolutional neural network is redesigned, and the convolutional neural network is combined with a recurrent neural network, so that parameters of the neural network are greatly reduced, and the training speed is increased; and the expression capability of spatial characteristics of video frames is enhanced, and time domain motion information written by calligraphy words is extracted, so that high-accuracy fine-grained action recognition is achieved. According to the calligraphy copying guiding method, the stroke segmentation method based on the writing video is adopted; and by utilizing a stroke video obtained by stroke segmentation, a calligraphy copying process can be accurately guided.

Owner:NORTHWEST UNIV(CN)

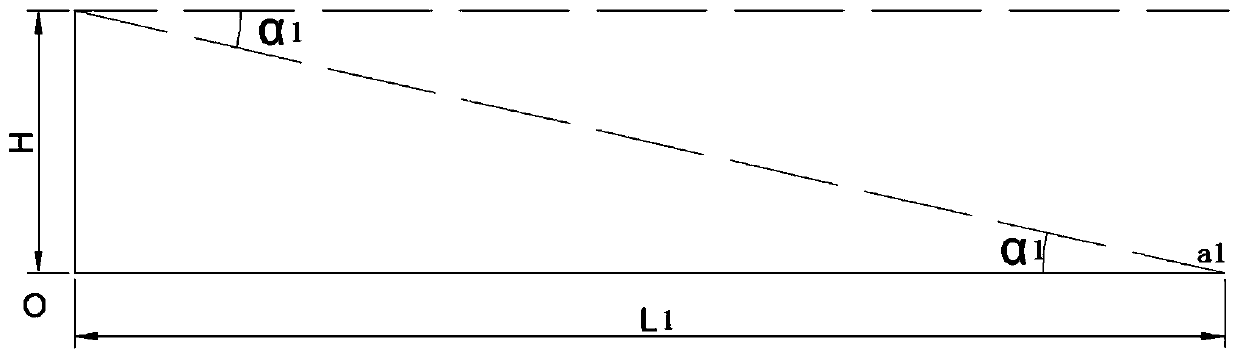

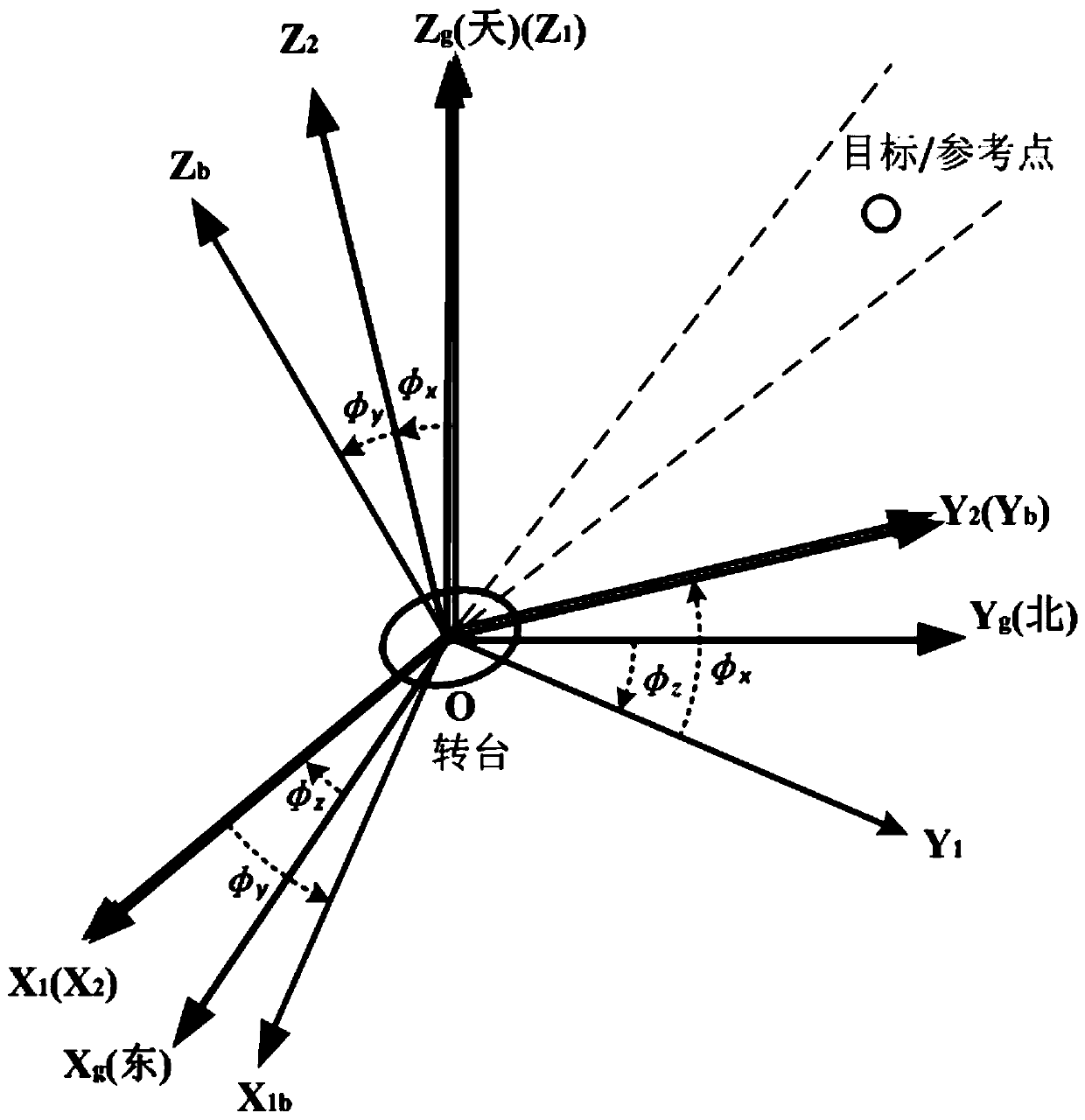

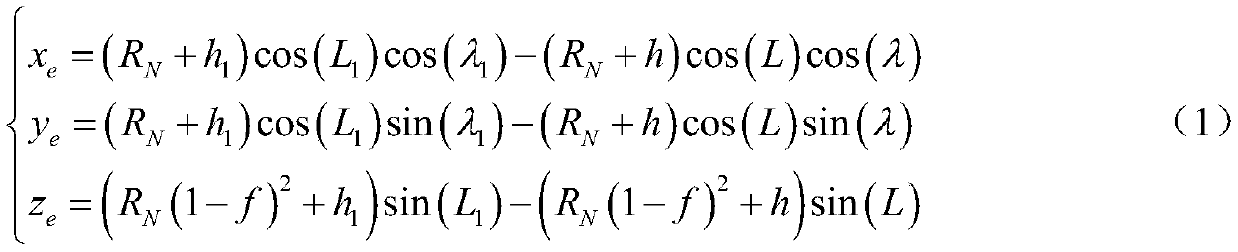

Pitching and azimuth calibration method for remote optical rotary table based on ground remote sensing image map

InactiveCN110274612AAchieve precise guidanceImprove operational efficiencyNavigation instrumentsClosed circuit television systemsComputer scienceHigh definition

The invention discloses a pitching and azimuth calibration method for a remote optical rotary table based on a ground remote sensing image map, and belongs to the field of monitoring. The invention aims at a condition that a servo rotary table optical monitoring device is difficult to quickly guide to align with a target position. The method comprises the following steps: configuring a high-definition satellite ground image map of a monitored area; adding the installation position and the installation height of the servo rotary table optical monitoring device to the high-definition satellite ground image map; establishing a 360-degree equant azimuth distance data matrix based on the installation position of the servo rotary table optical monitoring device; calibrating pitching data of the servo rotary table optical monitoring device of each unit of the azimuth distance data matrix to finish calibration; clicking any position according to the map, calculating azimuth, pitching and distance parameters for guiding the servo rotary table optical monitoring device through a matrix difference to which a position point belongs, and controlling the servo rotary table optical monitoring device to complete equipment control. The method achieves the accurate guidance of the servo turntable optical monitoring equipment by easily clicking a map.

Owner:DAQING ANRUIDA TECH DEV CO LTD +1

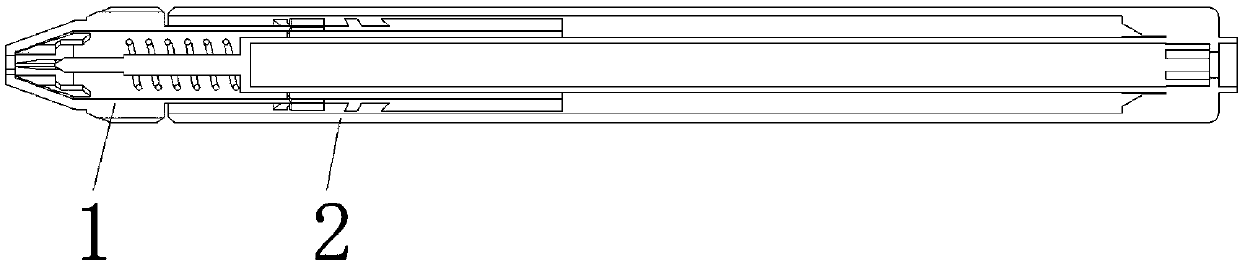

External rotary pulling-connecting pen

Owner:温州市简系文具有限公司

Radar optical device guiding error compensation method

InactiveCN110308437AAchieve precise guidanceQuality assuranceWave based measurement systemsGeographic coordinate systemAzimuth

The invention discloses a radar optical device guiding error compensation method. The implementation process is that a radar optical device is fixed on a turntable and the turntable is leveled to adjust the azimuth to a selected reference direction; one to two reference surface features are selected, a servo motion mechanism is controlled to align the foresight direction of the radar optical device with a reference point position, and a reference point surface feature is enabled to be located at the field of view center of the device; the position of the turntable, the longitude, latitude andheight of the reference point position, and the pitching azimuth angle of the servo mechanism are recorded to determine errors of the device relative to a geographic coordinate system; and error compensation is carried out on obtained guiding information. The method is used for the outfield test of radar optical device data acquisition; and compensation is carried out on the GPS guiding information through measuring error angles between turntable board coordinate systems and local geographic coordinate systems, so that accurate guiding for the radar optical devices is realized and the qualityof the acquired data is ensured.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

