Patents

Literature

46results about How to "Avoid rail gnawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

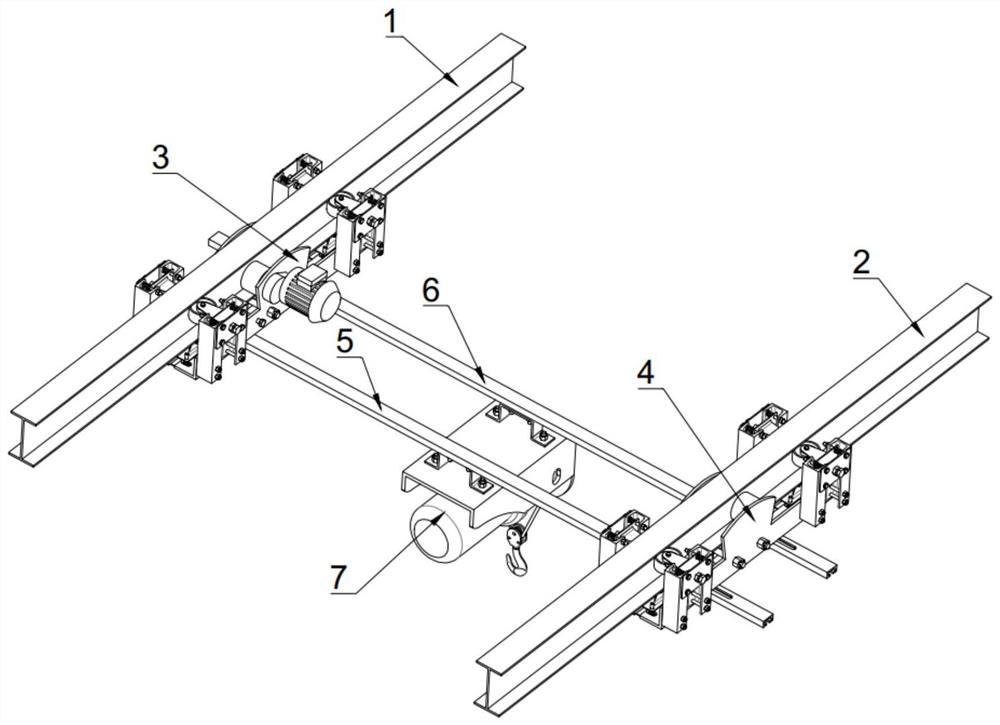

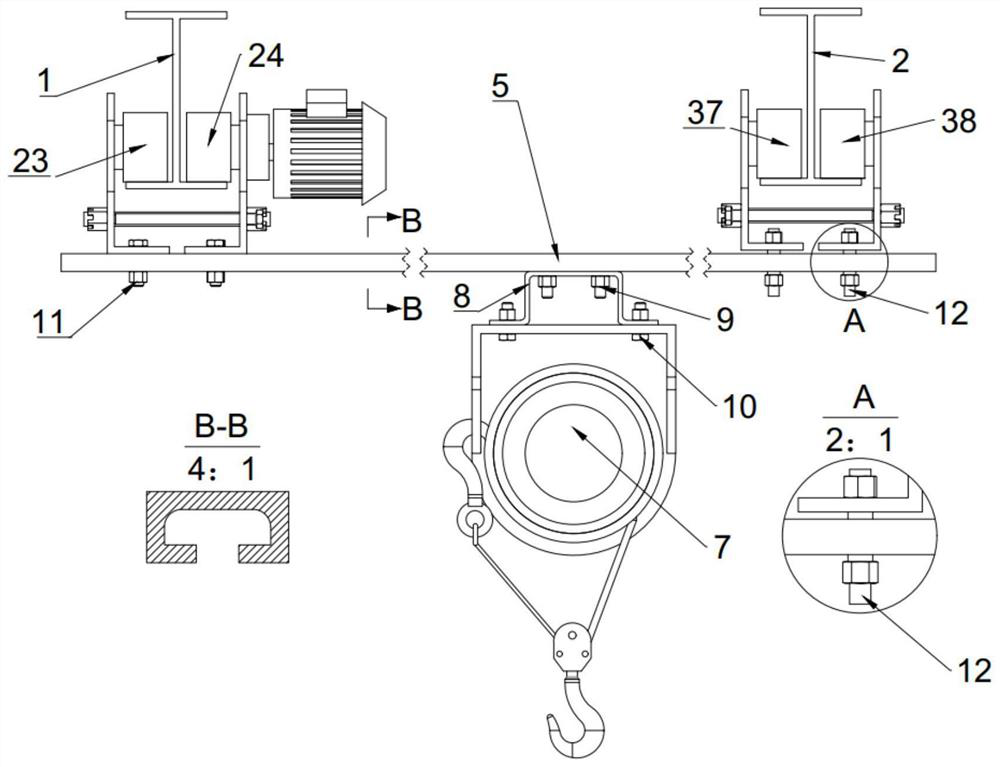

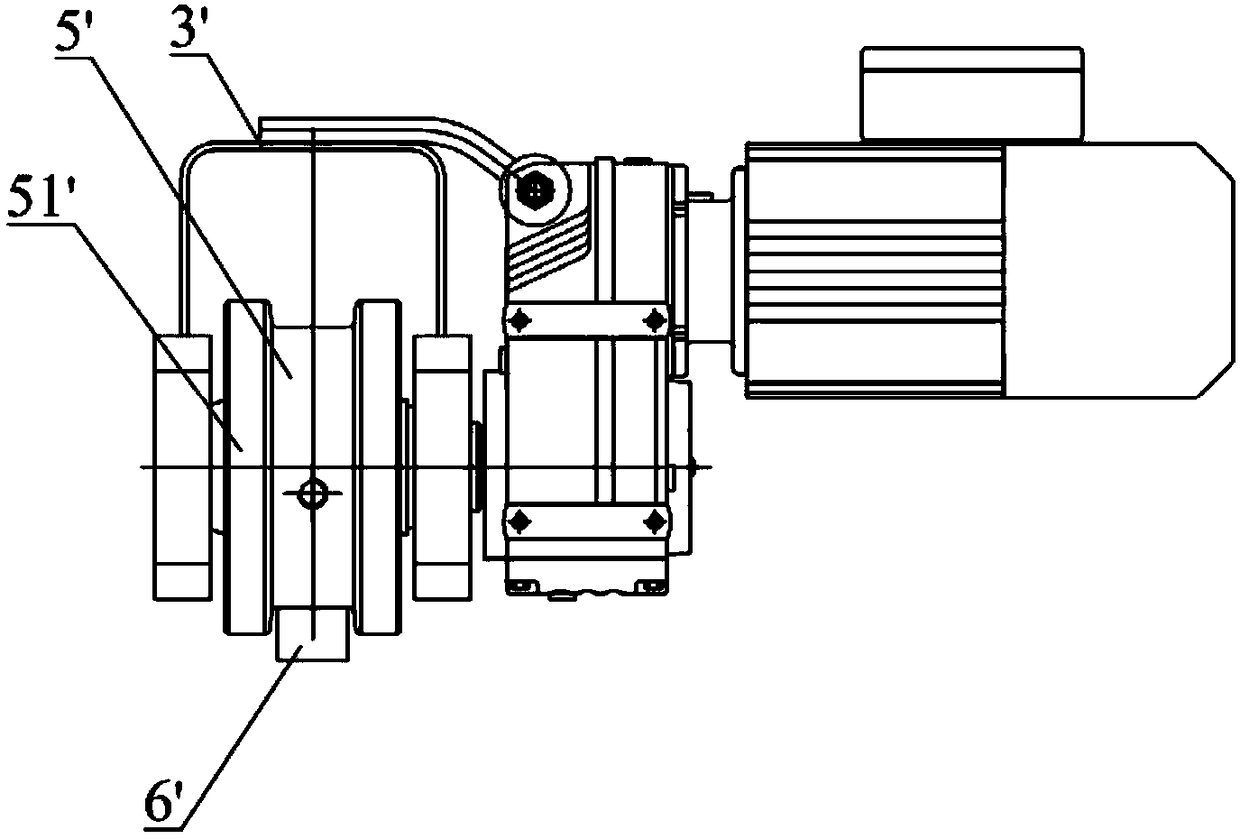

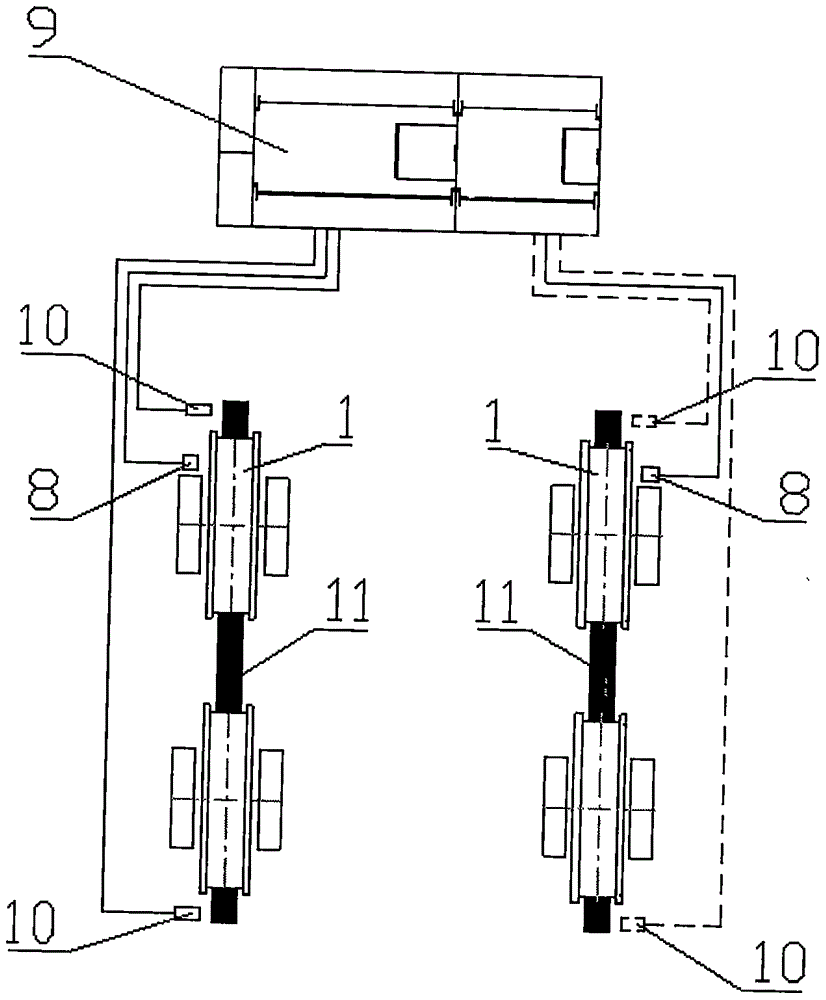

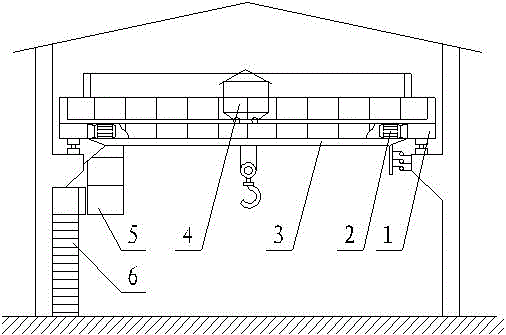

Constant-pressure friction driving trolley of hanging type hoisting equipment and method

InactiveCN103010950AExtended service lifeReduced service lifeTravelling gearRunwaysElectric machineryFriction force

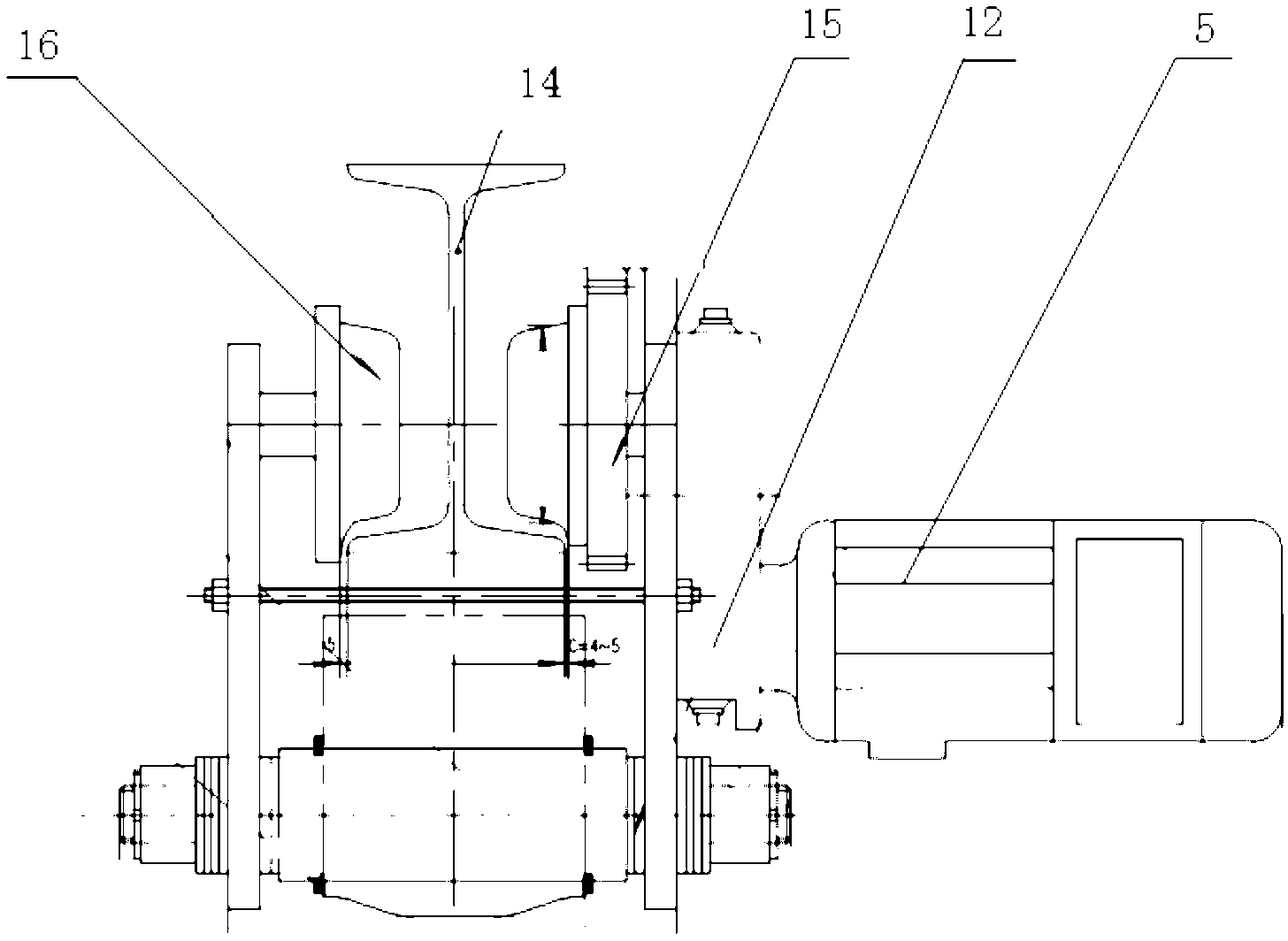

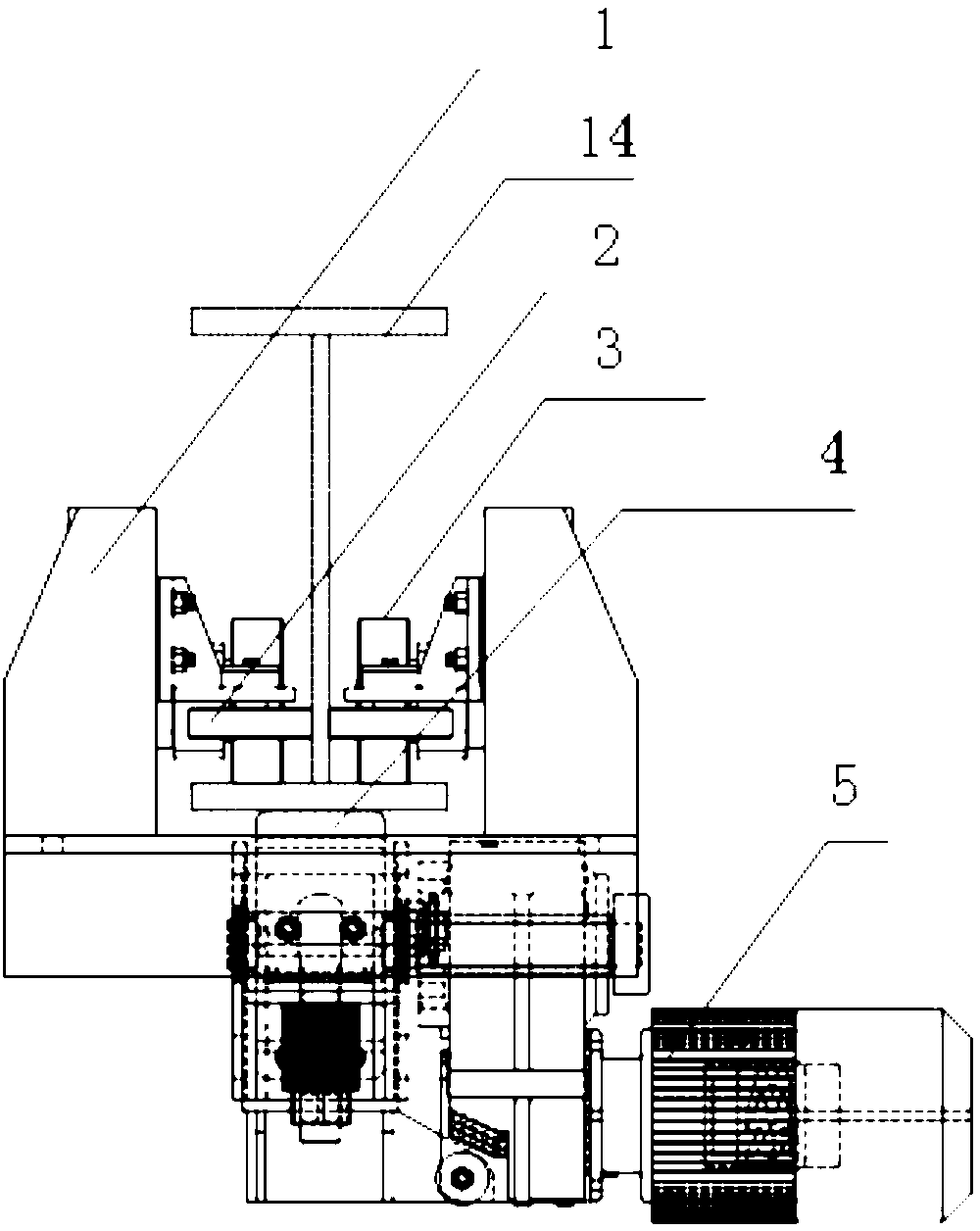

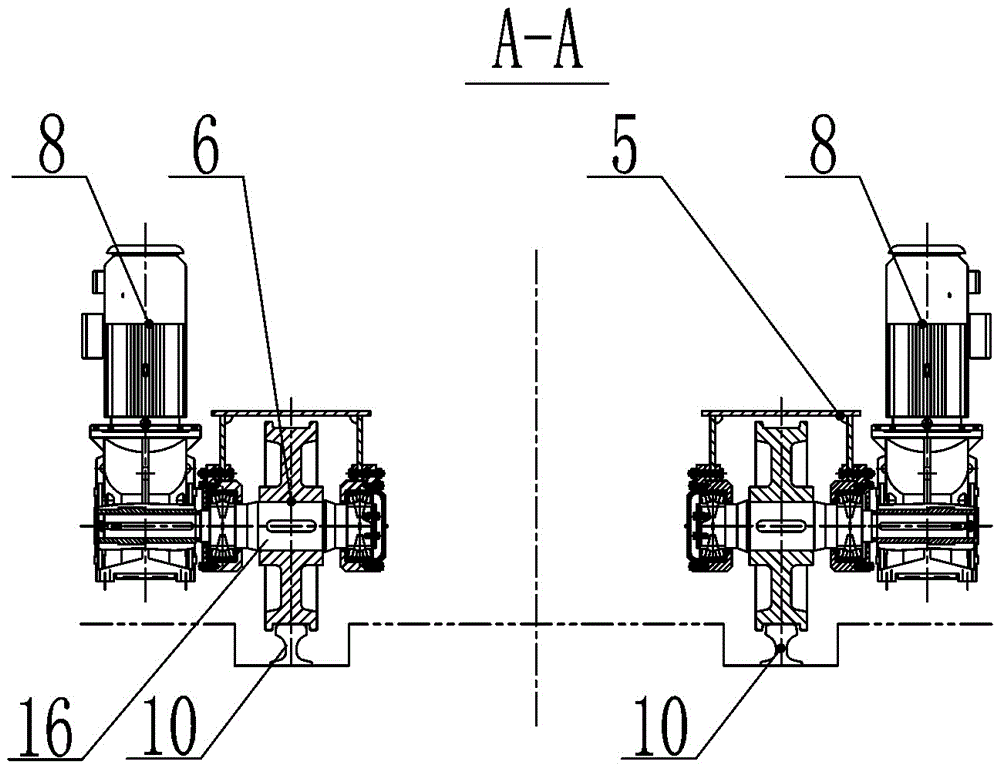

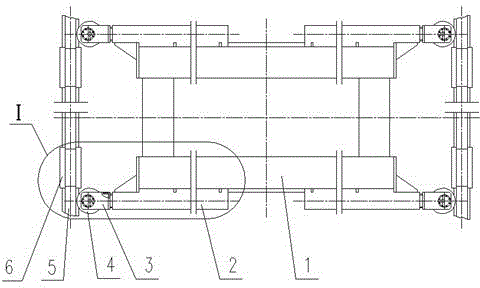

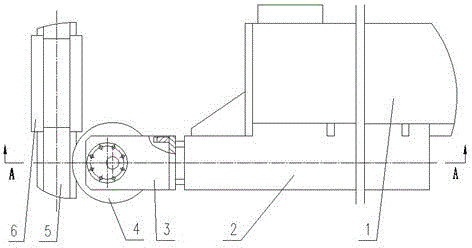

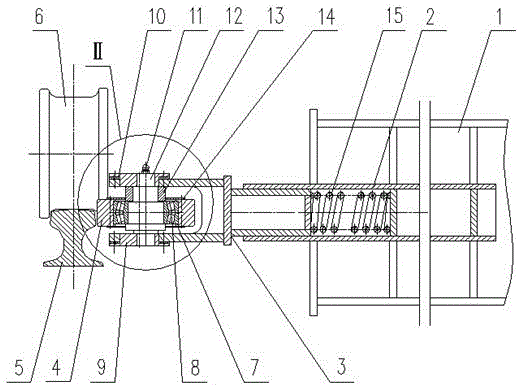

The invention relates to the technical field of hoisting equipment, and discloses a constant-pressure friction driving trolley of hanging type hoisting equipment and a method. The constant-pressure friction driving trolley comprises a hanging type trolley bearing device and a hanging type trolley driving device, wherein the hanging type trolley bearing device hung on a running rail is fixedly connected with the hanging type trolley driving device and is formed by connecting end beams clamped on two sides of the running rail with guide wheel devices and bearing wheel devices which are arranged on the end beams. Friction of running wheels is not related to the hoisting weight, the gravity and the stress, and the friction driving force of the running wheels is only related to pressure of a spring instead of being related to stress of a girder; therefore, the wheels run synchronously, and a phenomenon of rail gnawing is avoided; the service life of a motor is well prolonged; the constant-pressure friction driving trolley is small in size, light in mass, high in bearing capacity and anti-abrasion; and the problem of large noise during running is completely solved; and constant driving force is guaranteed.

Owner:洛阳卡瑞起重设备股份有限公司

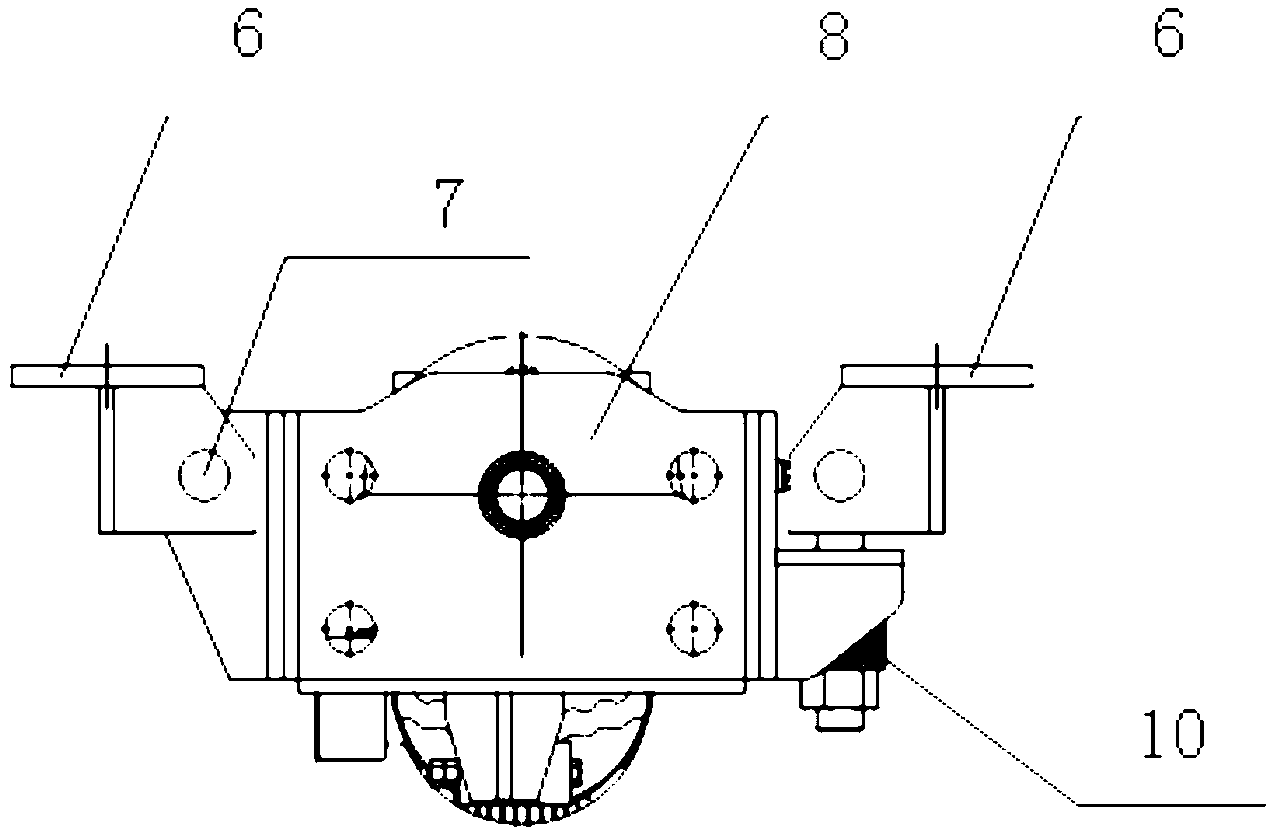

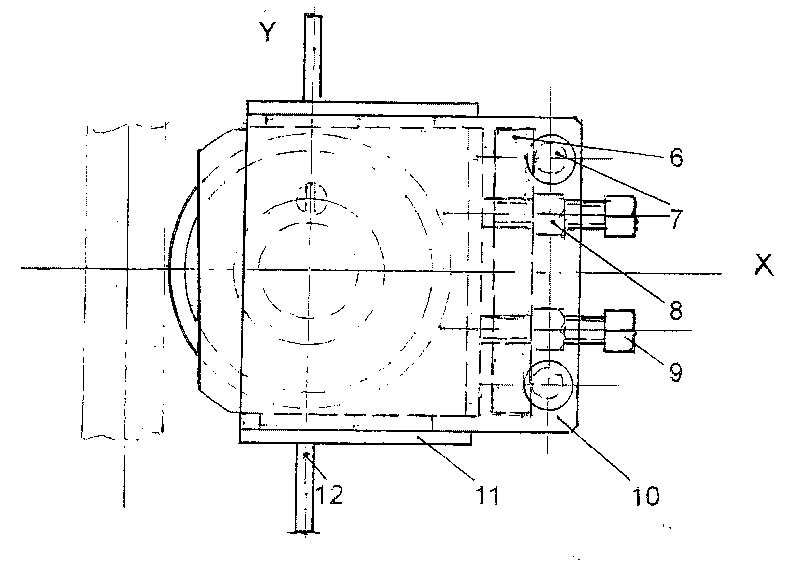

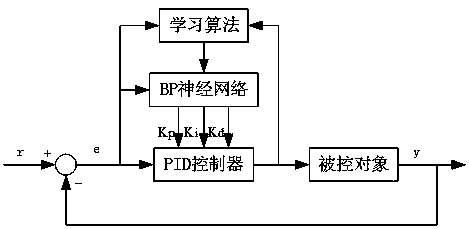

Side guide wheel of crane for preventing track biting of rim

The invention relates to a side guide wheel assembly of bridge type and gantry type cranes for preventing the track biting of a rim. The side guide wheel assembly comprises a side guide wheel (4), a bearing (2), a guide wheel shaft (1) and a guide wheel frame (5). In box-shaped slide slots (10) (11), the acting position of the side guide wheel of the assembly is regulated by a screw rod (9) so as to ensure that a minute gap is reserved between a crane rim (14) and the side face of a steel wheel to prevent that the rim has contacts and frictions with the side face of a steel track and thoroughly avoid a phenomenon that the rim bites the side face of the steel track.

