Traversing type double-trolley system and traversing type multi-trolley system

A double trolley, through-type technology, applied in the direction of load block, load suspension components, safety devices, etc., can solve the problems of shaking, interference, and increased energy consumption of the upper trolley and the lower trolley

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

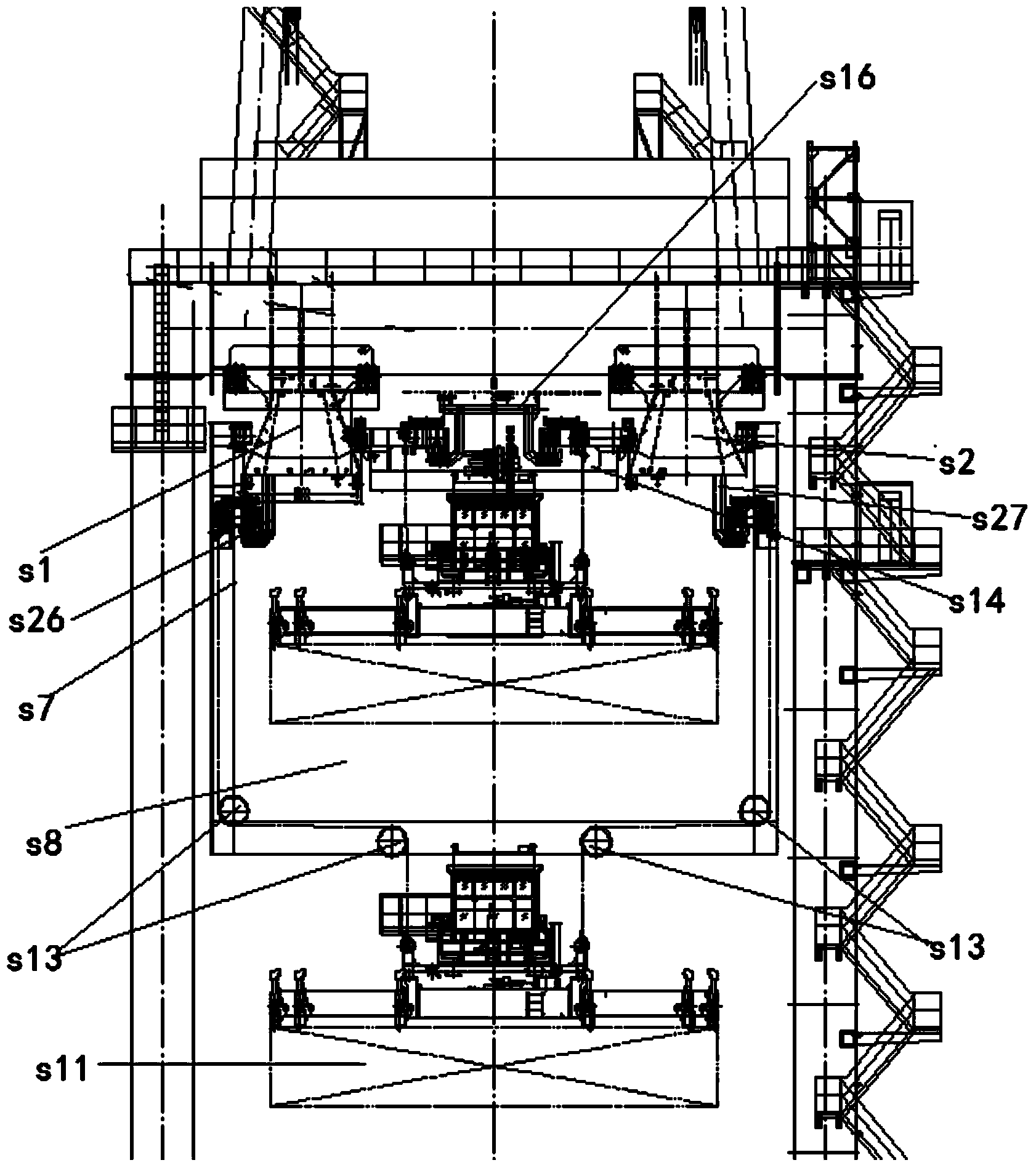

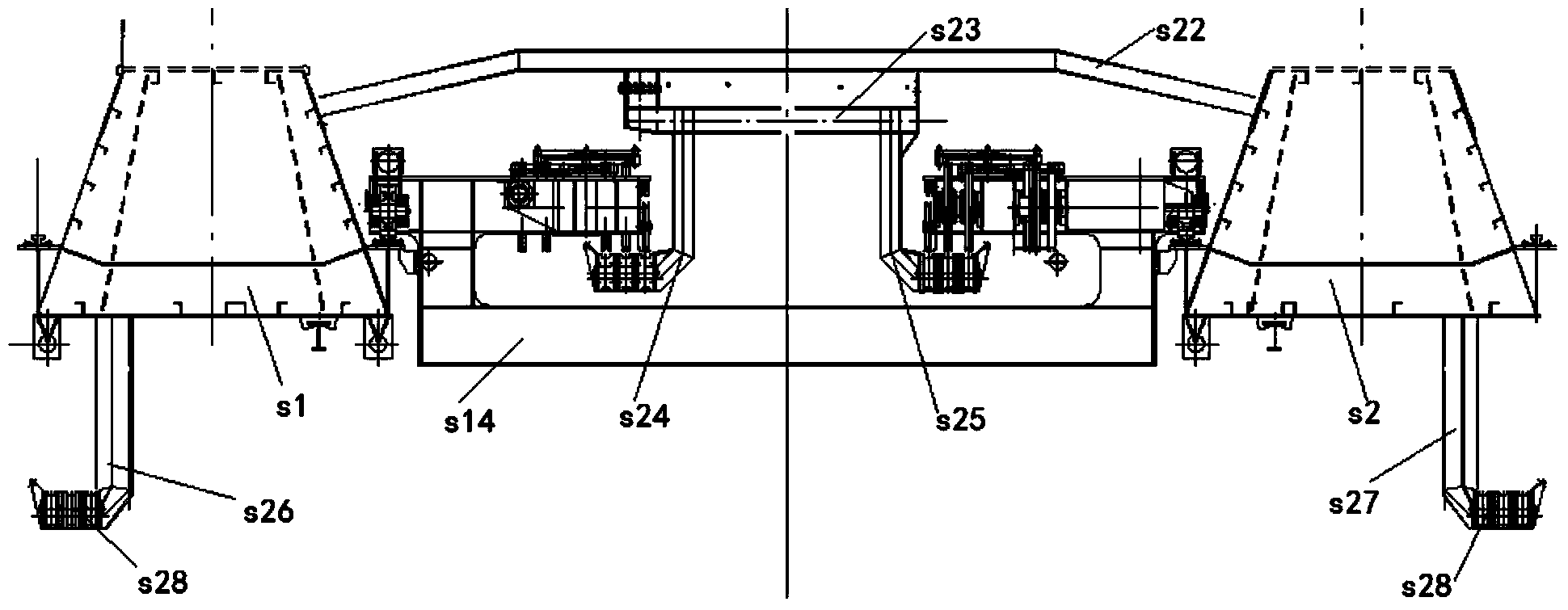

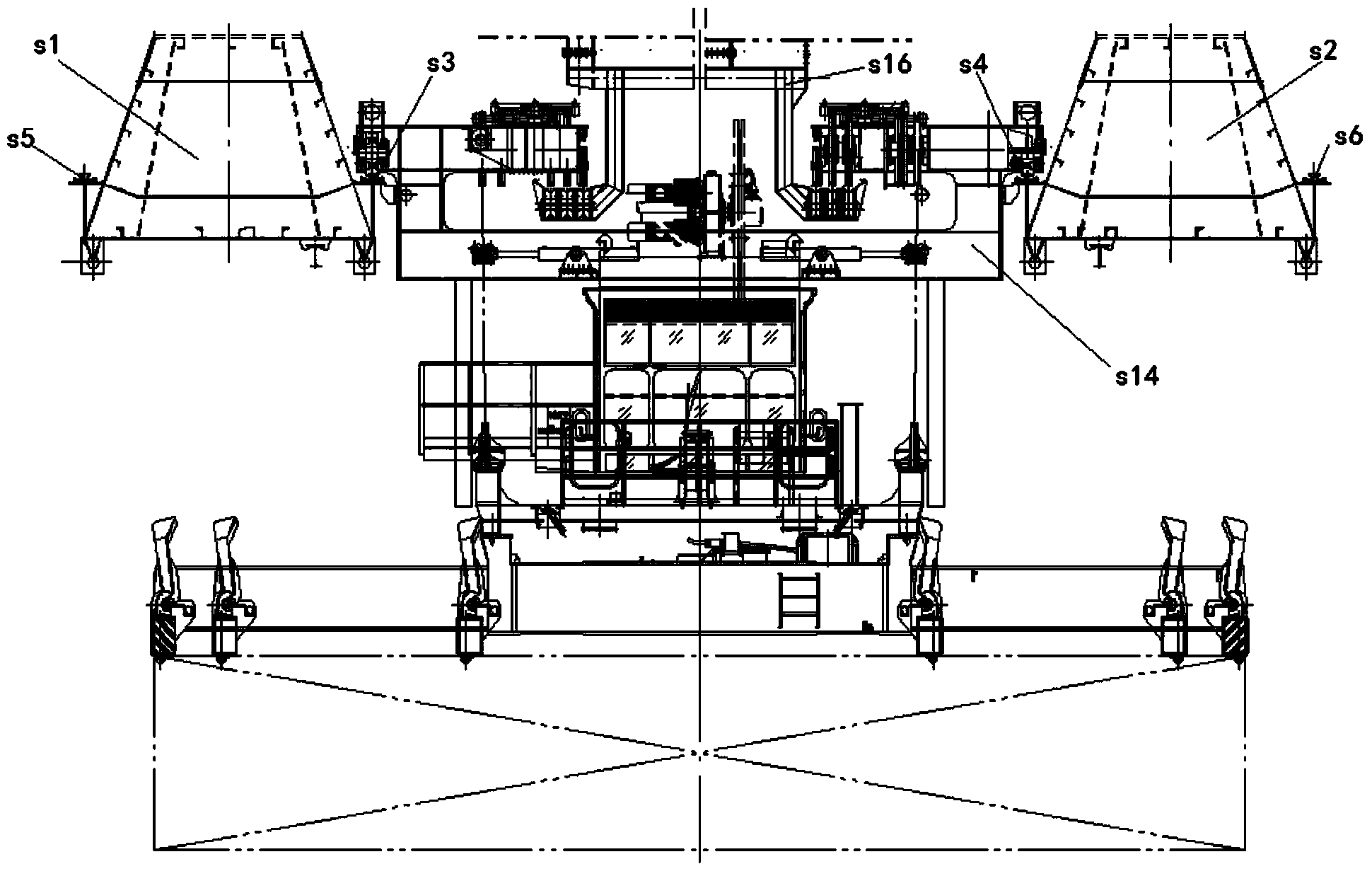

[0051] The following embodiments will be used to further illustrate the present invention in conjunction with the accompanying drawings.

[0052] Such as Figure 1-Figure 10 As shown, a passing-through double trolley system described in this embodiment includes an upper trolley s14 and a lower trolley s15, and the lower trolley s15 includes a first traveling mechanism that can walk and be installed on guide rails located on both sides of the upper trolley s14 s12 and the second traveling mechanism s29, the rigid vehicle frame s7 connecting the first traveling mechanism s12 and the second traveling mechanism s29, and the lower hanger s11 connected below the rigid vehicle frame s7; the rigid The frame s7 has a structural space s8 whose inner cavity size is larger than the outer edge size of the upper trolley s14 and is used for the upper trolley s14 to pass through, and the lower trolley s15 satisfies the following conditions: the stability caused by the gravity of the lower tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com