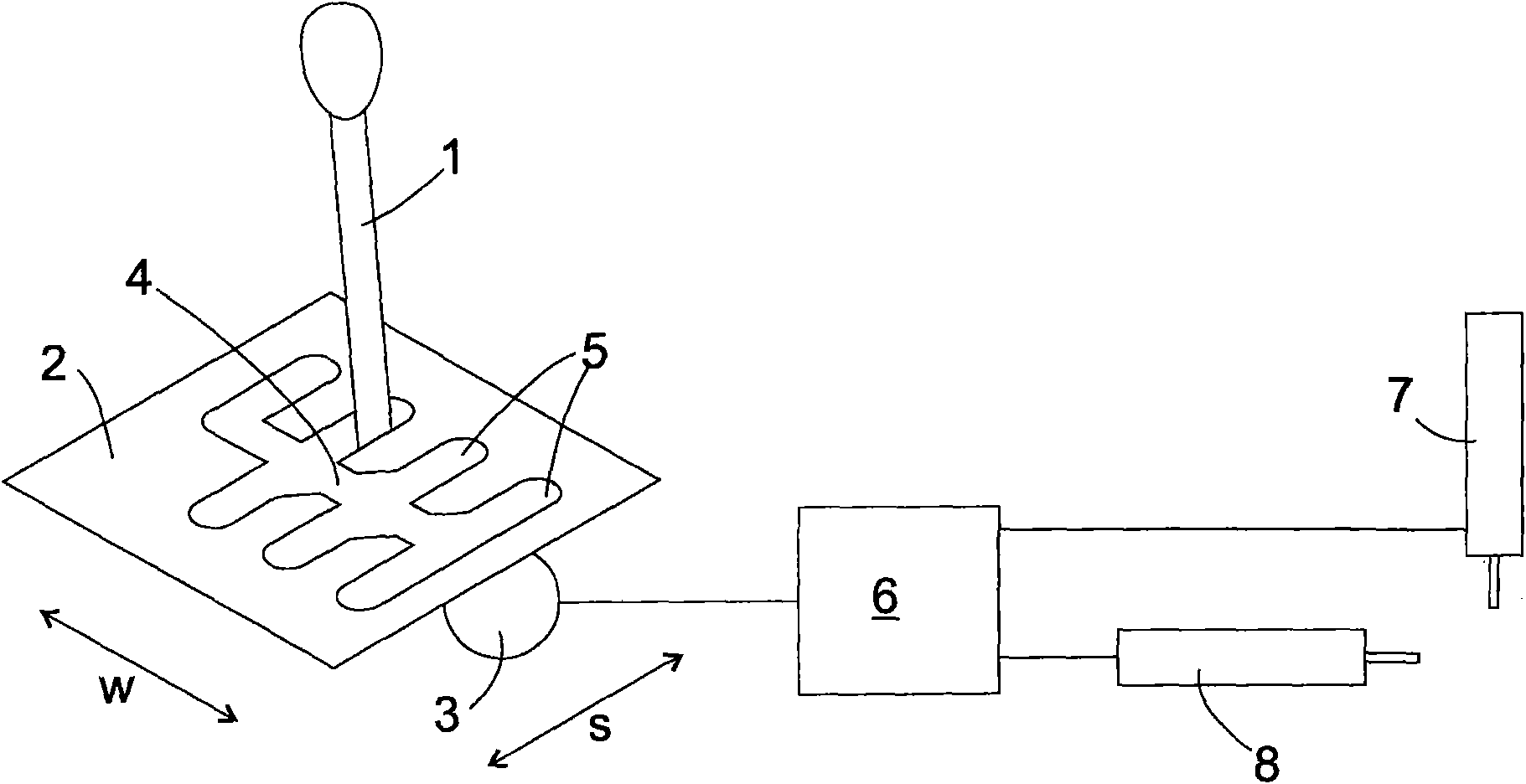

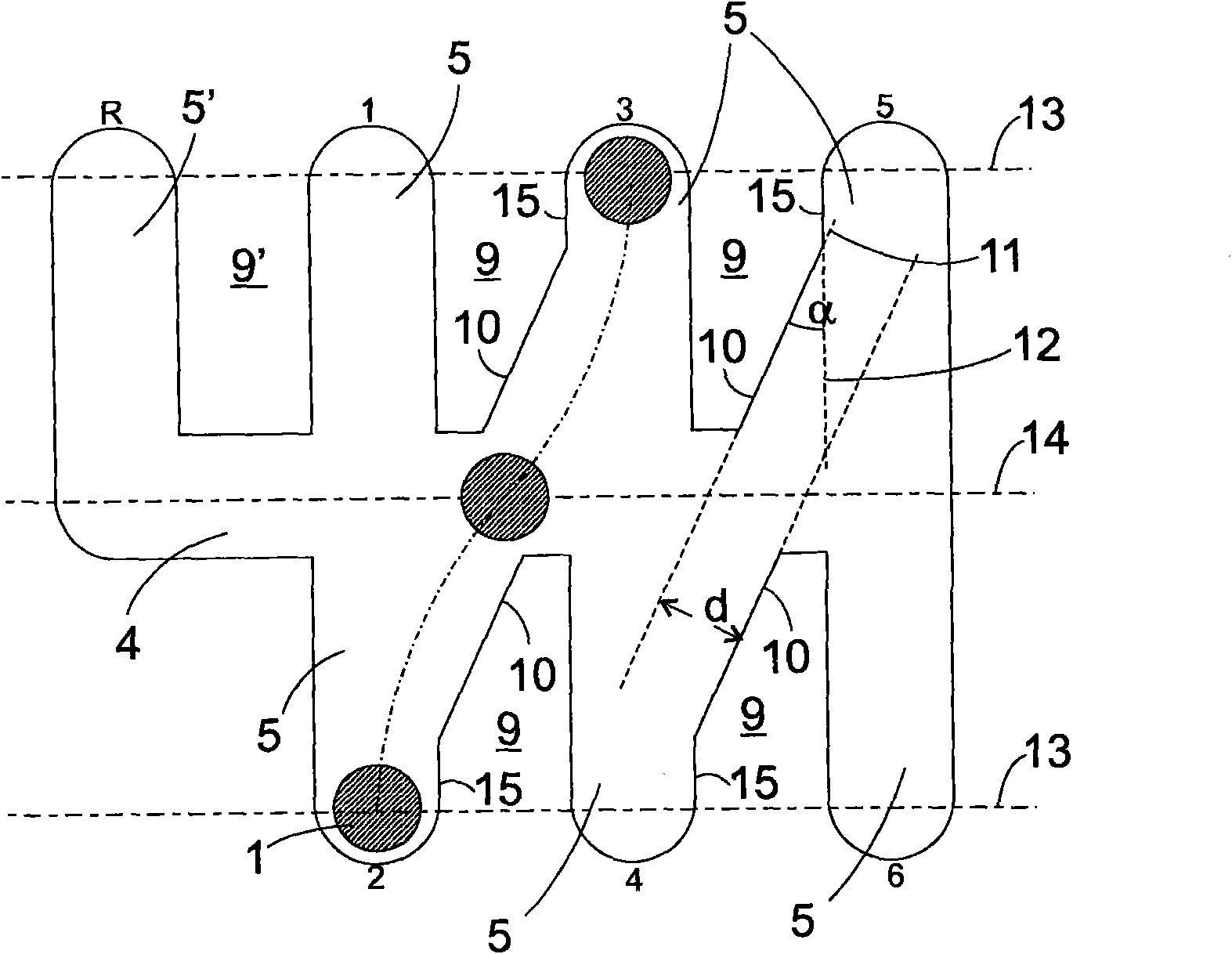

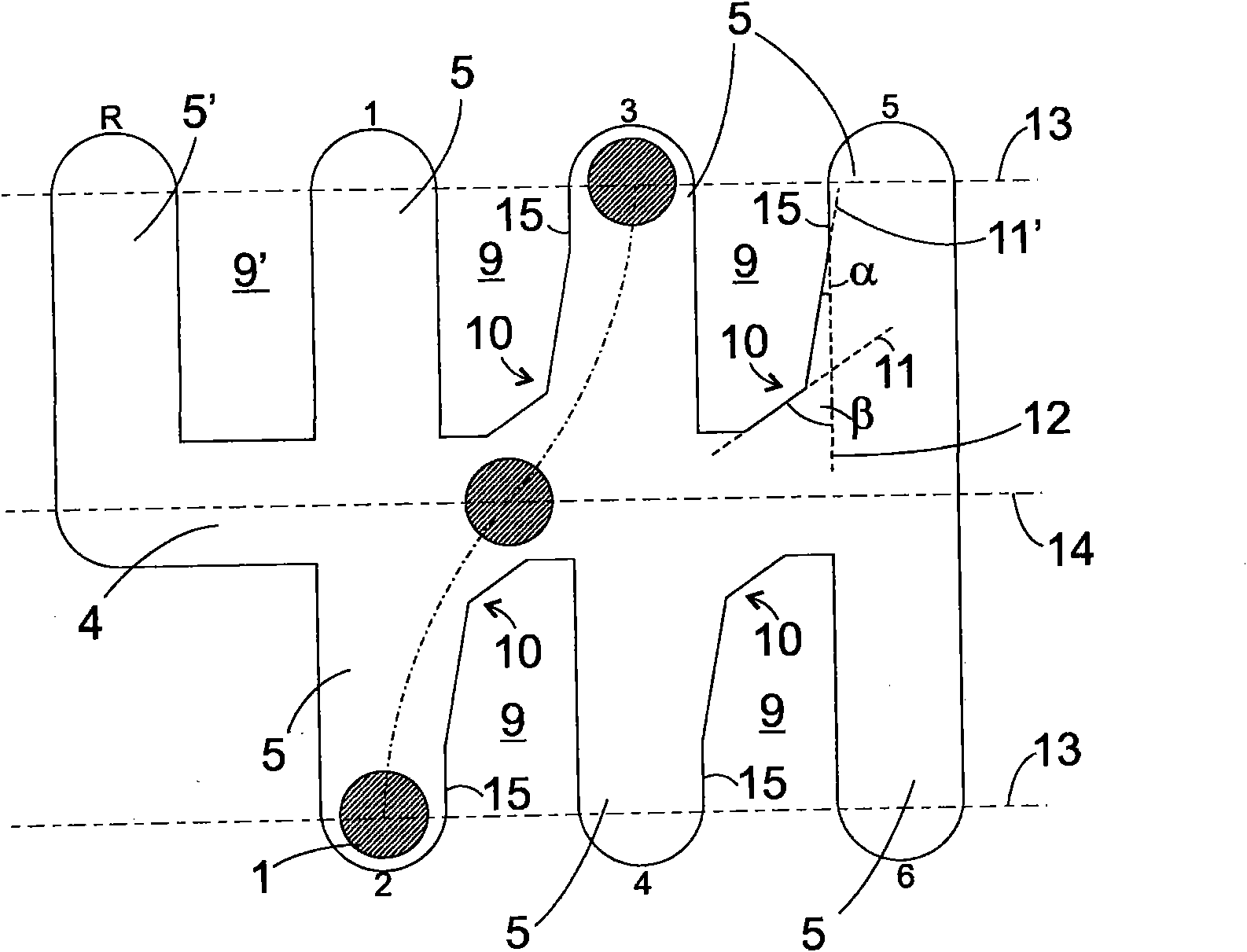

External gear shift for a manual transmission

An external gear shift for the gear selection in a manual transmission is provided that includes, but is not limited to a gearshift / selector lever, which is guided in a link plate and which is movablealong a selector track and a plurality of shifting tracks, and a measuring sensor to detect an instantaneous position (s, w) of the gearshift / selector lever. Guide fingers of the link plate disposedbetween shifting and selector tracks each have flanks oriented obliquely to the shifting and selector tracks.

Owner:GM GLOBAL TECH OPERATIONS LLC

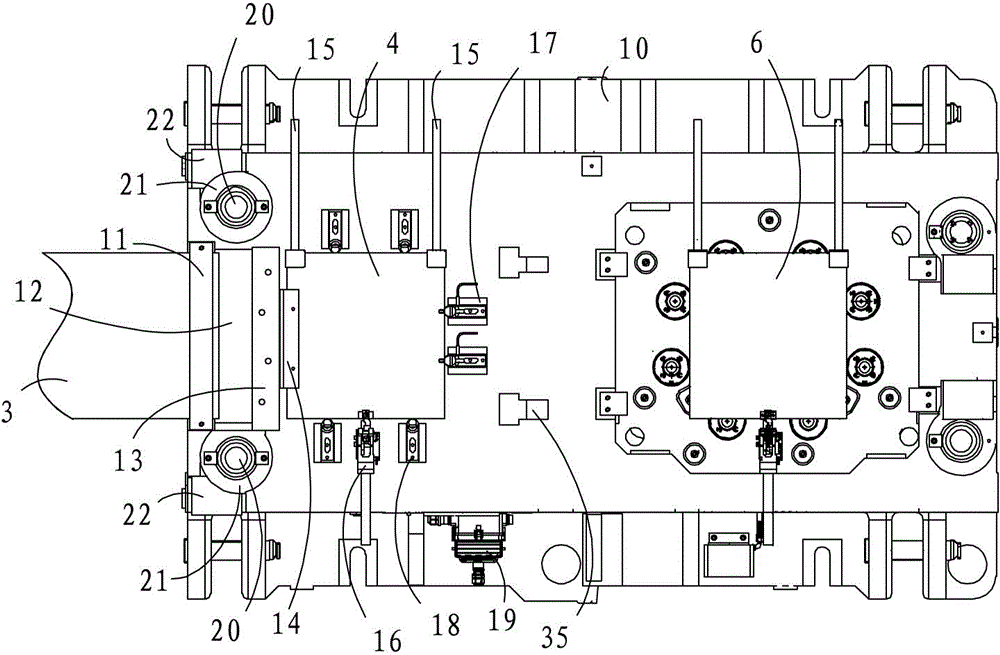

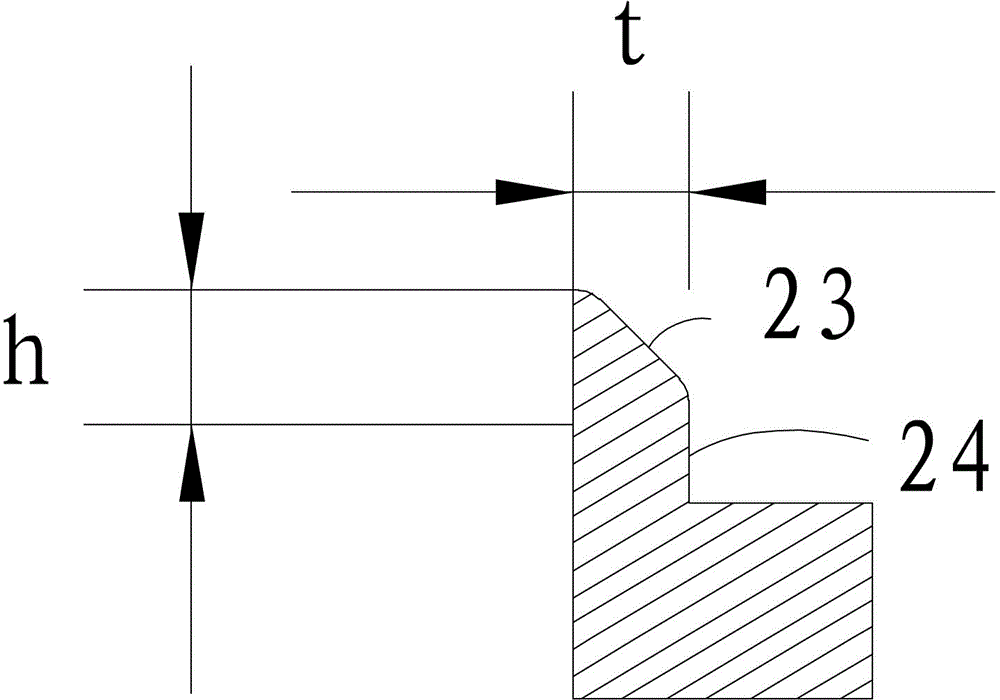

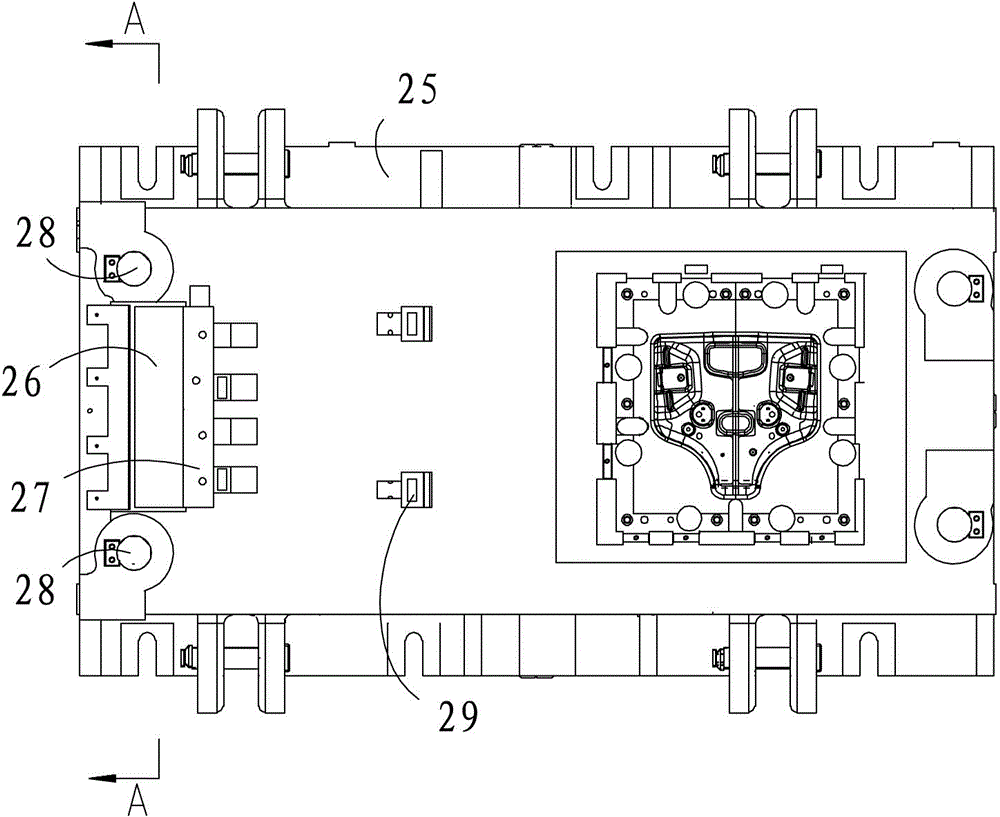

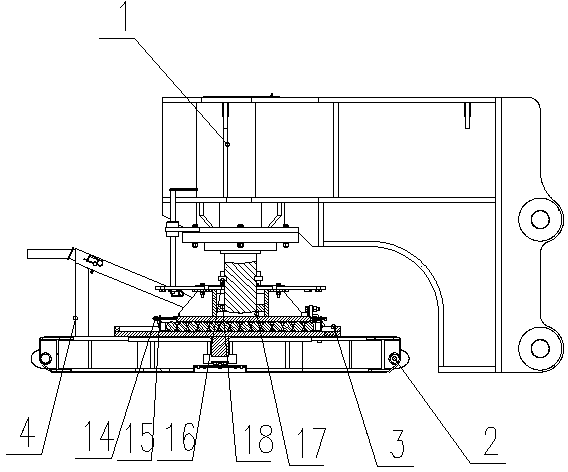

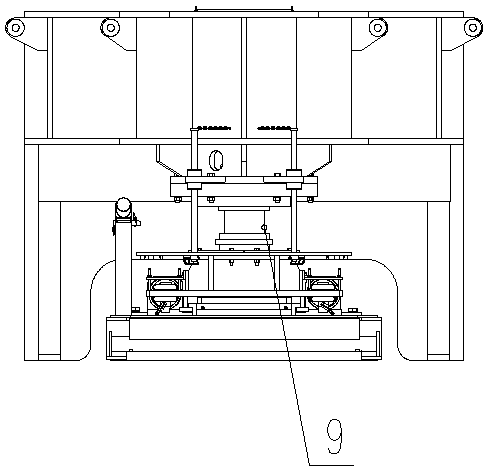

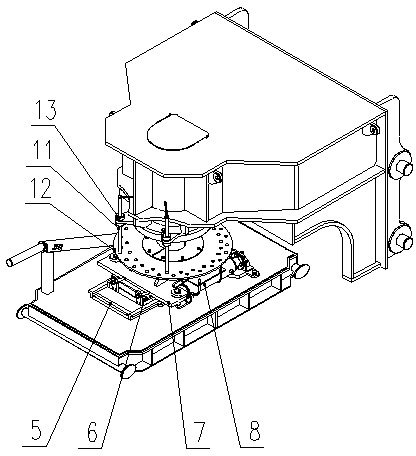

Uncoiling and blanking die and multi-station machining device

ActiveCN106140933AConvenient pick-up operationPrecise positioningShaping toolsMetal-working feeding devicesPunchingEngineering

The invention provides an uncoiling and blanking die. The uncoiling and blanking die comprises a lower die base and an upper die base which is located above the lower die base and matched with the lower die base for punching. A lower die deburring insert and a supporting plate located on one side of the lower die deburring insert are arranged on the lower die base. A pressing core is arranged on the portion, corresponding to the lower die deburring insert, of the upper die base. An upper die deburing insert is arranged on one side of the pressing core in an attached mode. A guide positioning plate is arranged on the lower die base and located between the lower die deburring insert and the supporting plate. An oblique guiding plane which is in smooth connection with the top end face of the lower die deburring insert, and a vertical positioning plate which is in smooth connection with the bottom of the guiding plane are formed at the top of the guide positioning plate. The bottom of the positioning plane intersects with the horizontal top end face of the guide positioning plate. The invention further provides a multi-station machining device provided with the uncoiling and blanking die. According to the uncoiling and blanking die, accurate positioning can be conducted during coil stock blanking, and workpieces can be taken conveniently after being blanked.