Owner:沈炎源

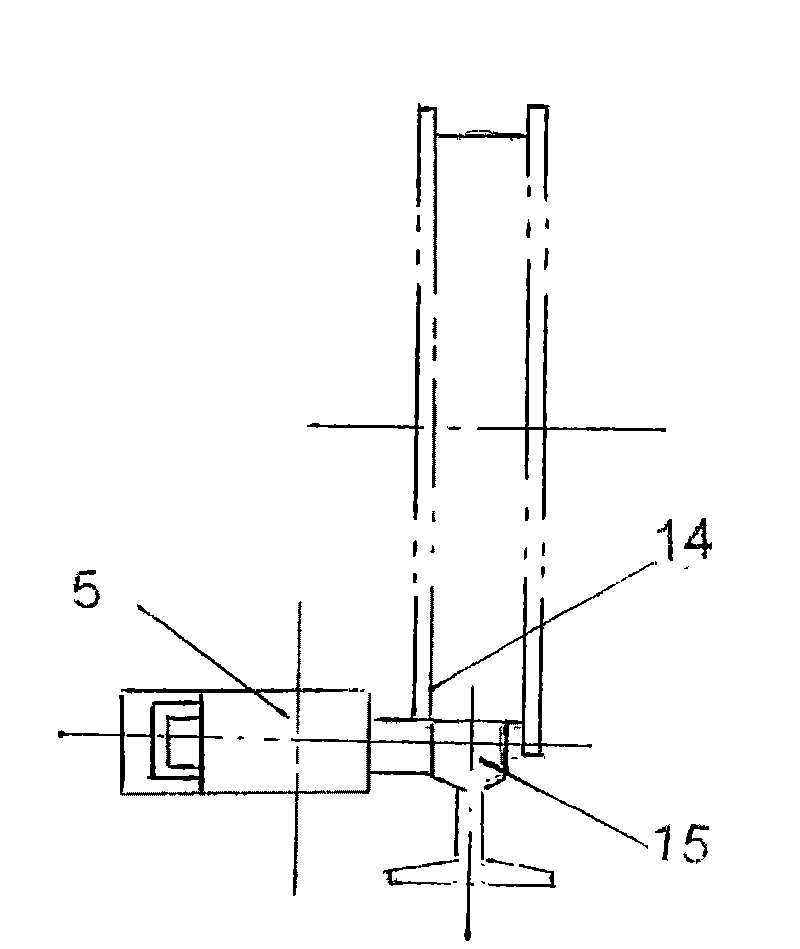

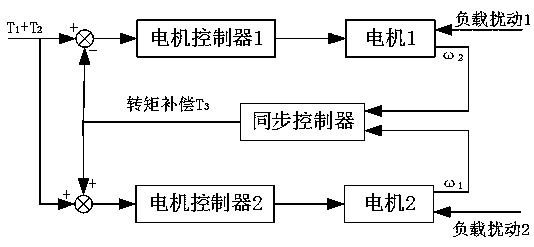

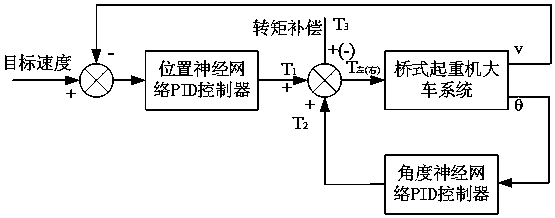

Bridge crane anti-swing control method based on neural network PID

The invention discloses a bridge crane anti-swing control method based on a neural network PID, and relates to the field of bridge cranes. A BP neural network is combined with a traditional PID controller, the neural network is adopted as an on-line estimator, and an optimal PID control parameter is given in real time. An angle neural network PID controller and a position neural network PID controller are designed, and the swing angle and position of an objected lifted by a crane are controlled. Meanwhile, in order to solve the problem that motors on the two sides are unbalanced in rotation speed due to load disturbance in the operation process of a crane cart, a motor rotation speed synchronous controller is designed and used for torque compensation. Through the bridge crane anti-swing control method, the crane can be precisely positioned, lifted object swing can be eliminated, and in addition, the rail gnawing phenomenon caused by the unequal rotation speeds of the two motors of thecart in the crane transport process can be avoided.

