A system and method for loading and unloading a quayside crane with two trolleys

The technology of a loading and unloading system and double trolleys is applied in the field of containers, which can solve the problems of low loading and unloading efficiency, and achieve the effect of not easy to shake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

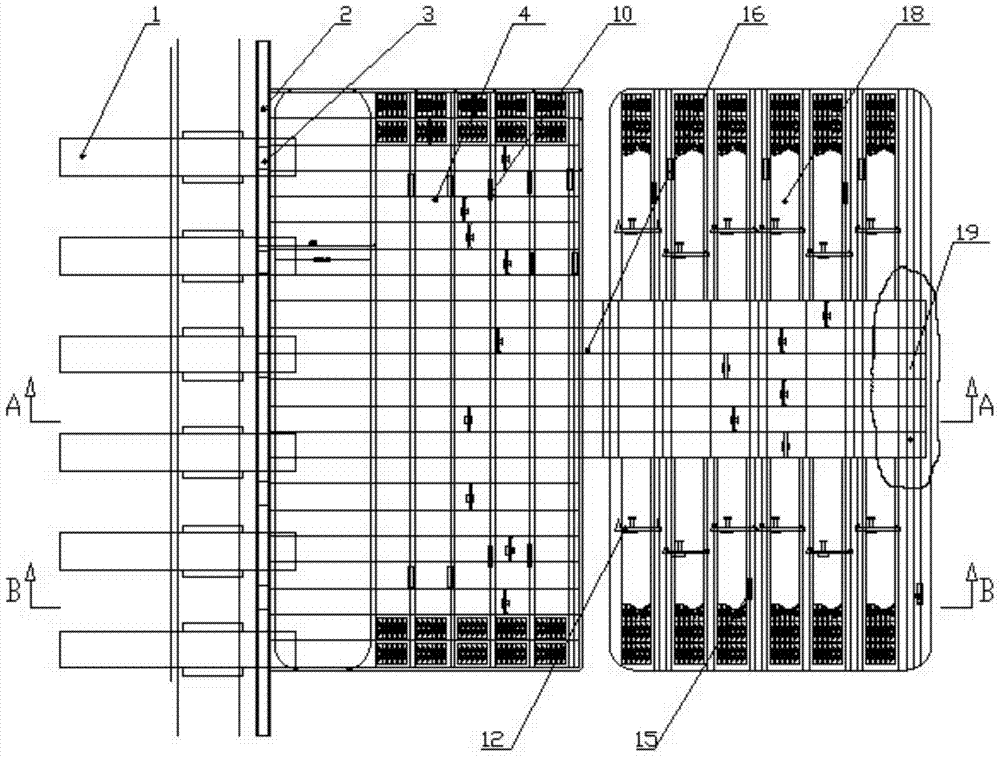

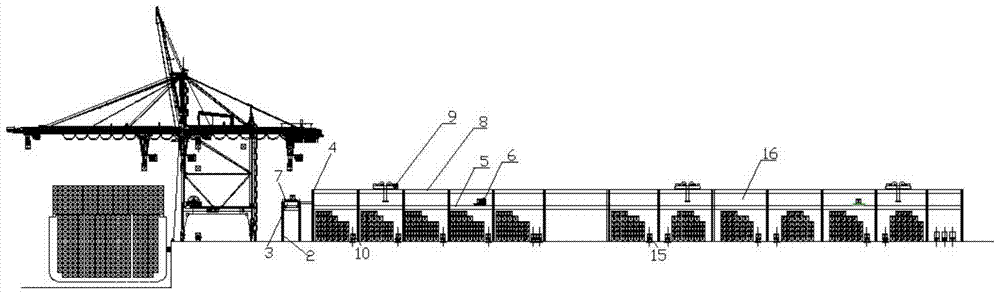

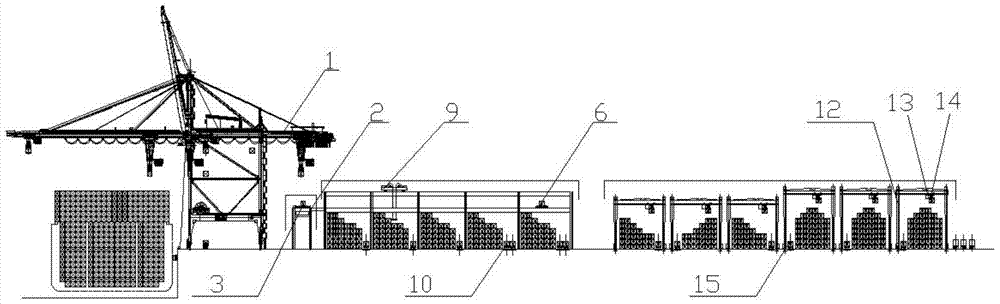

[0082] Such as Figure 1-Figure 3 As shown, a kind of through-type double-car quay crane loading and unloading system in this embodiment includes a quay crane system, a ferry system, a yard bridge system and an open-air storage yard system; On the side, the ferry system includes a ferry bridge 2 arranged perpendicular to the length direction of the quay bridge structure 1 of the quay bridge system, a first vertical guide rail structure arranged along the length direction of the ferry bridge 2, and several The ferry dolly 3 that the first vertical guide rail structure moves; the field bridge system includes a three-dimensional field bridge 4, several first transverse guide rail structures 5 arranged in the three-dimensional field bridge 4, and at least one can move along the first horizontal direction The three-dimensional field bridge transfer trolley 6 that the guide rail structure 5 moves; wherein, the top of the ferry trolley 3 is also provided with a second transverse guid...

Embodiment 2

[0090] On the basis of embodiment 1, the present embodiment provides a container loading and unloading method:

[0091] 1. Ship unloading process:

[0092] Such as Figure 4 As shown in the route ①, the spreader on the quay crane structure 1 of the quay crane system grabs the container from the ship, and transfers the container to the tail end of the quay crane structure 1, and the quay crane structure 1 The container is located above the ferry bridge 2; at the same time, the three-dimensional field bridge transfer trolley 6 moves to the intersection of the first transverse guide rail structure 5 and the first vertical guide rail structure and moves to the On the second transverse guide rail structure 7 on the ferry trolley 3, then the ferry trolley 3 transports the three-dimensional field bridge transfer trolley 6 to directly below the quay bridge structure 1; at this time, the quay bridge The spreader of structure 1 places the container on the three-dimensional field bridg...

Embodiment 3

[0096] On the basis of embodiment 1, the present embodiment provides a method for container collection and port dredging:

[0097] 1. The port collection process:

[0098] Such as Figure 5 As shown in route ③, after the external collection truck enters the collection truck loading and unloading area 19, the three-dimensional field bridge lifting trolley 9 on the above three-dimensional field bridge fast track 16 grabs the container on the collection truck , and then the container is placed on the corresponding second automatic rail car 15, and the second automatic rail car 15 loads the container into the open-air storage yard system, and transports the container to the target open-air storage area 18; finally Correspondingly, the automatic rail crane 12 puts the container into the stack area, thereby completing the harbor collection process.

[0099] 2. The port dredging process:

[0100] Such as Figure 5 As shown in the ④ route in , the port dredging process is the reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com