Owner:GREAT WALL MOTOR CO LTD

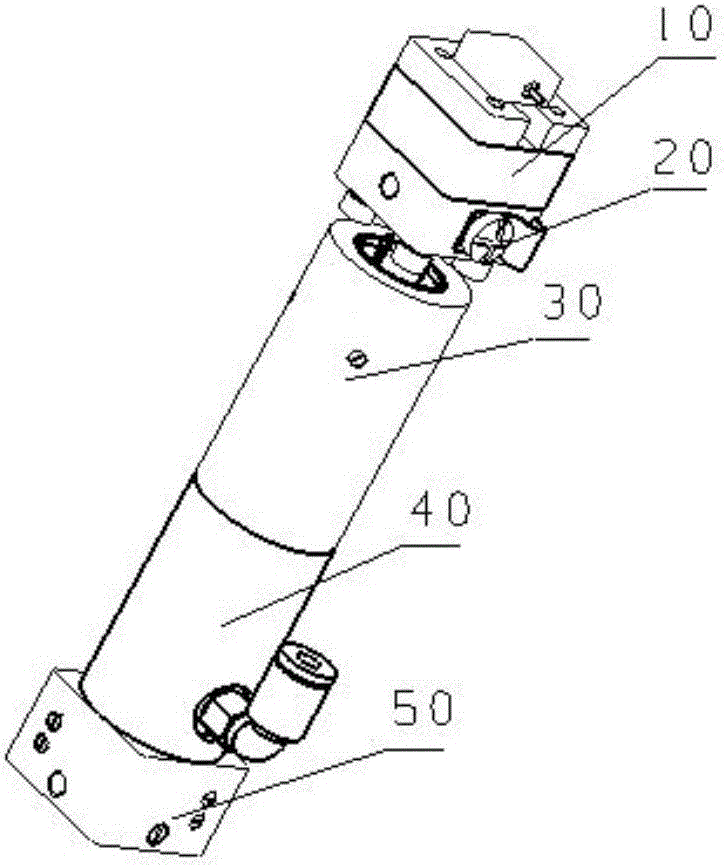

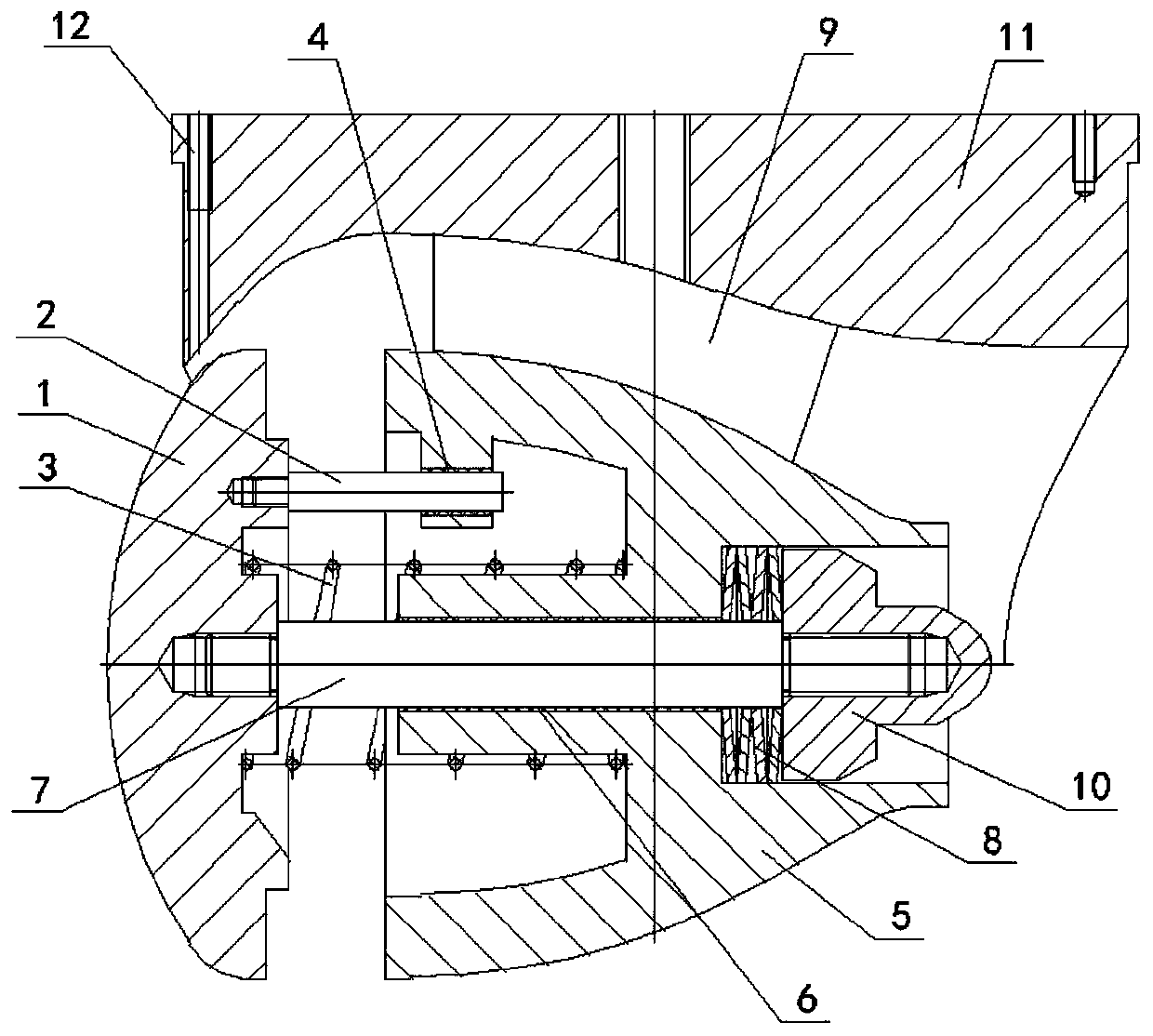

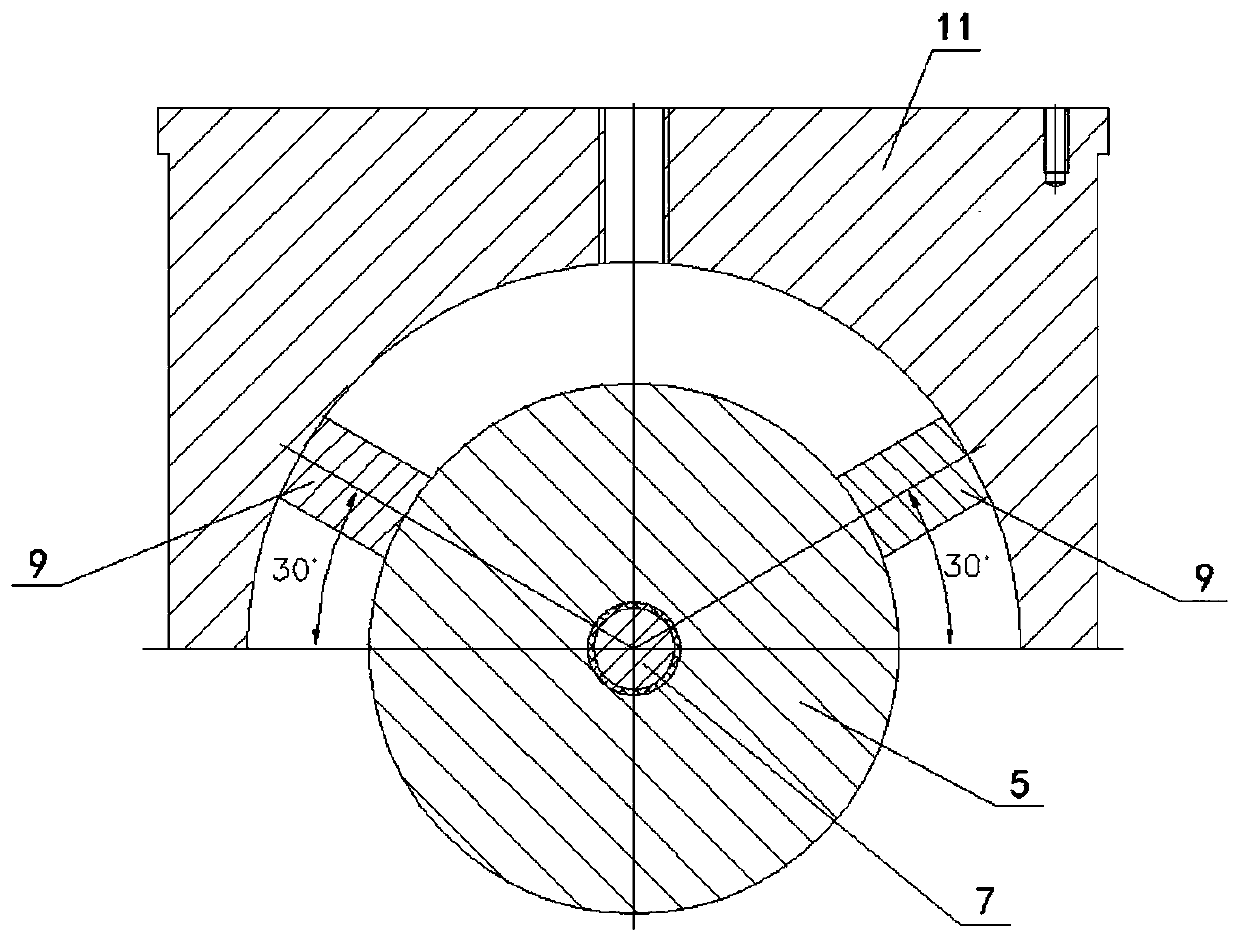

Roller row type omni-directional drilling rig whole step-by-step moving device

ActiveCN104373051ARotate in placeImprove adaptabilityDerricks/mastsDrilling machines and methodsOmni directionalSubstructure

Provided is a roller row type omni-directional drilling rig whole step-by-step moving device. A support is fixed to a cluster well rig substructure through connecting pin shafts, and a reversing rotating mechanism and a trolley are installed on a skid. The trolley is composed of a tray, an upper trolley base, a roller row and horizontal movement oil cylinders. The roller row is formed by installing 14 rollers on a frame, the horizontal movement oil cylinders are connected with the upper trolley base through pin shafts, piston rods of the horizontal movement oil cylinders are connected with the tray through bolts, guide rolling wheels are installed on the two sides of the front end of the upper trolley base, lug plates are installed at the two ends of the roller row, the roller row is connected with the upper trolley base through an adjusting rod, the trolley is connected with a jacking oil cylinder through a spherical surface tray and a clamping plate set, the jacking oil cylinder is installed on the support through bolts, and the spherical surface tray is installed on the upper trolley base. A limiting ring is installed on the spherical surface tray. Through the roller row type omni-directional drilling rig whole step-by-step moving device, on-site rotation of a whole drilling rig can be achieved, well site adaptability of the moving device is improved, the same moving device can be shared by multiple drilling rigs, and investment is saved.

Owner:中石化四机石油机械有限公司 +1

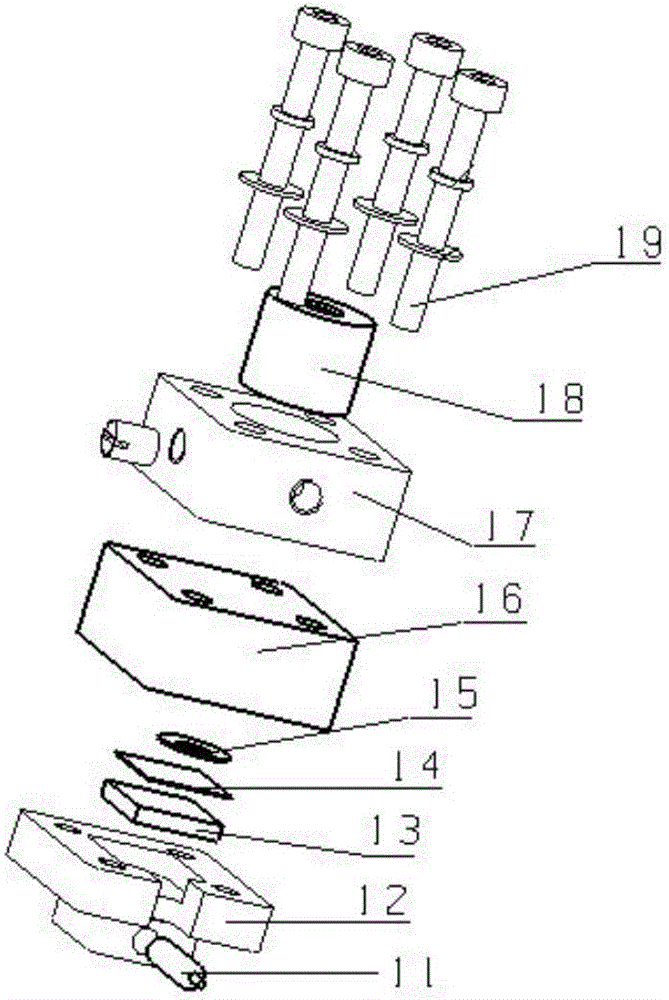

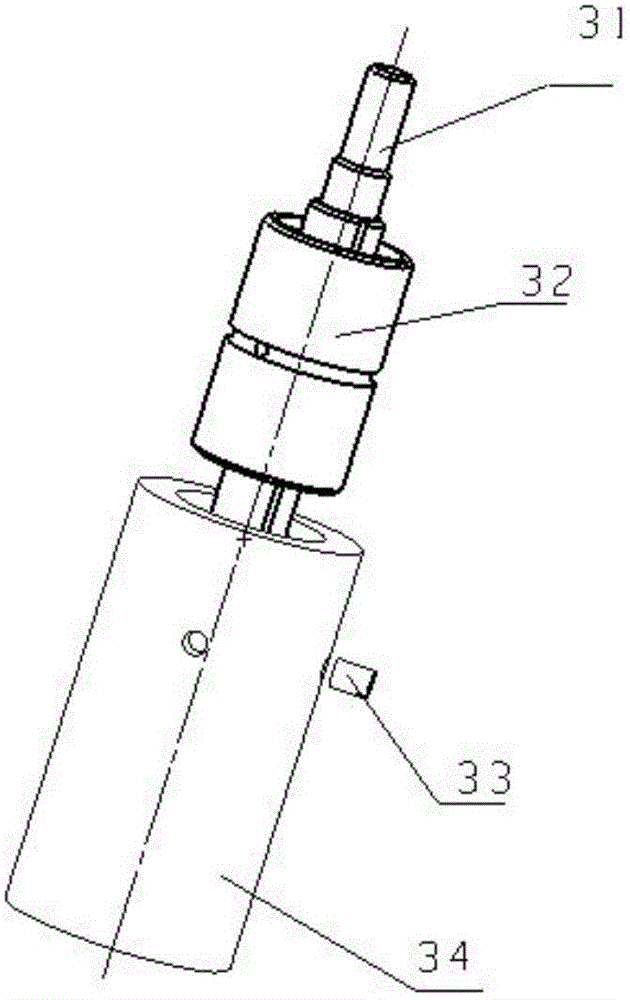

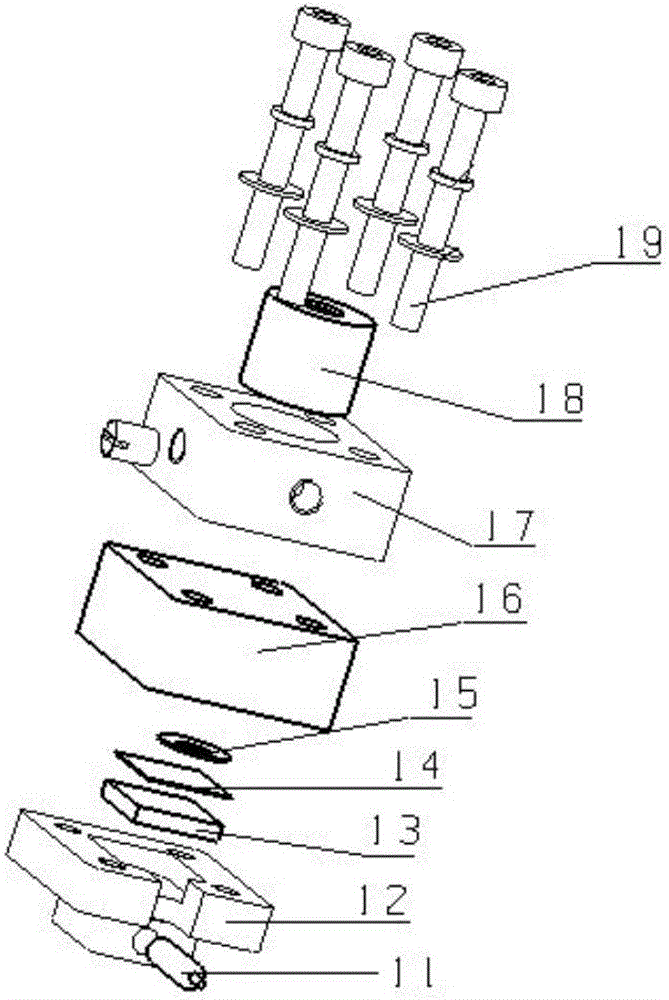

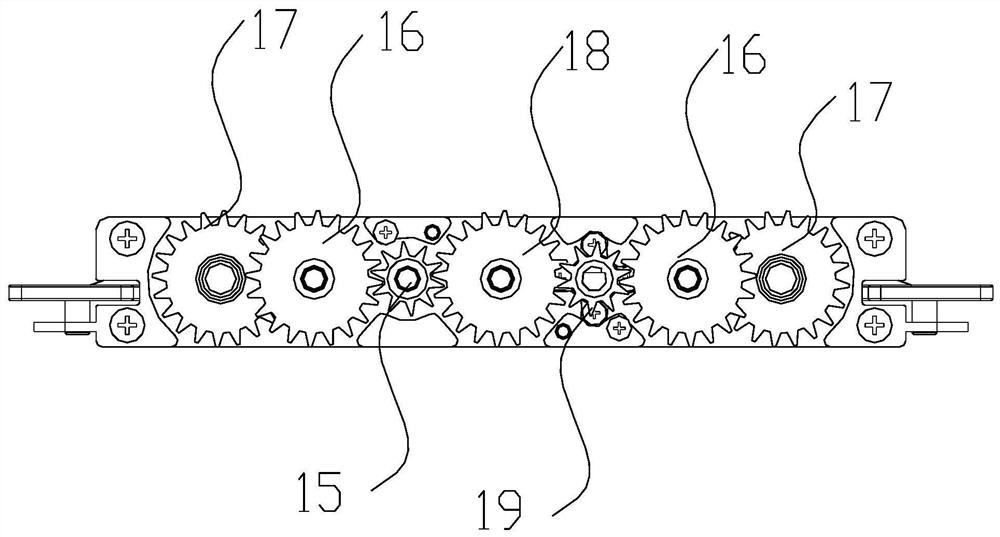

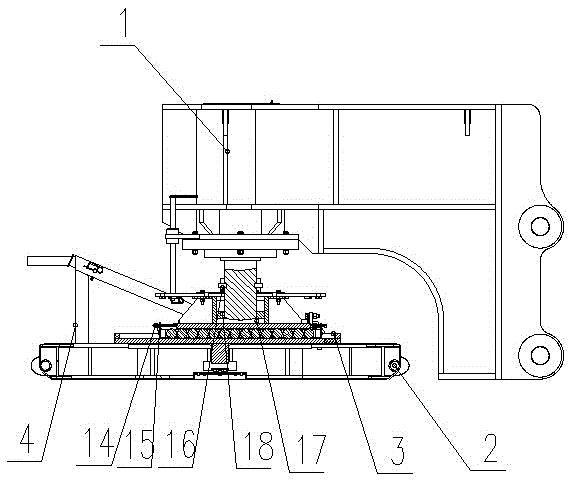

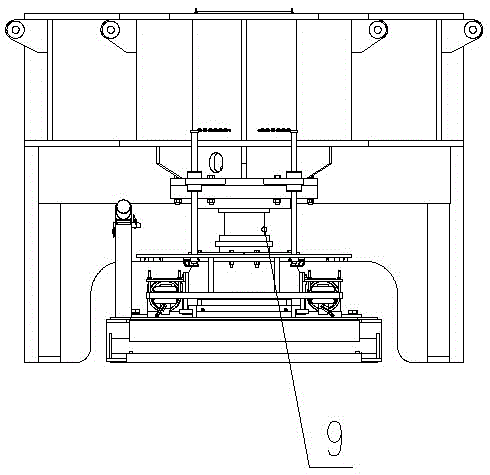

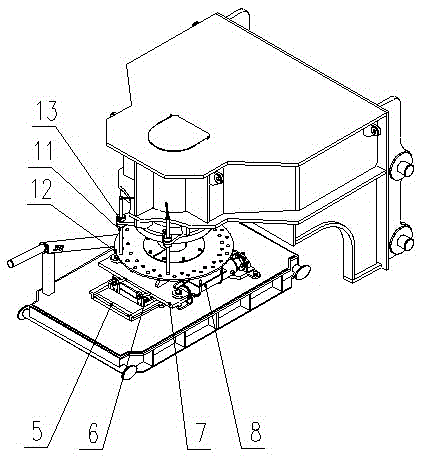

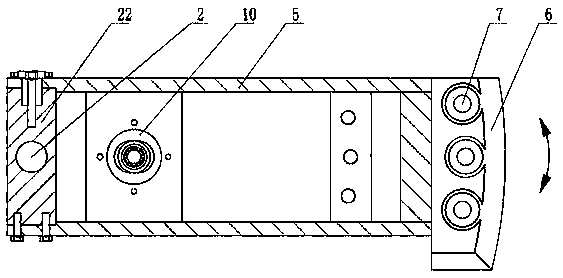

Punch die indexing mechanism of numerical control punch press

InactiveCN103599996ANo frequent replacementAchieve precise guidanceShaping toolsNumerical controlPunch press

A punch die indexing mechanism of a numerical control punch press comprises a rack. A rotating shaft is mounted on the rack through a bearing device, the rotating shaft is in rotating connection with an upper die frame, a pressing plate frame and a lower die frame from top to bottom in sequence, a punch die seat is fixedly mounted at the tail end of the lower die frame, a plurality of punch dies are mounted on the punch die seat, corresponding punching rods are arranged at the positions, directly facing the punch dies, of the upper die frame, and the punching rods are fixedly mounted on a fixing seat at the tail end of the upper die frame. A movable plate is fixedly connected on the bottom of the lower die frame, the piston rod of a longitudinal shifting oil cylinder is mounted in a mounting hole of the movable plate through bearings, and the shifting oil cylinder is fixedly connected on the rack. A locating plate is fixedly connected on the upper die frame, the locating plate is provided with an arc-shaped groove, a locating column is in sliding connection with the arc-shaped groove of the locating plate, and the locating column is fixedly connected on the rack. One end of a piston rod of a pressing plate oil cylinder is hinged to the pressing plate frame, and the cylinder body of the pressing plate oil cylinder is fixed on the upper die frame. The punch die indexing mechanism of the numerical control punch press can meet hole punching requirements of different hole diameters, and is simple in structure, convenient to operate, and stable in operation.