Owner:HARBIN INST OF TECH AT WEIHAI

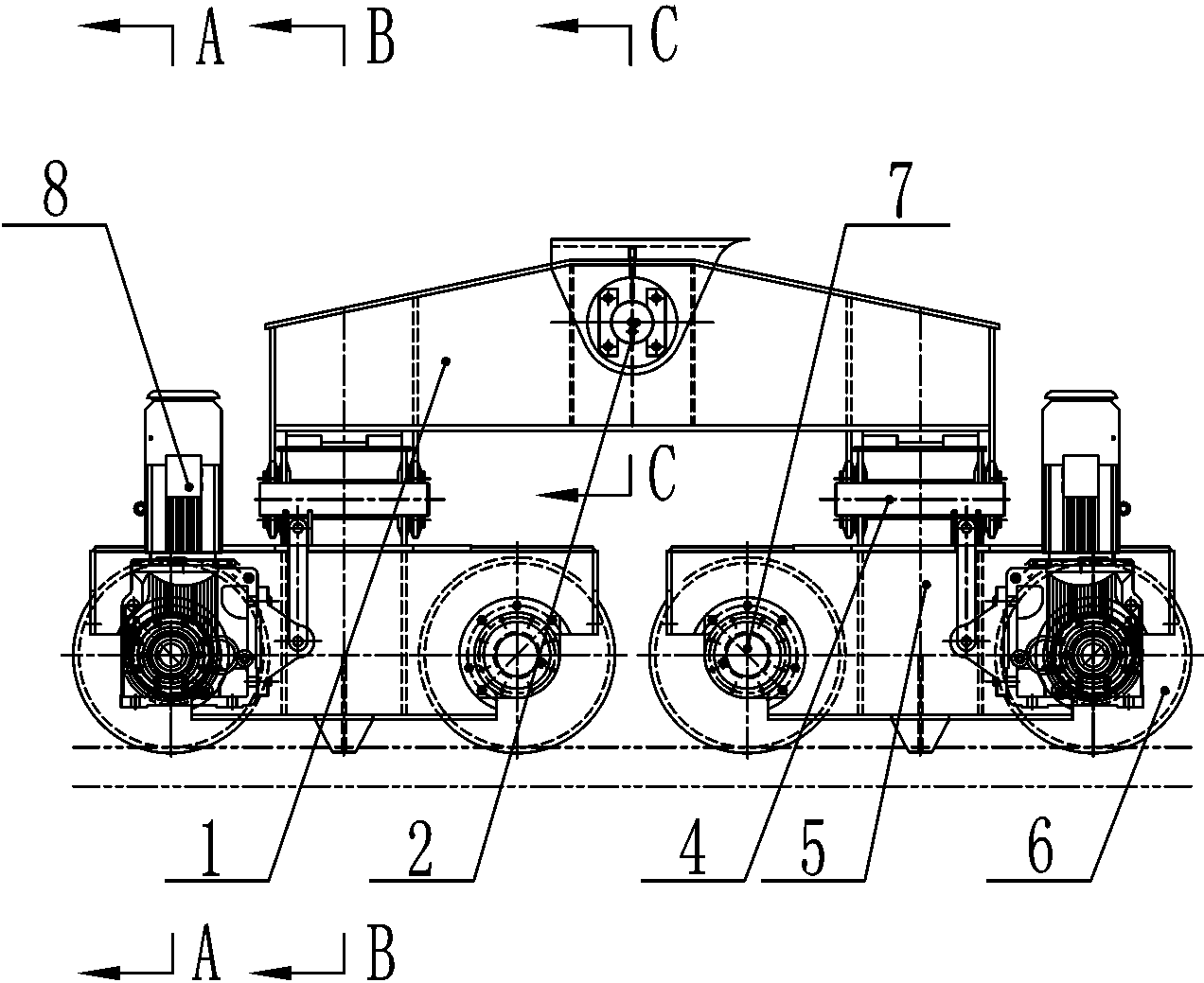

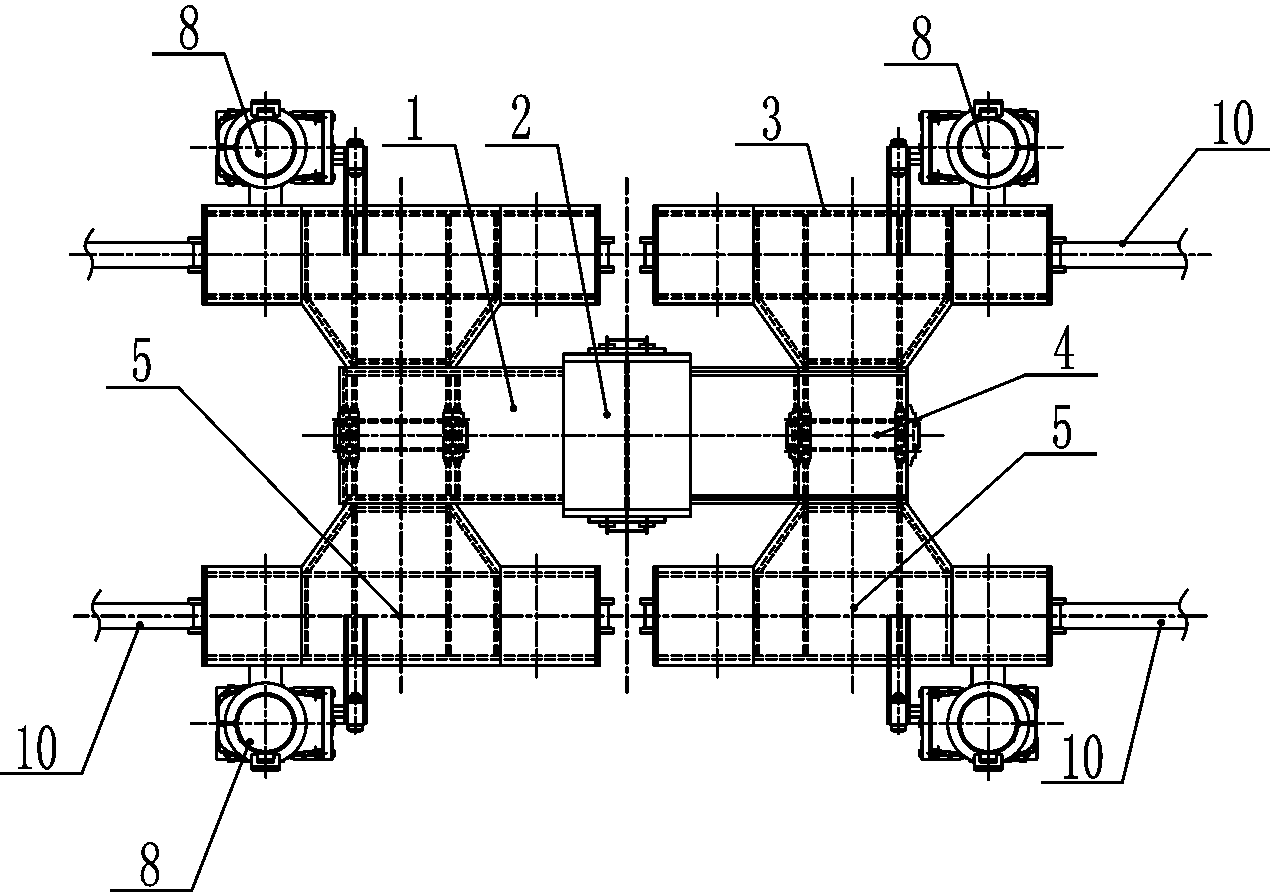

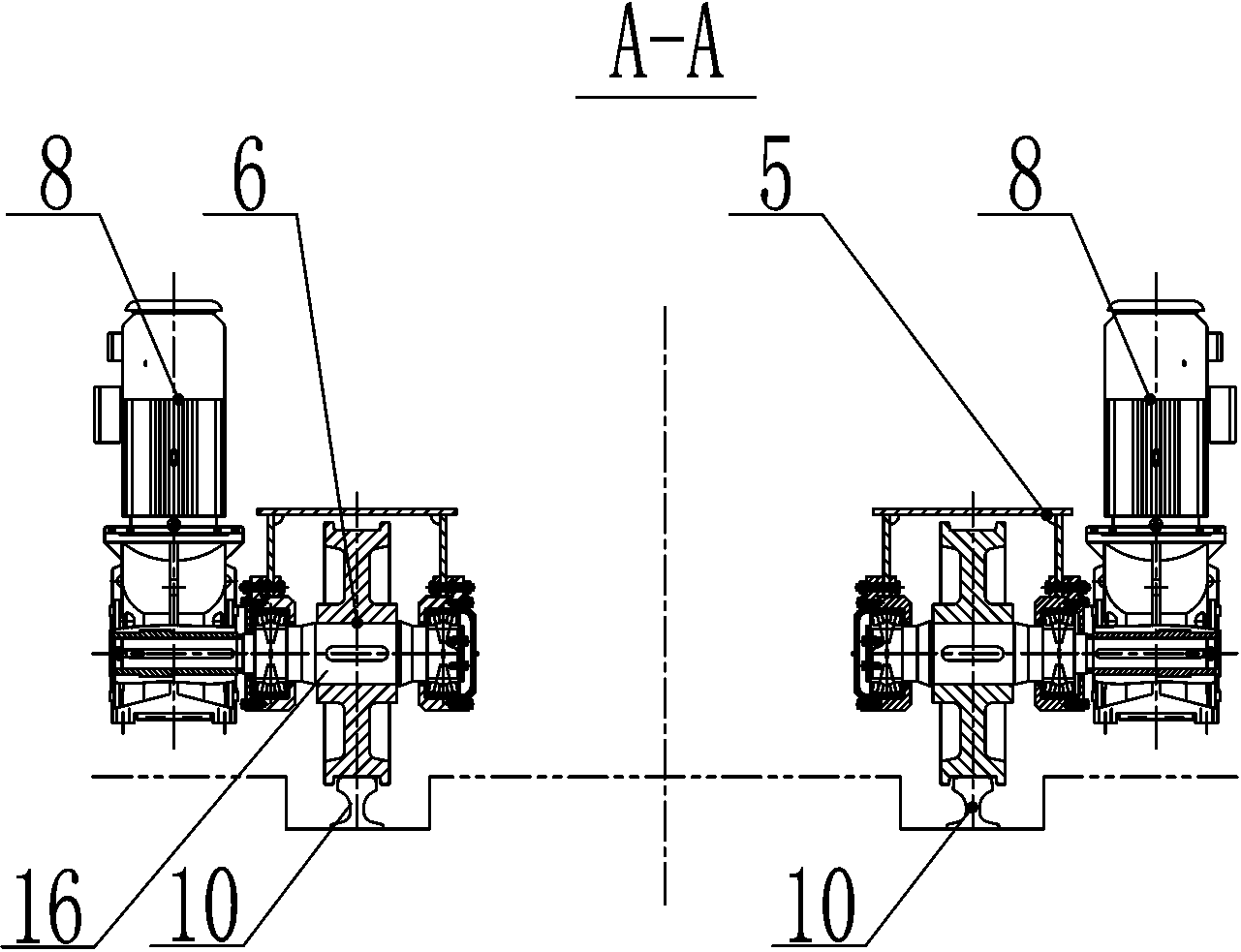

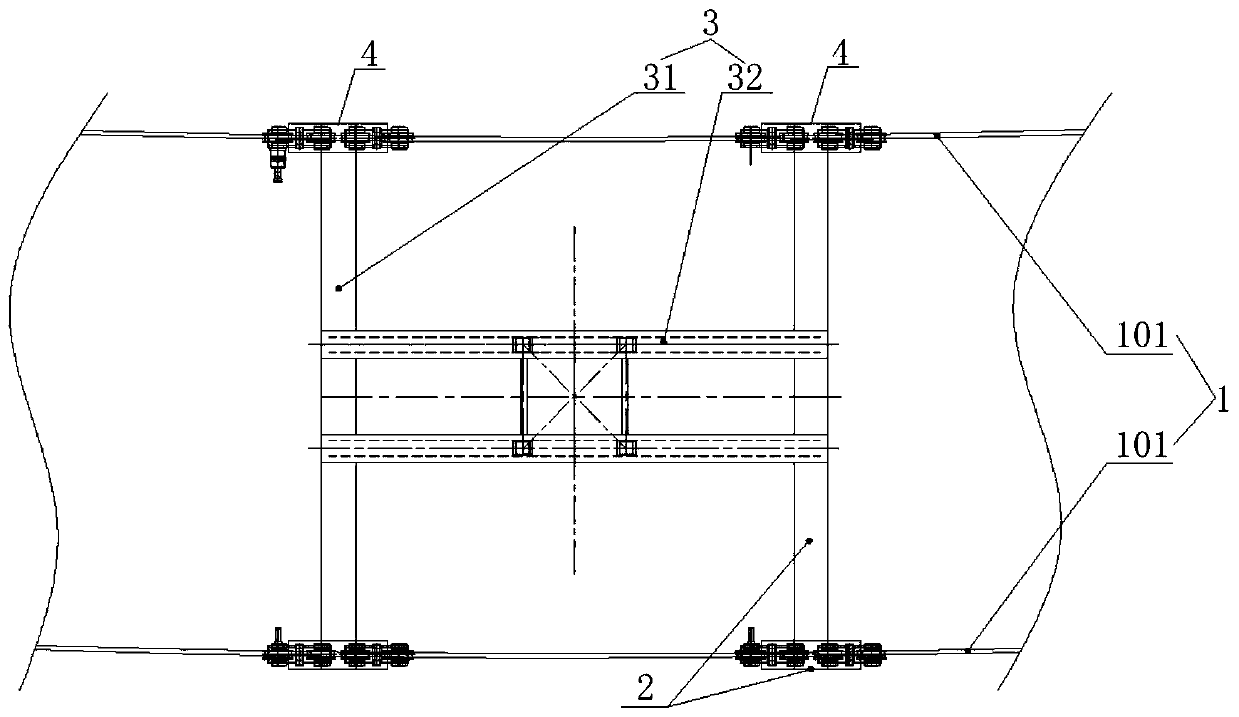

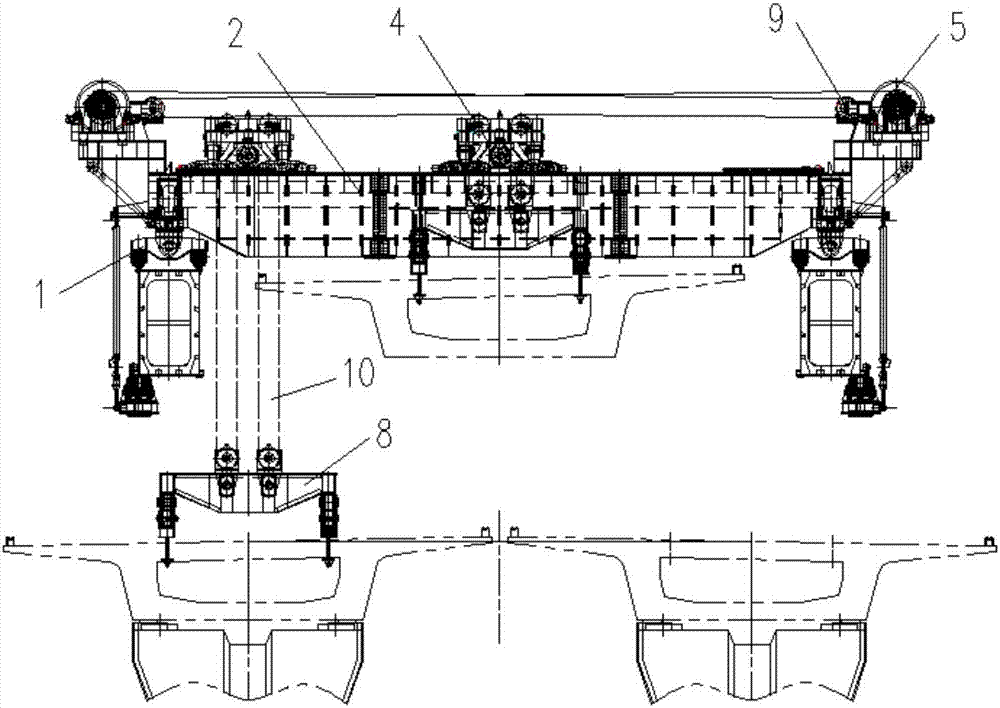

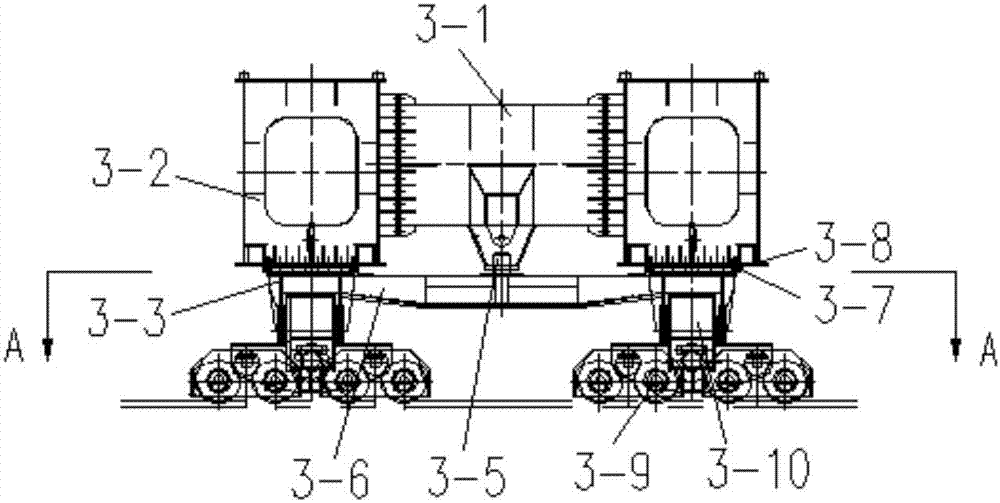

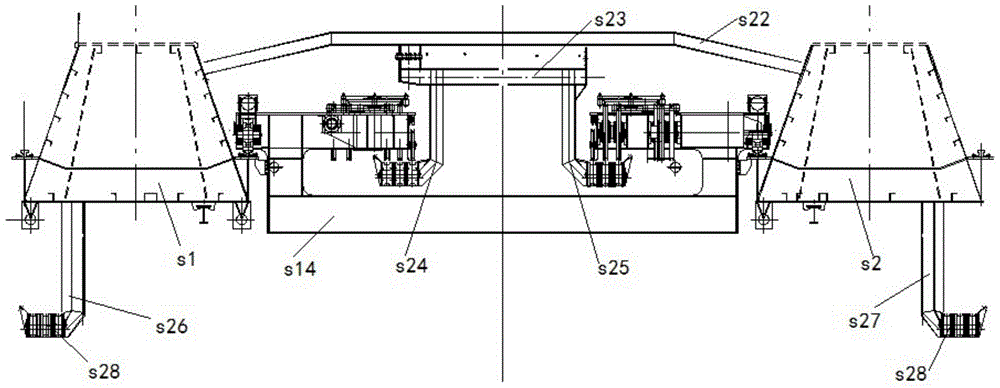

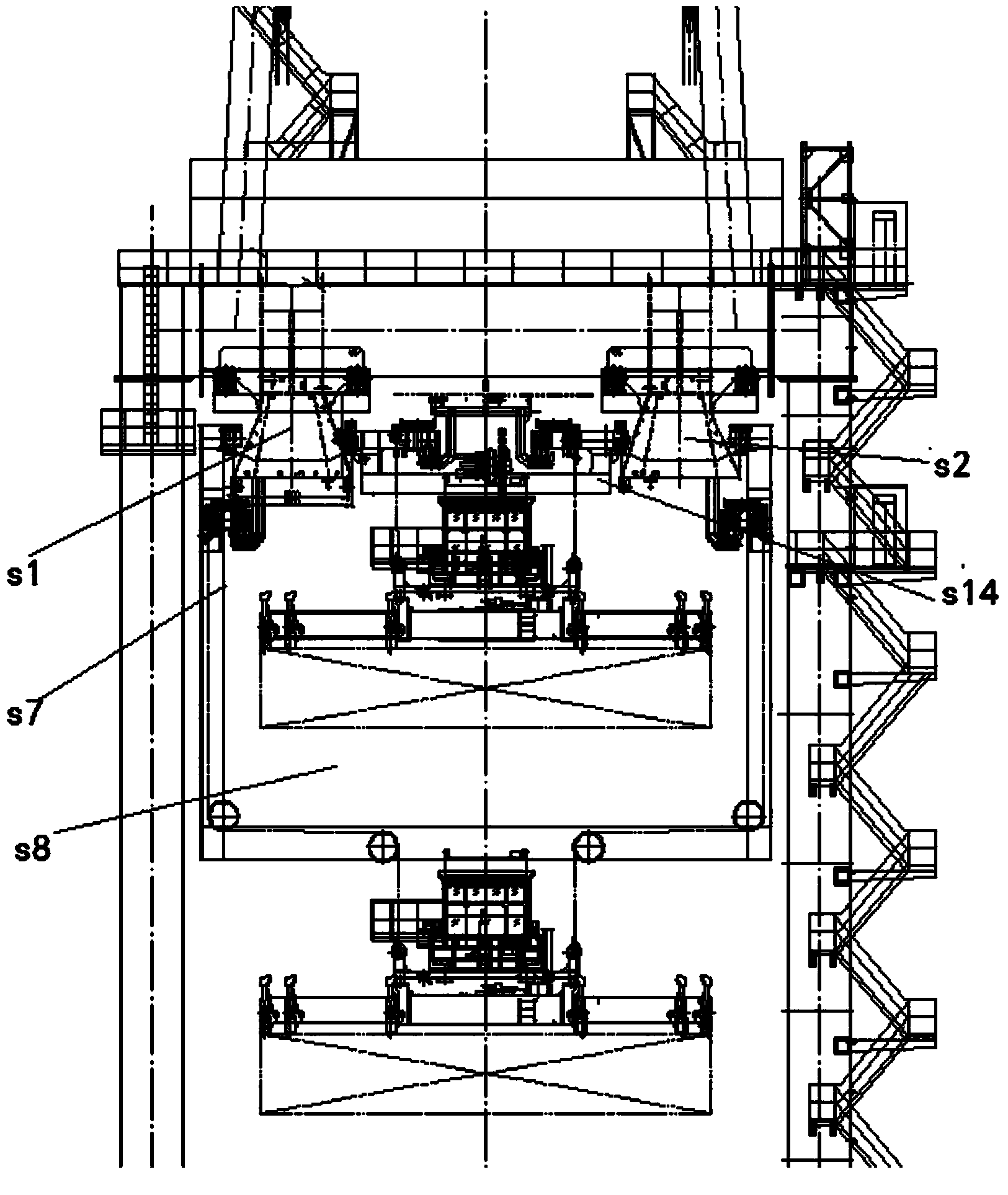

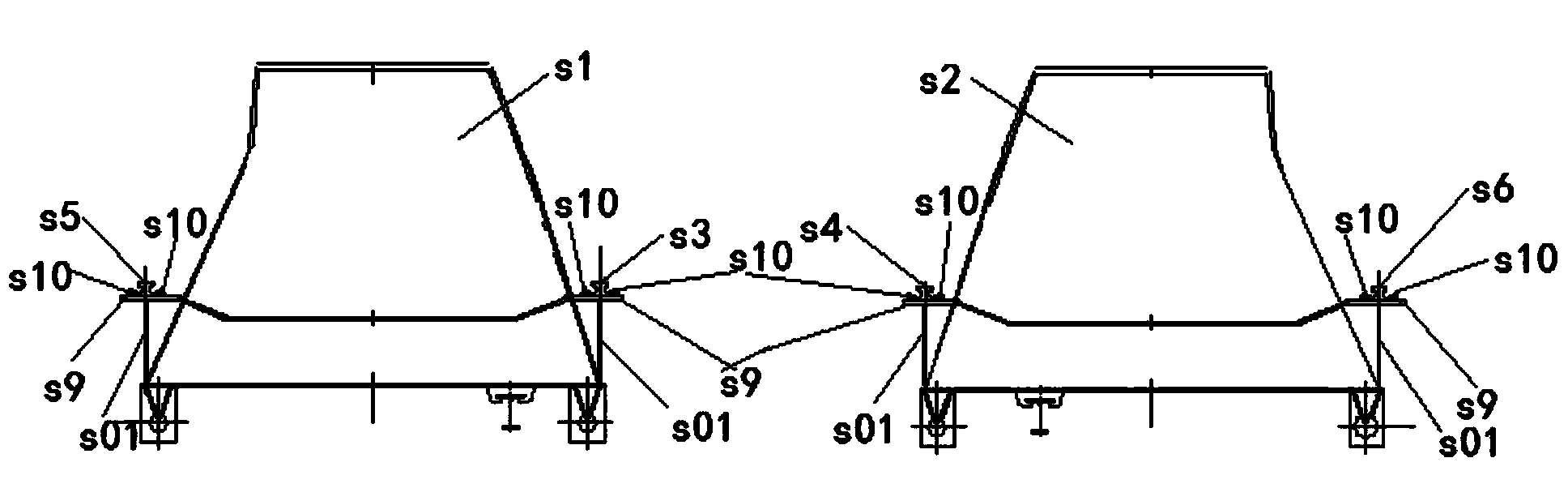

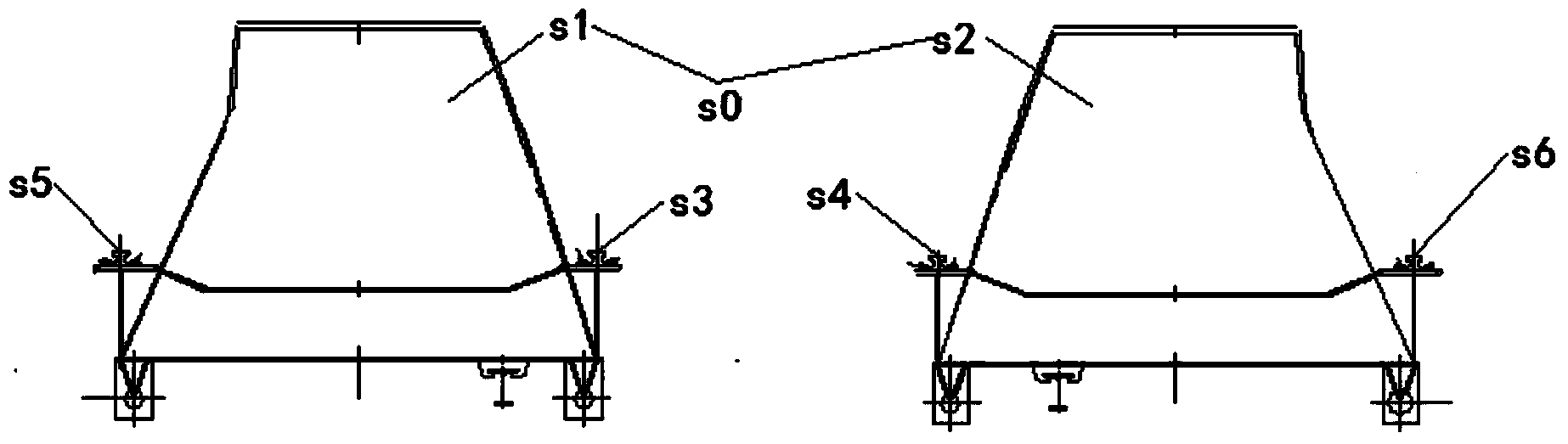

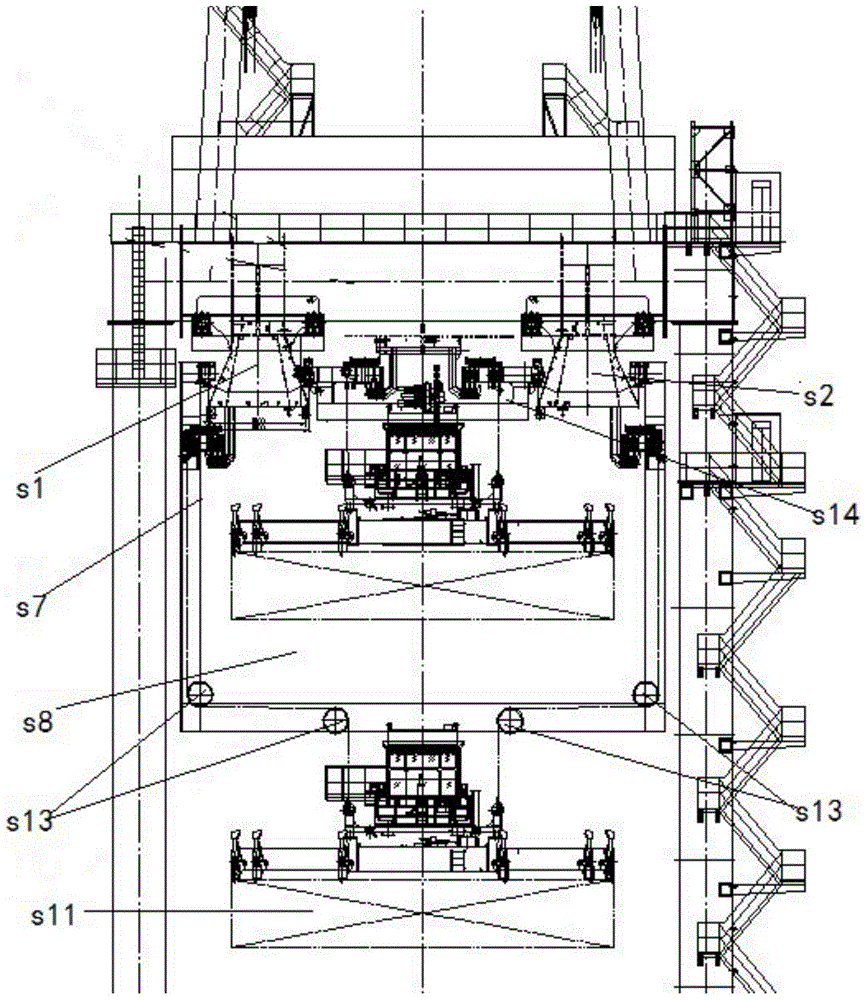

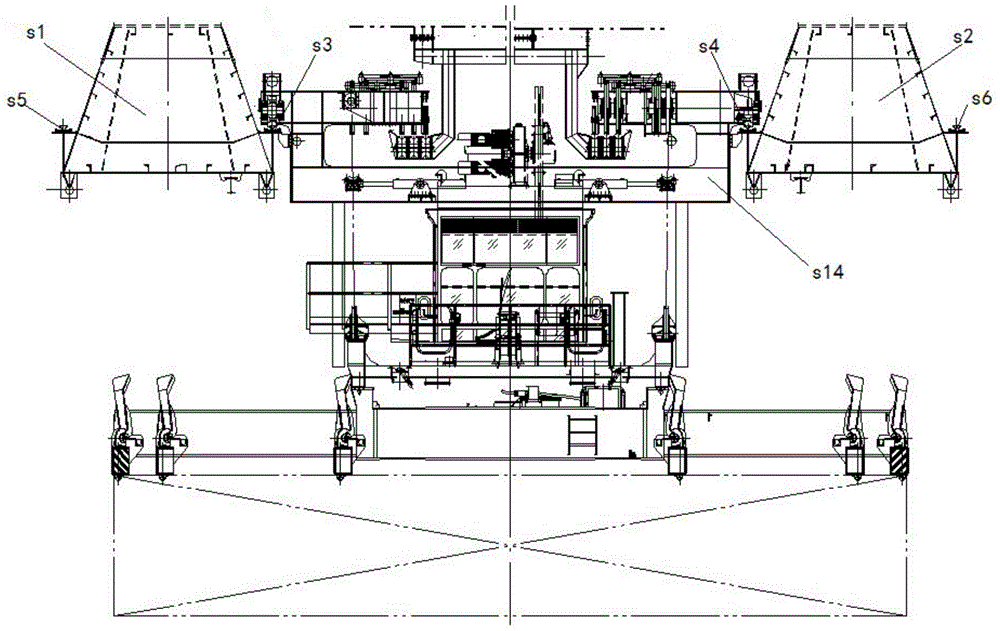

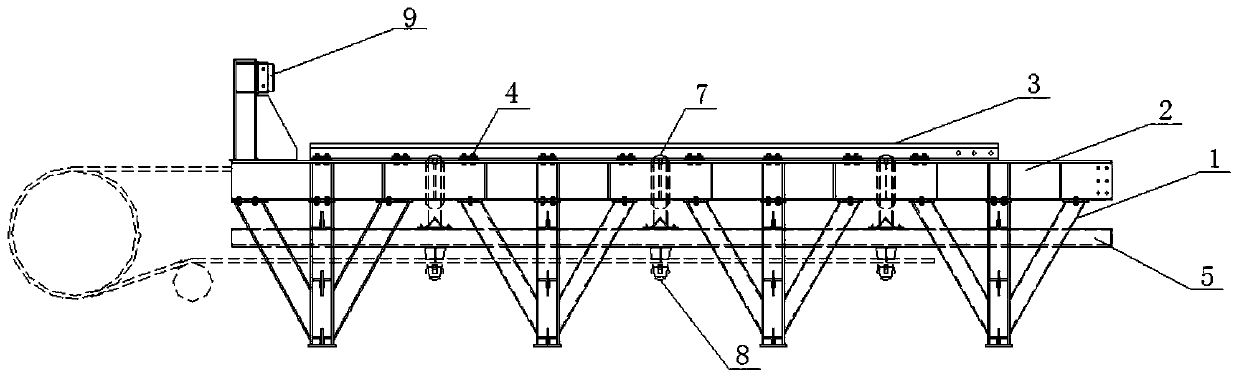

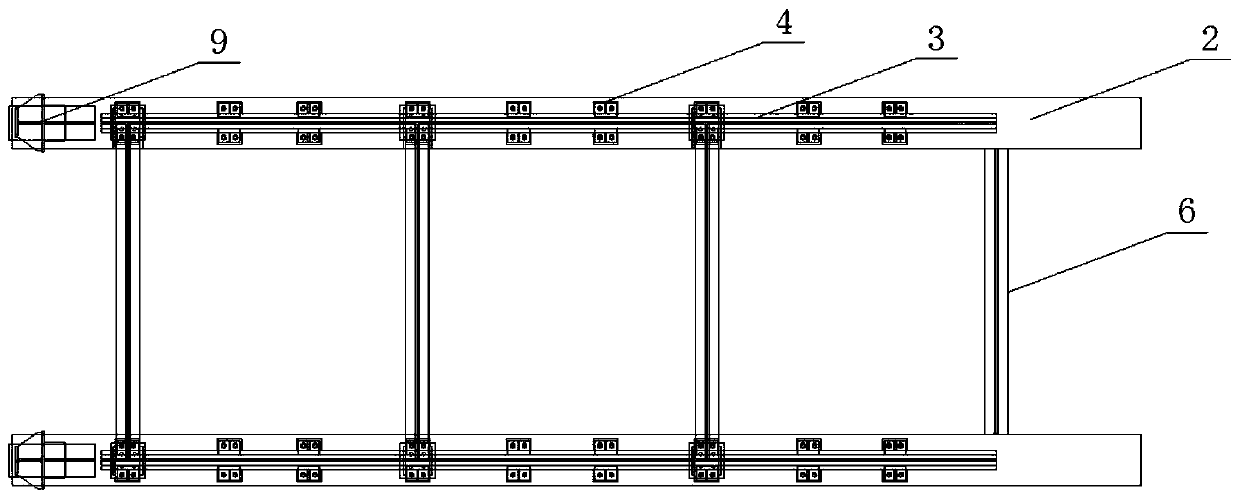

Double-track trolley group running mechanism for ultra-large gantry crane

ActiveCN104176633AImprove uniform distributionReduce lateral forceTravelling gearRunwaysVehicle frameDrive wheel

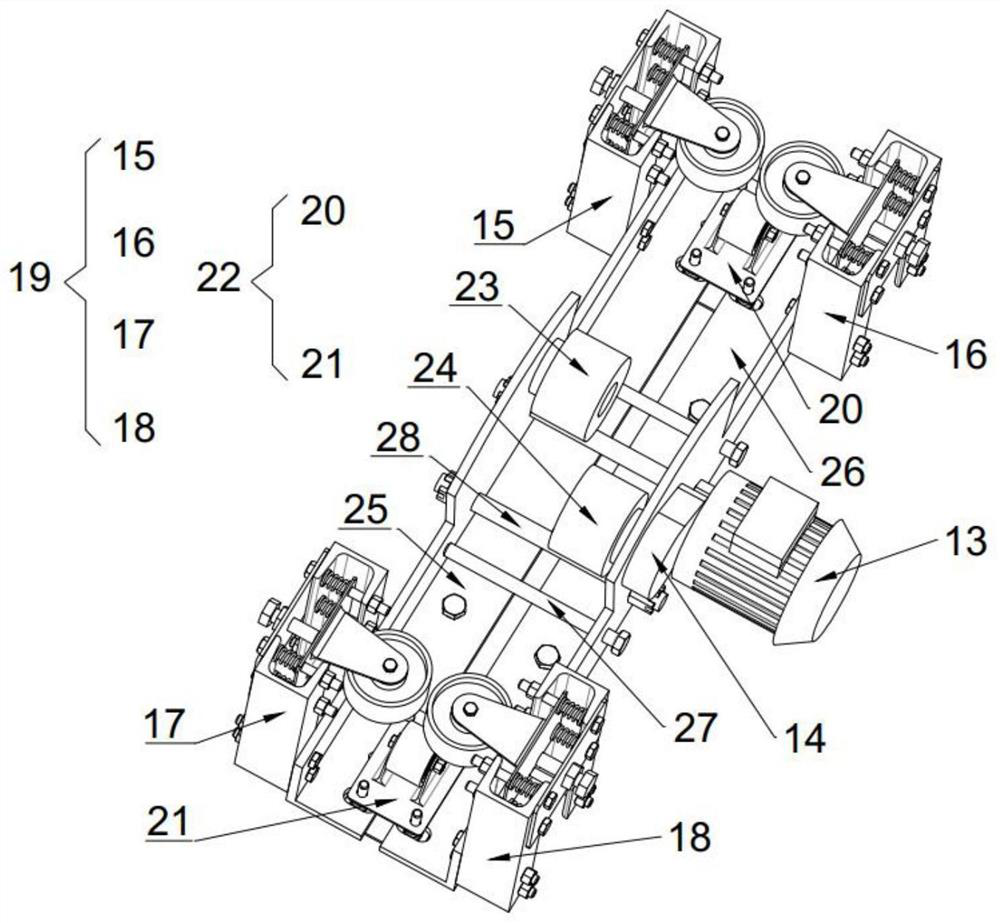

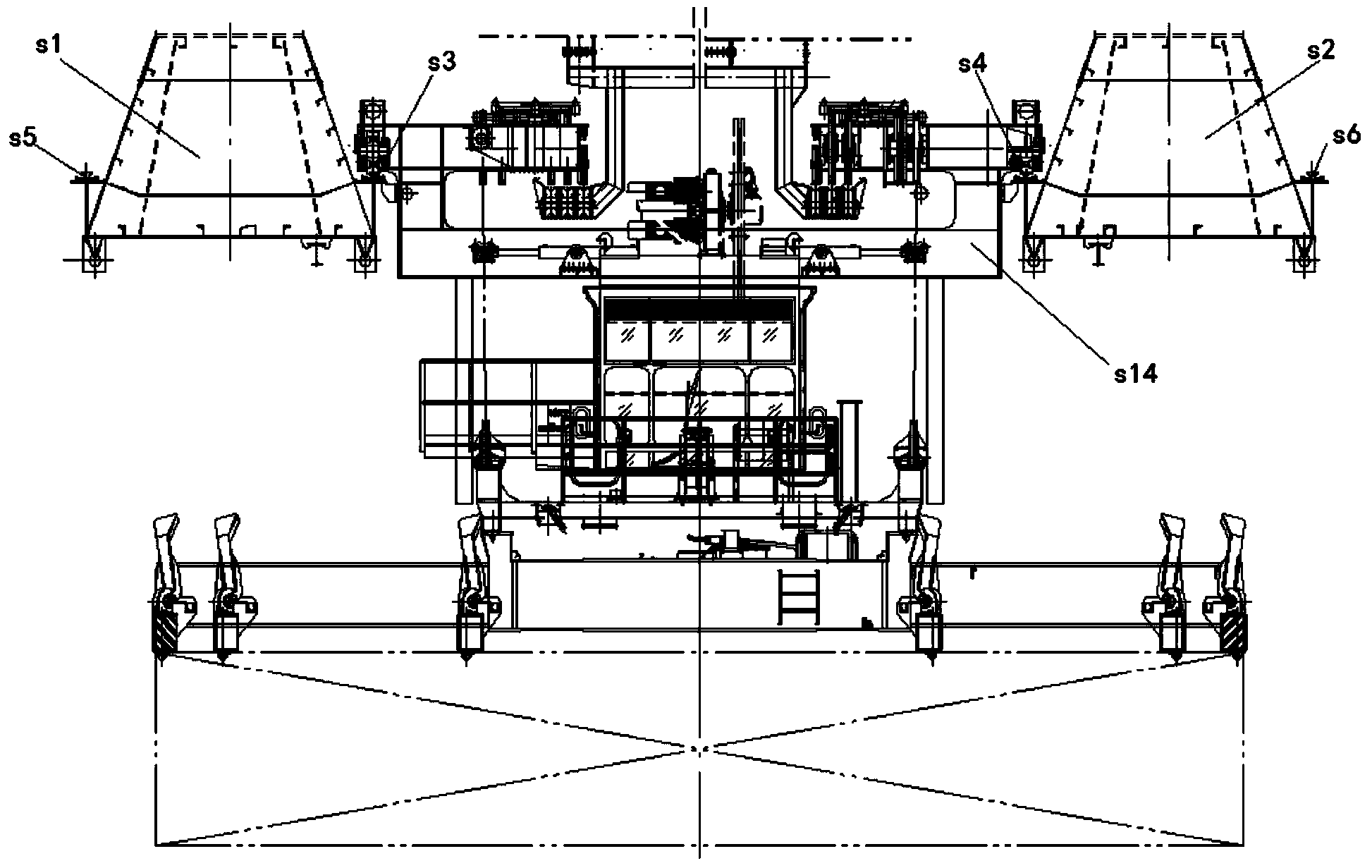

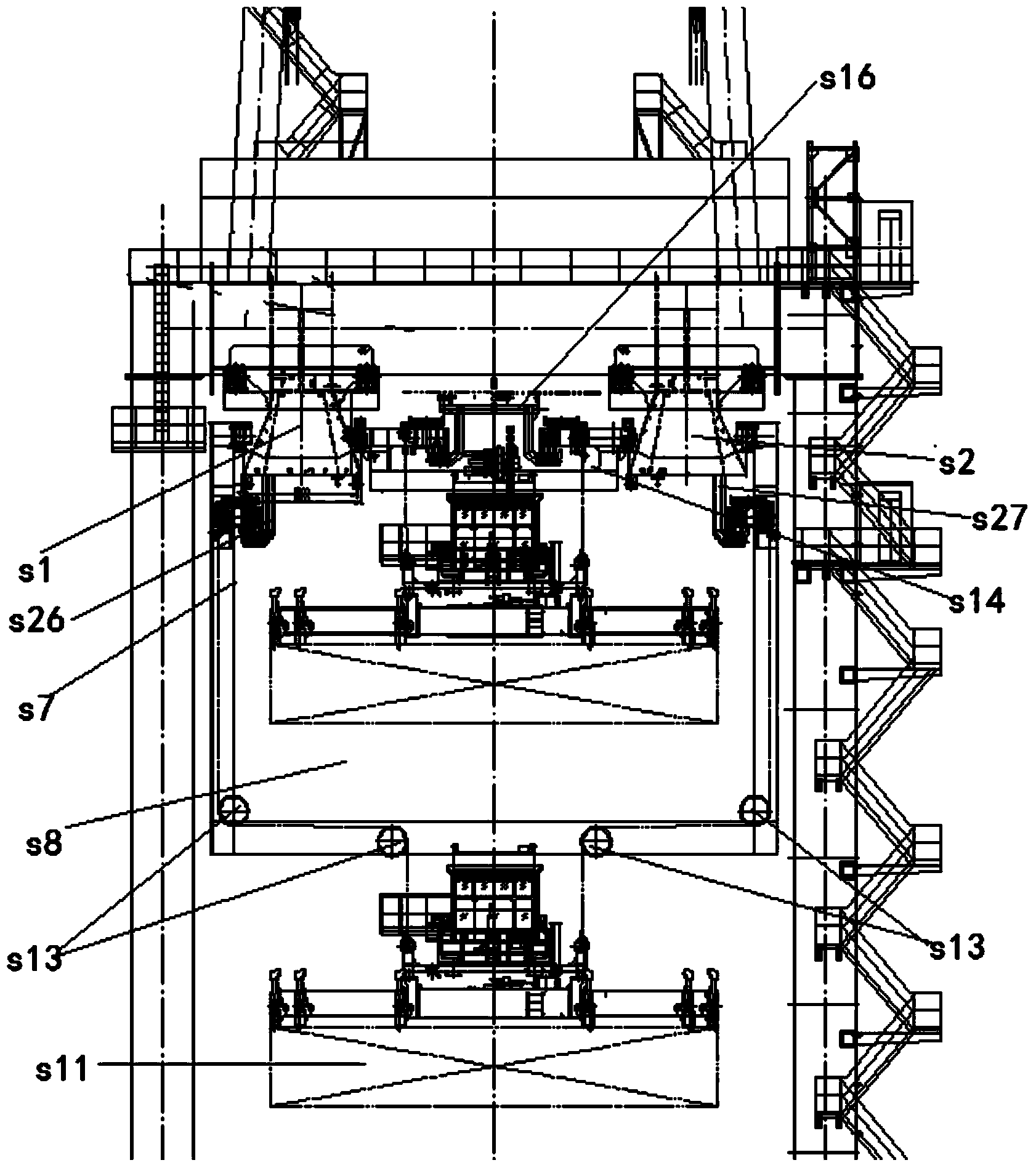

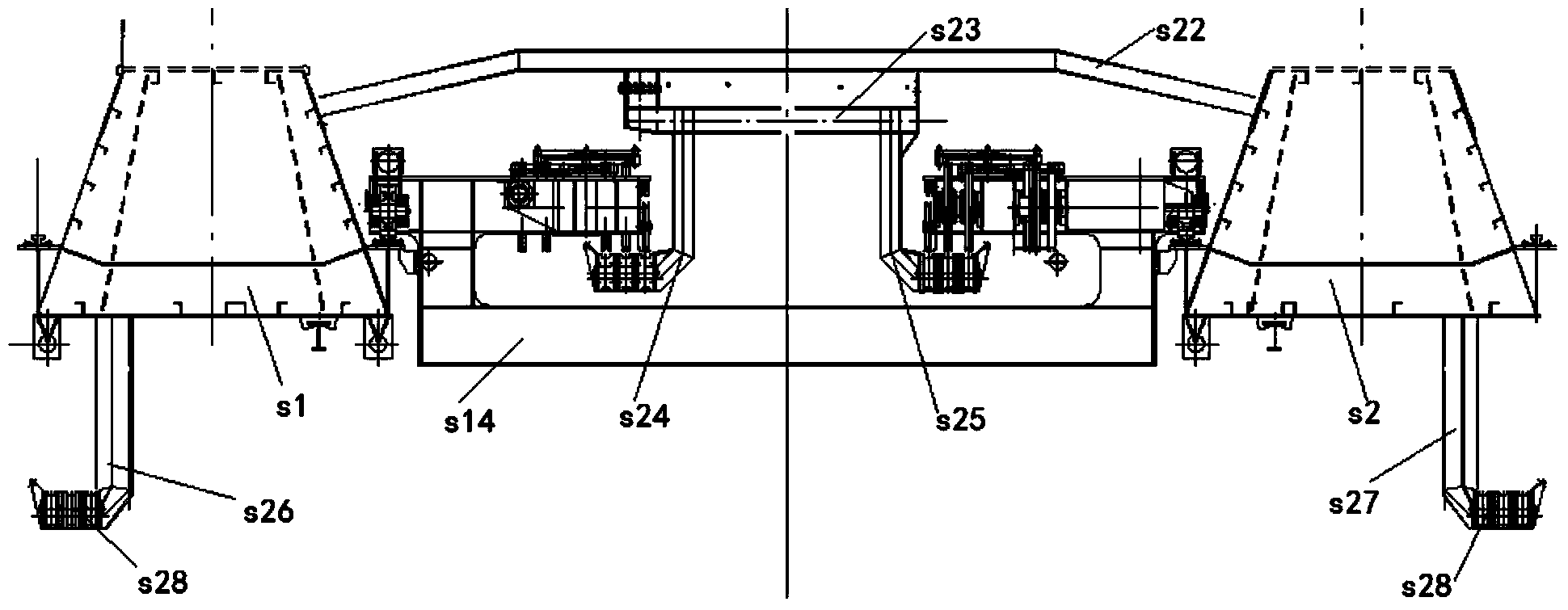

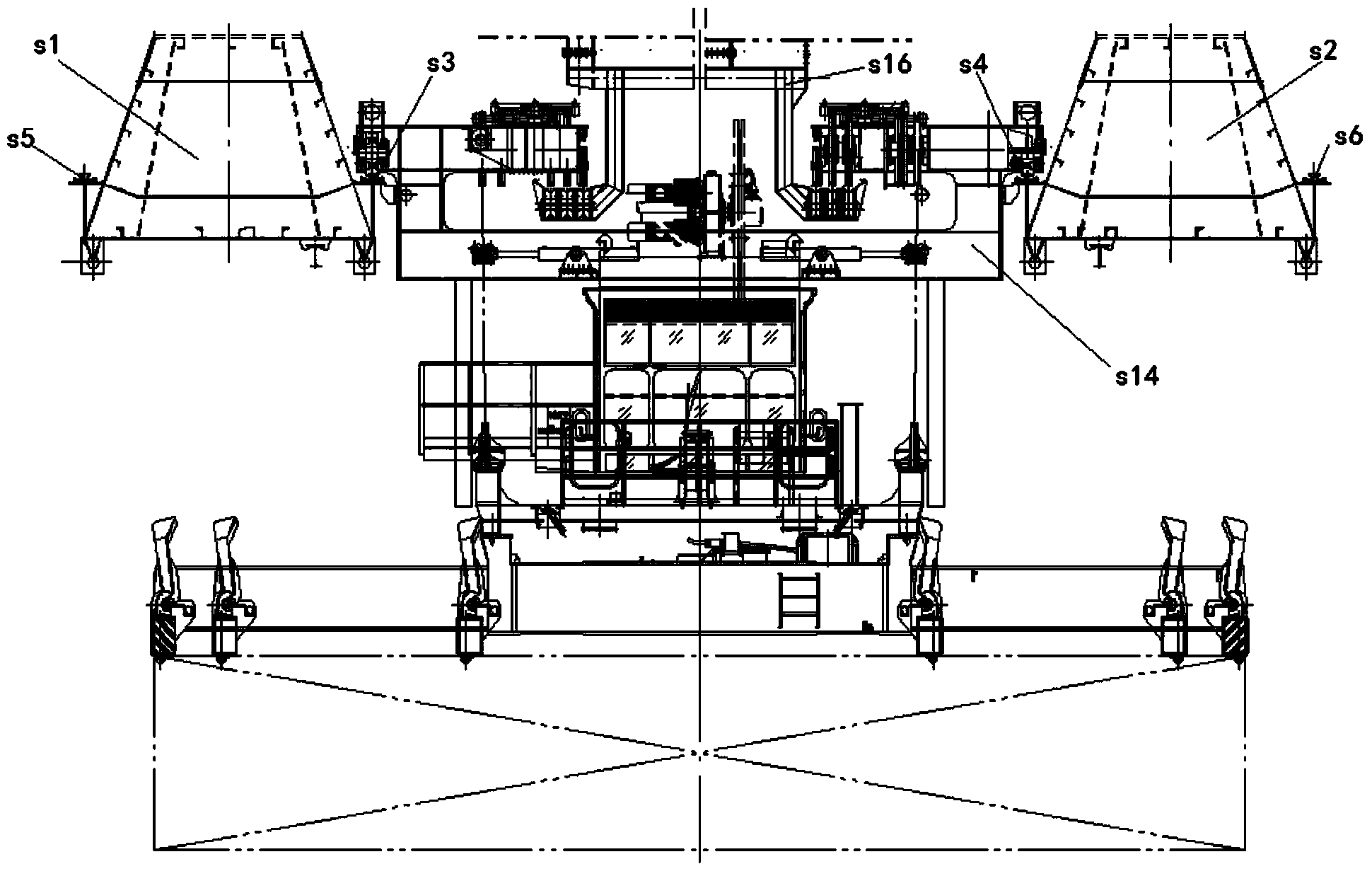

The invention discloses a double-track trolley group running mechanism for an ultra-large gantry crane. The double-track trolley group running mechanism comprises an equalizing beam and double-track trolleys. The double-track trolley group running mechanism is characterized in that each double-track trolley is a four-wheel double-drive mechanism which is formed by travelling wheels and driven wheels which are symmetrically arranged on two sides of a trolley frame; the double-track trolleys are fixedly arranged at the two ends of the equalizing beam through hinged shafts, and the double-track trolleys are in hinged connection with the equalizing beam; the trolley frame is of an I-shaped box structure; the travelling wheels are driving wheels provided with driving mechanisms, and the driving mechanisms can enable the traveling wheels and the driven wheels to drive a trolley group composed of the two double-track trolleys to run on tracks. Compared with the prior art, the double-track trolley group running mechanism has the advantages of low wheel pressure of the traveling wheels, uniform distribution of wheel pressure, and is capable of greatly weakening lateral force, effectively avoiding the rail gnawing phenomenon, enlarging the working range, reducing the working blind area and further reducing project construction cost. The double-track trolley group running mechanism is simple in structure and greatly convenient to maintain.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

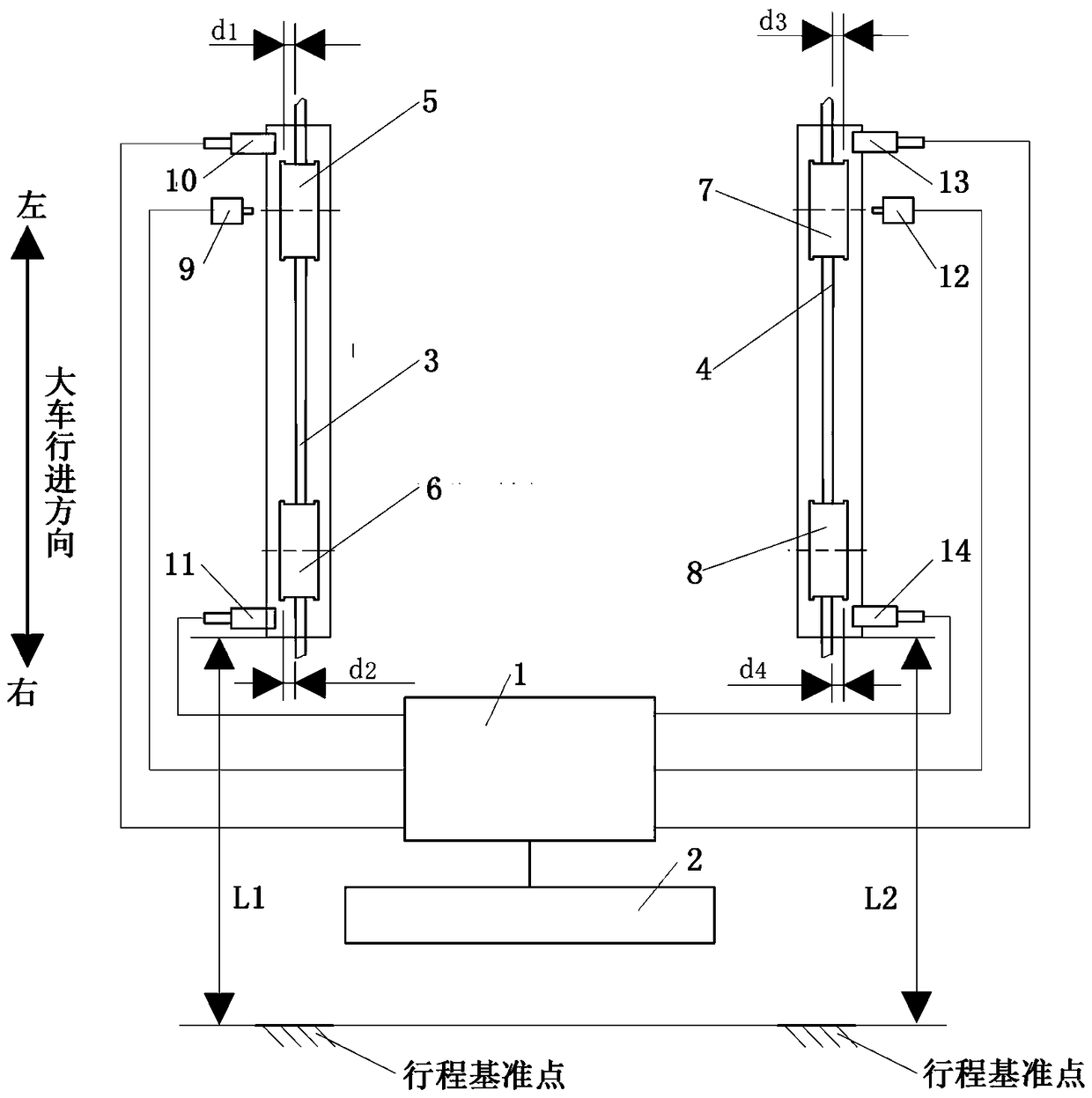

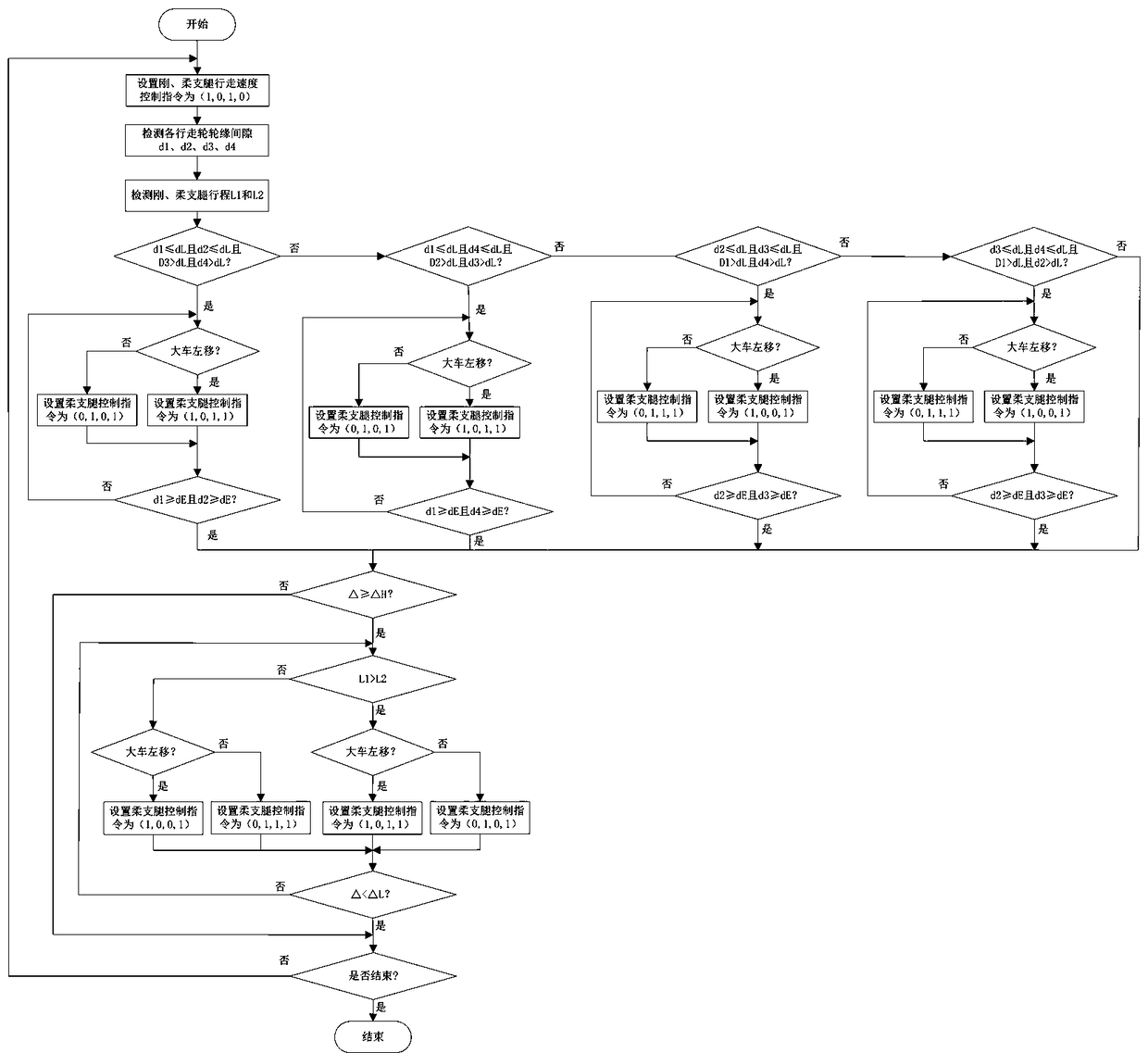

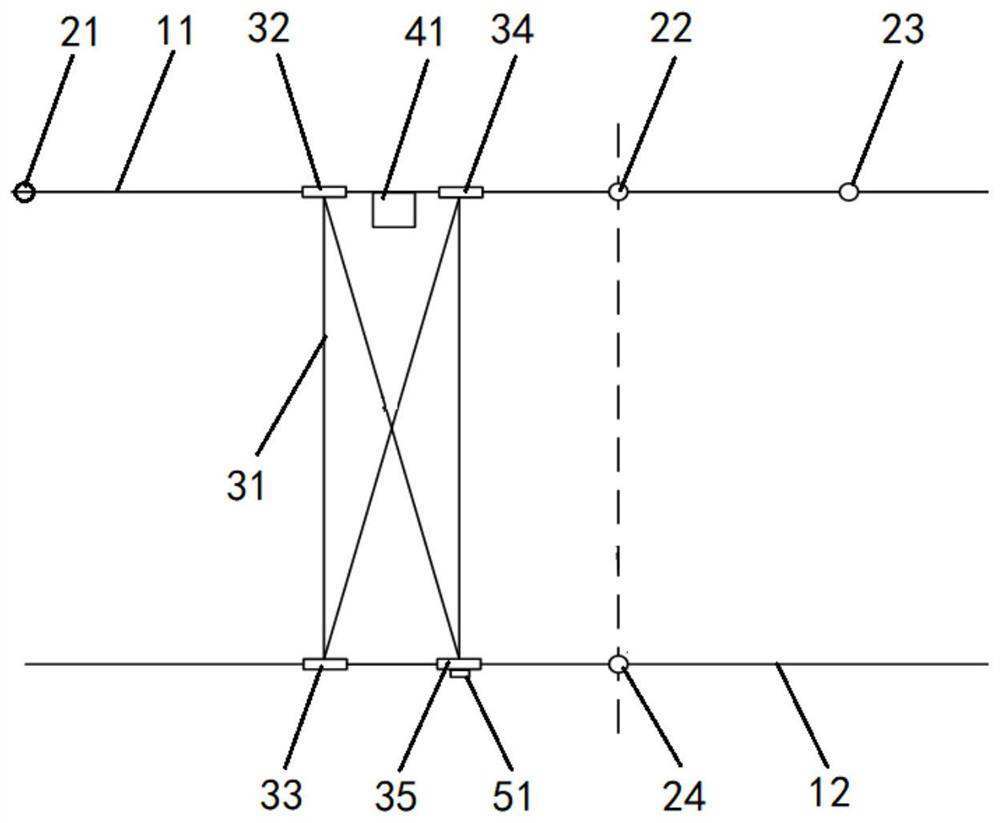

Bridge and portal crane trolley walking deviation rectifying and rail gnawing prevention device and method

