A horizontal wheel anti-gnawing rail device of a two-force rod system

A technology of two levers and horizontal wheels is applied in the field of horizontal wheel anti-gnawing rail devices, which can solve the problems of delaying production tasks, increasing maintenance costs, cumbersome assembly and disassembly methods, etc., to avoid wheel gnawing on the rail, reduce the possibility, reduce The effect of mechanical influences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

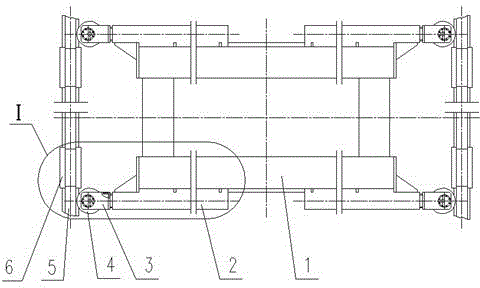

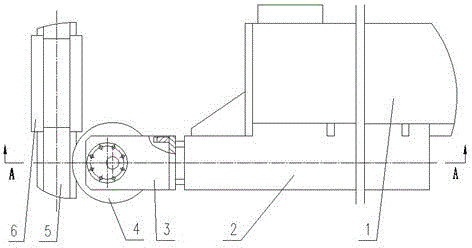

[0029] The utility model relates to a horizontal wheel anti-gnawing rail device of a two-force bar system. The device as figure 1 As shown, it includes four two-force link mechanisms, the fixed ends of the four two-force link mechanisms are symmetrically fixed on the four corners of the main girder 1 of the bridge frame, and the four two-force bar mechanisms are located on both sides of the main beam 1 of the bridge frame. Such as Figure 4 As shown, the installation gap e between the movable ends of the four two-force lever mechanisms and the inner side of the track 5 is 4-6mm. Such as figure 2 As shown, the stiffener plate is welded at the end of main beam 1 and the outer web.

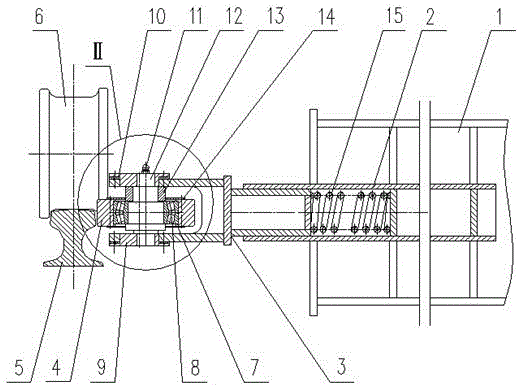

[0030] The size and structure of the 4 two-force lever mechanisms are identical, and all consist of a fixed frame group and a horizontal wheel group.

[0031] Such as image 3 As shown, the fixed frame set includes a box-shaped fixed frame 2 , a pressing frame 3 and a compression spring 15 ...

Embodiment 2

[0036] The utility model relates to a horizontal wheel anti-gnawing rail device of a two-force bar system. Except following technical parameter, all the other are with embodiment 1.

[0037] The installation clearance e between the movable ends of the four two-force rod mechanisms and the inner side of the track 5 is 6-8 mm; there are 5-8 radial oil holes on the wall of the stepped hole of the shaft sleeve 13; the eccentric transparent cover 9 is evenly arranged with 4 ~7 or 9~12 screw holes; the distance between the eccentric holes of the eccentric transparent cover 9 is b=20~25mm.

[0038] In this specific embodiment, during installation, the vertical centerline of the wheel 6 and the vertical centerline of the track 5 tend to be close to or even overlap, so as to balance the force couple and the reaction couple produced by the lateral force on the track 5 on both sides, and reduce the size of the lateral force on the rail. .

[0039] Compared with the prior art, this spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com