Owner:WUXI HUALIAN PRECISION MACHINERY

A kind of hot pressing head and hot pressing device

The invention discloses a hot-press device. The hot-press device comprises a hot-press head pair, a hot-press head pressure control system and a hot-press head temperature control system, wherein the hot-press head pair comprises an upper hot-press head and a lower hot-press head; the hot-press head pressure control system is connected with a power assembly of the lower hot-press head by an air pipe and is used for providing gas with stable pressure to the power assembly by closed loop feedback pressure control, and heating assemblies are driven to do reciprocating linear movement by the power assembly under the action of the pressure gas; and the hot-press head temperature control system is electrically connected with a first heating assembly of the upper hot-press head and a second heating assembly of the lower hot-press head, and is used for stabilizing the temperatures of the heating assemblies by closed loop feedback temperature control. According to the hot-press device, the power assemblies of the hot-press heads are connected into a control air path in parallel, and the same air pressure is provided by the pressure control system, so that the pressure output from a plurality of hot-press heads can be consistent. The temperatures of the multiple hot-press heads are stabilized by the closed loop feedback temperature control, so that the problems of an existing hot-press head that the pressure is inconvenient to adjust, and the stability and the consistency of the pressure and the temperature are difficult to ensure can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

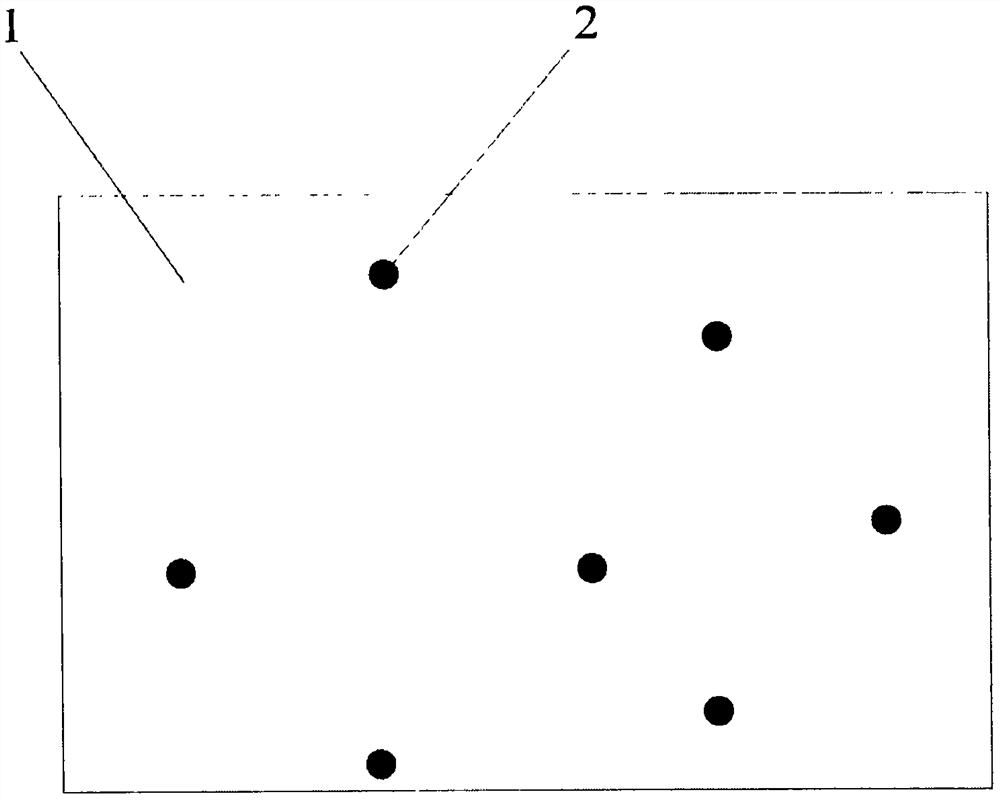

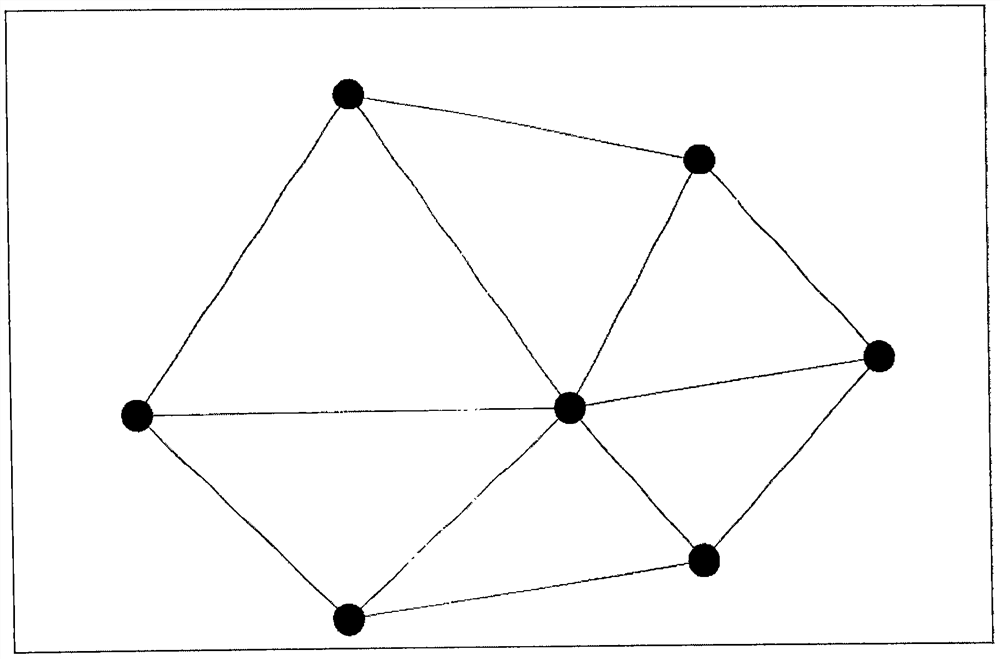

A tourist attraction tourist guiding method

PendingCN113918668AImprove operational efficiencyAchieve precise guidanceData processing applicationsCounting mechanisms/objectsRectangular coordinatesDisplay device

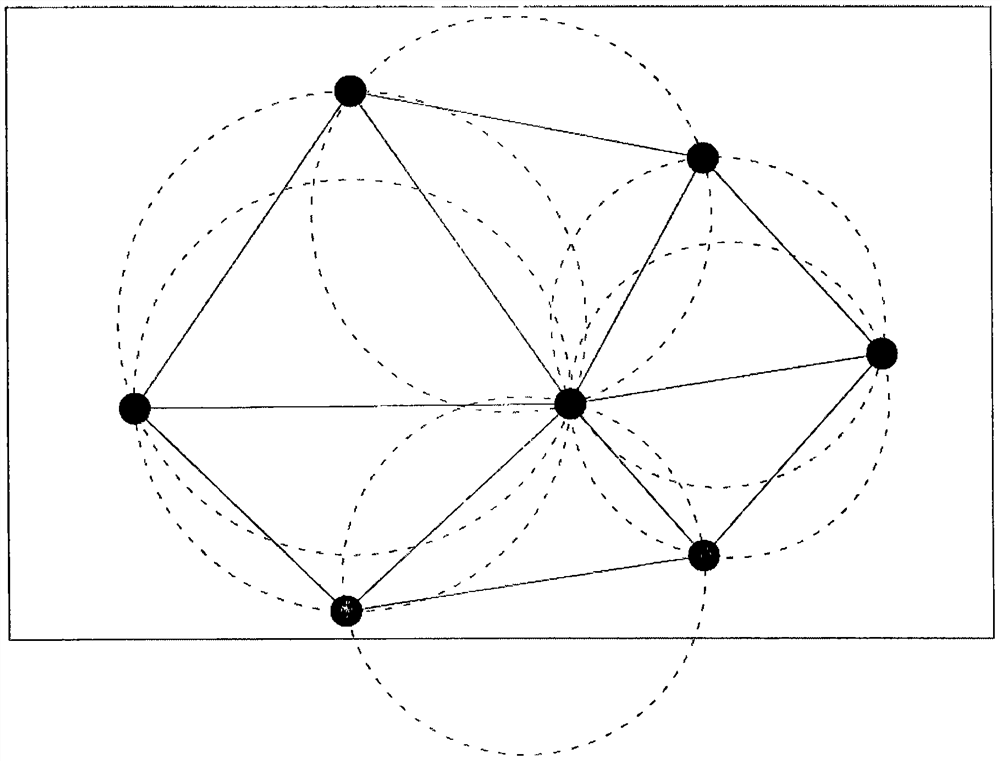

The invention relates to the field of tourist attractions, in particular to a tourist attraction people stream directing / guiding method. A tourist guiding method in a tourist attraction comprises a geographic position display device with a tourist attraction map, the position of a tourist is displayed on the tourist attraction map through the geographic position display device, a plurality of scenic spots are marked on the tourist attraction map, and the tourist guiding method comprises the following steps: building a rectangular coordinate system; drawing a Thiessen polygon of the scenic spot; taking the edge of each polygon in the Thiessen polygon as a detection line, setting an entrance and exit position on the detection line, and arranging a people flow statistical device; detecting the visitor flow at each entrance and exit in real time, and obtaining the number of people in the scenic spot area and feeding back to the geographic position display device. According to the invention, the geographic position display device with the scenic spot map is used for guiding the tourist, accurate guidance of the tourist is realized through reasonable planning of scenic spots in the tourist scene and statistics of the number of people, the operation efficiency of the scenic spot and the number of tourists which can be accommodated per day are improved, the playing time of the tourist per unit is reduced, and the economic benefit is improved.

Owner:朱乐敏

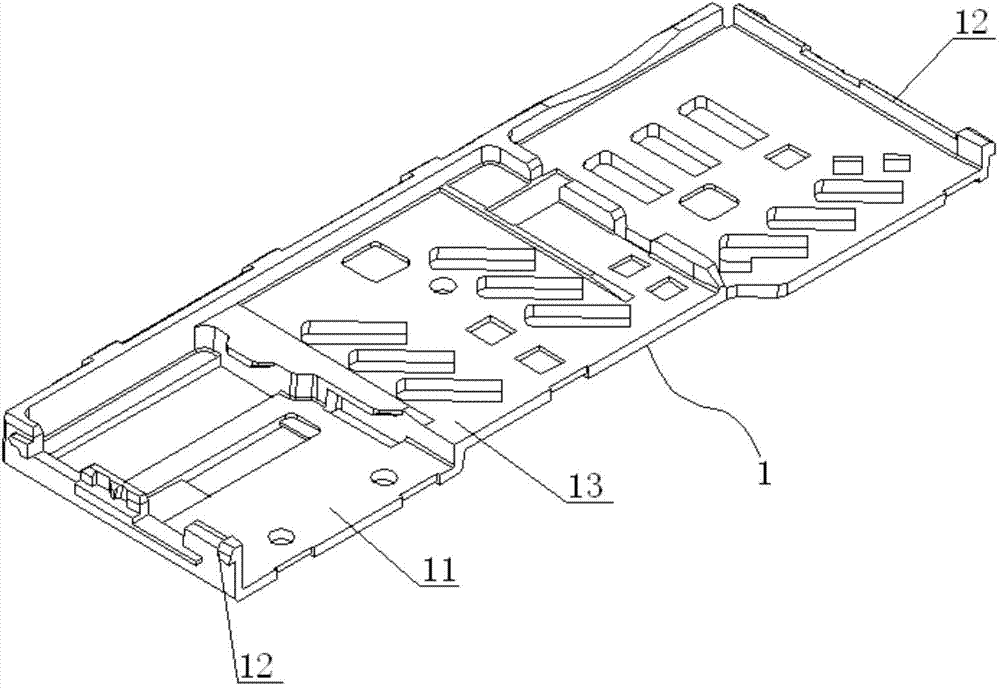

Card locking structure for card holder connector

InactiveCN104716504AHigh strengthEasy Guided InsertionCouplings bases/casesTelephone set constructionsEngineeringCard holder

The invention discloses a card locking structure for a card holder connector. The card locking structure for the card holder connector comprises an insulating bottom shell and a metal upper cover, wherein the insulating bottom shell comprises a bottom shell body and bottom shell side walls, the metal upper cover comprises an upper cover body, each of the two sides of the upper cover body is bent and extends to form an upper cover side wall, the upper cover side walls of the metal upper cover are combined with the bottom shell side walls of the insulating bottom shell to form an overlapped clamping groove with a card insertion opening, one upper cover side wall is bent and extends towards the middle of the overlapped clamping groove and penetrates through the upper cover side wall to form at least one guiding partition piece, and the overlapped clamping groove is divided into at least two card insertion grooves allowing cards to be inserted therein by the guiding partition piece. According to the card locking structure for the card holder connector, the approximate card insertion opening design can be achieved, a card is guided once the card is inserted, and thus the ideal requirement for blind insertion can be achieved; compared with a traditional card locking structure, the strength of the card locking structure can be greatly improved.