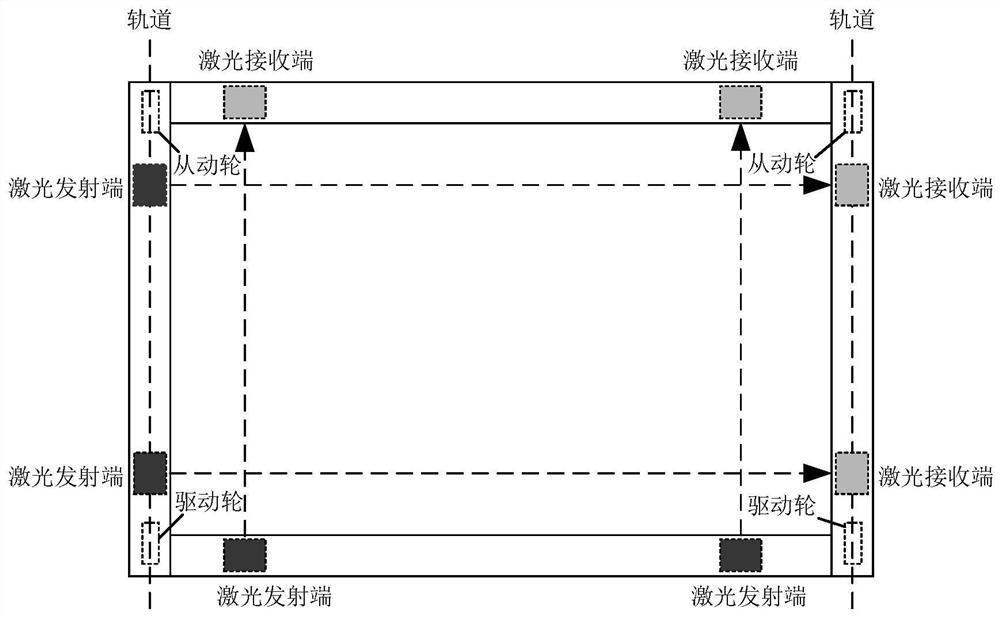

ActiveCN109019337AHighlight substantive featuresSignificant progressTravelling gearWalking distanceGantry crane

The invention provides a bridge and portal crane trolley walking deviation rectifying and rail gnawing prevention device. The bridge and portal crane trolley walking deviation rectifying and rail gnawing prevention device comprises two sets of information acquiring devices, a main control unit and a flexible landing leg walking control frequency converter, wherein the two sets of information acquiring devices are used for measuring the actual walking distance of a flexible landing leg of a crane, the actual walking distance of a rigid landing leg of the crane and the space values of wheel flanges at the two ends of each landing leg and a track; the main control unit is connected with the two sets of information acquiring devices and generates a flexible landing leg control instruction according to the actual walking distance of the flexible landing leg, the actual walking distance of the rigid landing leg and the space values of the wheel flanges at the two ends of each landing leg andthe track; and the flexible landing leg walking control frequency converter is connected with the main control unit and controls the walking speed of the flexible landing leg according to the flexible landing leg control instruction. The invention further provides a deviation rectifying and rail gnawing prevention method. It can be guaranteed that the walking deviations of the two sides of the crane and the space between the wheel flanges and the track are in the tolerance range, and the rail gnawing phenomenon is avoided. The bridge and portal crane trolley walking deviation rectifying and rail gnawing prevention device and method have the advantages that the design is scientific, practicality is high, the structure is simple, and measuring is accurate.

Owner:ZHENGZHOU UNIV +1

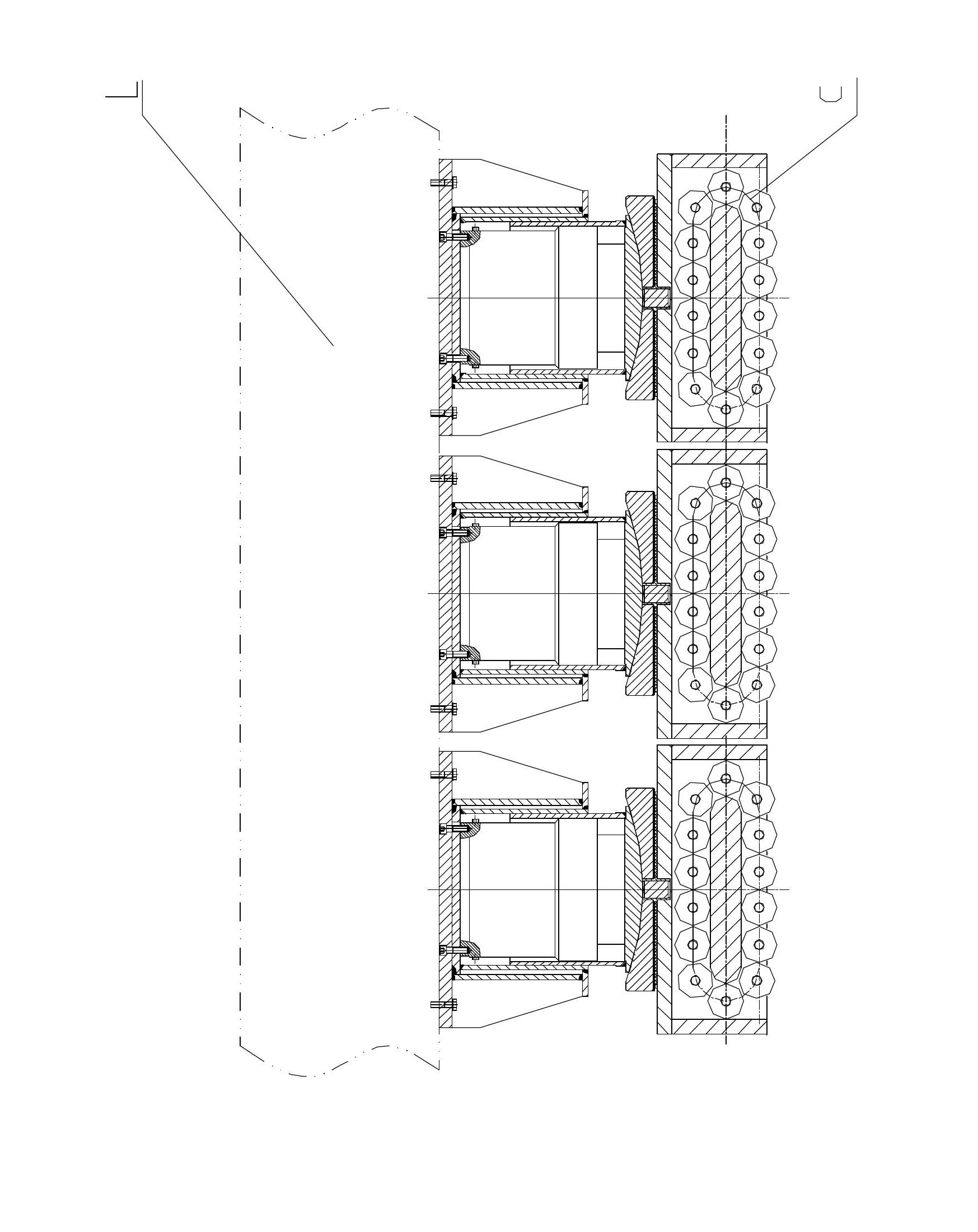

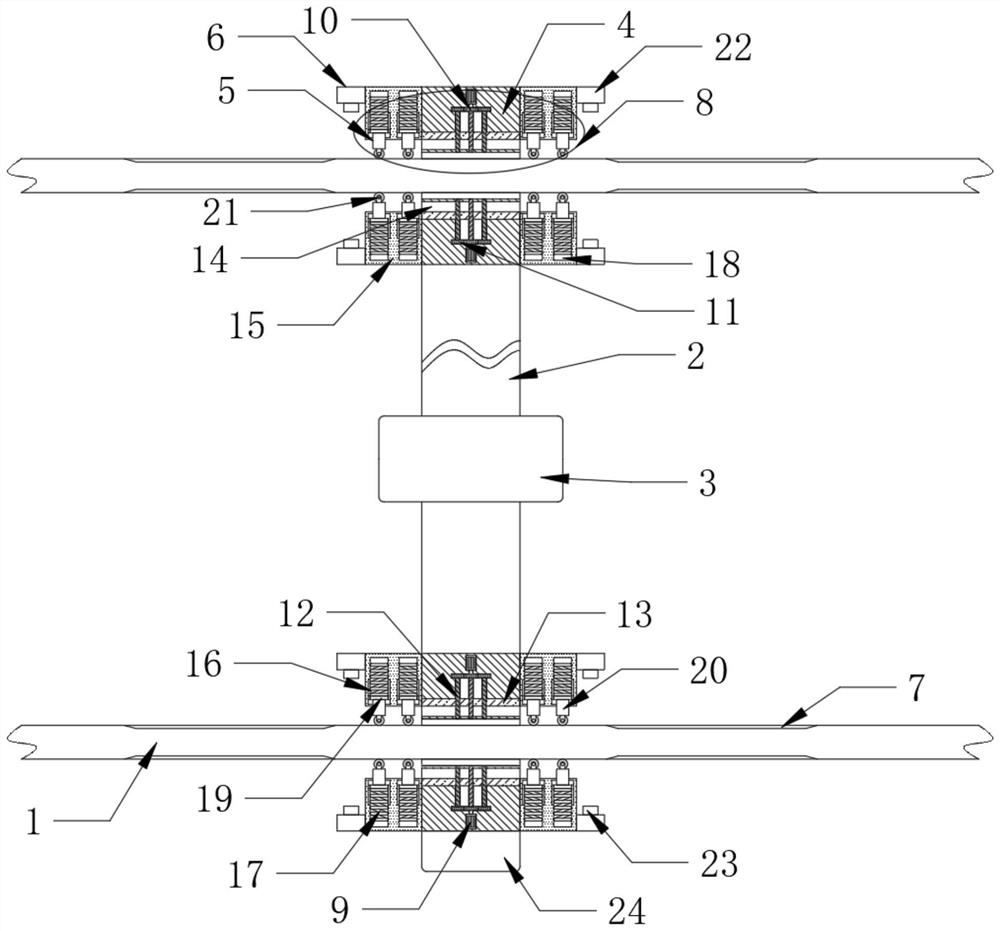

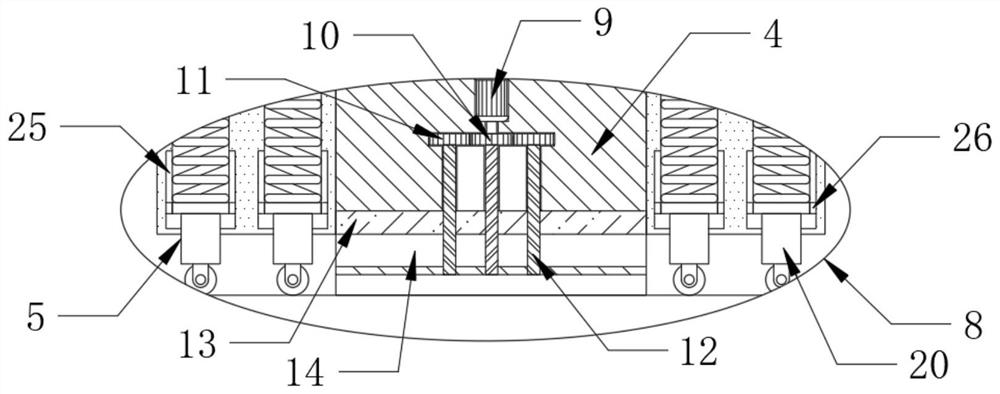

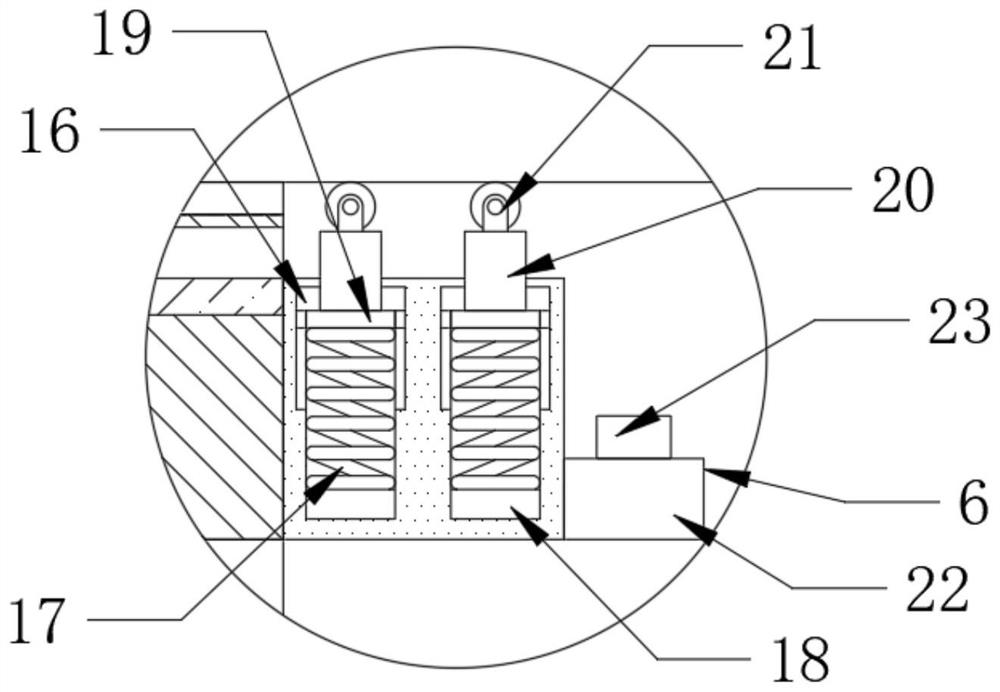

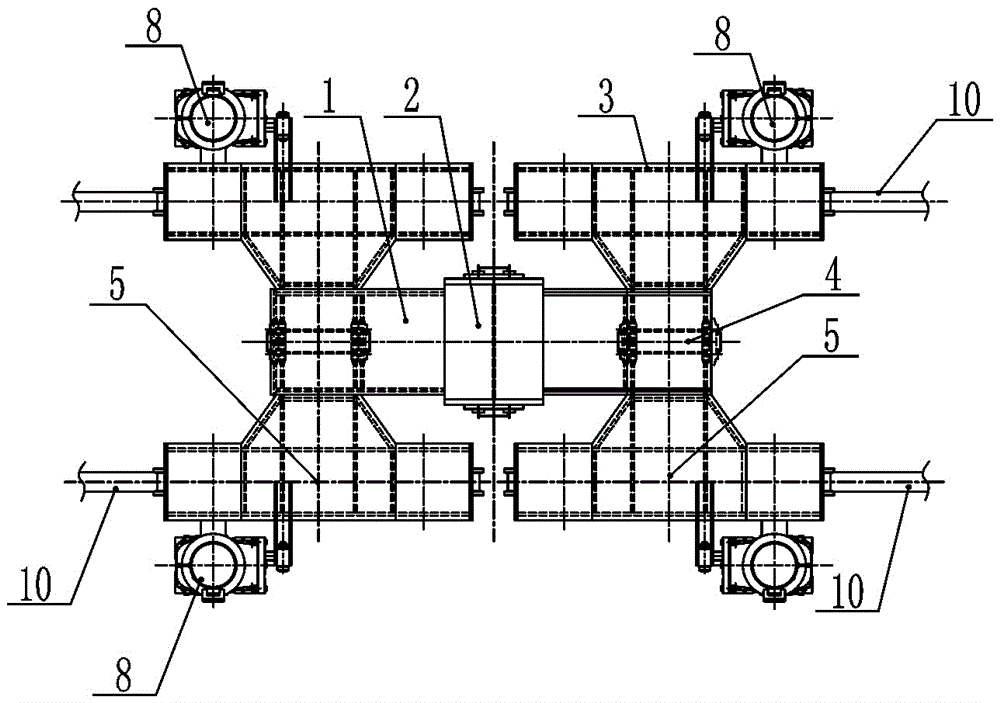

Rail gnawing prevention walking device self-adaptive to rail gauge and wheel pressure

ActiveCN113200450AAutomatically adapt to gauge deviationReduce stress imbalanceTravelling gearRunwaysElectric machineryStructural engineering

