Hot-press heads and hot-press device

A technology of a hot pressing device and a hot pressing head, which is applied in the field of RFID label hot pressing and curing, can solve the problems of difficulty in ensuring the stability and consistency of pressure and temperature, and inconvenient adjustment of the pressure of the hot pressing head, so as to ensure the stability and consistency. , the effect of low friction, easy and precise pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Now further describe the present invention in detail in conjunction with the preferred embodiments of the accompanying drawings.

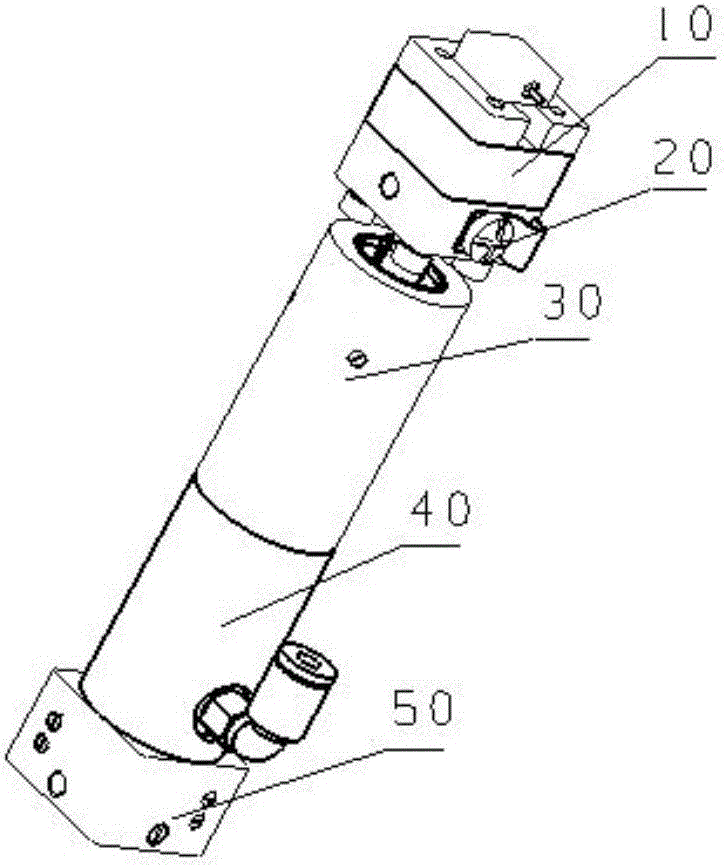

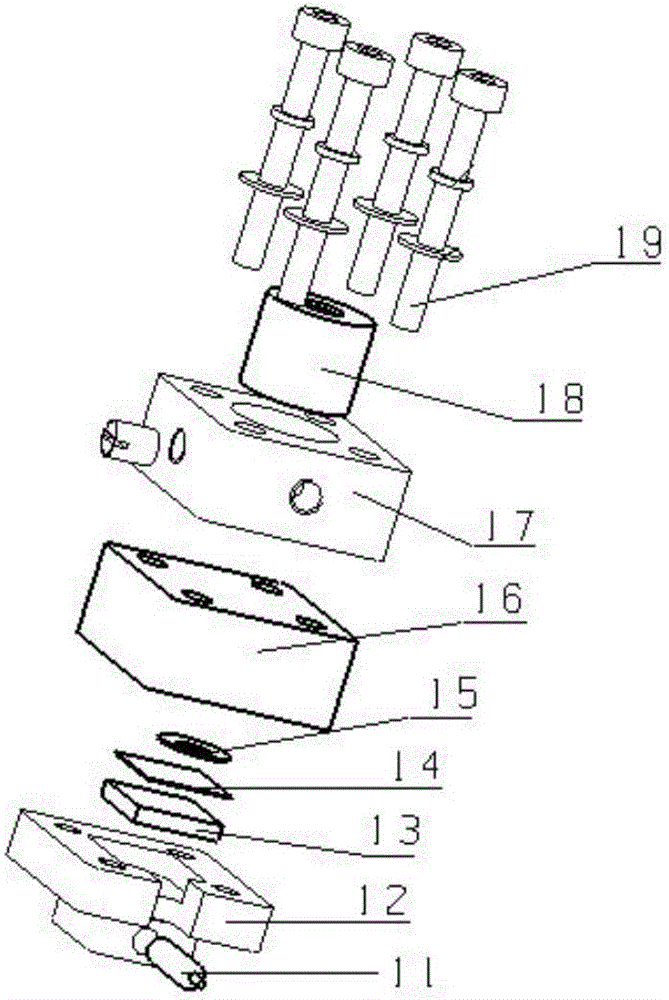

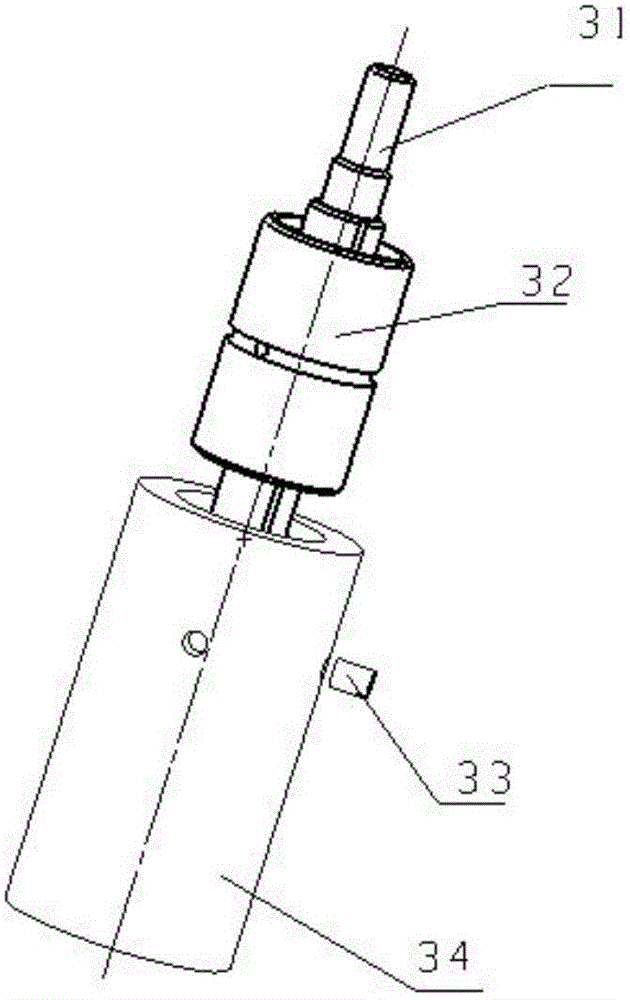

[0044] Such as figure 1 As shown, the preferred embodiment of the present invention mainly includes a heating assembly 10 , a wire clip 20 , a guide assembly 30 , a power assembly 40 and an installation assembly 50 . The heating assembly 10 is fixed on the top of the guide assembly 30, and is used to generate a constant high temperature on the working surface according to the requirements of the hot pressing process, and provide effective heat insulation protection for other components. The wire clamp 20 is fixed on the heating assembly 10, and is used to fix power lines, signal lines and other lines, and reduce the influence of line tension on the output pressure of the thermal head. The guide assembly 30 is connected with the power assembly through the connecting rod 51, and is used to ensure the axial linear movement of the thermal head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com