Owner:SUZHOU HANMAI ELECTRONICS

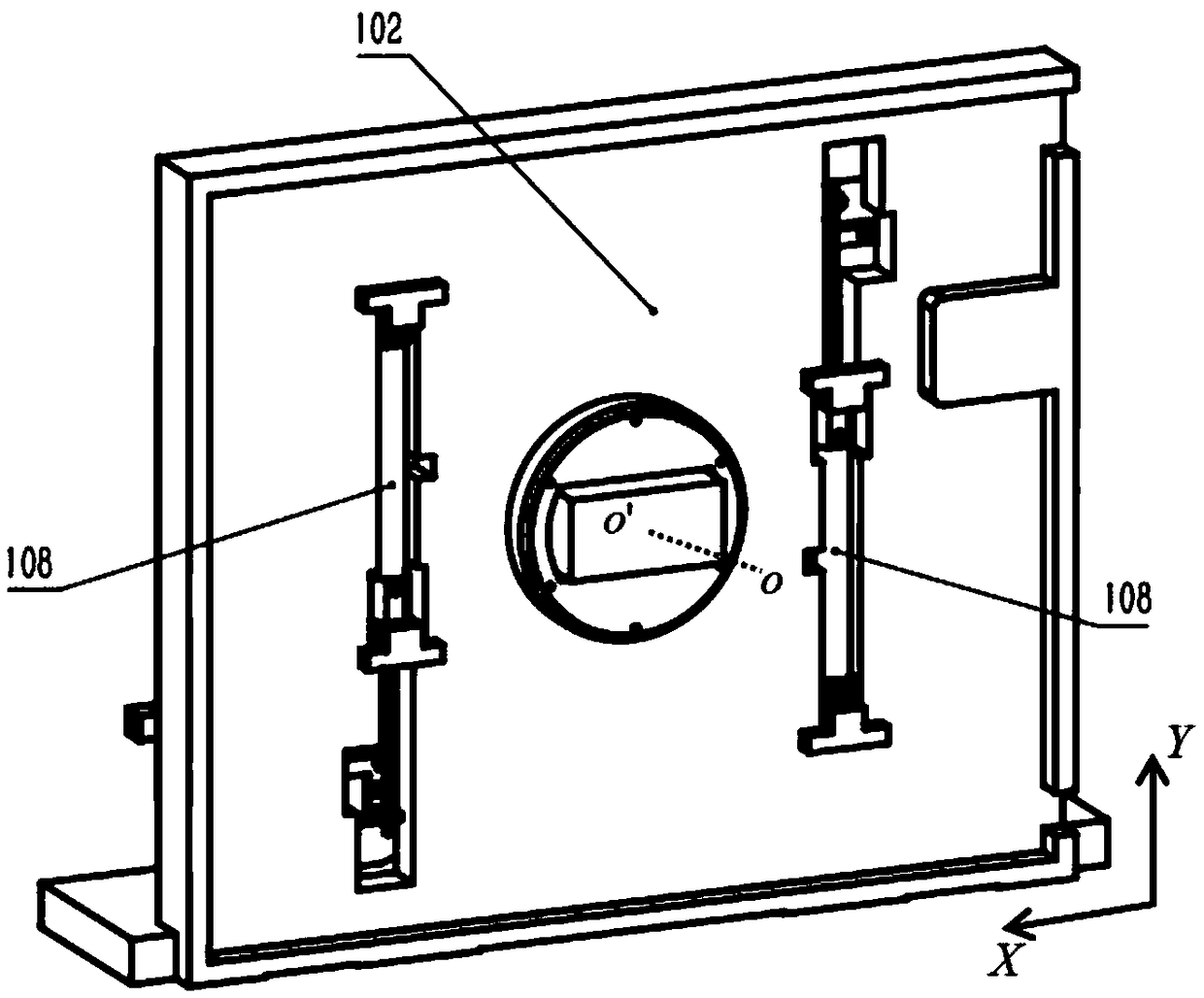

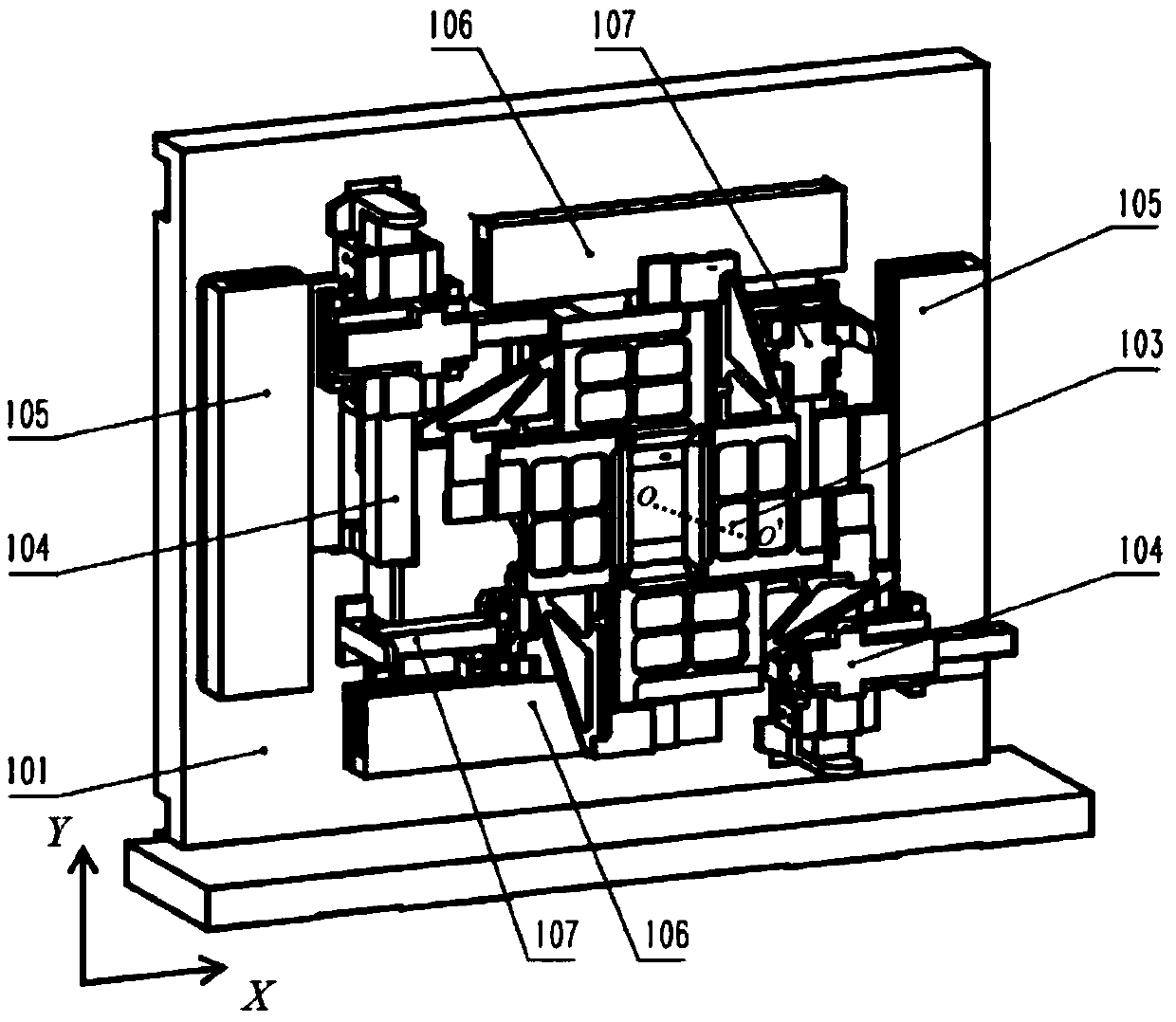

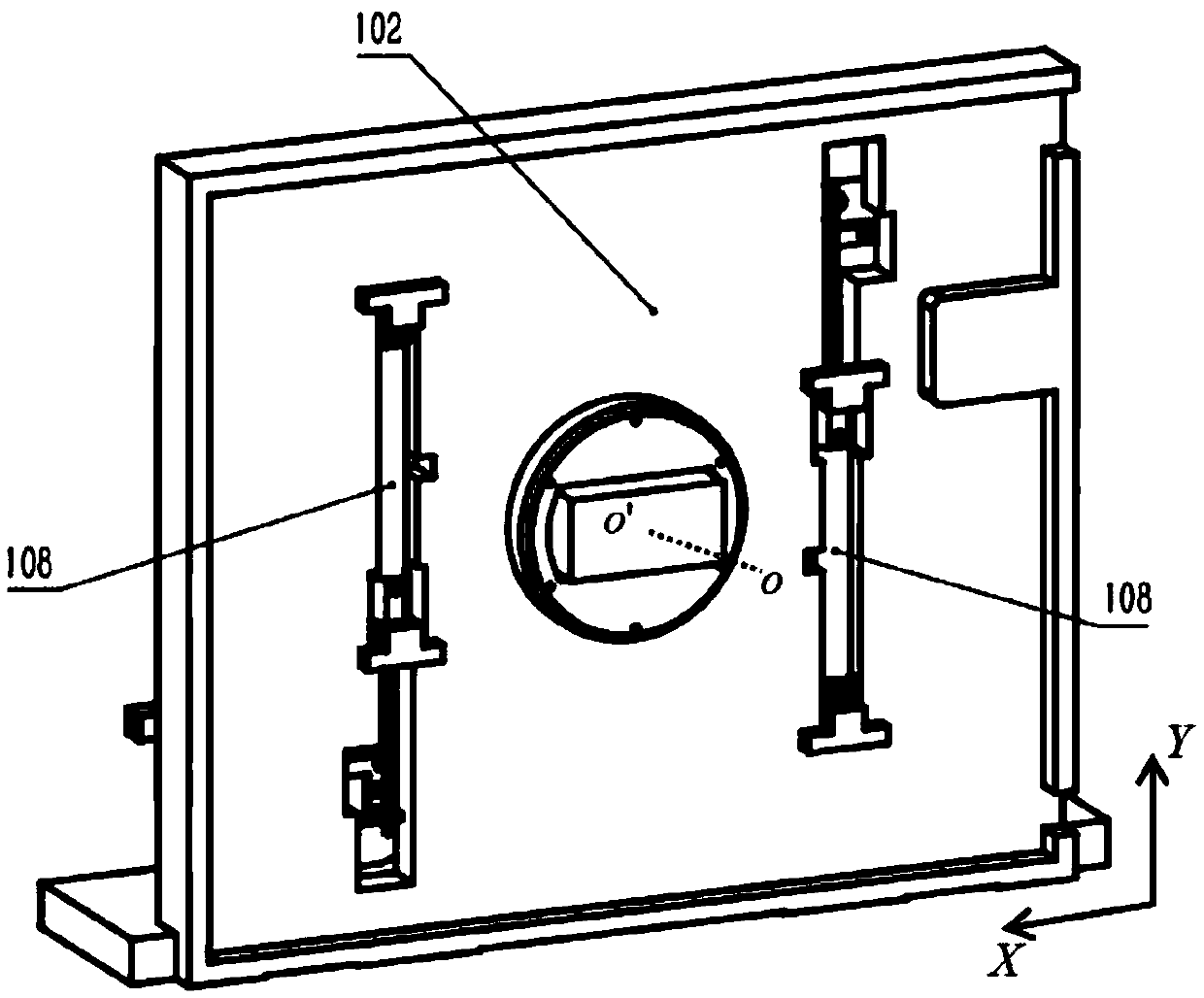

Slit-type iris diaphragm based on air floating guiding

The invention discloses a slit-type iris diaphragm based on air floating guiding. Two X-direction driving control units, two Y-direction driving control units, two X-direction support guiding units, two Y-direction support guiding unit and a diaphragm window are mounted on a front panel of the slit-type iris diaphragm; two gravity compensation units are mounted on a back panel; the diaphragm window is composed of two X-direction diaphragm plates, two Y-direction diaphragm plates, two X-direction driven air floating guide rails and two Y-direction driven air floating guide rails; the pair of units are rotationally symmetrical with respect to an optical central axis oo' of a system; the slit-type iris diaphragm comprises four support guiding units based on an air floating principle, four driven guide rails are guided, the four diaphragm plates are controlled through the driving control units and the gravity compensation units respectively and connected end to end to form a coplanar rectangular window, and scanning in a plane in an arbitrary range is finally achieved. The established slit-type iris diaphragm based on air floating guiding has high precision and stability.

Owner:HARBIN INST OF TECH

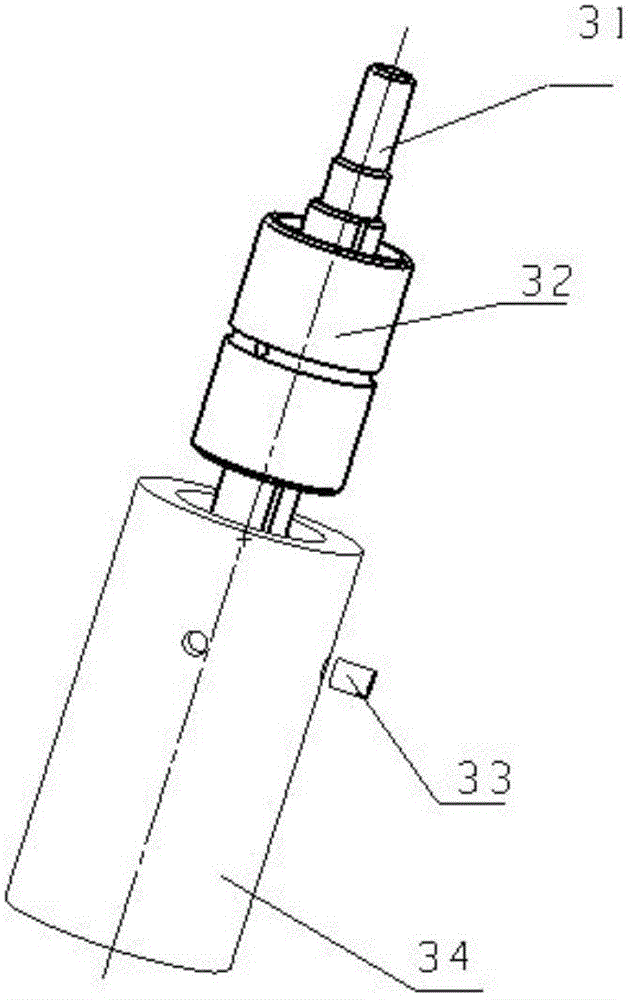

Sensor fixing device for thermal error measurement of numerical control machine tool

ActiveCN113770807AImprove versatilityEasy maintenanceMeasurement/indication equipmentsNumerical controlControl engineering

The invention discloses a sensor fixing device for thermal error measurement of a numerical control machine tool. A fastening module is arranged on a standard connecting rod and can move along the standard connecting rod; one side of the fastening module is connected with a fine adjustment fixing base of a sensor fine adjustment module; and the fine adjustment fixing base is provided with a support for installing an eddy current sensor. The universality and the thermal error measurement efficiency of the fixing device can be remarkably improved, and the problem that the measurement precision of the eddy current sensor is reduced due to the installation precision is avoided.

Owner:XI AN JIAOTONG UNIV

Arc-shaped guide rail shaping device for automobile skylight

PendingCN113976694AAchieve partial shapingAchieve precise guidanceMetal-working feeding devicesPositioning devicesElectric machineryStructural engineering

The invention relates to an arc-shaped guide rail shaping device for automobile skylight, which comprises a base, a shaping device body, a driving device and a guiding device are sequentially arranged on the base from front to back, the shaping device body comprises a pair of positioning rollers, the positioning rollers are rotationally connected to a sliding rod, and a guide rail is arranged between the positioning rollers on the left side and the right side in a penetrating mode; a mounting seat is arranged at the left end of the base, an electric push rod is fixedly connected to the mounting seat, the tail end of a telescopic rod of the electric push rod is aligned to the left end of the sliding rod, the driving device comprises a limiting roller and a driving roller, a set of bosses are arranged on the outer wall of the circumference of the limiting roller, the bosses extend into grooves of the guide rails, and the driving roller is in driving connection with a motor fixedly connected to the bottom of the base. The device is simple in structure, high in automation degree, high in machining efficiency and high in precision.

Owner:ANHUI ANJIAN AUTO SKYLIGHT TECH CO LTD LUAN CITY

A Slit Iris Diaphragm Based on Air Float Guide

The invention discloses a slit-type variable aperture based on air bearing guidance; the front panel of the device is equipped with 2 X-direction drive control units, 2 Y-direction drive control units, 2 X-direction support guide units, 2 Y-direction support guide unit and diaphragm window; 2 gravity compensation units are installed on the back panel; the diaphragm window consists of 2 X-direction diaphragm plates, 2 Y-direction diaphragm plates, 2 X-direction driven air bearing guide rails and 2 A Y-direction driven air bearing guide rail; the paired units are rotationally symmetrical with respect to the optical central axis oo' of the system; the device includes 4 support guide units based on the air bearing principle, guiding the 4 driven guide rails, and passing through The drive control unit and the gravity compensation unit control the four diaphragm plates respectively, and the diaphragm plates connect end to end to form a coplanar rectangular window, and finally realize scanning in any range in the plane; the invention establishes a high-precision , High stability air bearing guided slit iris.

Owner:HARBIN INST OF TECH

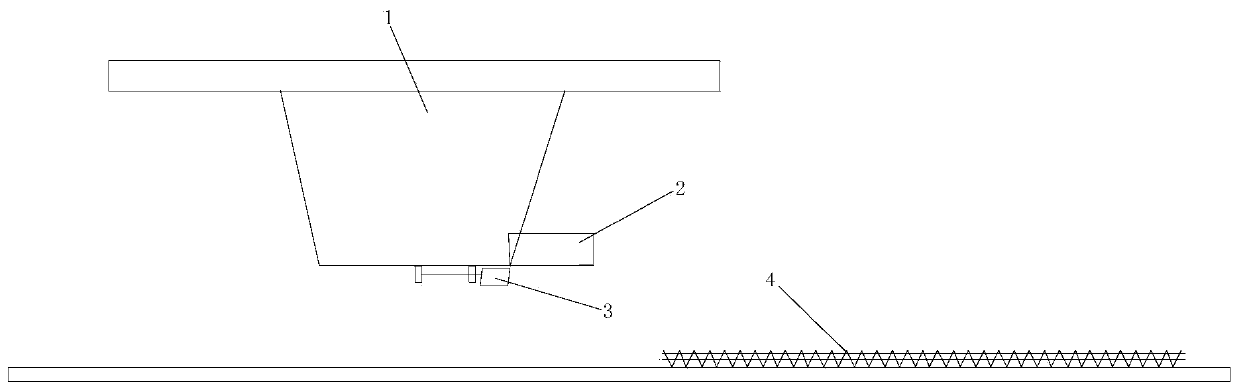

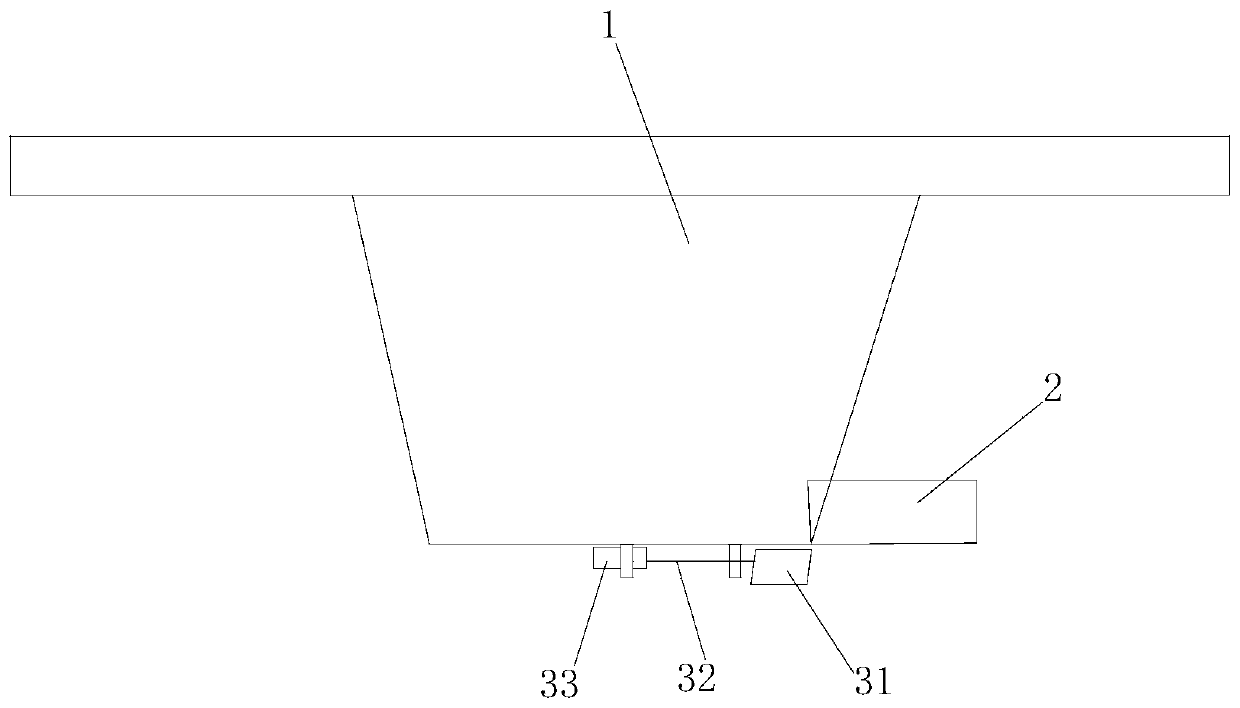

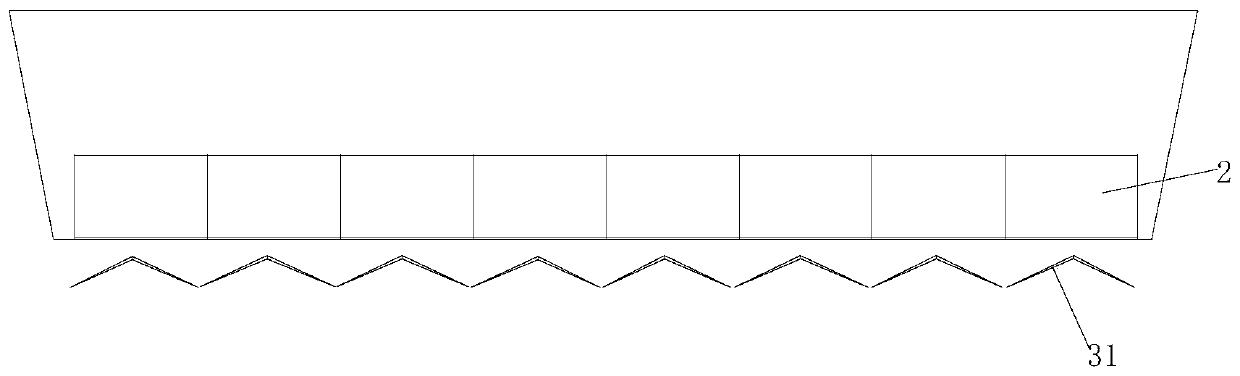

Overlapped plate material distribution machine and control system and control method thereof

PendingCN109927162AReduce dumpingHigh guiding precisionFeeding arrangmentsAuxillary shaping apparatusControl systemEngineering

The invention relates to the technical field of engineering machines, in particular to an overlapped plate material distribution machine and a control system and a control method thereof. A hopper isincluded. A discharging port for conveying raw materials out of the hopper is formed in the hopper. The overlapped plate material distribution machine further comprises a stop assembly capable of stretching and contracting in the horizontal direction. The stop assembly is arranged on the hopper and used for guiding the raw materials flowing out of the discharging port. By means of the overlapped plate material distribution machine and the control system and the control method thereof, the possibility that concrete is poured onto a truss can be effectively reduced.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