Owner:XIAMEN UNIV

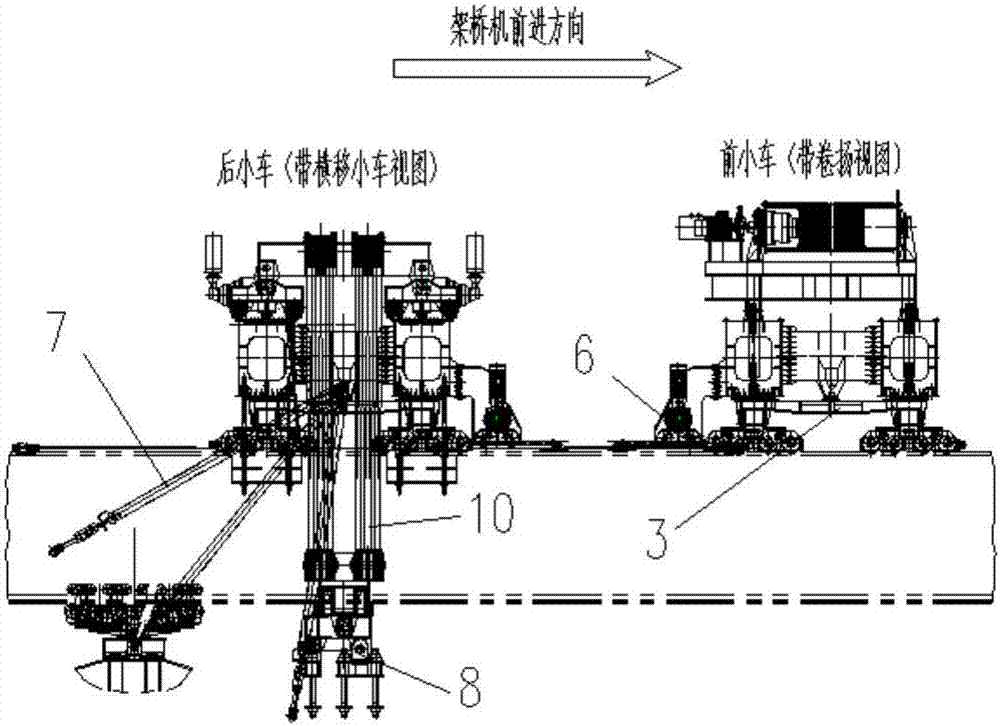

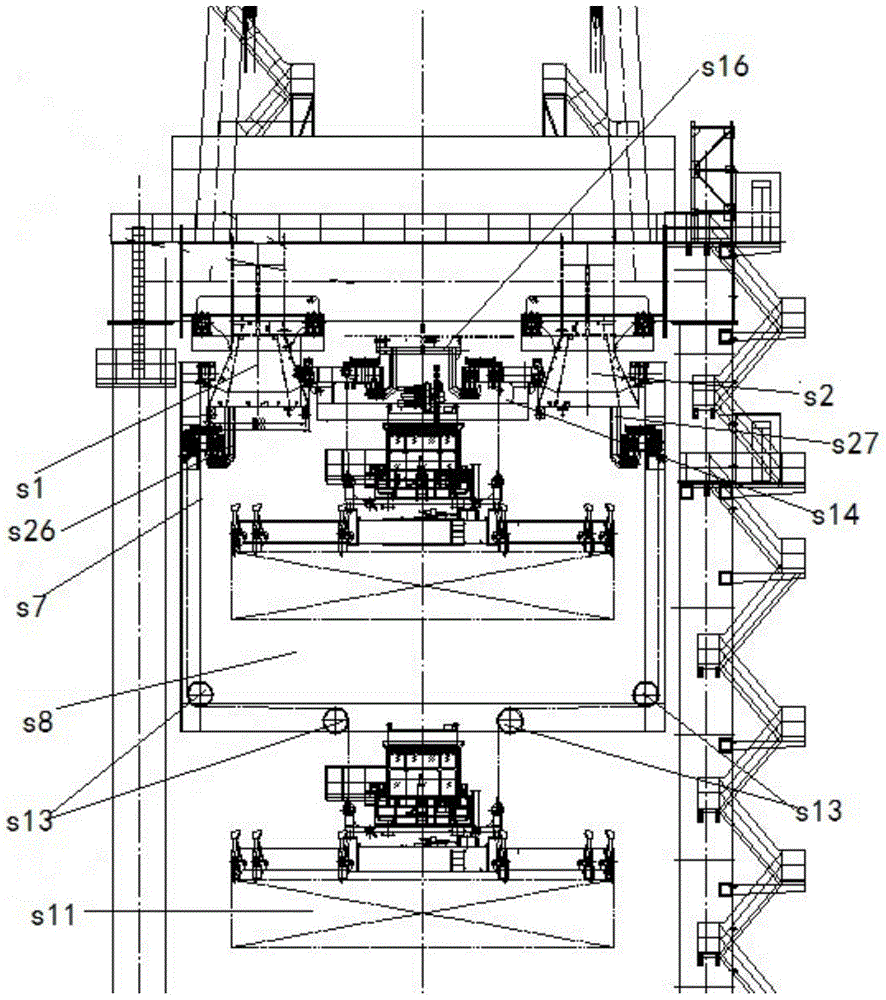

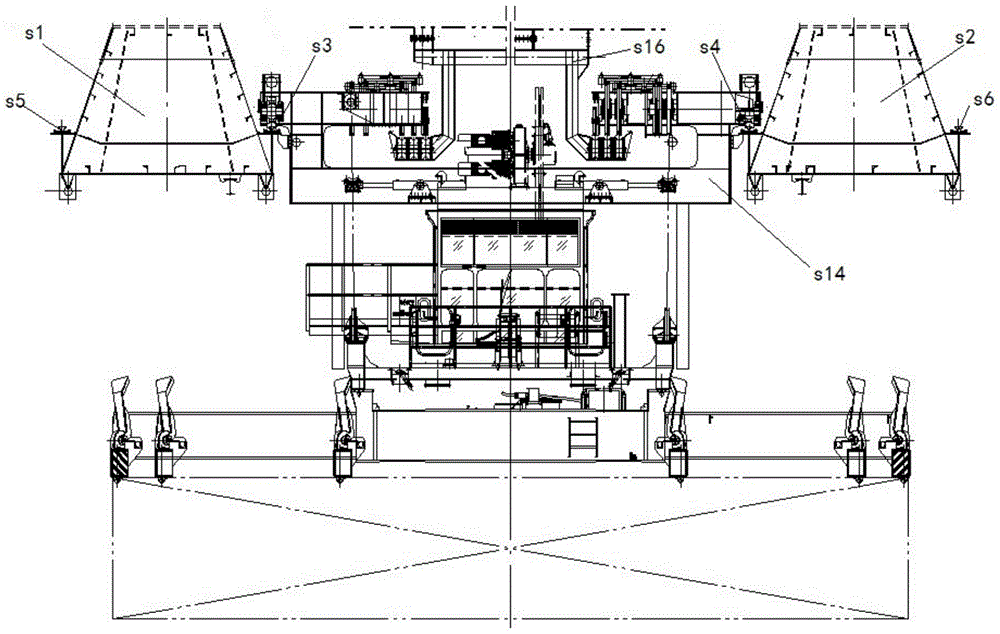

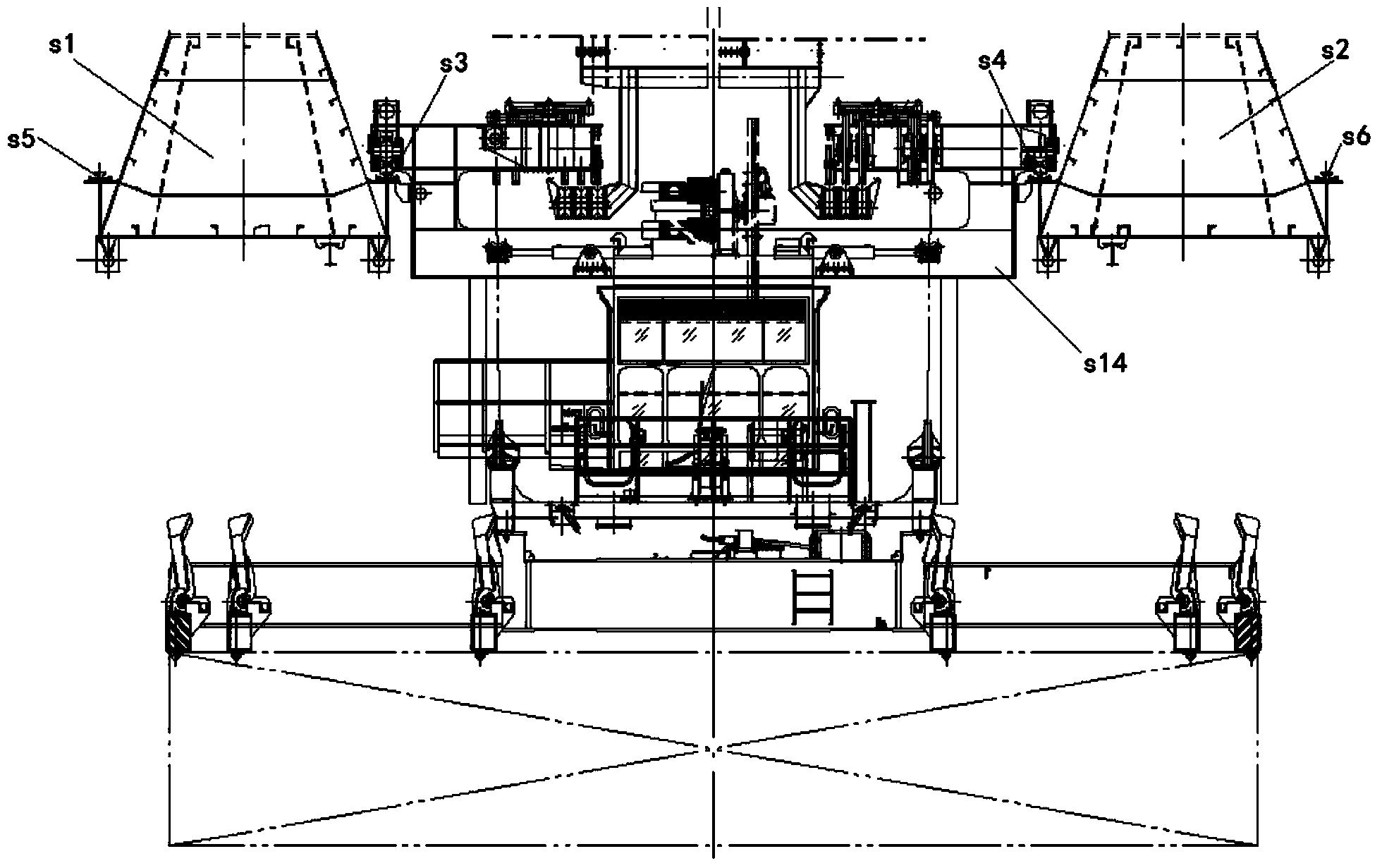

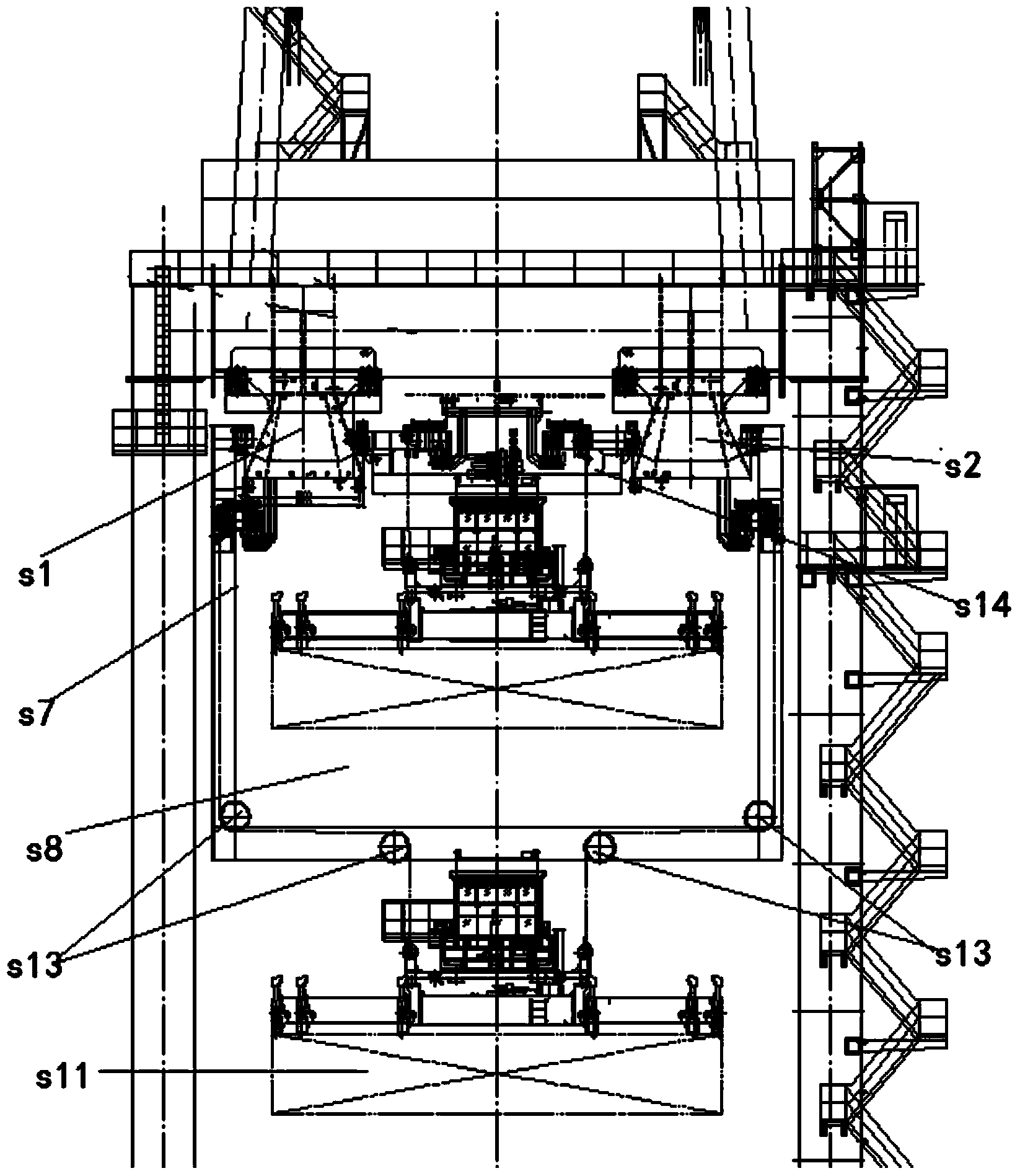

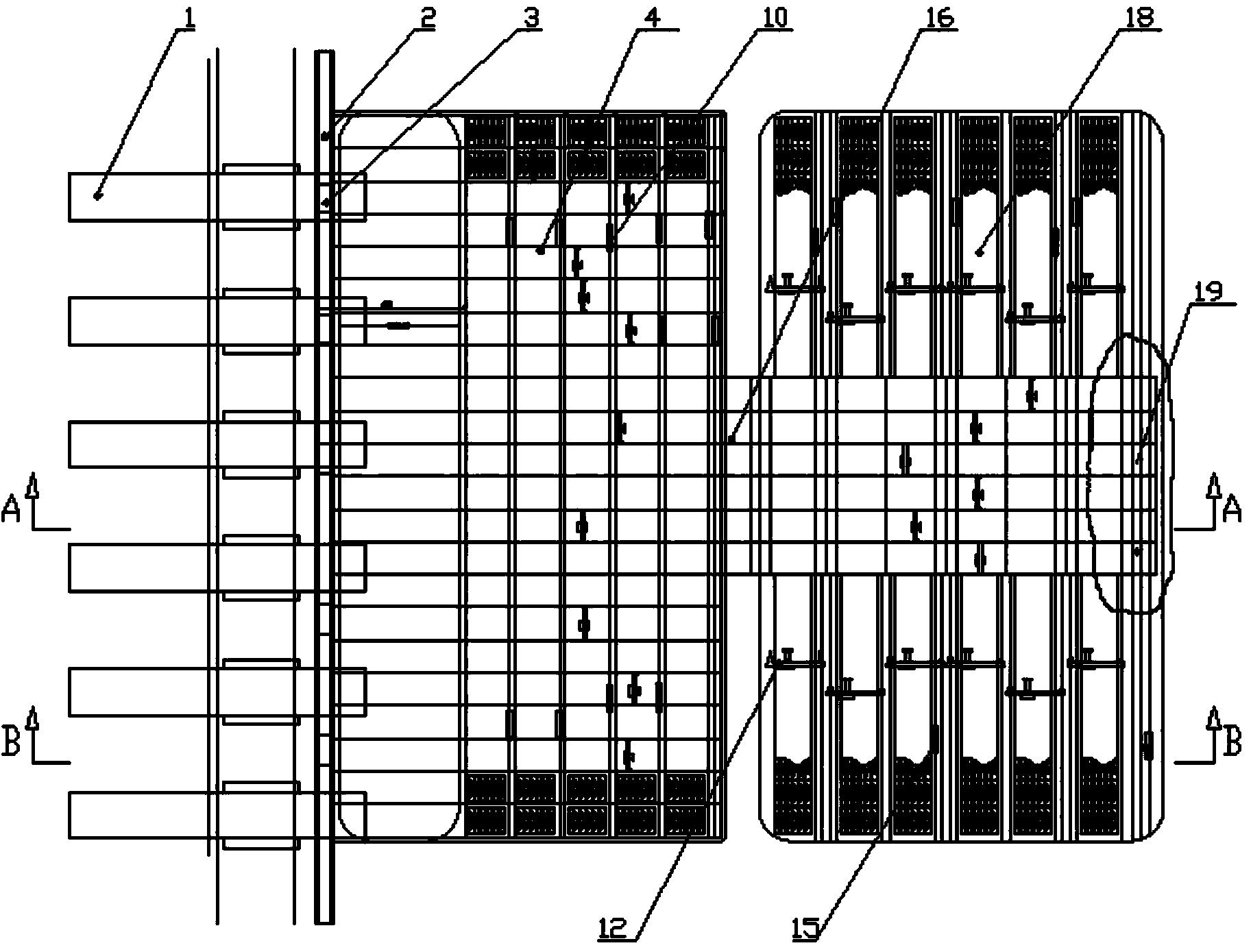

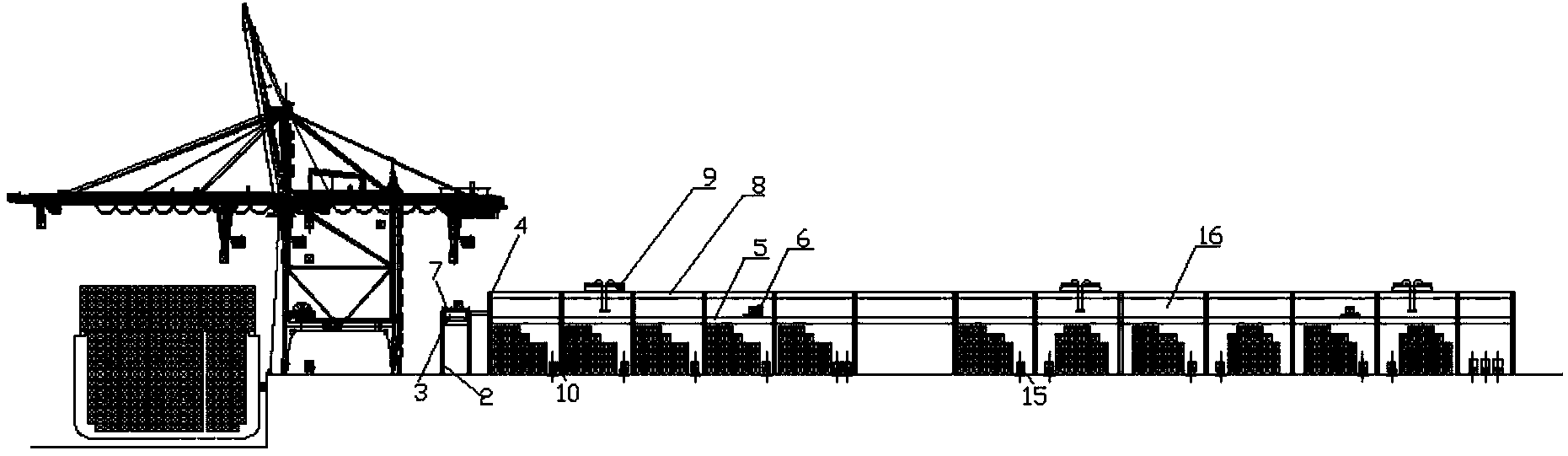

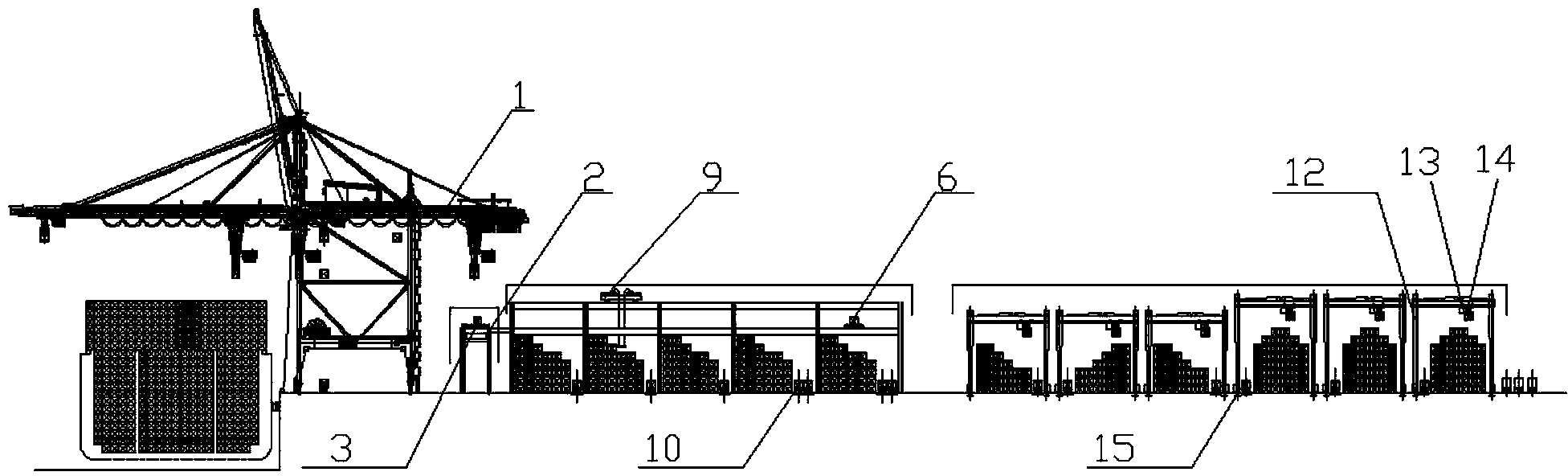

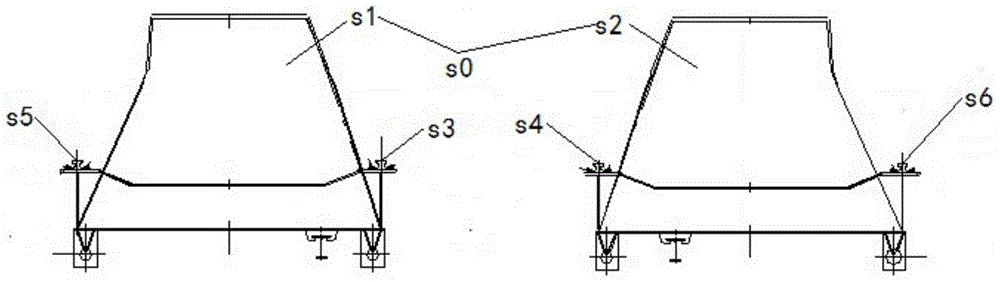

Energy-saving quayside container crane system provided with crossing type double trolleys

ActiveCN104261267AReduce energy consumptionSimple structureBase supporting structuresBraking devices for hoisting equipmentsCompensation windingPotential energy

The invention discloses an energy-saving quayside container crane system provided with crossing type double trolleys. The energy-saving quayside container crane system comprises an upper trolley, a lower trolley and potential energy compensation systems, wherein the upper trolley and the lower trolley are mounted on a girder structure; each potential energy compensation system comprises a counterweight, a potential energy compensation winding system and a potential energy compensation steel wire rope, and the potential energy compensation winding system is used for transmitting driving force to lift and drop the counterweight; each potential energy compensation system further comprises a lifting winding drum allowing joint winding of a lifting steel wire rope and the potential energy compensation steel wire rope; the winding positions of each compensation steel wire rope and each lifting steel wire rope on the hoisting winding drum do not interfere with each other and are opposite; and the potential energy compensation systems comprise an upper trolley potential energy compensation winding subsystem and a lower trolley potential energy compensation winding subsystem. According to the system, forward torque generated by dead weight of lifting appliances is offset by backward torque generated by the counterweights, the overall energy consumption of the quayside container crane is reduced, further, one lifting winding drum is shared by each compensation steel wire rope and the corresponding lifting steel wire rope, accordingly, the structure is simplified, the cost is reduced, and rope winding is relatively simple and easy to achieve; and the potential energy compensation systems comprise the upper trolley potential energy compensation winding subsystem and the lower trolley potential energy compensation winding subsystem, so that the lifting appliances of the upper trolley and the lower trolley are compensated respectively.

Owner:华电蓝科科技股份有限公司

Novel tower crane curve walking device

PendingCN110902561AAvoid stickingAvoid stuck phenomenonTravelling gearDrive wheelStructural engineering

The invention discloses a novel tower crane curve walking device. The device comprises a curve track and a walking mechanism. The curve track comprises two steel rails. The walking mechanism comprisesa rack used for bearing tower crane standard knots. Two rows of wheel set mechanisms are arranged at the lower side of the rack; and each wheel set mechanism comprises a connecting base connected with the rack, a connecting beam arranged at the lower side of the connecting base, a driving wheel set and a driven wheel set, wherein the driving wheel set and the driven wheel set are rotationally connected at the lower side of the connecting beam. The driving wheel set and the driven wheel set each comprise a wheel carrier and a plurality of idler wheels arranged on the wheel carrier and connected with the curve track in a rolling mode; limiting rims and rolling faces are arranged on the peripheries of the idler wheels; and at least one idler wheel on each driving wheel set is connected witha driving component. By setting the driving speed of the inner and outer ring driving parts, the inner and outer ring speed is in harmony with the track; depended wheels are arranged to prevent the rim from making contact with the steel rails; and meanwhile, the driven wheel set and the driving wheel set can rotate around the connecting frame, curved rail walking is met, and the jamming phenomenonis effectively prevented.