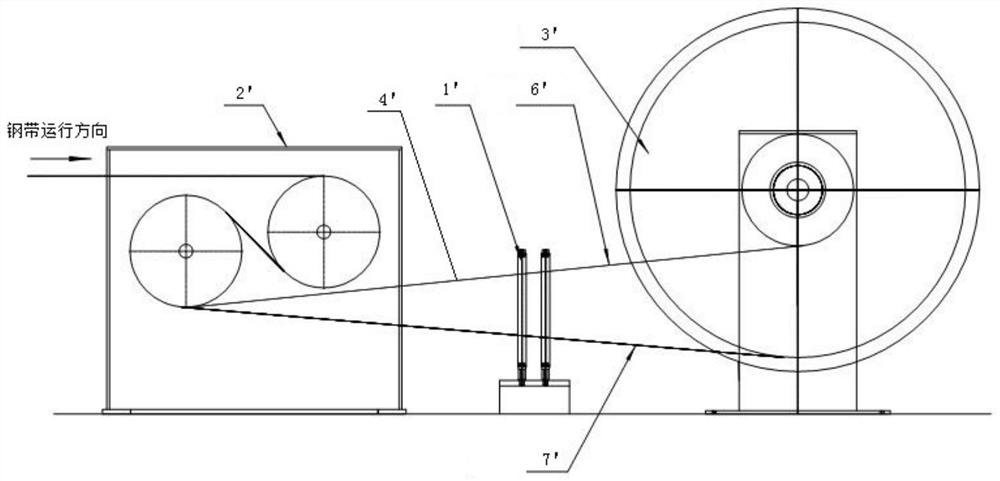

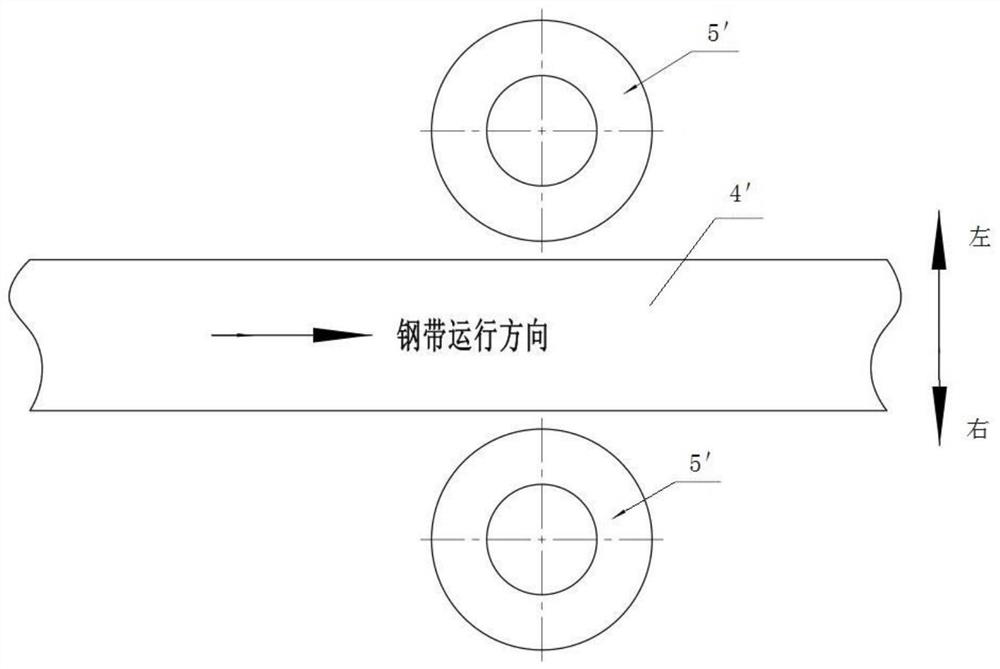

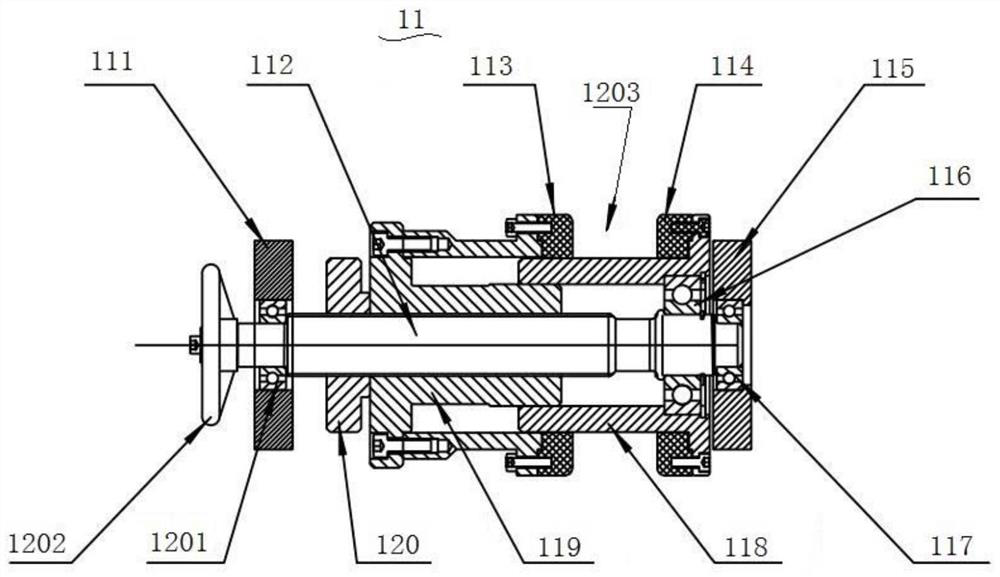

Guide roller, steel belt guide mechanism and material receiving system

ActiveCN112551240AReceiving levelNarrow band receiving is safe and reliableWebs handlingScrew threadSteel belt

The invention provides a guide roller, a steel belt guide mechanism and a material receiving system. The guide roller comprises a screw, an adjustable sleeve and a positioning sleeve, wherein a firstbearing support and a second bearing support are arranged at two ends of the screw respectively, an external thread section is arranged on the screw and is close to the first bearing support, the adjustable sleeve is in threaded connection with the external thread section, one end of the positioning sleeve is installed on the screw through a third bearing, and the other end of the positioning sleeve is connected with the corresponding end of the adjustable sleeve in a sleeved mode; a guide cavity is formed between the positioning sleeve and the adjustable sleeve; and a first check ring is arranged on the vertical side wall, forming the guide cavity, of the adjustable sleeve, and a second check ring is arranged on the vertical side wall, forming the guide cavity, of the positioning sleeve.Compared with the prior art, the guide roller solves the problem that edge cutting and material receiving are not orderly, guarantees that material receiving is smooth, guarantees that narrow-belt material receiving is safe and reliable, avoids the phenomenon of material collapse, and meanwhile greatly prolongs the service life of the guide mechanism.

Owner:BICHAMP CUTTING TECH (HUNAN) CO LTD

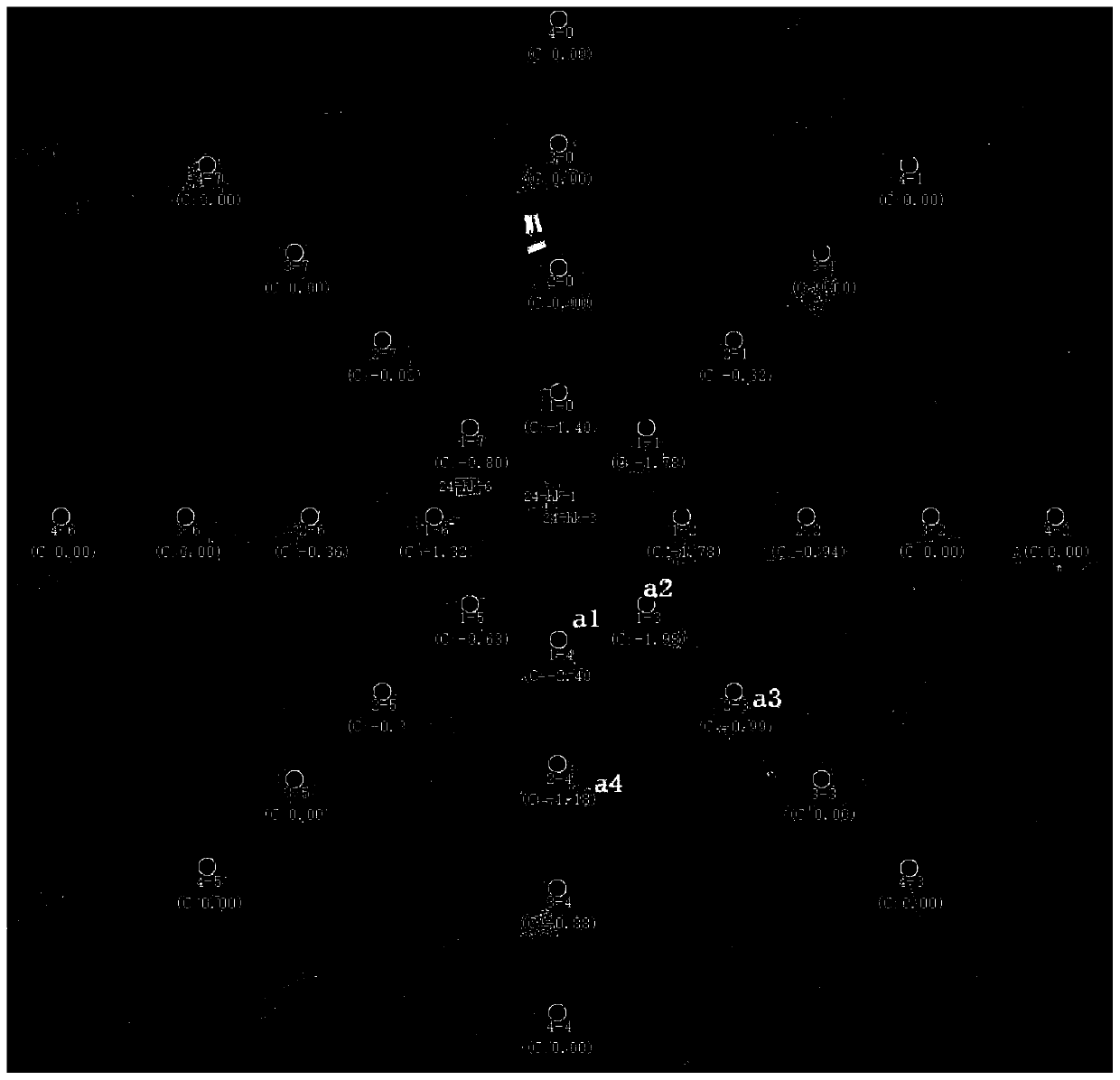

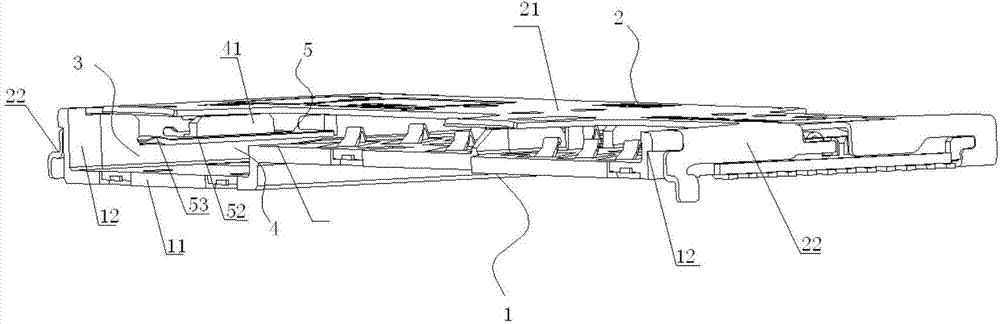

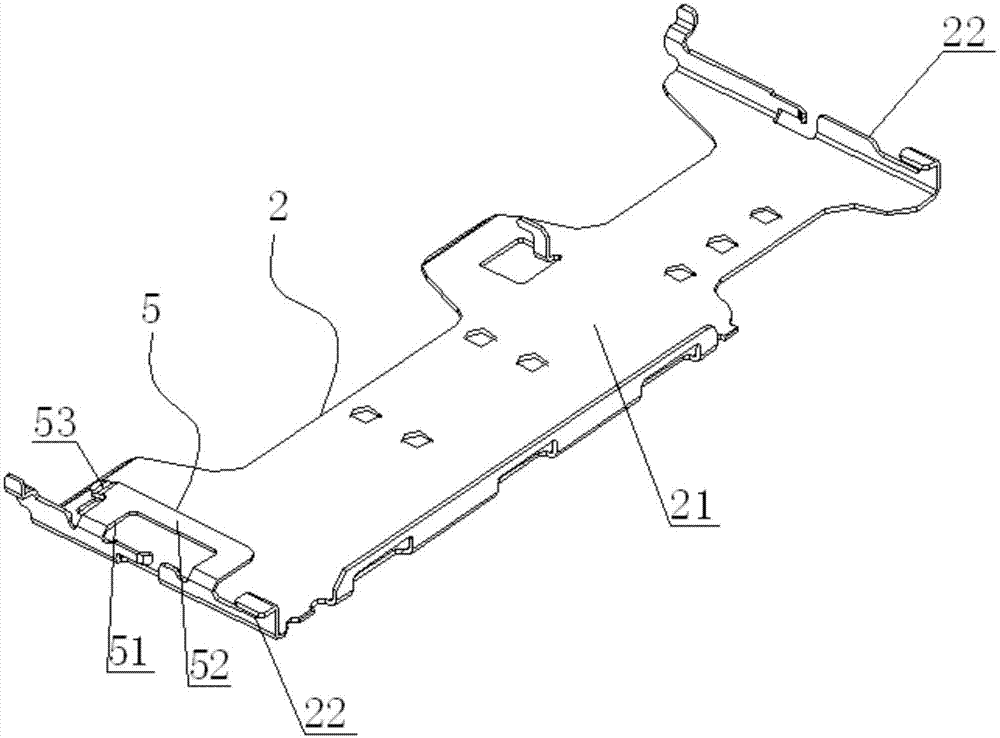

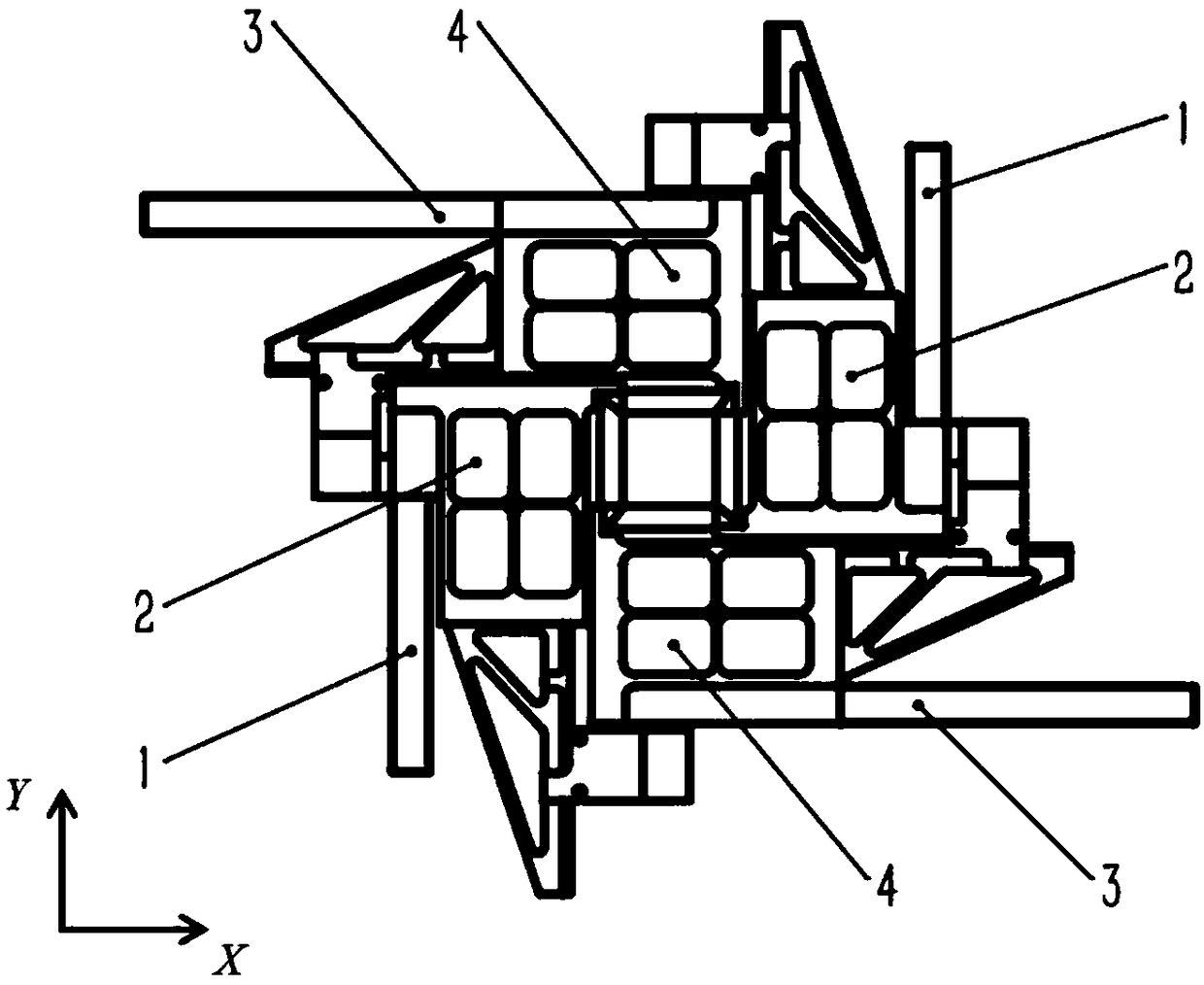

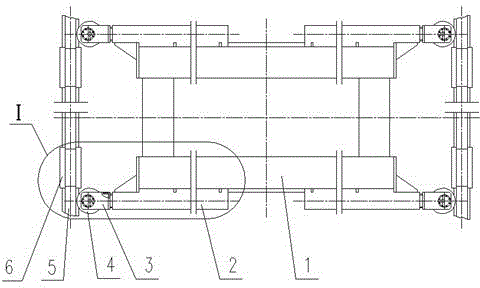

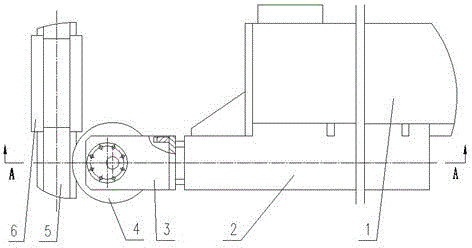

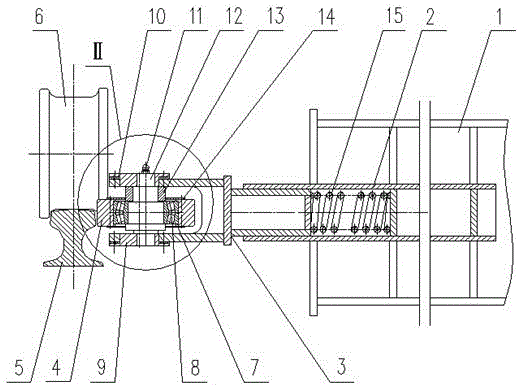

A Large-Scale Array Electronically Adjustable Antenna Phase Shifter Transmission Mechanism

The invention provides a large-scale array electrically-tunable antenna phase shifter transmission. The large-scale array electrically-tunable antenna phase shifter transmission comprises a driving assembly. The driving assembly comprises a driving motor. The driving motor is connected with a left transmission screw and a right transmission screw through a gear transmission mechanism. A transmission nut is arranged on each transmission screw. A positioning mechanism is arranged on one transmission screw and nut, and the driving motor drives the transmission screws to rotate through the transmission mechanisms so as to drive the transmission nut to move on the transmission screws. A frame-type transmission rod is of a frame-type structure. The transmission nut is connected with the frame-type transmission rod through a connecting arm. The frame-type connecting rod is provided with a plurality of connecting parts used for being connected with the phase shifter and guiding and fixing parts of the connecting rod. The phase shifter transmission device has the advantages of being more compact in structure, small in size, small in thickness, light in weight, small in transmission error and the like, and phase shifting synchronization of multiple paths of phase shifters can be achieved.