Owner:中昇建机(南京)重工有限公司

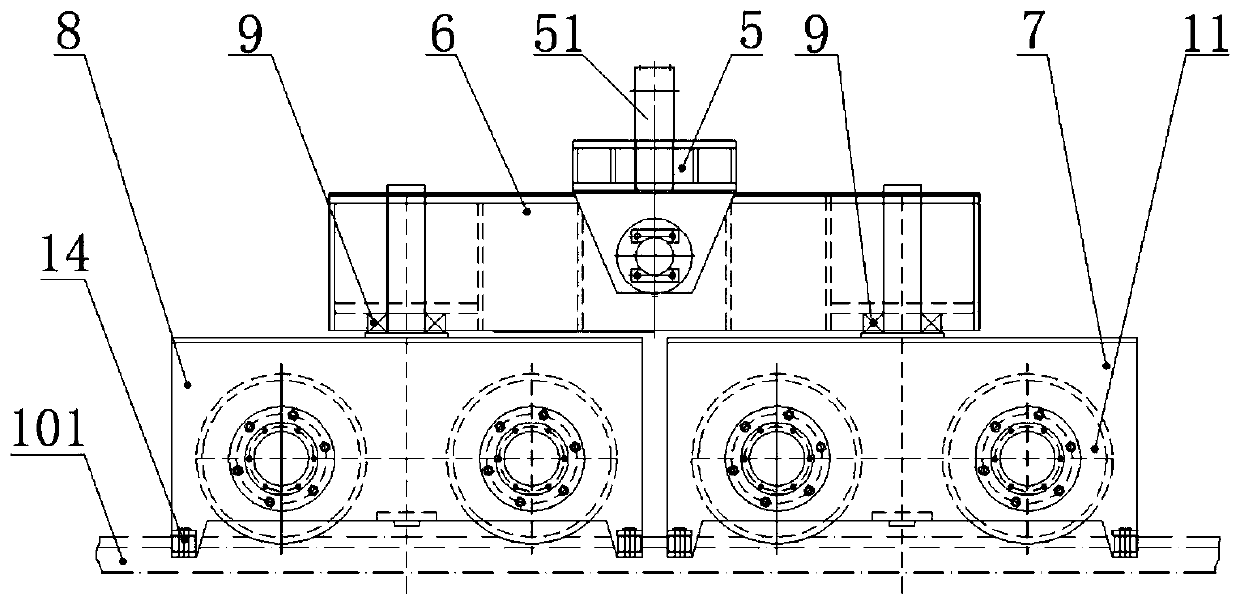

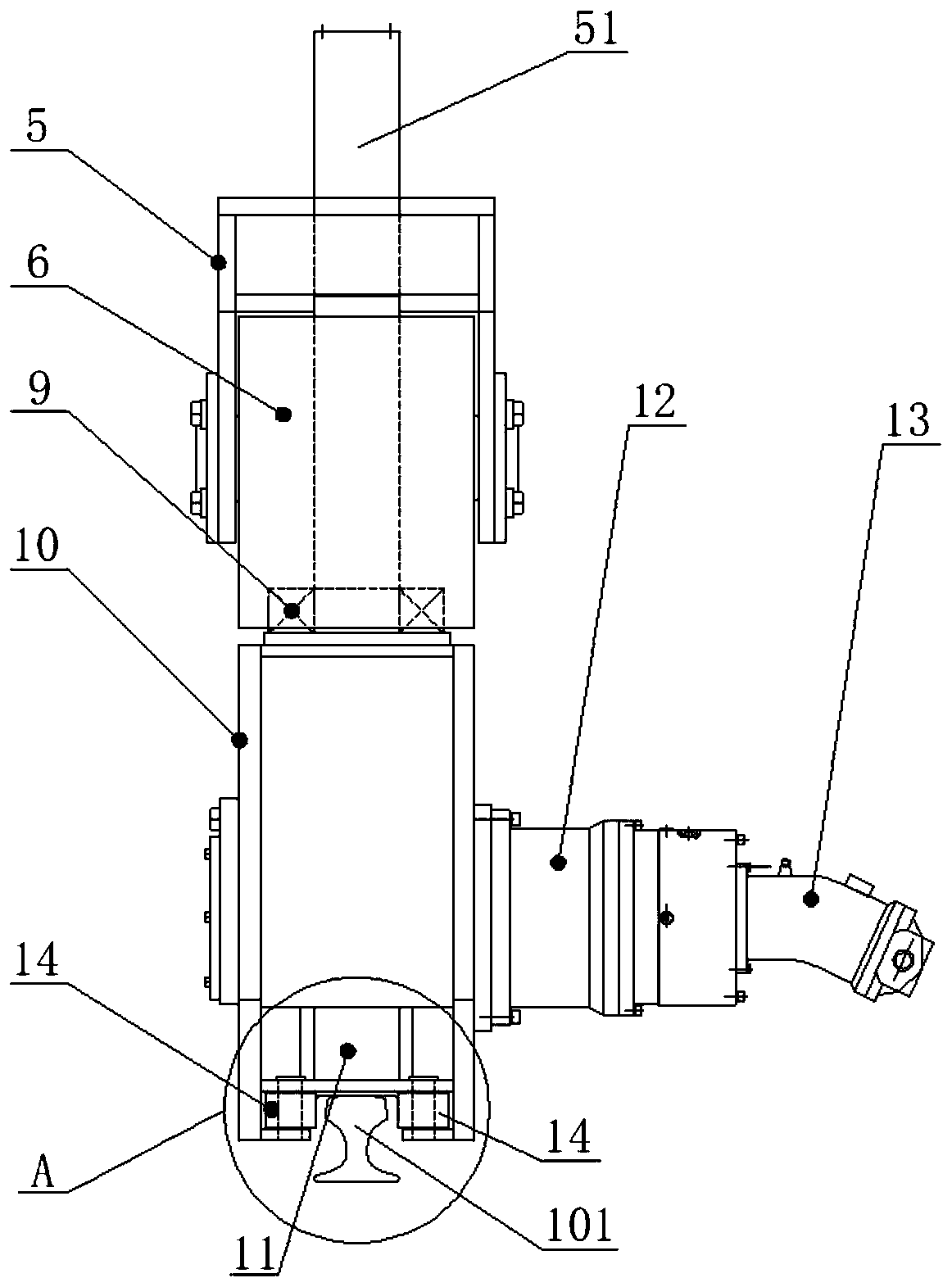

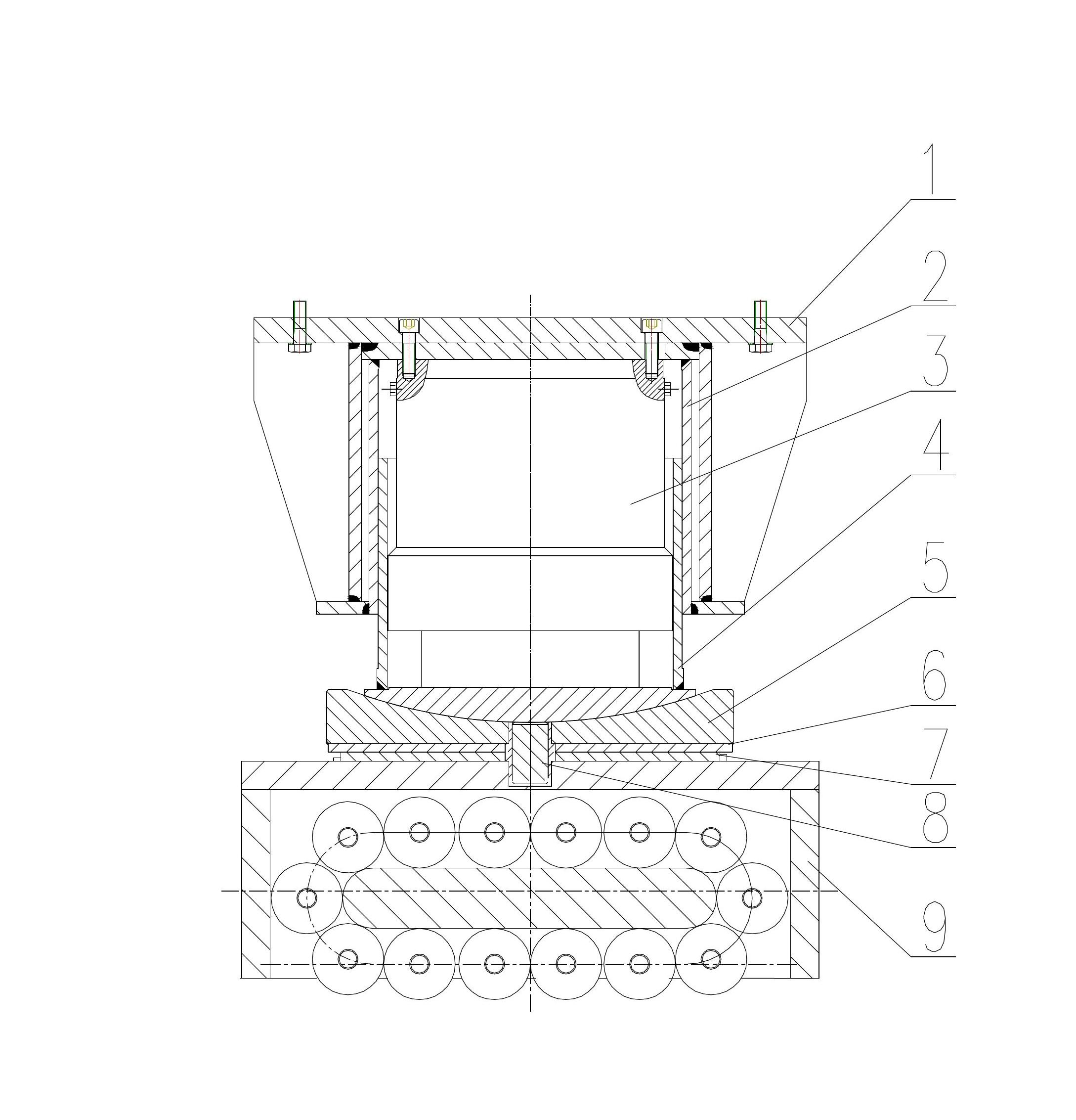

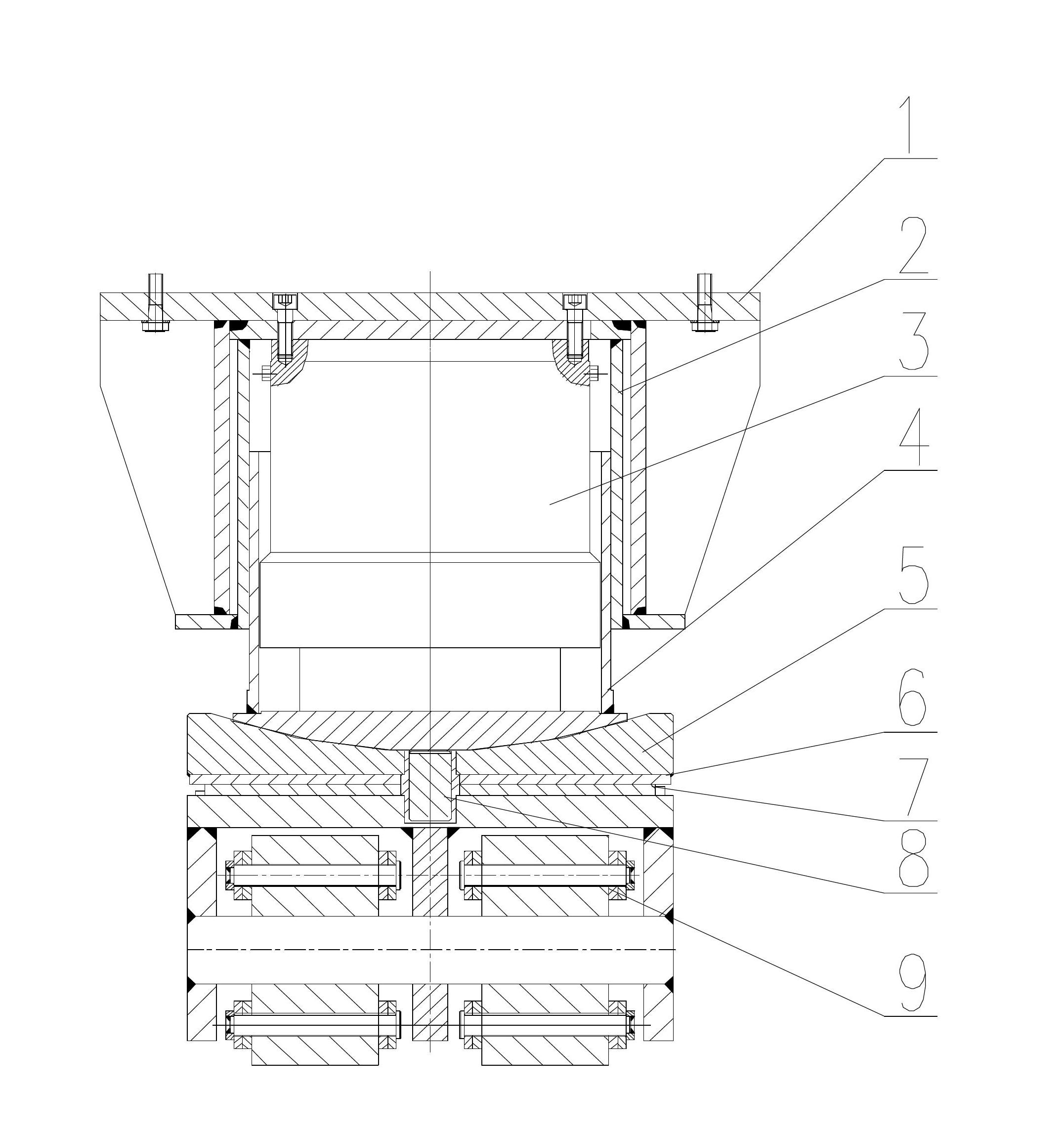

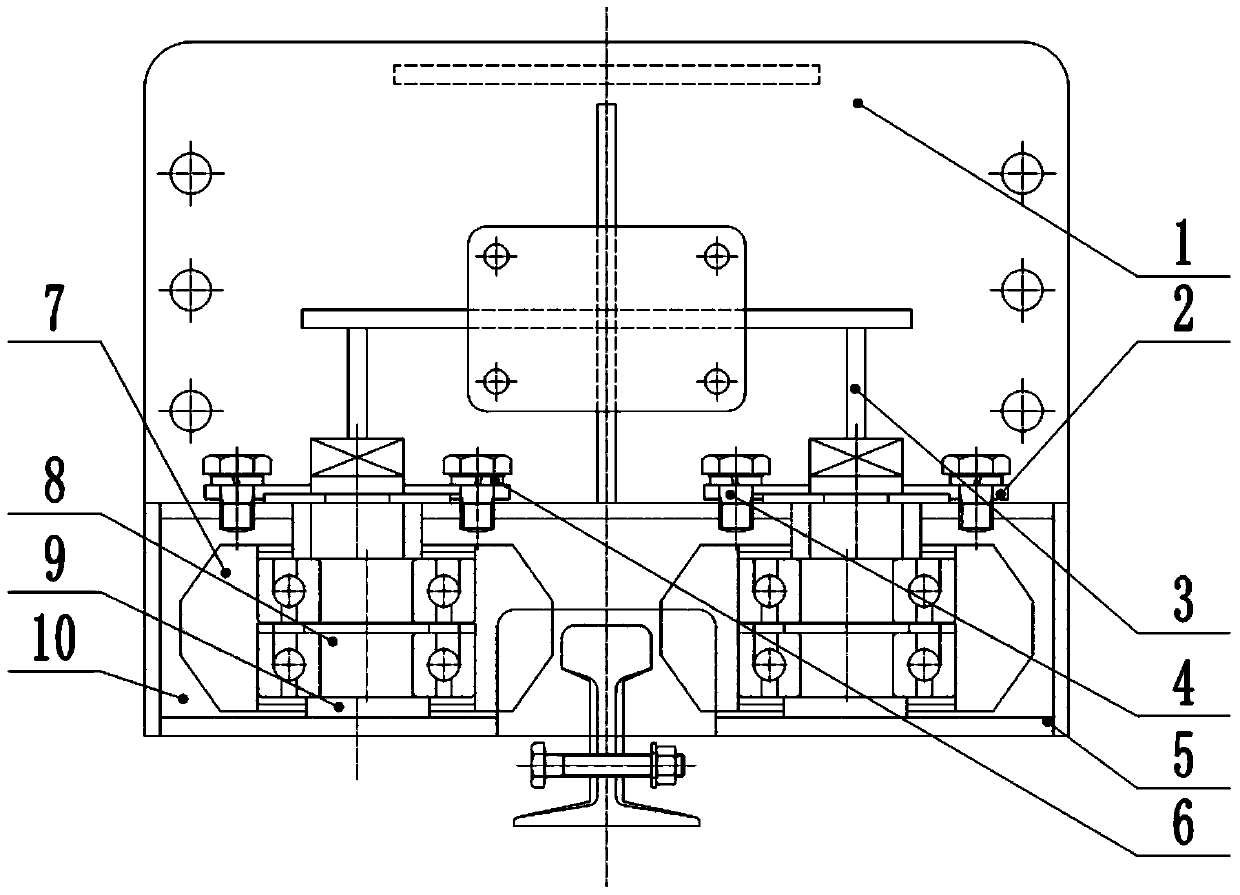

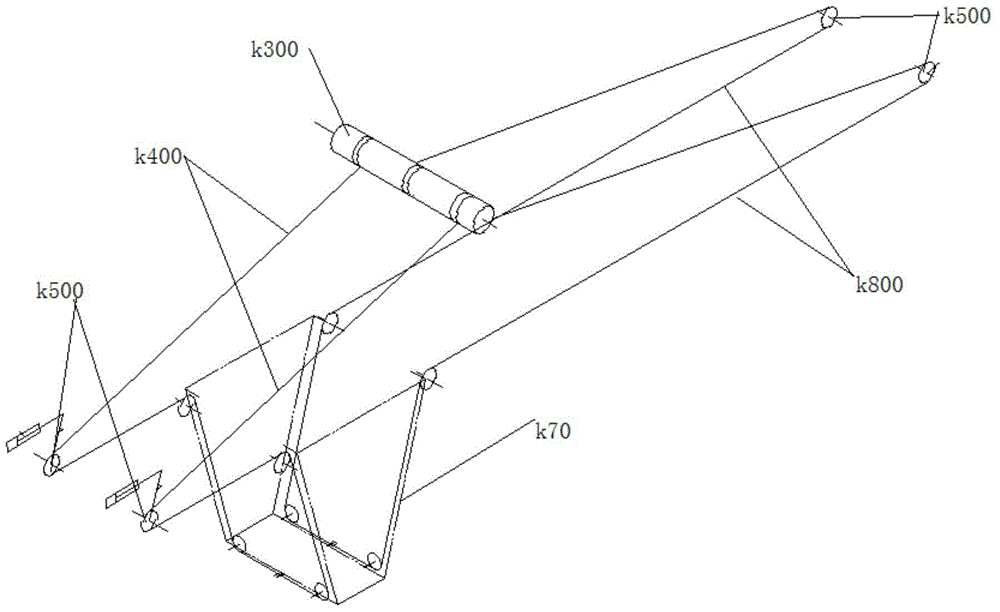

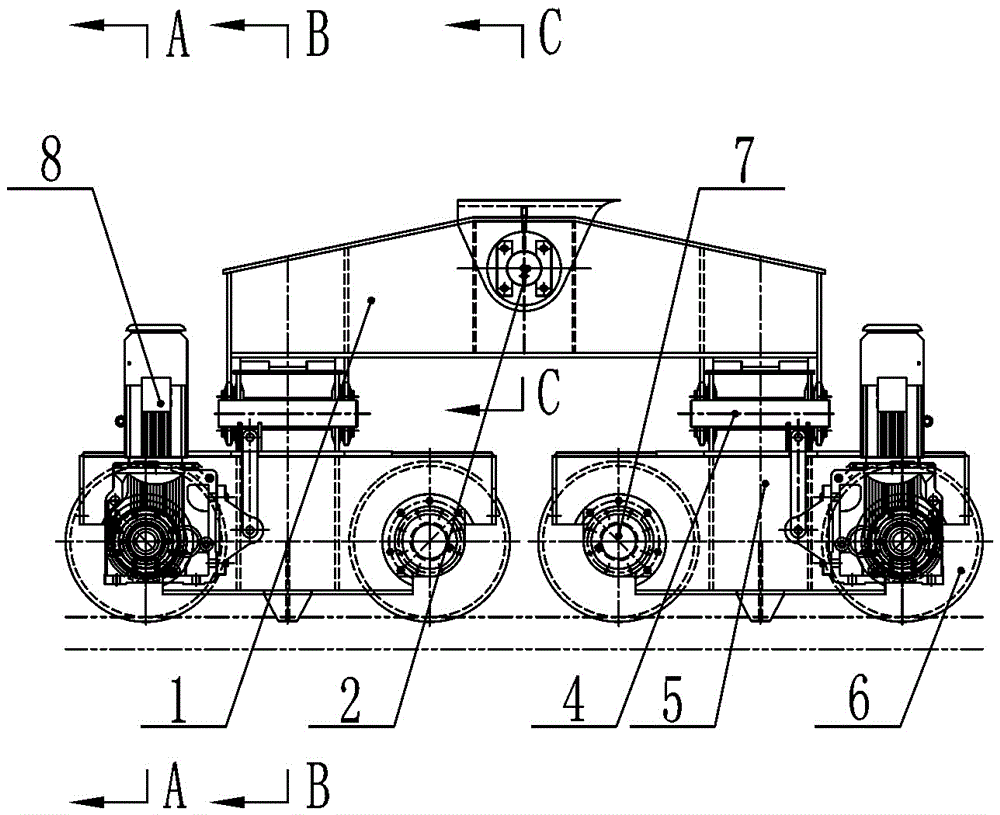

Supporting walking system for heavy transportation machinery

InactiveCN102633187AWide applicabilityAchieve modularityTravelling gearDegrees of freedomIdler-wheel

The invention discloses a supporting walking system for heavy transportation machinery, belonging to the field of heavy transportation equipment. The supporting walking system comprises a hydraulic control system and supporting walking trolleys; wherein the supporting walking trolley consists of an idler wheel car, an oil cylinder, a top supporting seat and a supporting seat; a sleeve at the upper part of the top supporting seat is sleeved in the inner cavity of the supporting seat and matched with the inner cavity in a sliding way; the oil cylinder is arranged in the sleeve at the upper part of the top supporting seat; the free end of the oil cylinder stretches and props at the bottom of the top supporting seat; the fixed end of the oil cylinder is connected with the top of the supporting seat; a ball head at the lower end of the top supporting seat is hinged with a ball hinged seat at the top of the idle wheel car; and the walking supporting trolleys are orderly arranged and connected with the bottom of a lower transverse beam of the heavy transportation machinery by the supporting seat for supporting the walking of the heavy transportation machinery. According to the supporting walking system for heavy transportation machinery, the advantage of large loading capacity of the idle wheel car is fully used to totally avoid the rail gnawing phenomenon; the influence of unbalance loading on the walking wheel is greatly reduced by releasing degree of freedom due to the ball hinged structure arranged between the idle wheel car and the oil cylinder; and the supporting walking system can meet the requirements of different wheel pressure conditions by installing the walking supporting trolleys with different quantities.

Owner:WUHAN BRIDGE HEAVY INDS GROUP

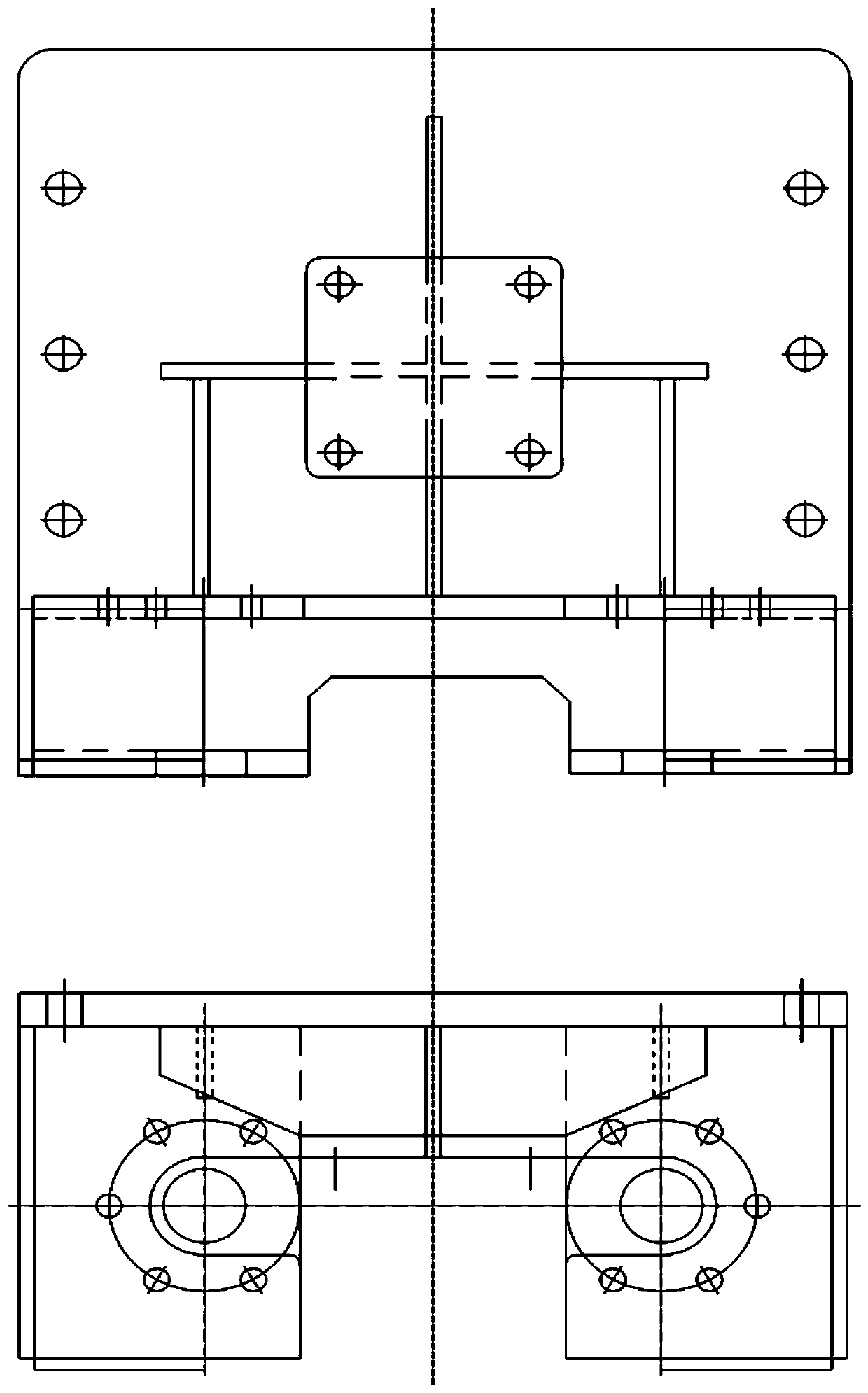

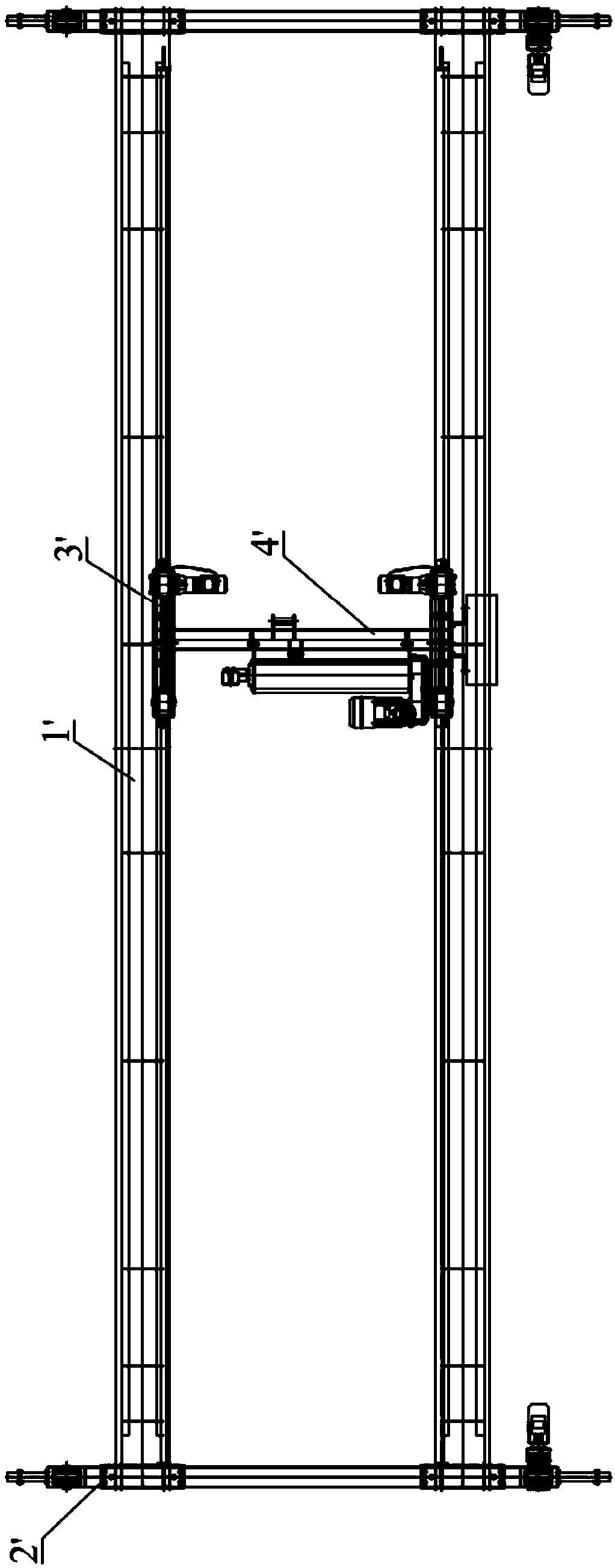

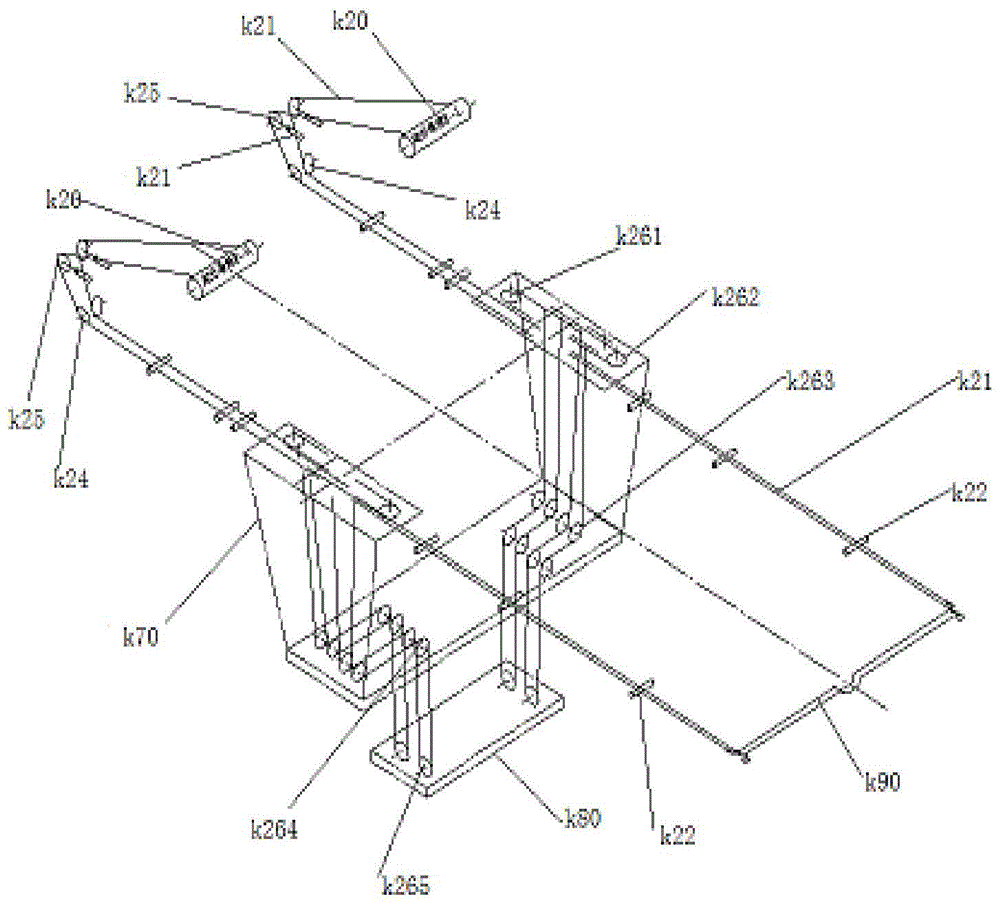

Rail gnawing preventing device for hanging beam crown block, hanging beam crown block and traveling method thereof

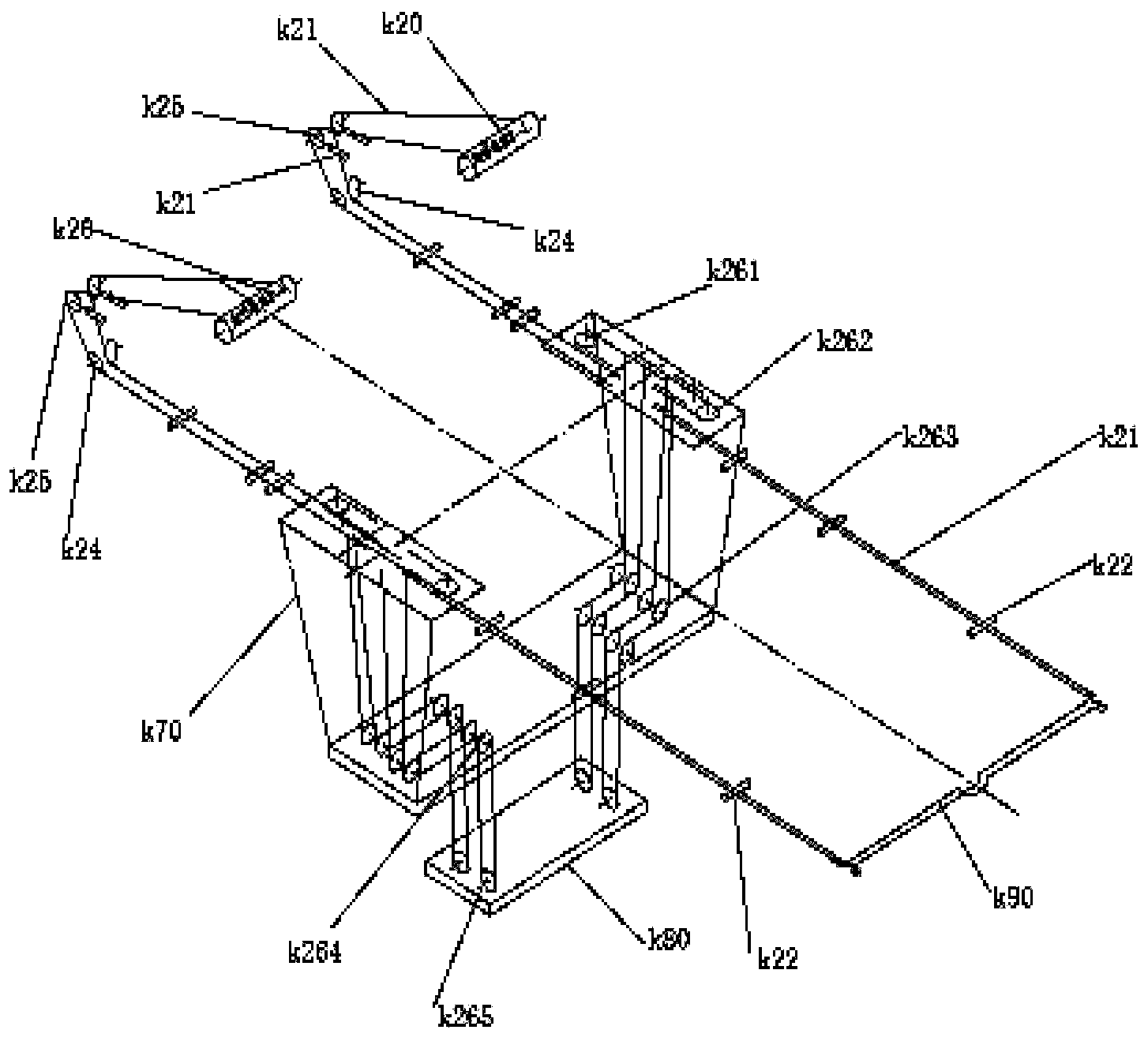

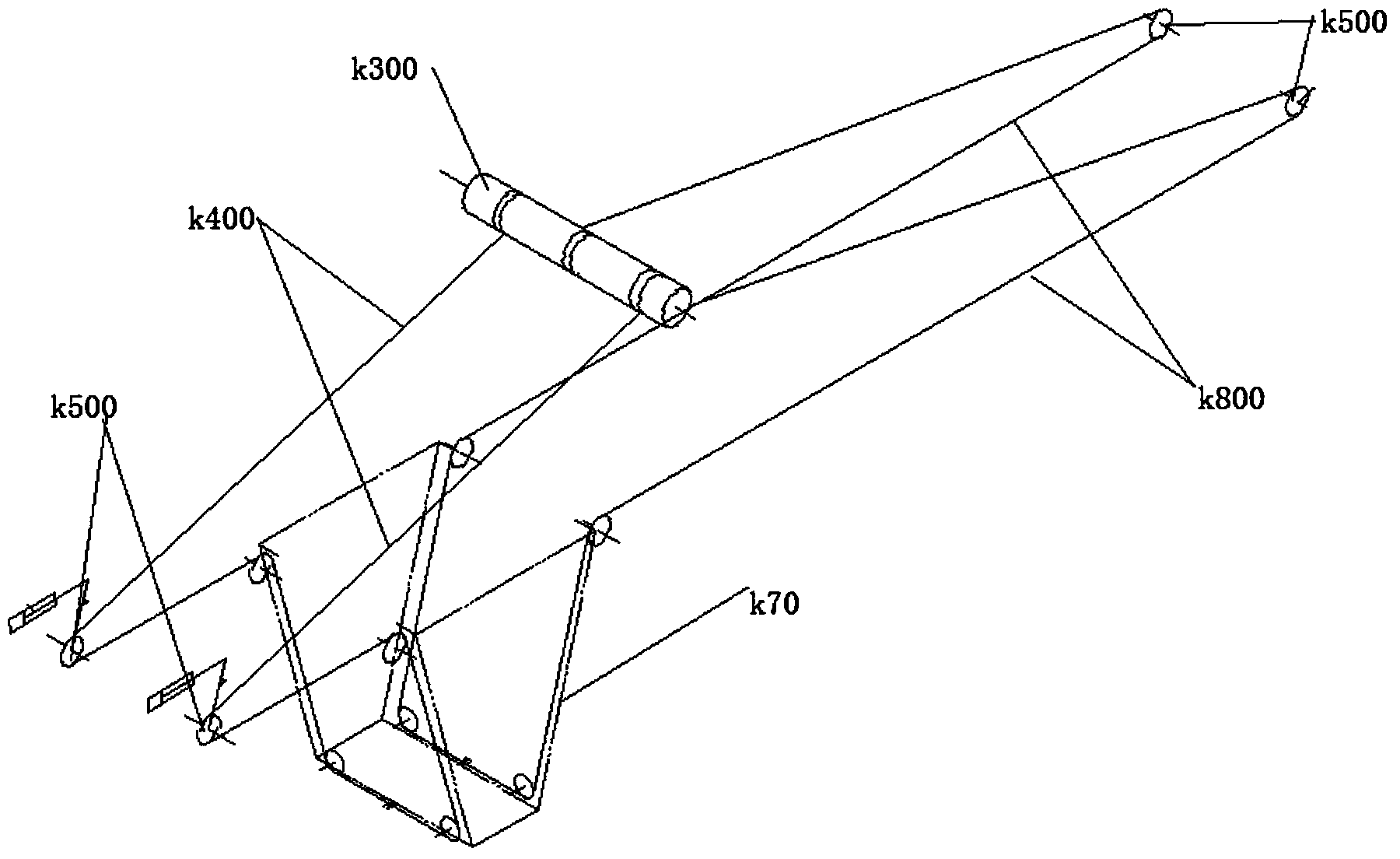

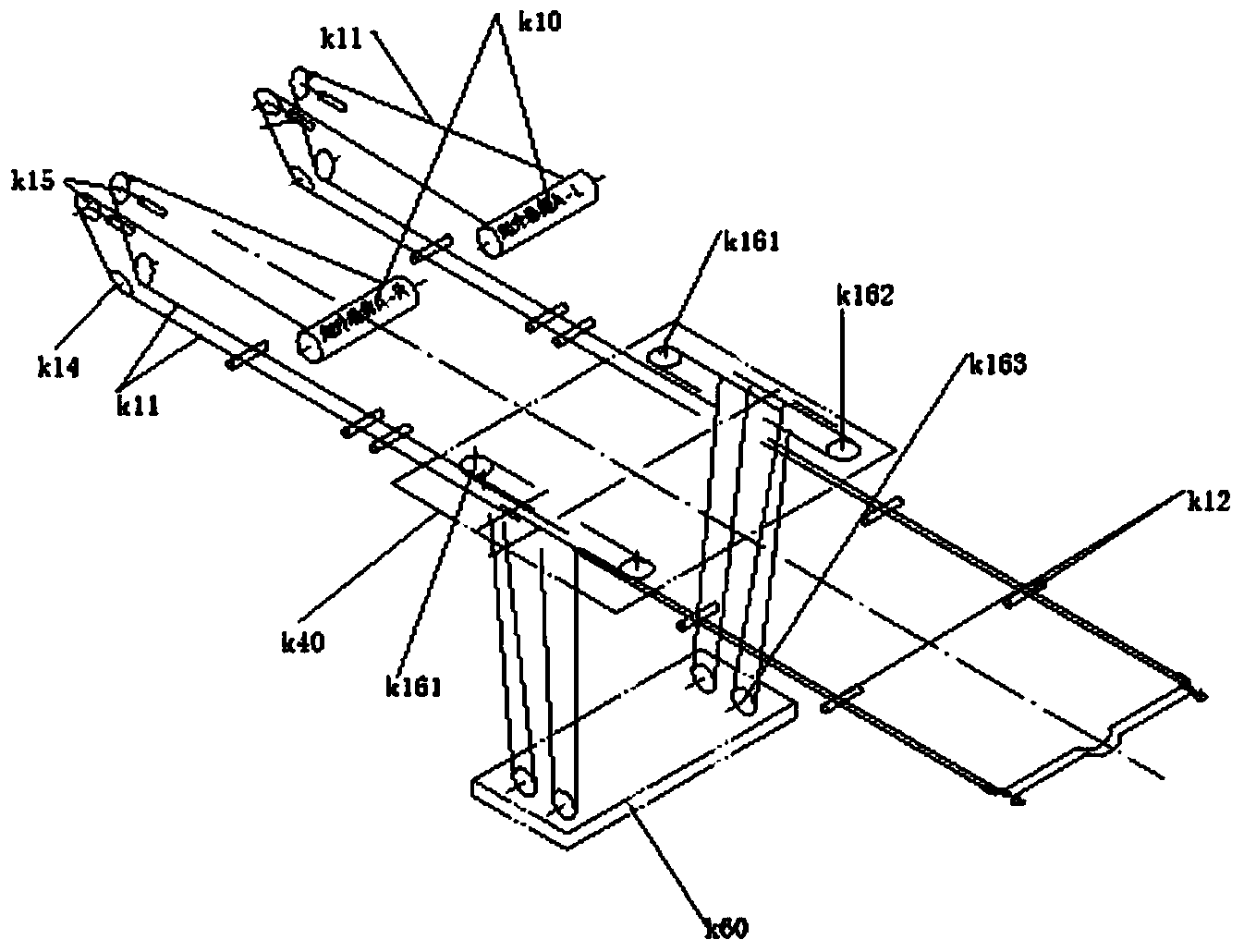

ActiveCN106915688AAutomatic release of lateral forceAdaptive strongTravelling gearSafety gearVehicle frameEngineering

The invention relates to rail gnawing preventing devices, crown blocks and traveling methods, belongs to the technical field of bridge girder erection machines, and particularly relates to a rail gnawing preventing device for a hanging beam crown block, the hanging beam crown block and a traveling method thereof. The rail gnawing preventing device comprises a connecting cross beam and a central hinge shaft, wherein the two ends of the connecting cross beam are connected with hinge supports of a trolley, one end of the central hinge shaft is fixedly connected with the middle of the cross beam, and the other end of the central hinge shaft extends into a connecting hole in the middle of a vehicle frame end beam. In order to guarantee that the longitudinal moving trolley is stressed in a balanced mode and adapts to sidewise bending deformation of a bridge girder erection machine arm, the middle of the crown block vehicle frame end beam is connected with the longitudinal moving trolley through the central hinge shaft, and the end of a vehicle frame main beam is directly supported on the longitudinal moving trolley. The rail gnawing preventing device can be automatically adjusted to adapt to rail gnawing, automatically release the sidewise action force between wheels and rails, and avoid long-time rail gnawing.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

Crane operation mechanism rail gnawing prevention device, crane operation mechanism rail gnawing prevention deviation rectification control system, and crane operation mechanism rail gnawing prevention deviation rectification control method

InactiveCN110589681AImprove stabilityReduce running lateral frictional resistanceTravelling gearFrequency changerControl system

The invention belongs to the technical field of cranes, and discloses a crane operation mechanism rail gnawing prevention device, a crane operation mechanism rail gnawing prevention deviation rectification control system, and a crane operation mechanism rail gnawing prevention deviation rectification control method. A plurality of first displacement sensors and a plurality of second displacement sensors are connected with a computer, the deflection angle of a crane frame relative to a rail is measured out by the displacement sensors, and then the deflection angle is converted into control voltage via proportional conversion through the computer; the control voltage is correspondingly added on first frequency converters and second frequency converters by a differential-action mode or a single-action mode, the first frequency converters and the second frequency converters are correspondingly connected with first control motors and second control motors, and the first control motors and the second control motors correspondingly adjust the stroke speed of a first driving wheel and the stroke speed of a second driving wheel. Rail gnawing between the inner side of a wheel flange of a wheel of an operation mechanism and the steel rail is effectively avoided, the stability of the crane in the operation process is enhanced, the operation side friction resistance of the crane is reduced,and friction noises between the wheel and the rail are reduced. Simultaneously, great potential safety hazards brought by the rail gnawing are eliminated, and safe operation of crane equipment and people safety are effectively ensured.