Owner:KUNSHAN ENDIAN COMM EQUIP CO LTD

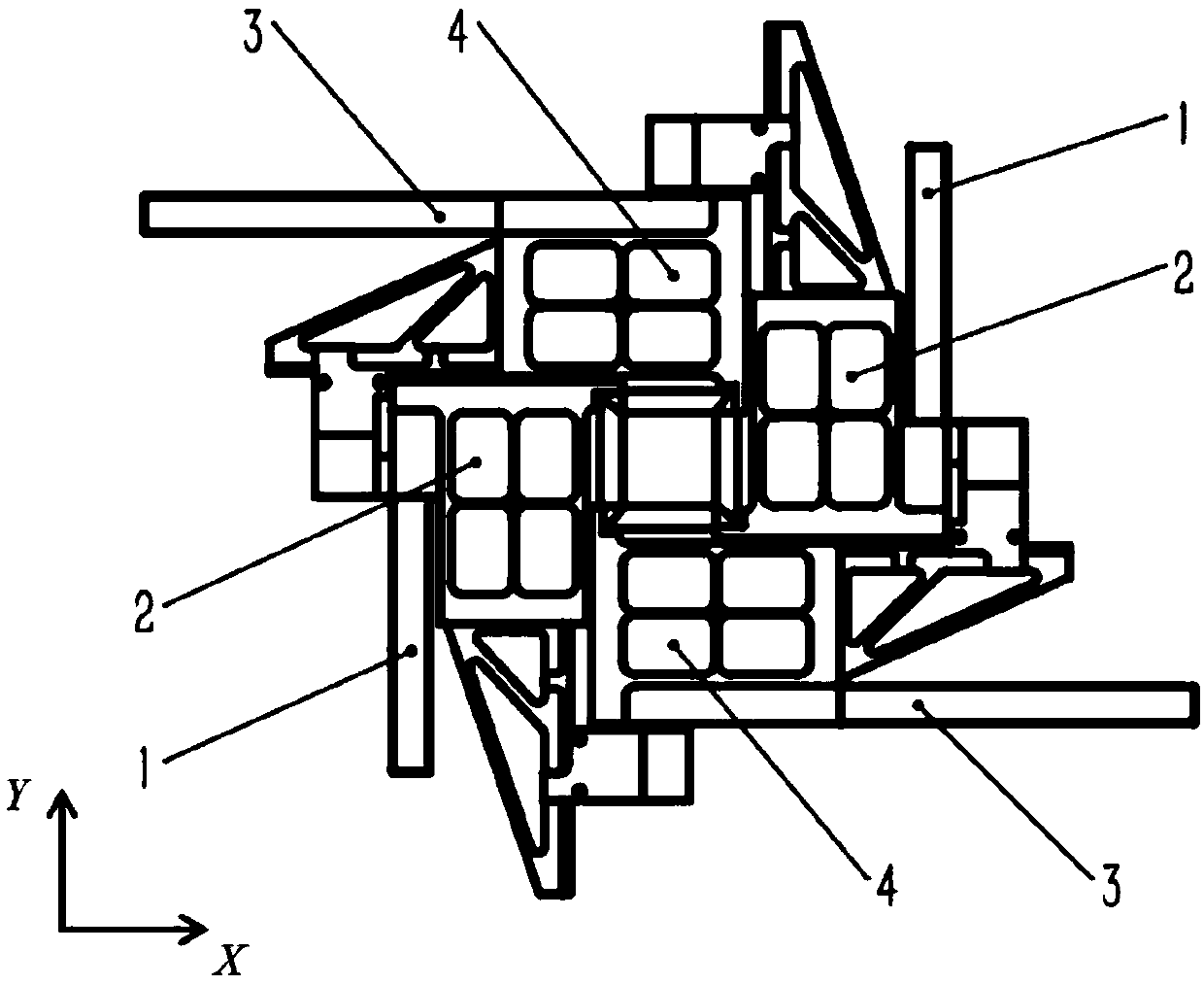

A horizontal wheel anti-gnawing rail device of a two-force rod system

InactiveCN103231987BExtended service lifeAvoid bending momentTravelling gearStructural engineeringControl theory

The invention relates to a horizontal wheel rail gnawing preventing device for a two-force rod system. The technical scheme is as follows: the device comprises four two-force rod mechanisms with the same size and structure, and the four two-force rod mechanisms are symmetrically fixed on four corners of a bridge girder (1). Each two-force rod mechanism is composed of a fixed frame set and a horizontal wheel set, wherein the fixed frame set comprises a box-shaped fixed frame (2), a pressing frame (3) and a compression spring (15); the horizontal wheel set comprises a horizontal wheel (4), a bearing (8), an eccentric transparent cover (9), an adjustable pad (10), a wheel axle (12) and a shaft sleeve (13). The box-shaped fixed frame (2) is fixed on web plates at two sides of the bridge girder (1); the pressing frame (3) slides inside the box-shaped fixed frame (2) through the compression spring (15); and the horizontal wheel (4) is fixed on the pressing frame (3) through the bearing (8), the wheel axle (12) and the eccentric transparent cover (9). By using the horizontal wheel rail gnawing preventing device, the precise guide for the operation of a crane is realized; and a track (5) is in flexible contact with the horizontal wheel (4), thus the wheel rail gnawing phenomenon is effectively avoided. The horizontal wheel rail gnawing preventing device has the characteristics of simple structure, easiness for maintenance, strong stability and long service life.

Owner:WUHAN UNIV OF SCI & TECH

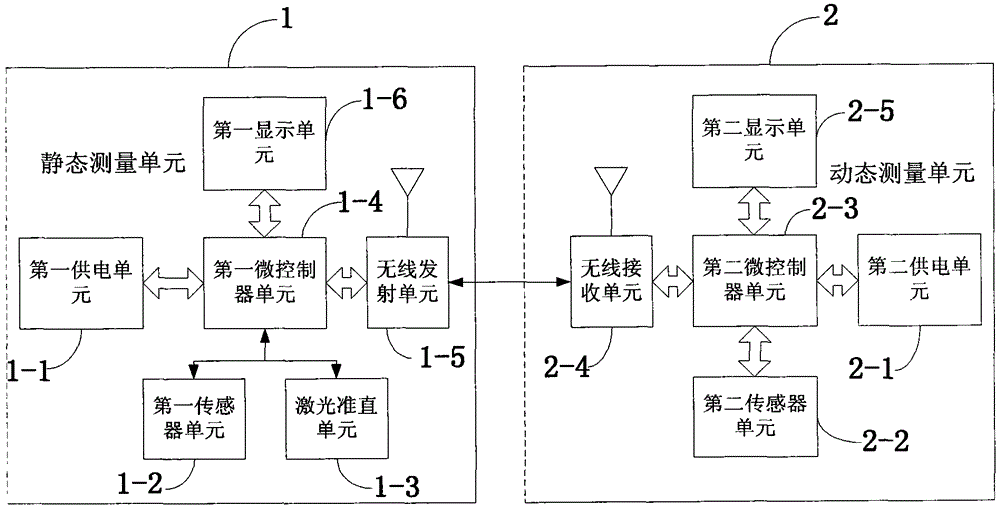

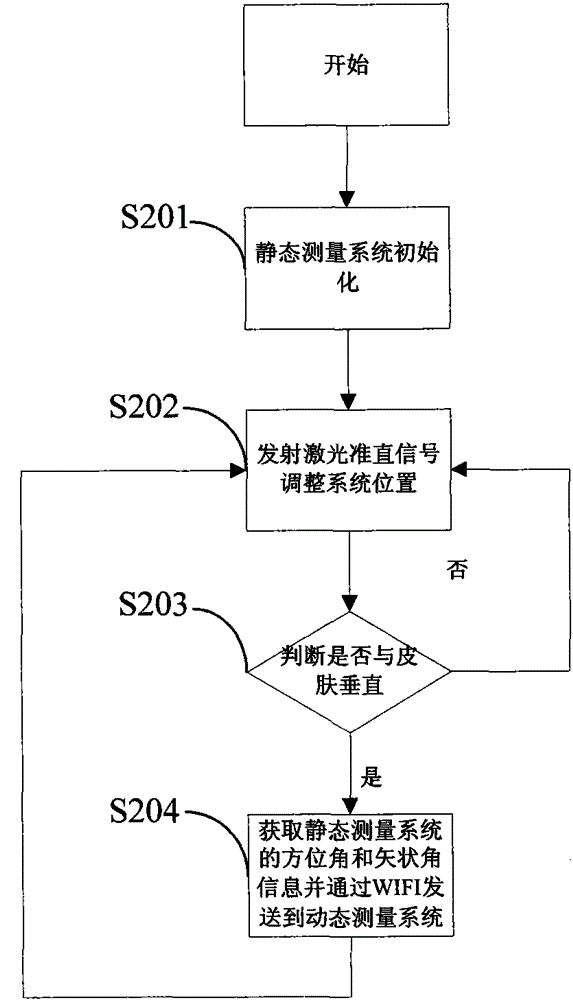

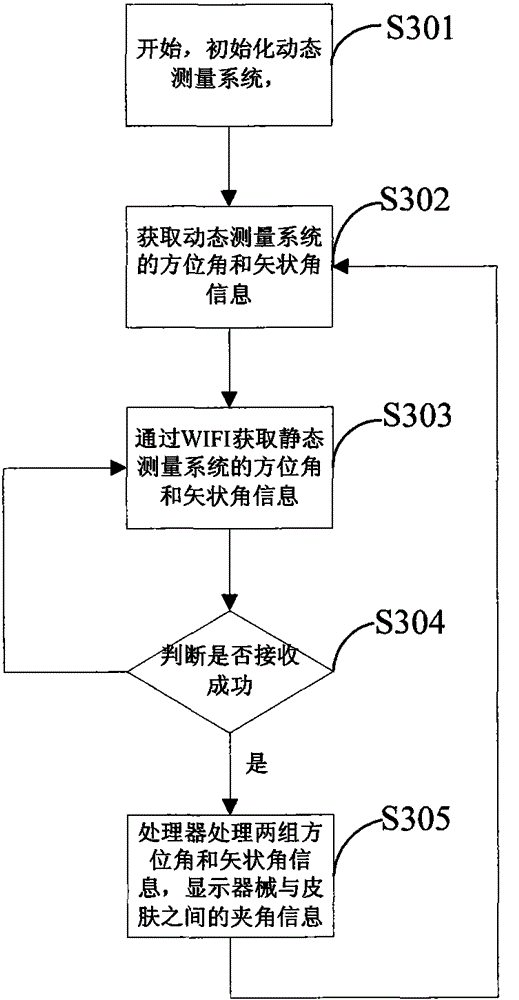

A three-dimensional positioning guide for medical orthopedic surgery

InactiveCN103892921BAchieve precise guidanceAvoid human errorInstruments for stereotaxic surgeryHuman errorOrthopedic Surgical Procedure

The invention discloses a medical three-dimensional positioning guider for an orthopedic surgery. The medical three-dimensional positioning guider is provided with two measuring systems comprising a static measuring unit and a dynamic measuring unit; an azimuth angle and a sagittal angle can be measured in real time in various environments; the static measuring unit provides a relatively static reference coordinate system for the dynamic measuring unit; the medical three-dimensional positioning guider is always perpendicular to the skin of a patient; deviation cannot be caused even if the patient moves; medical staffs can obtain real-time accurate position information; and the success rate of the orthopedic surgery and other surgeries is increased. By using the portable three-dimensional positioning guider for the orthopedic surgery, position conditions of an instrument can be displayed in real time, the medical staffs can accurately determine the sizes of the sagittal angle and the azimuth angle between the position of the instrument and the skin of the patient clinically, and accurate guiding is realized; and the medical three-dimensional positioning guider for the orthopedic surgery can be calibrated in real time, and various human errors are avoided.

Owner:陈红卫

An Axial Flow Check Valve with Online Maintenance

ActiveCN106838386BRemarkable resultsRealize online maintenanceCheck valvesValve members for absorbing fluid energyEngineeringCheck valve

The invention discloses an online maintainable axial flow check valve which is characterized in that a top opening is formed in the top of a valve body, a valve spool component is placed into the valve body from the top opening, a valve cover is arranged at the top opening of the valve body to seal the valve body, a valve spool of the valve spool component is suspended on a valve spool support by a supporting rib, and the valve spool support is fixedly clamped at the top opening of the valve body by the aid of a valve spool fixing clamp ring. The online maintainable axial flow check valve is low in flow resistance and noise, and can realize online maintenance.

Owner:HEFEI GENERAL MACHINERY RES INST

An overall step-by-step transfer device for a roller-row type omnidirectional drilling rig

ActiveCN104373051BRealize the transferRotate in placeDerricks/mastsDrilling machines and methodsOmni directionalSubstructure

Provided is a roller row type omni-directional drilling rig whole step-by-step moving device. A support is fixed to a cluster well rig substructure through connecting pin shafts, and a reversing rotating mechanism and a trolley are installed on a skid. The trolley is composed of a tray, an upper trolley base, a roller row and horizontal movement oil cylinders. The roller row is formed by installing 14 rollers on a frame, the horizontal movement oil cylinders are connected with the upper trolley base through pin shafts, piston rods of the horizontal movement oil cylinders are connected with the tray through bolts, guide rolling wheels are installed on the two sides of the front end of the upper trolley base, lug plates are installed at the two ends of the roller row, the roller row is connected with the upper trolley base through an adjusting rod, the trolley is connected with a jacking oil cylinder through a spherical surface tray and a clamping plate set, the jacking oil cylinder is installed on the support through bolts, and the spherical surface tray is installed on the upper trolley base. A limiting ring is installed on the spherical surface tray. Through the roller row type omni-directional drilling rig whole step-by-step moving device, on-site rotation of a whole drilling rig can be achieved, well site adaptability of the moving device is improved, the same moving device can be shared by multiple drilling rigs, and investment is saved.