Owner:温州市特种设备检测研究院

High-performance rail gnawing prevention multi-point positioning crane

PendingCN112850478AAvoid rail gnawingGuaranteed stabilityTravelling gearStructural engineeringMechanical engineering

The invention discloses a high-performance rail gnawing prevention multi-point positioning crane comprising sliding rails. Mounting plates are slidably mounted on the surfaces of the two sliding rails; hoisting modules are slidably mounted on the surfaces of the mounting plates; connecting plates are symmetrically and fixedly connected to the two ends of the mounting plates; adjusting devices are mounted in the connecting plates; the surfaces of the connecting plates are symmetrically and fixedly connected with movable devices; the two movable devices are fixedly connected with the adjusting devices; the left sides and the right sides of the connecting plates are each provided with an induction device; the induction devices are fixedly connected with the movable devices; and grooves are symmetrically formed in the surfaces of the sliding rails at equal intervals. The crane can be prevented from gnawing the rails by utilizing the elasticity of springs, the movable devices are matched with the adjusting devices, rollers are always in close contact with the sliding rails, the running stability of the crane is ensured, meanwhile, a heavy object can be lifted through multi-point accurate positioning, the structure is simple, and the practicability is high.

Owner:浙江华鑫起重机械有限公司

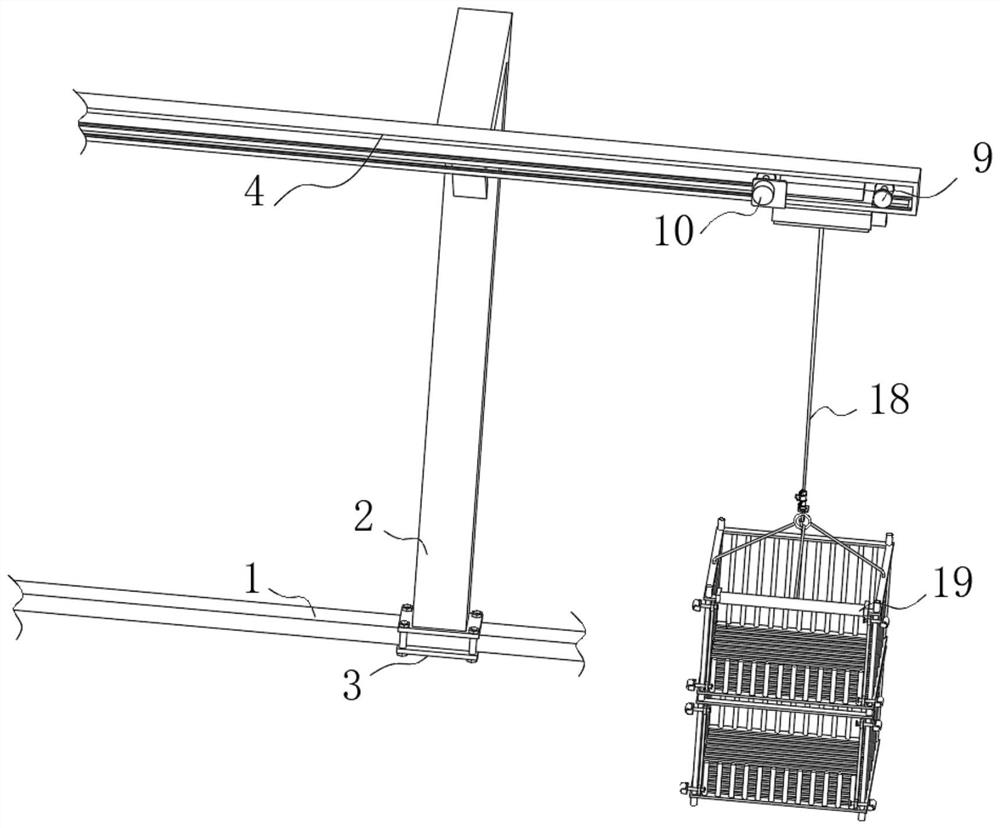

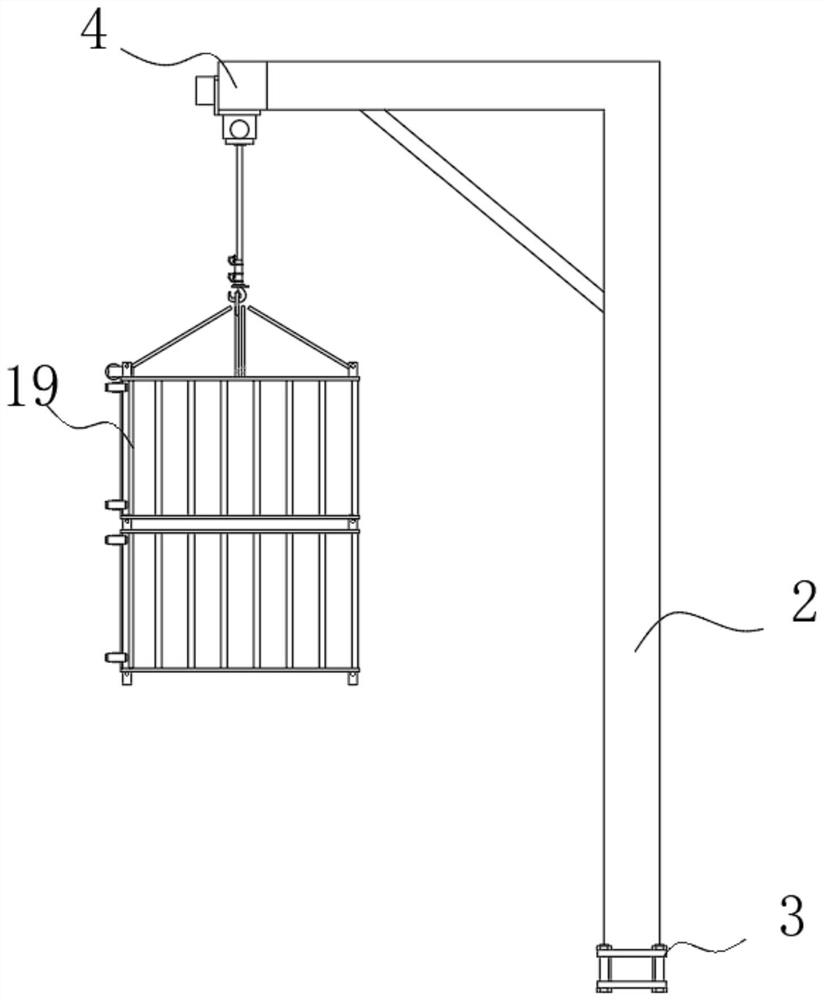

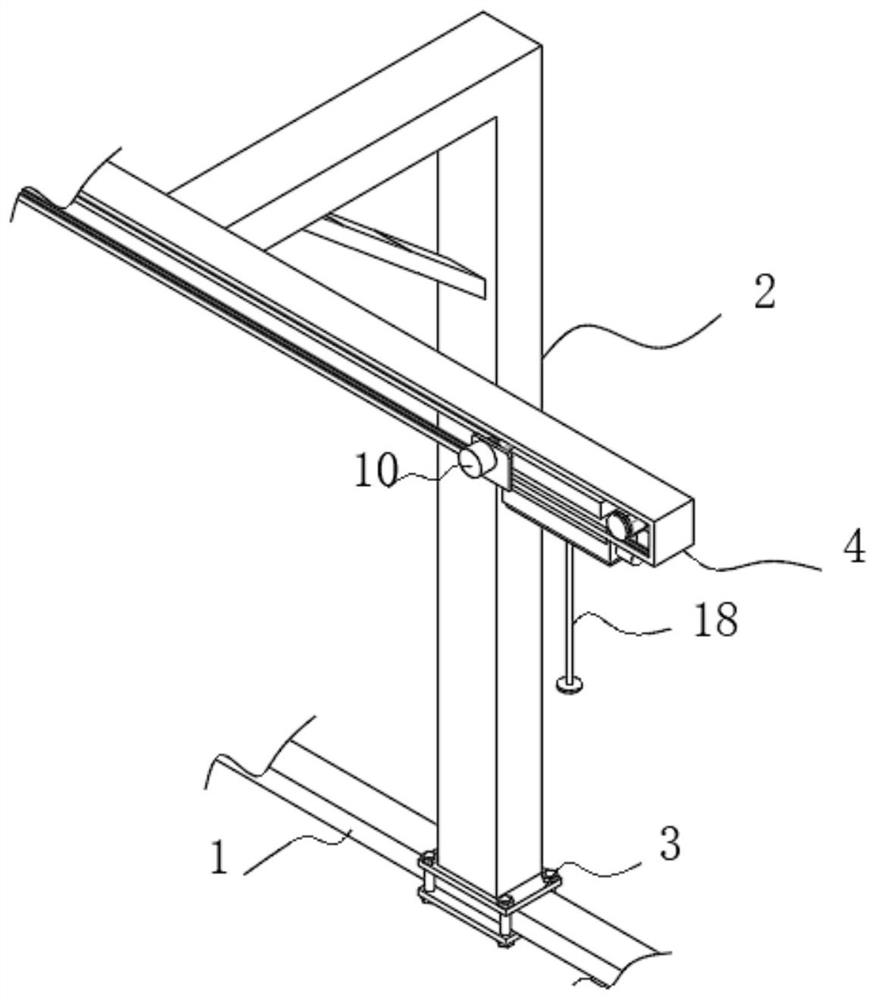

Rapid moving aerial work platform based on track device

PendingCN114645614AThere must be no loosenessImprove stabilityBuilding material handlingScaffold accessoriesTrackwayArchitectural engineering

The embodiment of the invention discloses a rapid moving aerial work platform based on a rail device, and belongs to the technical field of building construction, the rapid moving aerial work platform comprises a supporting beam installed on the outer side of a construction facade, the top of the supporting beam is provided with a suspension transverse displacement mechanism, and the bottom of the suspension transverse displacement mechanism is provided with a hanging basket protection mechanism. Through corresponding cooperative use of all the structures, the device can freely move in the air, the falling situation caused by accidental derailing is avoided, the safety of the device in use is improved, in the falling process of the platform body, the clamping strips can fall off, the situation that workers on the platform body are driven to fall off when the platform body falls off is avoided, and the working efficiency is improved. The flatness of the bottom surface of the platform and anti-skid measures can be guaranteed through the fine grids, the fine grids can effectively prevent people from being hurt due to falling of objects during vertical cross operation, operators can conveniently enter and exit a platform channel, the left guardrail, the right guardrail and the rear guardrail are high, and safe operation of the operators can be effectively guaranteed.

Owner:黑龙江省建筑安装集团有限公司

Calibration method for unmanned vehicle

InactiveCN113310444AAutomate CalibrationPrecise positioningMeasurement devicesClassical mechanicsControl theory

The invention provides a calibration method for an unmanned vehicle. The method specifically comprises the steps of carrying out translation of two sides of the unmanned vehicle on a first track and a second track, and obtaining a distance L from the unmanned vehicle to a reference point; when the unmanned vehicle moves to the first mark point, obtaining the distance L1 from the unmanned vehicle to the reference point at the moment; comparing (L1-Ls1) with [delta]1, wherein Ls1 is the distance from the first mark point to the reference point, [delta]1 is the maximum position calibration error allowed by the unmanned vehicle, if (L1-Ls1) is less than or equal to [delta]1, calibration is not needed, and if (L1-Ls1) is greater than [delta]1, the calibration distance Ls from the unmanned vehicle to the reference point is equal to L-(L1-Ls1); when the unmanned vehicle further moves to the second mark point, obtaining the distance L2 from the unmanned vehicle to the reference point at the moment; and comparing [L2-(L1-Ls1)] with [delta]s1, wherein [delta]s1 is the maximum test error, if [L2-(L1-Ls1)] is less than or equal to [delta]s1, a calculation formula Ls = L-(L1-Ls1) is stored, and if [L2-(L1-Ls1)] is greater than [delta]s1, an alarm is prompted to be given. The method has the advantages of accurate positioning and the like.

Owner:FOCUSED PHOTONICS

A traversing double-car system and a traversing multi-car system

ActiveCN104340863BGuaranteed uptimeNot easy to shakeTravelling gearSafety gearVehicle frameEngineering

The invention discloses a traversing type double-trolley system. The system comprises an upper trolley and a lower trolley, wherein the lower trolley comprises a first walking mechanism and a second walking mechanism mounted on guide rails at two sides of the upper trolley in a walking manner, a rigid frame for connecting the first walking mechanism and the second walking mechanism, and a sling connected below the rigid frame; the rigid frame is provided with a structure space with the cavity size greater than the outer wall size of the upper trolley so as to allow the upper trolley to pass, and the lower trolley meets the condition that the stabilizing moment Sigma Ms of the lower trolley is greater than capsizing moment Sigma Mo; the first walking mechanism is connected with the second walking mechanism through the rigid frame; the structure space size of the rigid frame is greater than the outer wall size of the upper trolley, so that the upper trolley sling carrying a tank can directly pass through the structure space without rotating; under the condition that the stabilizing moment Sigma Ms caused by the gravity of the lower trolley is greater than the capsizing moment Sigma Mo caused by horizontal inertia force of the lower trolley, the capsizing moment Sigma Mo caused by wind load or other reasons is overcome under the effect of the stabilizing moment of the lower trolley, so that the lower trolley always maintains steady in the operational process.

Owner:华电蓝科科技股份有限公司

Rail-gnawing preventing end beam device and hoisting equipment

PendingCN109052165AAvoid rail gnawingImplementation orientationTravelling gearEngineeringDrive shaft

Owner:EUROCRANE

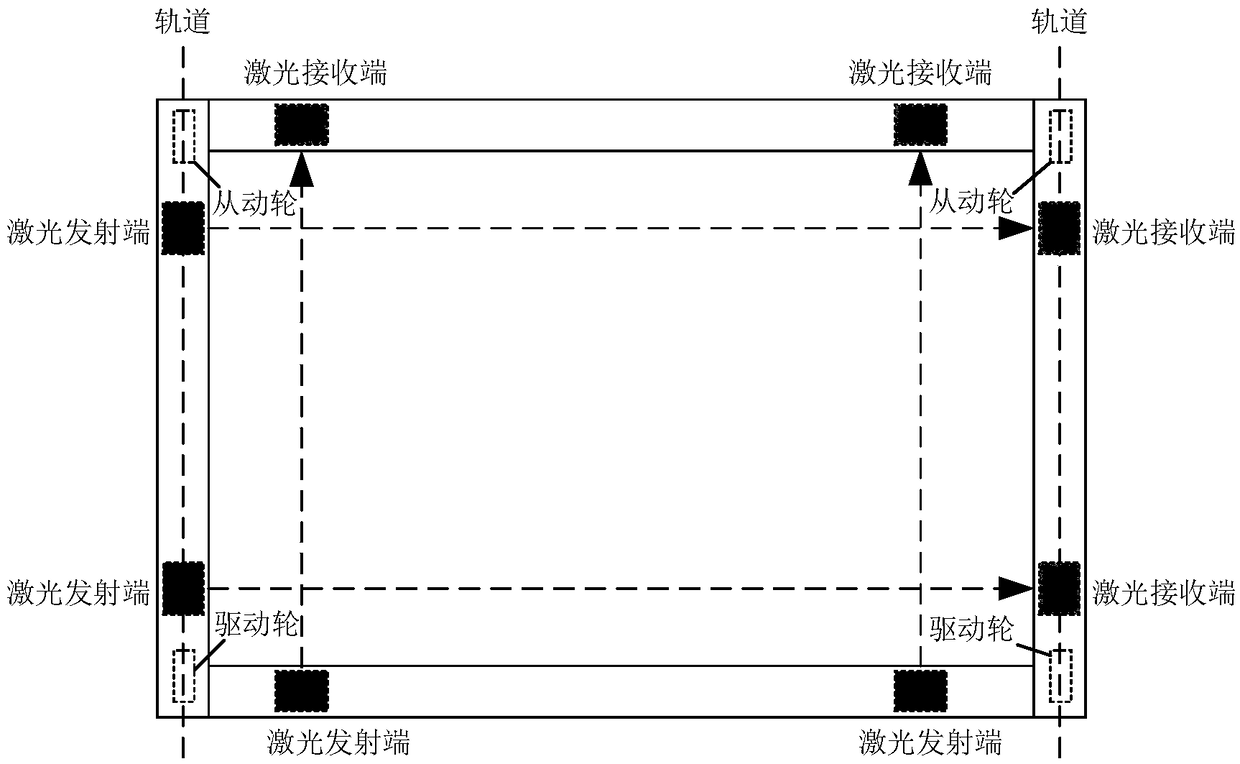

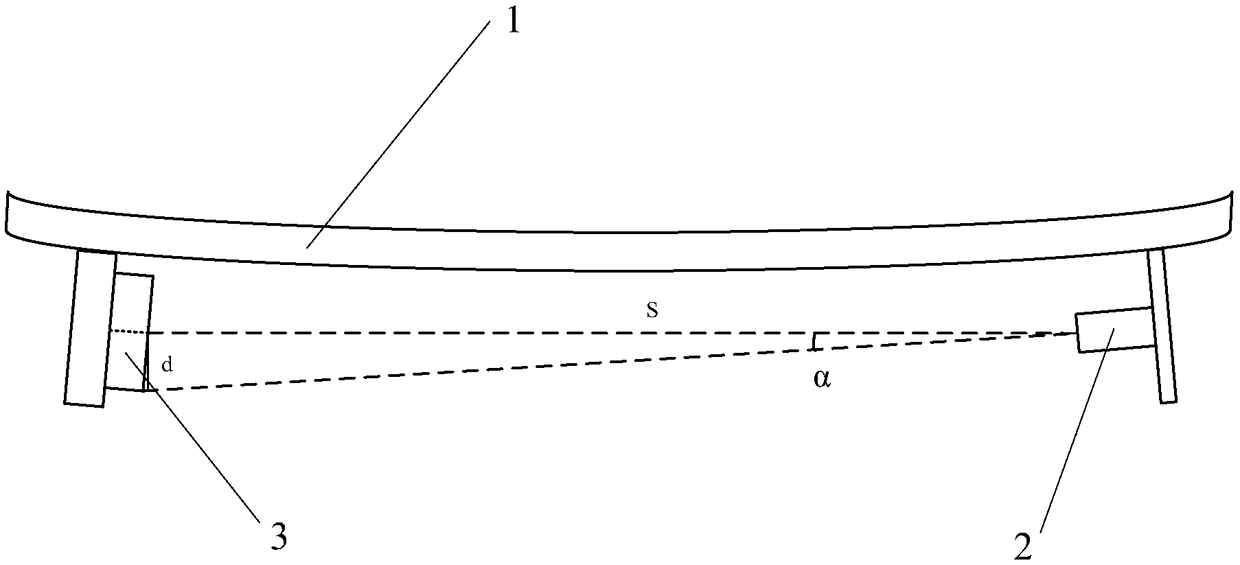

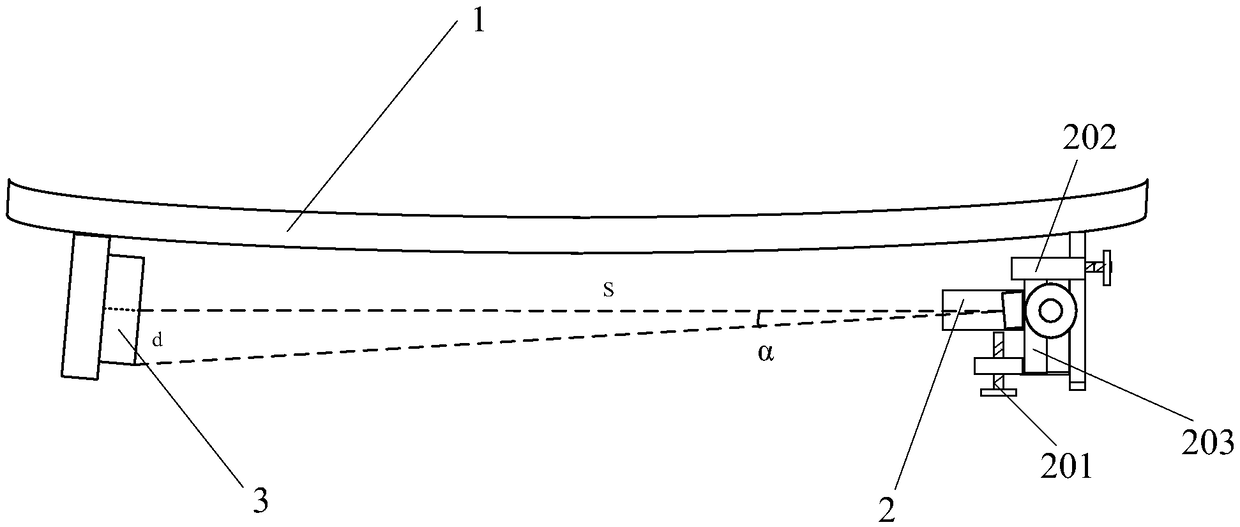

Micro deformation detection device of double girder crane trolley

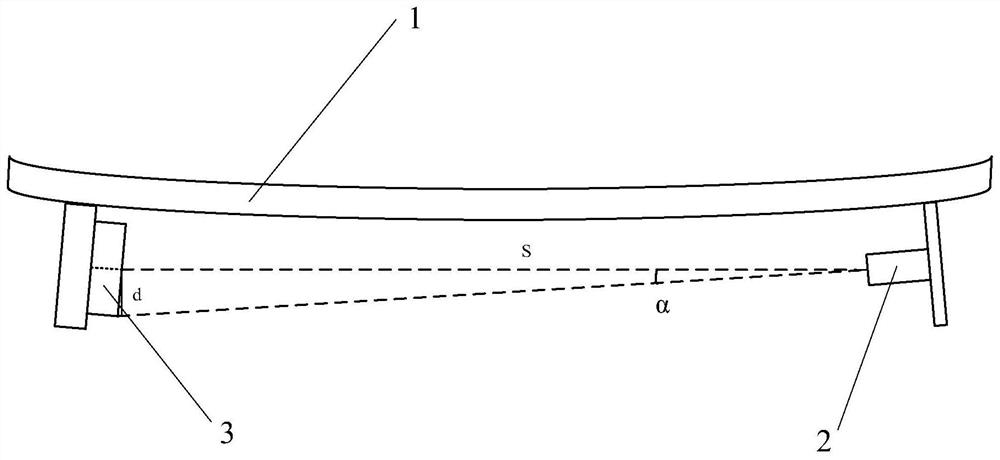

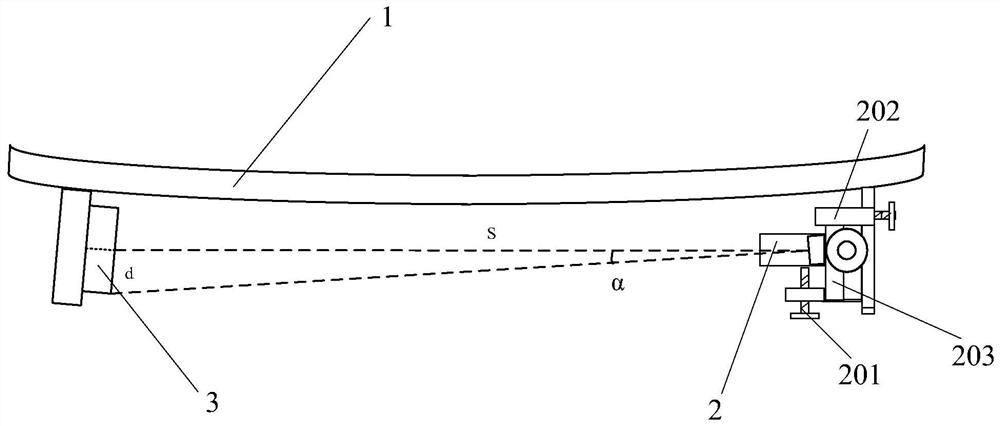

ActiveCN109484977AAvoid rail gnawingHigh precisionLoad-engaging elementsLaser transmitterOffset distance

The patent for the invention belongs to the field of double girder crane devices, and particularly discloses a micro deformation detection device of a double girder crane trolley. The micro deformation detection device of the double girder crane trolley comprises laser emitters and photosensitive receiving lattices which are mounted at the two ends of steel girders on both sides of the double girder crane trolley correspondingly; each photosensitive receiving lattice comprises a plurality of photosensitive audions connected with a micro controller through an interface circuit; each interface circuit is an and gate circuit with a plurality of diodes in parallel connection; and the micro controller obtains the position information of a plurality of laser radiation points according to laser light signals received by the photosensitive receiving lattices, obtains the offset distance information of the corresponding laser radiation points according to the position information and spaces between the adjacent photosensitive audions, and obtains the offset angle information of the corresponding laser radiation points according to the offset distance information. By means of the technical scheme, micro deformation of the double girder crane trolley is precisely detected, and the rail gnawing phenomenon of the crane trolley is avoided.

Owner:河南工学院

An energy-saving quayside crane system with double trolleys

ActiveCN104261267BReduce energy consumptionLow costBase supporting structuresBraking devices for hoisting equipmentsWind systemContainer crane

The invention discloses an energy-saving quayside container crane system provided with crossing type double trolleys. The energy-saving quayside container crane system comprises an upper trolley, a lower trolley and potential energy compensation systems, wherein the upper trolley and the lower trolley are mounted on a girder structure; each potential energy compensation system comprises a counterweight, a potential energy compensation winding system and a potential energy compensation steel wire rope, and the potential energy compensation winding system is used for transmitting driving force to lift and drop the counterweight; each potential energy compensation system further comprises a lifting winding drum allowing joint winding of a lifting steel wire rope and the potential energy compensation steel wire rope; the winding positions of each compensation steel wire rope and each lifting steel wire rope on the hoisting winding drum do not interfere with each other and are opposite; and the potential energy compensation systems comprise an upper trolley potential energy compensation winding subsystem and a lower trolley potential energy compensation winding subsystem. According to the system, forward torque generated by dead weight of lifting appliances is offset by backward torque generated by the counterweights, the overall energy consumption of the quayside container crane is reduced, further, one lifting winding drum is shared by each compensation steel wire rope and the corresponding lifting steel wire rope, accordingly, the structure is simplified, the cost is reduced, and rope winding is relatively simple and easy to achieve; and the potential energy compensation systems comprise the upper trolley potential energy compensation winding subsystem and the lower trolley potential energy compensation winding subsystem, so that the lifting appliances of the upper trolley and the lower trolley are compensated respectively.

Owner:华电蓝科科技股份有限公司

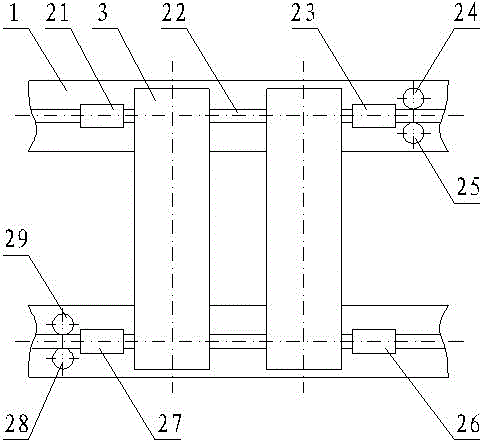

Connecting structure of crossing type double trolleys

InactiveCN104261268AReduce weightSimplify the installation processBase supporting structuresBraking devices for hoisting equipmentsContainer craneEngineering

The invention discloses a connecting structure of crossing type double trolleys. The connecting structure comprises a first girder and a second girder, wherein a first guide rail and a second guide rail are arranged on opposite inner sides of the first girder and the second girder and jointly form a first guide rail structure for supporting operation of an upper trolley; a third guide rail and a fourth guide rail are arranged on opposite outer sides of the first girder and the second girder and jointly form a second guide rail structure for supporting operation of a lower trolley; and the connecting structure further comprises a U-shaped frame structure which adopts a rigid connecting structure which is arranged between a first traveling mechanism and a second traveling mechanism and used for connecting the first traveling mechanism and the second traveling mechanism. According to the connecting structure, the second guide rail structure for supporting the lower trolley is only provided with two guide rails, two guide rails are reduced while compared with the prior art, the mounting technology is simplified, the overall weight of a quayside container crane is reduced, further, stress between the first traveling mechanism and the second traveling mechanism is balanced due to the rigid connecting structure, and the first traveling mechanism and the second traveling mechanism are prevented from separating from the third guide rail and the fourth guide rail.

Owner:HUADIAN HEAVY IND CO LTD

Novel lower trolley system

ActiveCN104261253AThe size of the space does not changeAccurate extractionTravelling gearTrolleysVehicle frameShore

The invention discloses a novel lower trolley system. The system comprises first and second traveling mechanisms capable of traveling along first and second guide rails installed on a shore bridge girder, a rigid frame for rigidly connecting the first and second traveling mechanisms and a lifting appliance, wherein the rigid frame has a structural space through which an upper trolley passes, and a lower trolley meets the following condition: the stabilizing moment sigmaMs caused by the gravity of the lower trolley is larger than the capsizing moment sigmaMo of the horizontal inertia force of the lower trolley. The first and second traveling mechanisms of the lower trolley are rigidly connected with the lifting appliance, and when the stabilizing moment sigmaMs is larger than the capsizing moment sigmaMo, the lower trolley travels stably. During movement of the lower trolley, the lifting appliance and containers cannot shake easily, the lower trolley can travel stably, and abrasion between the first and second traveling mechanisms and the shore bridge girder is reduced; stable traveling consumes lower power than shaking traveling, and the loading and unloading efficiency of a whole shore bridge system is improved; compared with shaking traveling, stable traveling has advantages that the safety is improved, and potential risks are fewer.

Owner:华电蓝科科技股份有限公司

Traversing type double-trolley system and traversing type multi-trolley system

ActiveCN104340863AThe size of the space does not changeAccurate extractionTravelling gearSafety gearVehicle frameGreek letter sigma

The invention discloses a traversing type double-trolley system. The system comprises an upper trolley and a lower trolley, wherein the lower trolley comprises a first walking mechanism and a second walking mechanism mounted on guide rails at two sides of the upper trolley in a walking manner, a rigid frame for connecting the first walking mechanism and the second walking mechanism, and a sling connected below the rigid frame; the rigid frame is provided with a structure space with the cavity size greater than the outer wall size of the upper trolley so as to allow the upper trolley to pass, and the lower trolley meets the condition that the stabilizing moment Sigma Ms of the lower trolley is greater than capsizing moment Sigma Mo; the first walking mechanism is connected with the second walking mechanism through the rigid frame; the structure space size of the rigid frame is greater than the outer wall size of the upper trolley, so that the upper trolley sling carrying a tank can directly pass through the structure space without rotating; under the condition that the stabilizing moment Sigma Ms caused by the gravity of the lower trolley is greater than the capsizing moment Sigma Mo caused by horizontal inertia force of the lower trolley, the capsizing moment Sigma Mo caused by wind load or other reasons is overcome under the effect of the stabilizing moment of the lower trolley, so that the lower trolley always maintains steady in the operational process.

Owner:华电蓝科科技股份有限公司

Passing type double-trolley quay-crane loading and unloading system and method

ActiveCN104261144ARapid transitNot easy to shakeStorage devicesRunwaysEngineeringMechanical engineering

The invention provides a passing type double-trolley quay-crane loading and unloading system. The passing type double-trolley quay-crane loading and unloading system is characterized in that a ferry system comprises a ferry bridge, a first vertical guide rail structure and a ferry trolley; a transtainer system comprises a three-dimensional transtainer, a first transverse guide rail structure, and at least one three-dimensional transtainer transferring trolley, wherein the first transverse guide rail structure is arranged in the three-dimensional transtainer; the at least one three-dimensional transtainer transferring trolley moves along the first transverse guide rail structure; a second transverse guide rail structure is also arranged on the top part of the ferry trolley; when the ferry trolley runs to a part in which the first vertical guide rail structure is connected with the first transverse guide rail structure, the three-dimensional ferry transferring trolley can be moved from the first transverse guide rail structure to the second transverse guide rail structure. According to the passing type double-trolley quay-crane loading and unloading system, the second transverse guide rail structure is arranged on the ferry trolley, thus any three-dimensional transtainer transferring trolley can smoothly arrive at the place below a container caught by a quay crane system through the transtainer, and as a result, the aligning efficient of the three-dimensional transtainer transferring trolley and the quay crane system can be raised; in addition, the three-dimensional transtainer transferring trolley can be continuously circulated, and thus the loading and unloading efficiency of the whole loading and unloading system can be raised.

Owner:华电蓝科科技股份有限公司

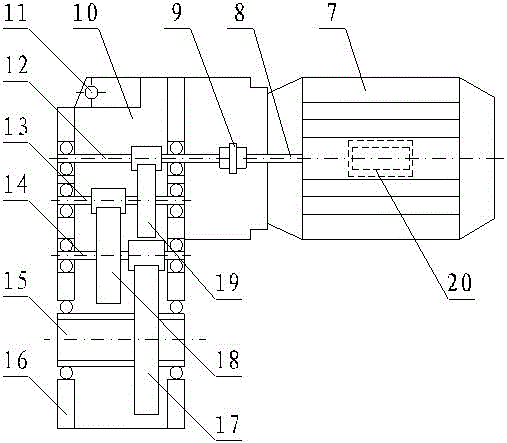

Novel crane crown block wheel structure with automatic deviation rectifying function

InactiveCN106044557ASolve serious wear and tear problemsThe overall structure is simple and reliableTravelling gearProgrammable logic controllerDrive shaft

The invention discloses a novel crane crown block wheel structure with an automatic deviation rectifying function. The novel crane crown block wheel structure with the automatic deviation rectifying function comprises a crown block wheel installed on a crown block wheel fixing shaft. An axle is sleeved with the portion, located on one side of the crown block wheel, of the crown block wheel fixing shaft. The axle is sequentially sleeved with a bearing, a bearing sleeve and a supporting base from inside to outside. A reset cushion block is arranged between the supporting base and the bearing sleeve. Holes are punched in the two sides of the supporting base. A reset spring is installed in the hole in one side of the supporting base, and one end of a driving shaft is fixed in the hole in the other side of the supporting base. The other end of the driving shaft is connected with a driving device. A plurality of position sensors are arranged on the two sides of the crown block wheel, and all the position sensors are all connected with a programmable logic controller (PLC) simultaneously. The controller controls the driving device which is installed beside the crown block wheel and used for driving the crown block wheel. The controller controls the driving device so as to drive the crown block wheel to deviate. The novel crane crown block wheel structure with the automatic deviation rectifying function is simple and reliable in overall structure and ingenious in design, the problem of severe abrasion caused by deviation of the crown block wheel is effectively solved, the overall manufacturing cost is low, and large-scale application and popularization are facilitated.

Owner:张丙奇

A new type of trolley system

Owner:华电蓝科科技股份有限公司

Light bridge crane guided by horizontal wheel opposite angles

InactiveCN106672812ASimple structureImprove transmission efficiencyTravelling cranesTravelling gearLow speedCoupling

The invention relates a light bridge crane guided by horizontal wheel opposite angles. The light bridge crane comprises a main beam; large trolley travelling mechanisms are installed at the left end and the right end of the upper side surface of the main beam correspondingly; each large trolley travelling mechanism comprises an electromotor, wherein the electromotor is connected with a coupling through an electromotor output shaft, the coupling is connected with a gear A through a gear shaft A, the gear A is connected with a gear B through a gear shaft B, the gear B is connected with a gear C through a gear shaft C, and the gear C is connected with a low speed shaft; the low speed shafts are installed on a large trolley wheel B and a large trolley wheel D in a sleeving mode correspondingly; a horizontal guide pulley A and a horizontal guide pulley B are installed on the outer side of the large trolley wheel B and on the two sides of a rail correspondingly; and a horizontal guide pulley C and a horizontal guide pulley D are installed on the outer side of the large trolley wheel D and on the two sides of the rail correspondingly. The light bridge crane guided by the horizontal wheel opposite angles has the advantages that the structure is simple, transmission efficiency is high, the integration level is high, the size is small, the weight is light, and rail gnawing can be effectively avoided.

Owner:李相迎 +6

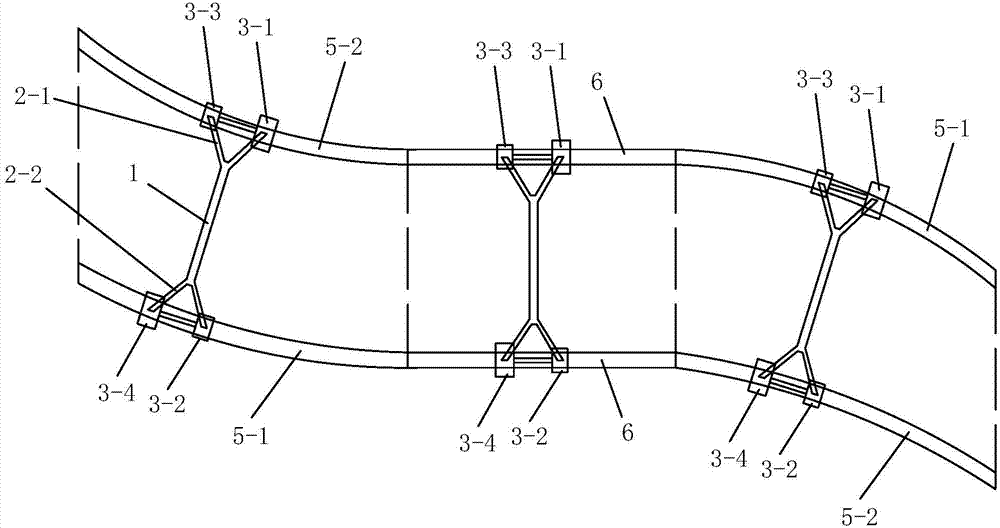

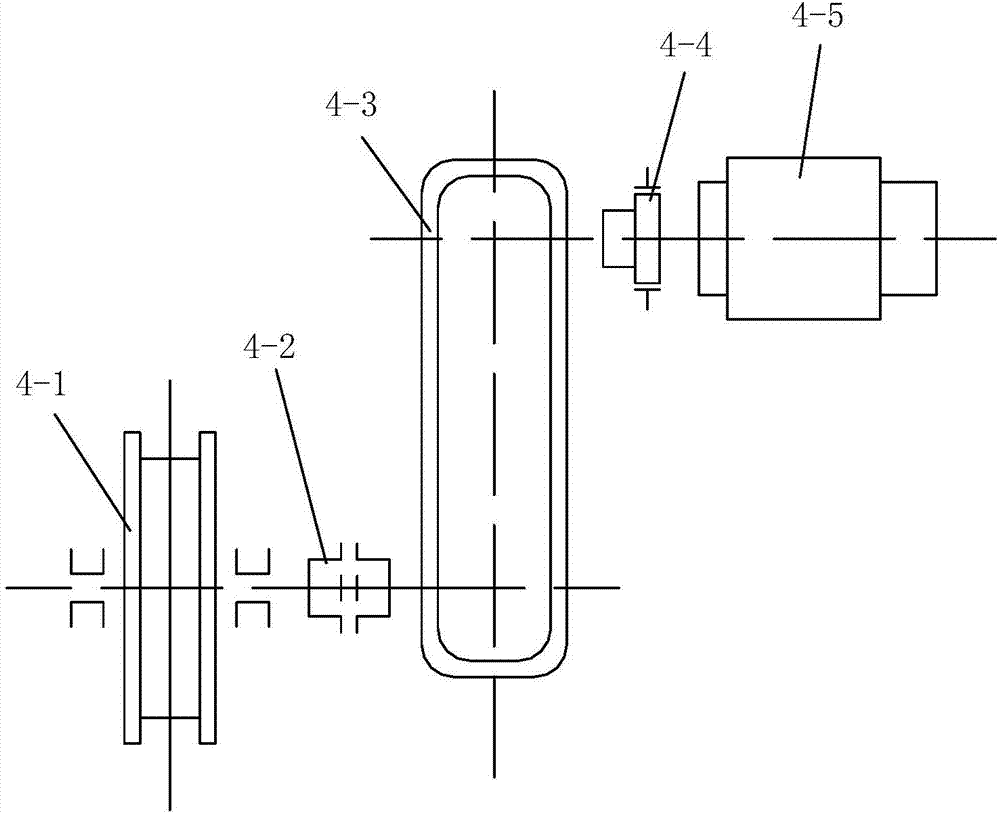

Gantry crane with cart capable of walking on curved rail and walking control method thereof

ActiveCN103466463BSimple structureReasonable designTrolley cranesTravelling gearEngineeringPortal frame

The invention discloses a gantry crane with a cart capable of walking on a curved rail and a walking control method thereof. The gantry crane comprises a portal frame and a cart walking mechanism. The cart walking mechanism comprises a first walking wheel, a third walking wheel, a second walking wheel and a fourth walking wheel, wherein the first walking wheel and the third walking wheel are mounted on the lower portions of the front side and the rear side of each left supporting leg respectively, and the second walking wheel and the fourth walking wheel are mounted on the lower portions of the front side and the rear side of each right supporting leg respectively. The external diameter of the first walking wheels and the external diameter of the fourth walking wheels are both D1, the external diameter of the second walking wheels and the external diameter of the third walking wheels are both D2, D1 / D2=R, and r1 and R1 are the radius of an inner side circular arc rail and the radius of an outer side circular arc rail. The walking control method includes the steps that first, walking is achieved on a current rail section, and the specific processes comprise rail section shape judging, straight line rail section walking and circular arc rail section walking; second, the step one is repeated again and again until the walking process of the walking rail is completed. According to the gantry crane with the cart capable of walking on the curved rail and the walking control method thereof, the structure is simple, the design is reasonable, installation and arrangement are convenient, using operation is simple and convenient, the using effect is good, the cart can walk on the curved rail, and rail gnawing can be avoided.

Owner:CHINA RAILWAY FIRST GRP CO LTD

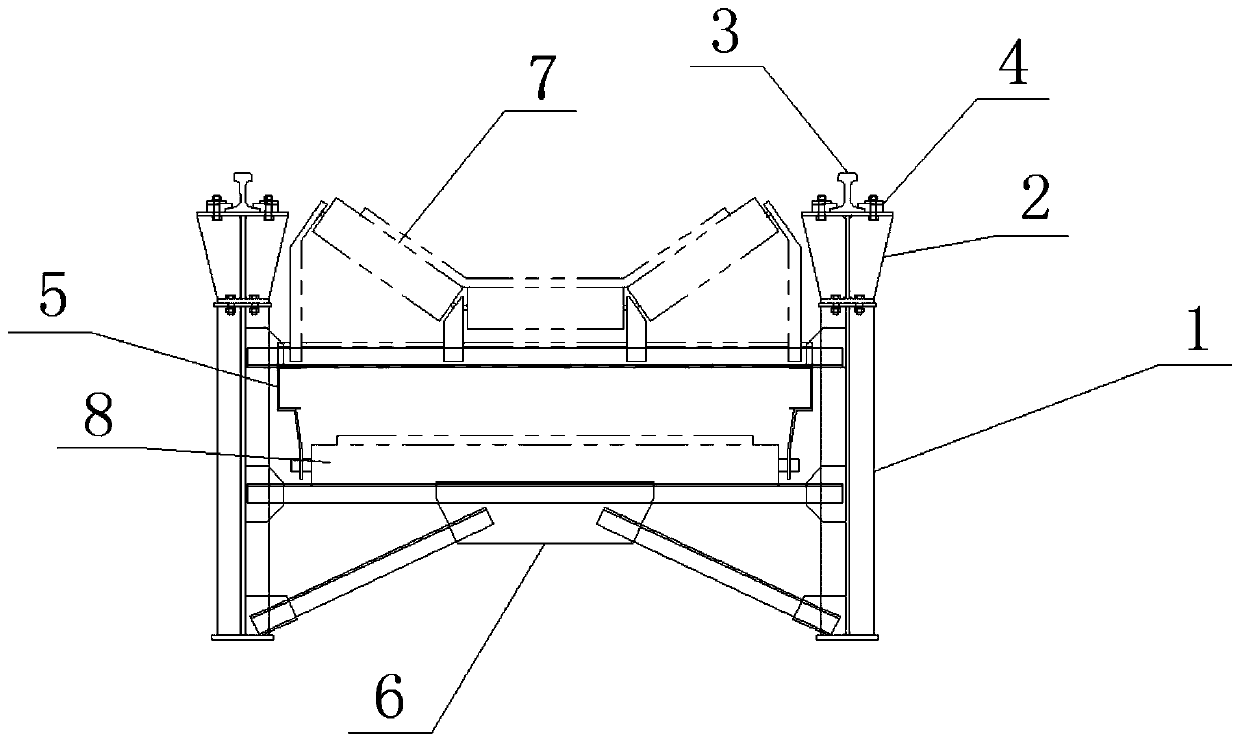

Belt conveyor bracket

PendingCN109878984ASimple structureEasy to installConveyorsSupporting framesEngineeringBelt conveyor

The invention provides a belt conveyor bracket, and belongs to the field of belt conveyors. The belt conveyor bracket can be widely applied to various belt conveyors or working fields equipped with heavy unloading vehicles. The belt conveyor support is fixed through triangular supports and inclined supporting legs between the supports. Rails are in surface contact with cross beams, and the stressis uniform. Shaking, deformation, rail biting and the like of a vehicle body of an unloading vehicle can be avoided. Parts are fixed by bolts, so that dismounting is convenient to carry out, and maintenance is facilitated. The belt conveyor support is simple in structure, convenient to install, durable in use and low in maintenance cost.

Owner:BAOTOU IRON & STEEL GRP

A kind of running mechanism of double-track trolley group of super-large gantry crane

ActiveCN104176633BImprove uniform distributionReduce lateral forceTravelling gearRunwaysDrive wheelVehicle frame

The invention discloses an operating mechanism for a double-track trolley group of a super-large gantry crane, which includes a balance beam and a double-track trolley, and is characterized in that the double-track trolley is composed of four wheels composed of running wheels and driven wheels symmetrically arranged on both sides of the frame Double-drive mechanism, the double-track trolley is fixed at both ends of the balance beam by the hinge shaft, and the double-track trolley is hinged to the balance beam; the frame is an "I"-shaped box structure; The driving wheel of the mechanism, and the driving mechanism make the traveling wheel and the driven wheel drive the trolley group composed of two double-track trolleys to run on the track. Compared with the prior art, the present invention has the advantages of small running wheel pressure and good uniform distribution, which greatly weakens the lateral force, effectively avoids the phenomenon of rail gnawing, increases the working range, reduces the working blind area, and further reduces the construction cost. The structure is simple, which greatly facilitates the maintenance and maintenance of the equipment.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

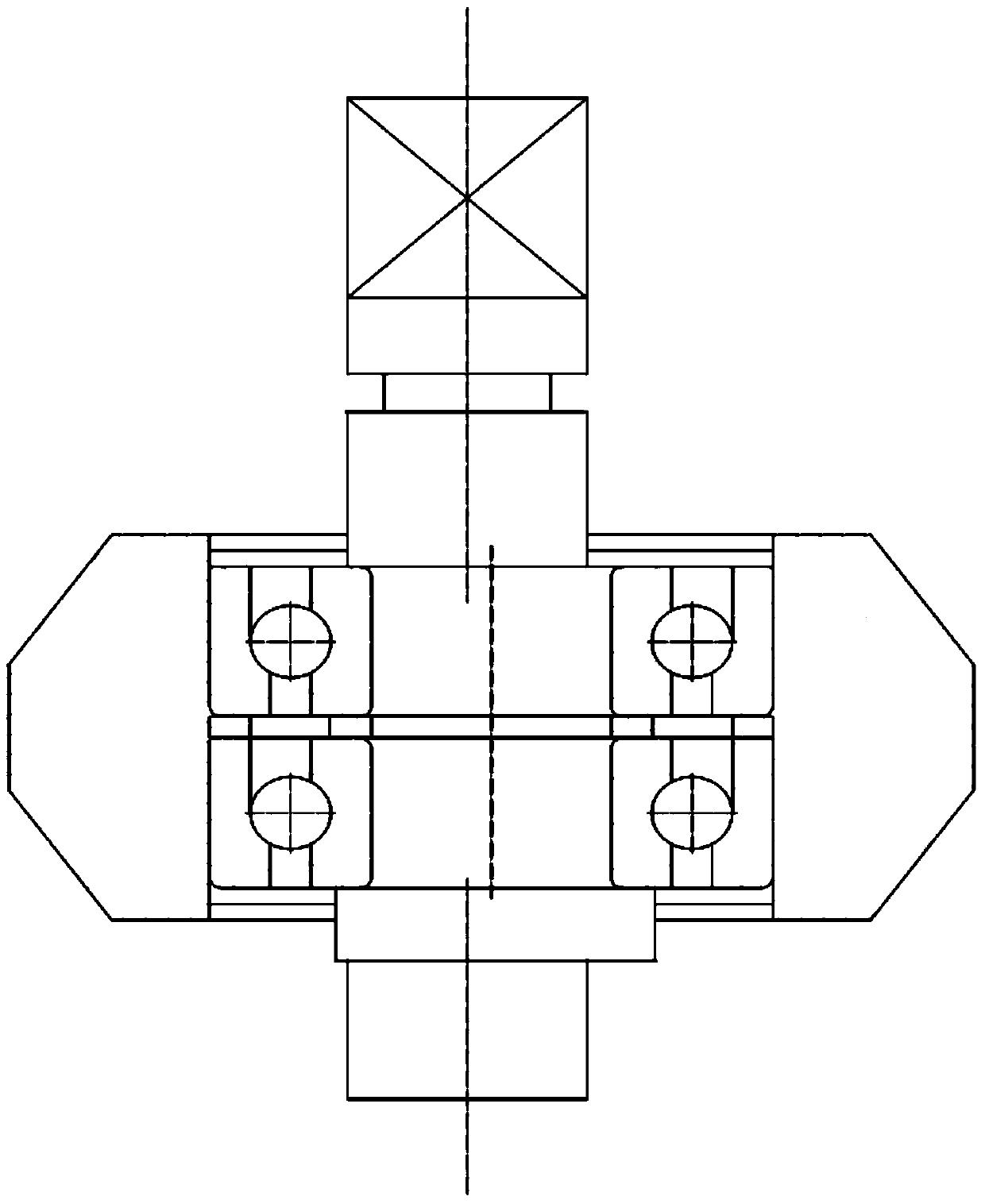

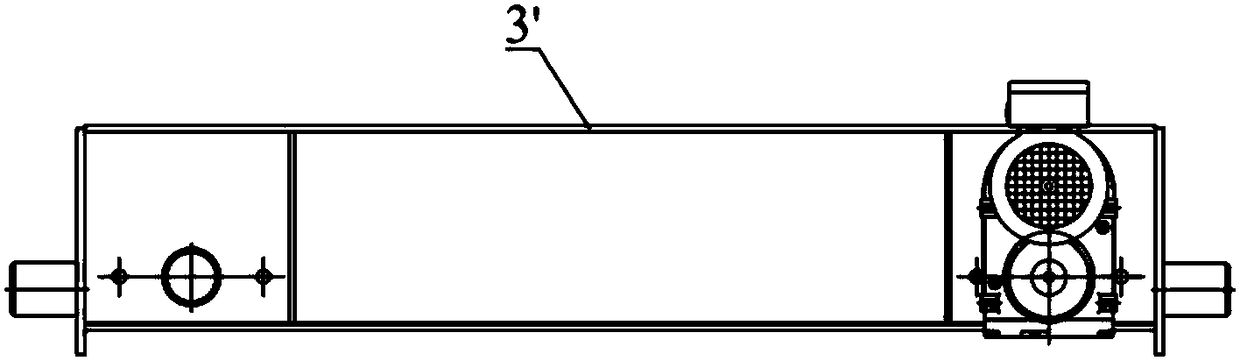

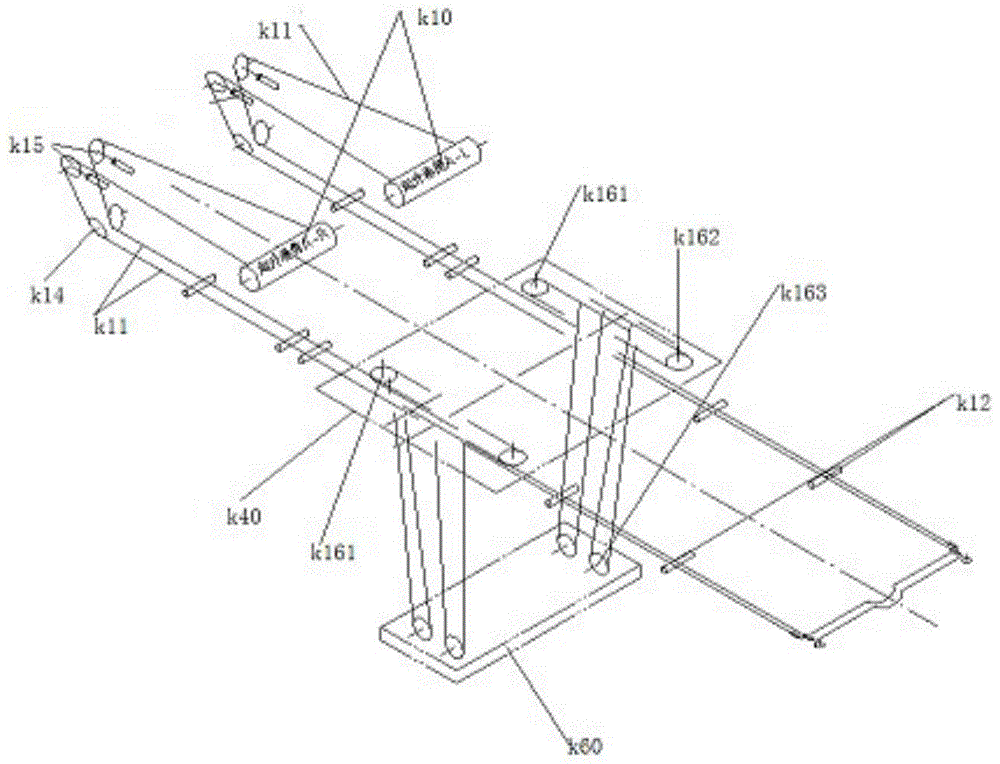

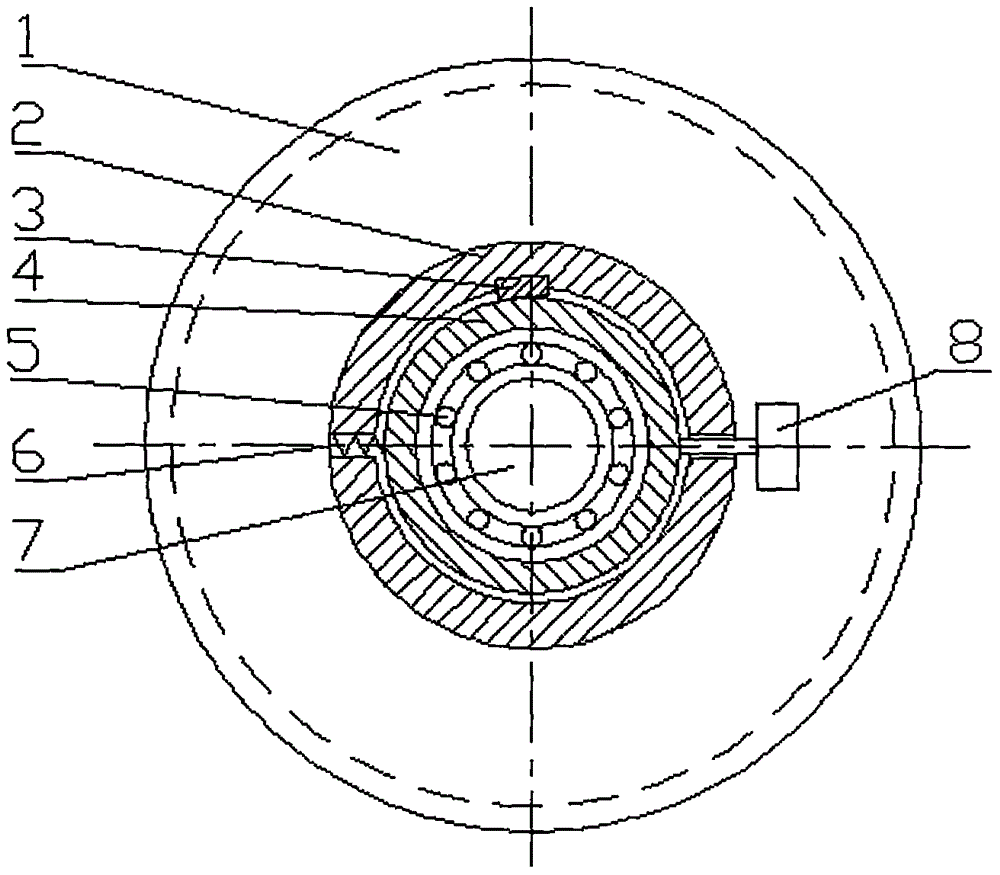

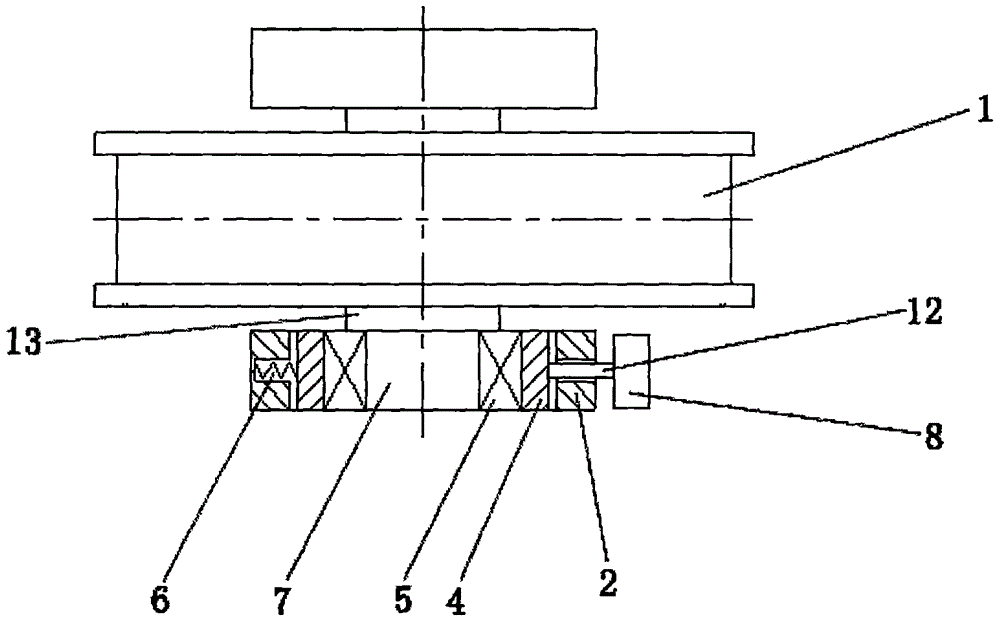

A horizontal wheel anti-gnawing rail device of a two-force rod system

InactiveCN103231987BExtended service lifeAvoid bending momentTravelling gearStructural engineeringControl theory

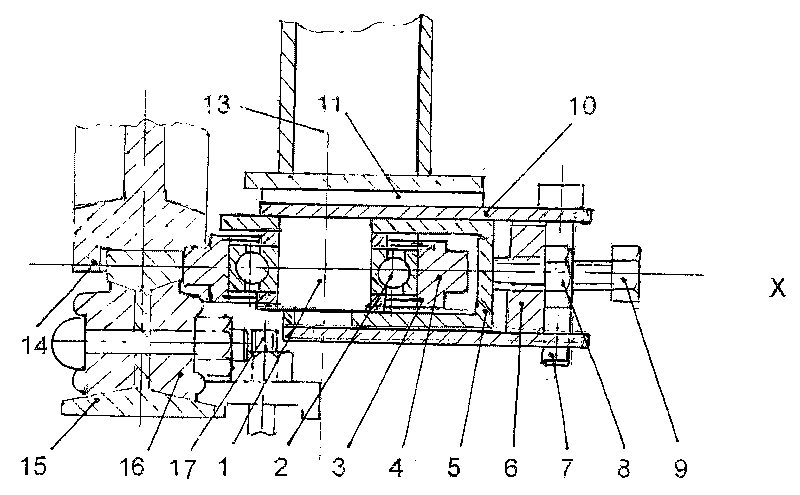

The invention relates to a horizontal wheel rail gnawing preventing device for a two-force rod system. The technical scheme is as follows: the device comprises four two-force rod mechanisms with the same size and structure, and the four two-force rod mechanisms are symmetrically fixed on four corners of a bridge girder (1). Each two-force rod mechanism is composed of a fixed frame set and a horizontal wheel set, wherein the fixed frame set comprises a box-shaped fixed frame (2), a pressing frame (3) and a compression spring (15); the horizontal wheel set comprises a horizontal wheel (4), a bearing (8), an eccentric transparent cover (9), an adjustable pad (10), a wheel axle (12) and a shaft sleeve (13). The box-shaped fixed frame (2) is fixed on web plates at two sides of the bridge girder (1); the pressing frame (3) slides inside the box-shaped fixed frame (2) through the compression spring (15); and the horizontal wheel (4) is fixed on the pressing frame (3) through the bearing (8), the wheel axle (12) and the eccentric transparent cover (9). By using the horizontal wheel rail gnawing preventing device, the precise guide for the operation of a crane is realized; and a track (5) is in flexible contact with the horizontal wheel (4), thus the wheel rail gnawing phenomenon is effectively avoided. The horizontal wheel rail gnawing preventing device has the characteristics of simple structure, easiness for maintenance, strong stability and long service life.

Owner:WUHAN UNIV OF SCI & TECH

A micro-deformation detection device for a double-girder crane trolley

ActiveCN109484977BAvoid rail gnawingHigh precisionLoad-engaging elementsLaser transmitterMicrocontroller

The patent of the present invention belongs to the field of double-girder crane devices, and specifically discloses a micro-deformation detection device for a double-girder crane trolley, including: laser transmitters and photosensitive receiving lattices respectively installed at both ends of the steel beams on each side of the double-girder crane trolley. The photosensitive receiving dot matrix includes a plurality of photosensitive triodes, and the photosensitive triodes are connected with a microcontroller through an interface circuit; the interface circuit is an AND circuit connected in parallel by a plurality of diodes; the microcontroller according to the According to the laser light signal received by the photosensitive receiving dot matrix, the position information of multiple laser irradiation points is obtained; and according to the position information and the distance between adjacent photosensitive three-stage tubes, the offset distance information of the corresponding laser irradiation point is obtained; and according to The offset distance information obtains the offset angle information of the corresponding laser irradiation point. Through the above technical proposal, the present invention accurately detects the micro-deformation of the double-girder crane trolley, and avoids the rail gnawing phenomenon of the crane trolley.

Owner:河南工学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com