Owner:中石化四机石油机械有限公司 +1

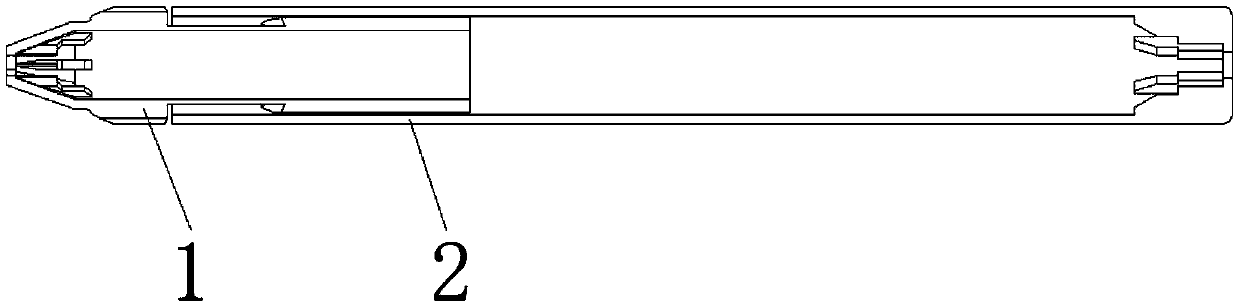

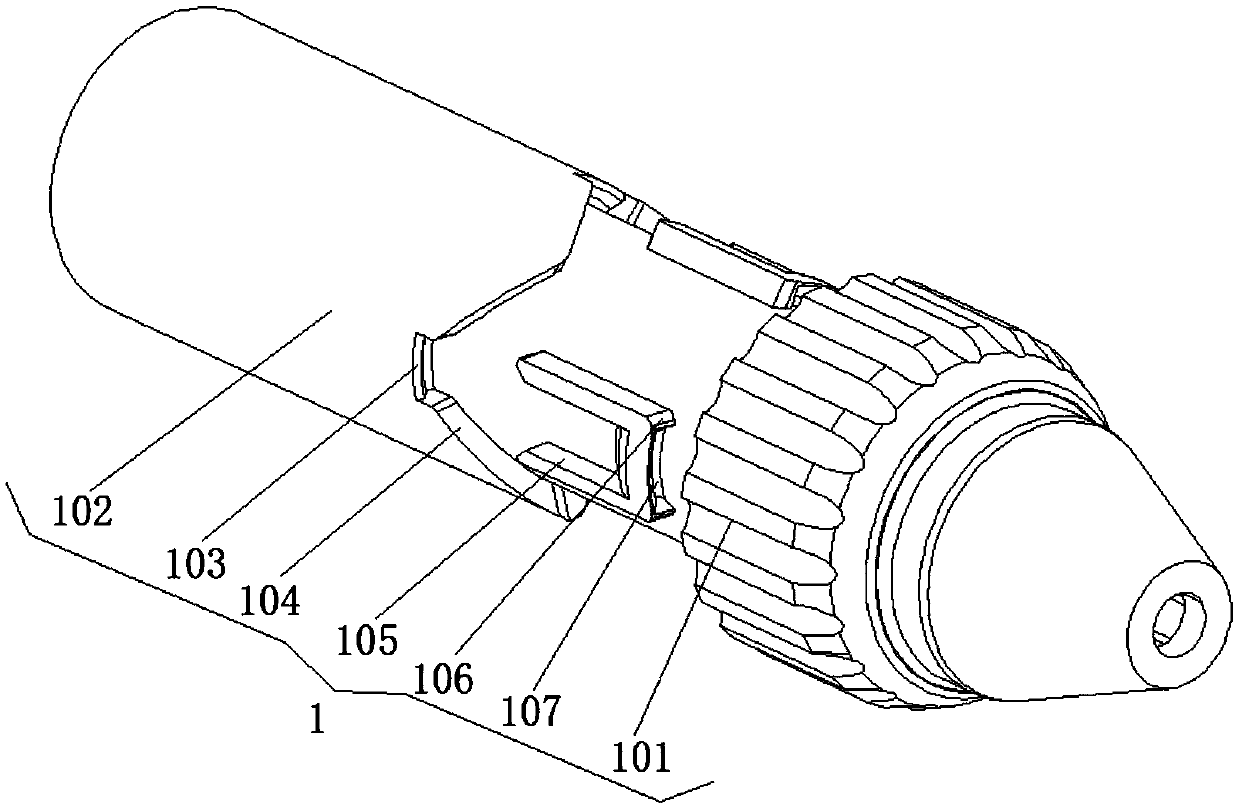

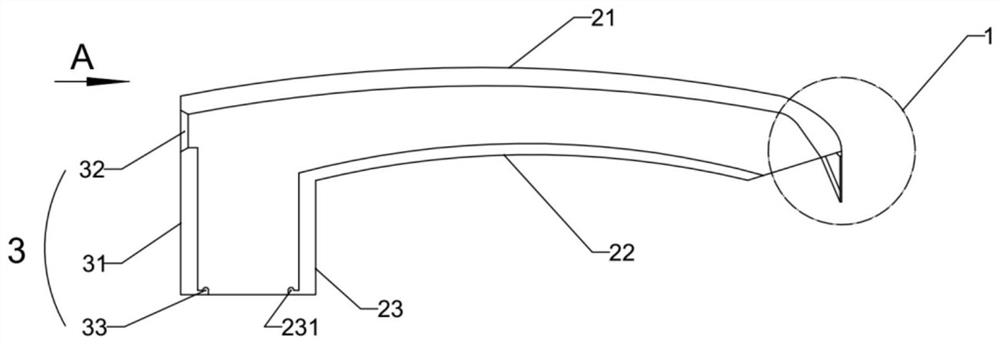

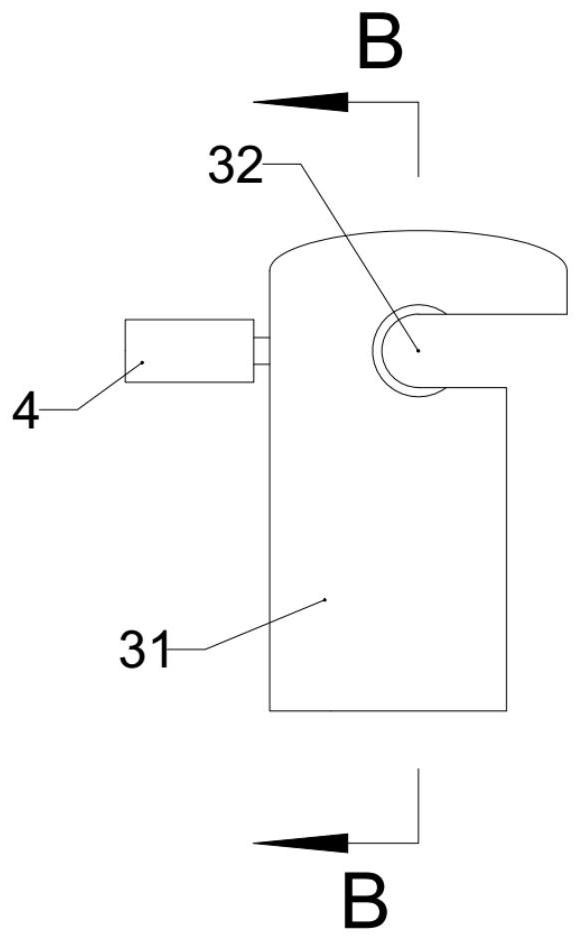

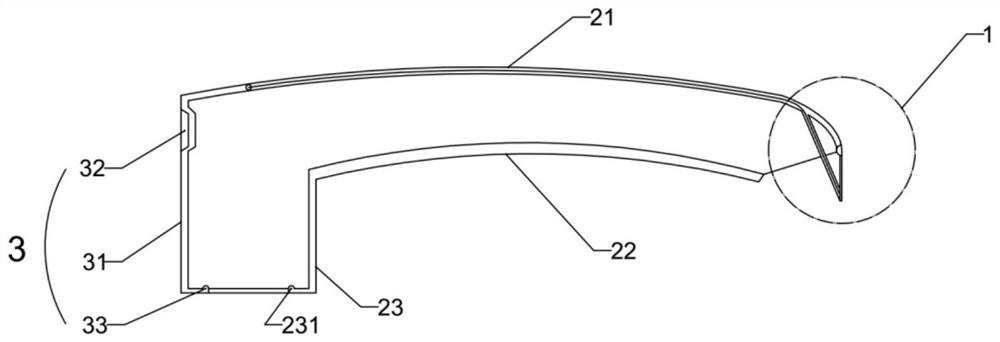

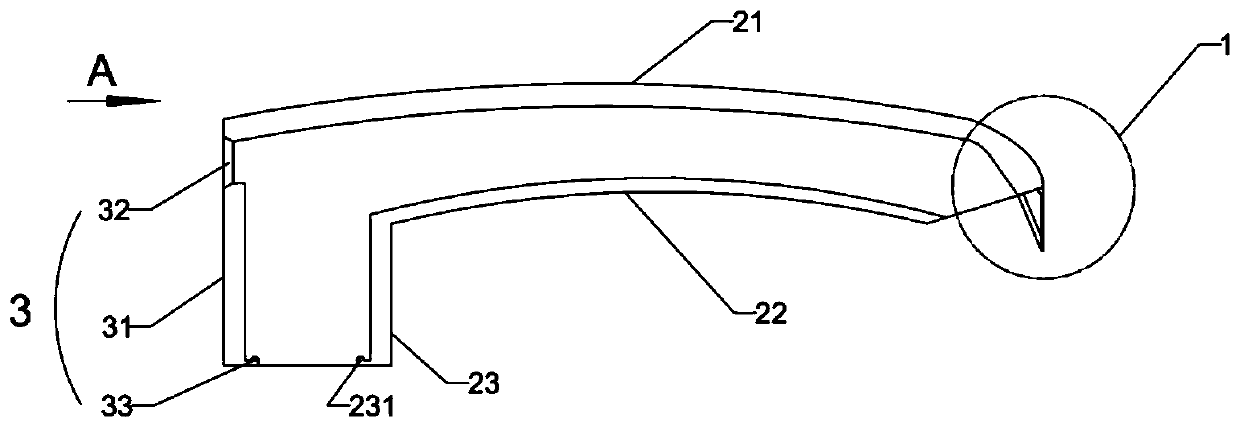

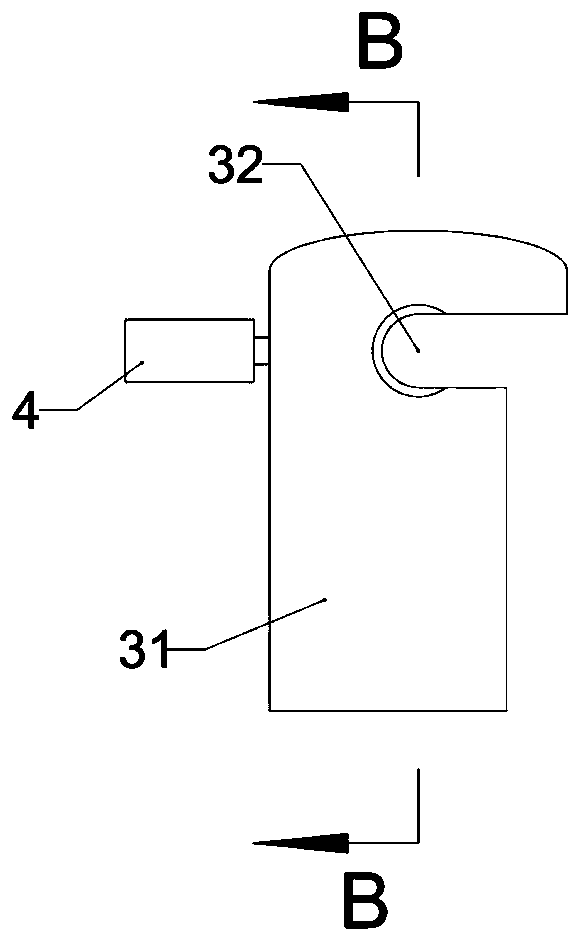

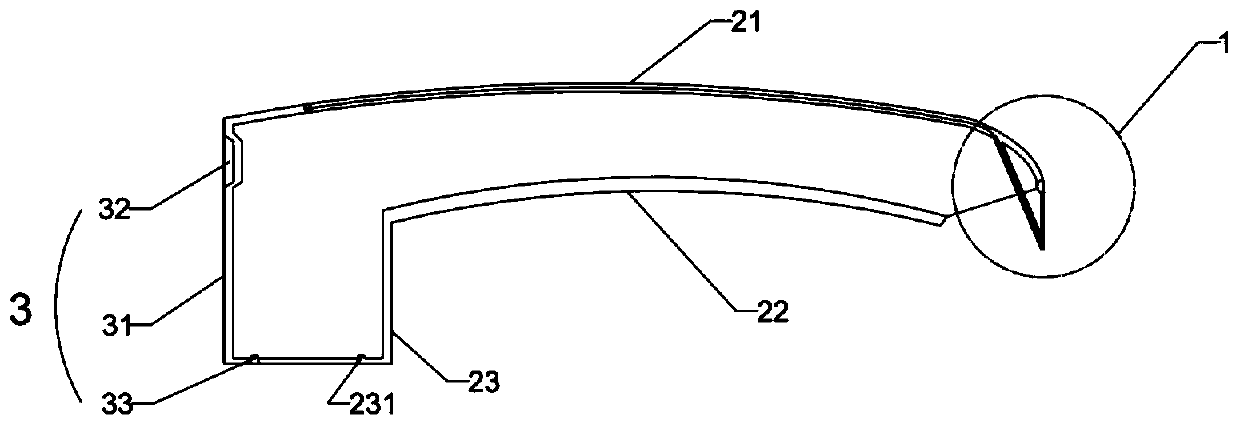

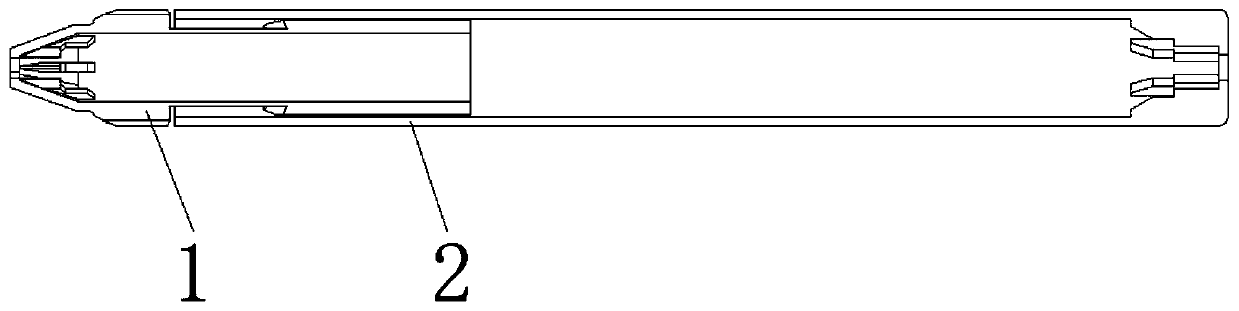

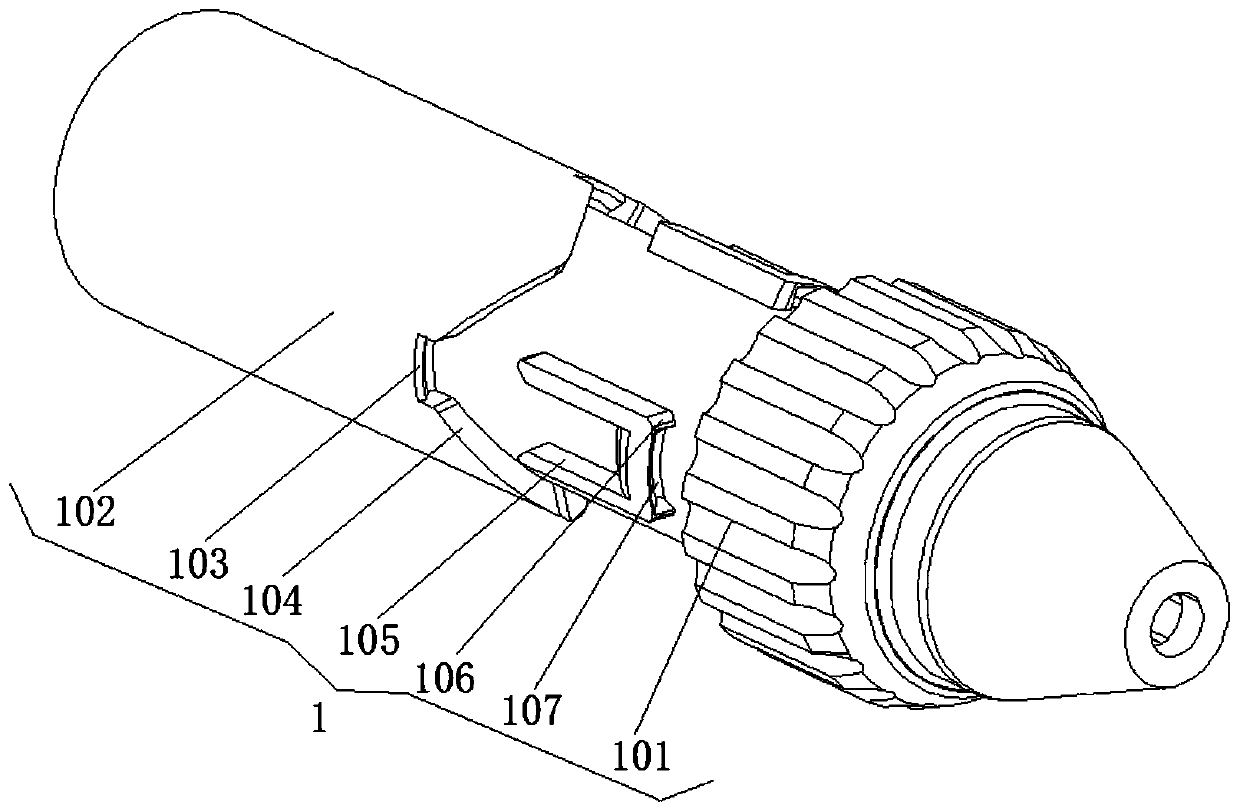

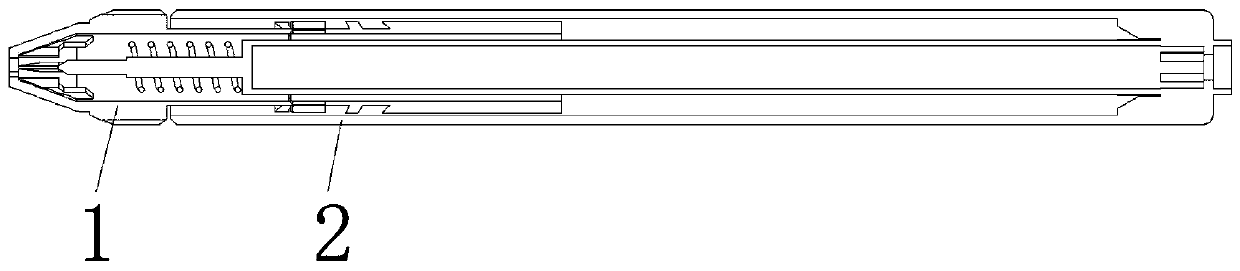

A laryngoscope blade auxiliary kit and video laryngoscope system

ActiveCN109893076BAchieve precise guidanceIncrease success rateBronchoscopesLaryngoscopesVideo laryngoscopeEngineering

The invention discloses an auxiliary set of laryngoscope blades, which is characterized in that it comprises a front movable assembly, a main body shell, a rear end shell assembly and a knob assembly; the main body shell includes an outer arc portion, an inner arc portion and a semicircle part, the outer arc part and one side of the inner arc part are correspondingly spliced to form a channel cavity for accommodating the intubation tube and the blade of the laryngoscope, and the two ends of the channel cavity are respectively a narrow opening and a wide opening; A gap window is reserved between the outer arc portion and the other side of the inner arc portion, and the intubation tube and the blade of the laryngoscope enter the channel cavity through the gap window. The invention realizes the precise guidance of the intubation through the front movable assembly on the blade auxiliary kit of the laryngoscope, significantly improves the success rate of intubation, and at the same time reduces the discomfort caused by the contact between the intubation tube and the patient's soft palate.

Owner:YANGTZE UNIVERSITY

Laryngoscope blade assisting suite and videostroboscopy system

ActiveCN109893076AIncrease success rateReduce discomfortBronchoscopesLaryngoscopesEngineeringLaryngoscope blade

The invention discloses a laryngoscope blade assisting suite. The assisting suite is characterized by comprising a front end movable assembly, a main body shell, a rear end shell assembly and a knob assembly, wherein the main body shell comprises an outer arc part, an inner arc part and a semi-arc part, the outer arc part and one side of the inner arc part are spliced correspondingly, a channel cavity for accommodating a cannula and a laryngoscope blade is formed inside, a narrow through opening and a wide through opening are formed in d two ends of the channel cavity respectively; a clearancewindow is reserved between the outer arc part and the other side of the inner arc part, and the cannula and the laryngoscope blade enter the channel cavity through the clearance window. Accurate guidance of intubation is realized by the front end movable assembly on the laryngoscope blade assisting suite, so that the success rate of intubation is obviously increased, and discomfort caused by contact of the cannula and soft palate of a patient is also reduced.

Owner:YANGTZE UNIVERSITY

An external rotary puller pen

ActiveCN109551936BEasy location orientationAccurate entryWriting unitsStructural engineeringMechanical engineering

Owner:温州市简系文具有限公司

Punch die indexing mechanism of numerical control press

InactiveCN103990691ANo frequent replacementAchieve precise guidanceShaping toolsNumerical controlPunching

A punch die indexing mechanism of a numerical control press comprises a rack, a rotating shat is mounted on the rack through a bearing device, an upper die frame, a press plate frame and a lower die frame are rotationally connected to the rotating shaft from top to bottom in sequence, a punch die seat is fixedly mounted at the tail end of the lower die frame, the punch die seat is provided with a plurality of punch dies, the upper die frame is provided with corresponding punch rods at the positions exactly facing the punch dies, and the punch rods are fixedly mounted on a fixing seat at the tail end of the upper die frame. The bottom of the lower die frame is fixedly connected with a movable plate, a piston rod of a longitudinal shifting oil cylinder is mounted in a mounting hole of the movable plate through a bearing, and the shifting oil cylinder is fixedly connected to the rack. The upper die frame is fixedly connected with a locating plate, the locating plate is provided with an arc groove, a locating column is in sliding connection with the arc groove of the locating plate, and the locating column is fixedly connected to the rack. A piston rod of a press plate oil cylinder is hinged to the press plate frame, and a cylinder body of the press plate oil cylinder is fixed to the upper die frame. The punch die indexing mechanism of the numerical control press can meet the punching requirements for different hole diameters and is simple in structure, convenient to operate and stable in operation.

Owner:WUXI HUALIAN PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com