Rail gnawing prevention walking device self-adaptive to rail gauge and wheel pressure

A walking device, self-adaptive technology, applied in safety devices, walking mechanisms, transportation and packaging, etc., can solve the problems of motor equipment damage, slippage, deviation, etc., to reduce the degree of unbalanced force and avoid three legs.” phenomenon, the effect of preventing rail gnawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The invention will be further described below with reference to the accompanying drawings and specific embodiments.

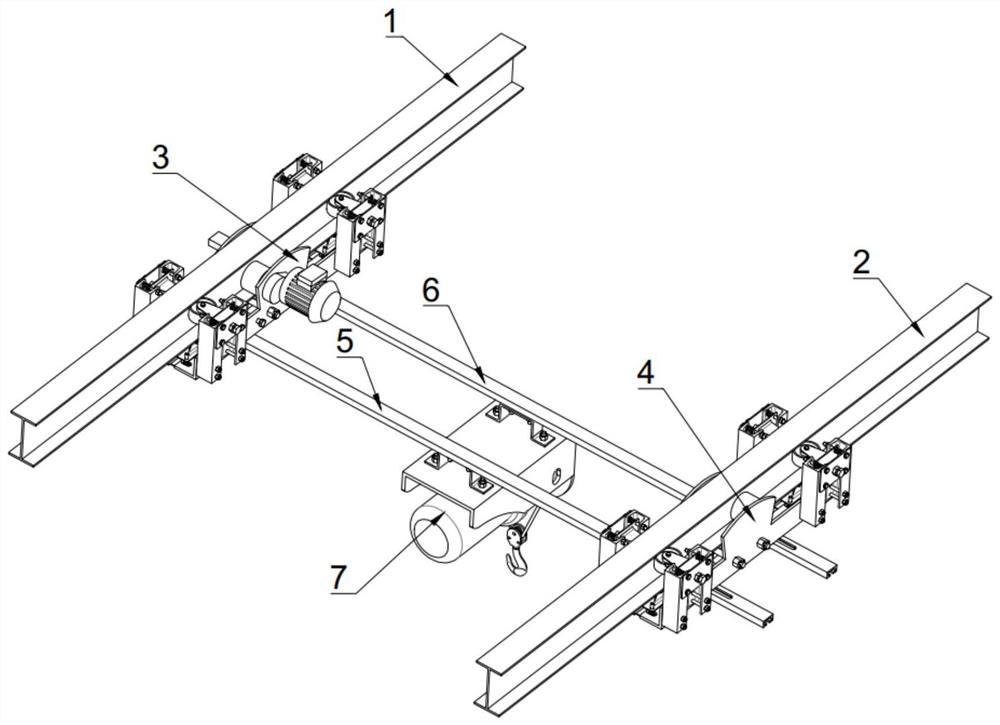

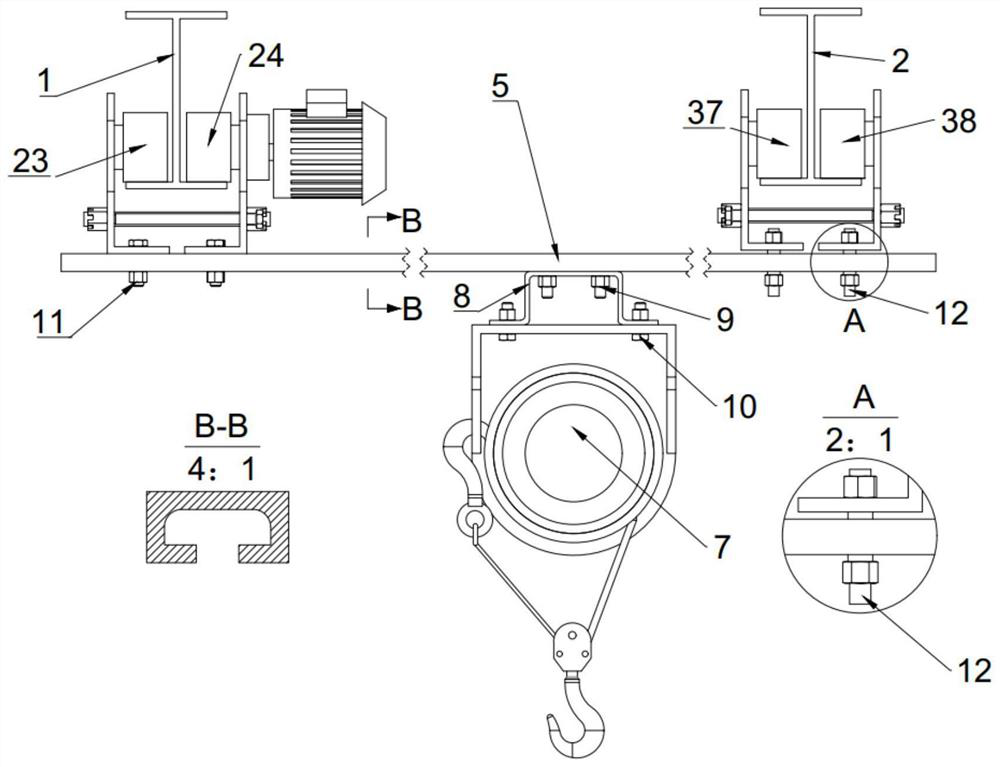

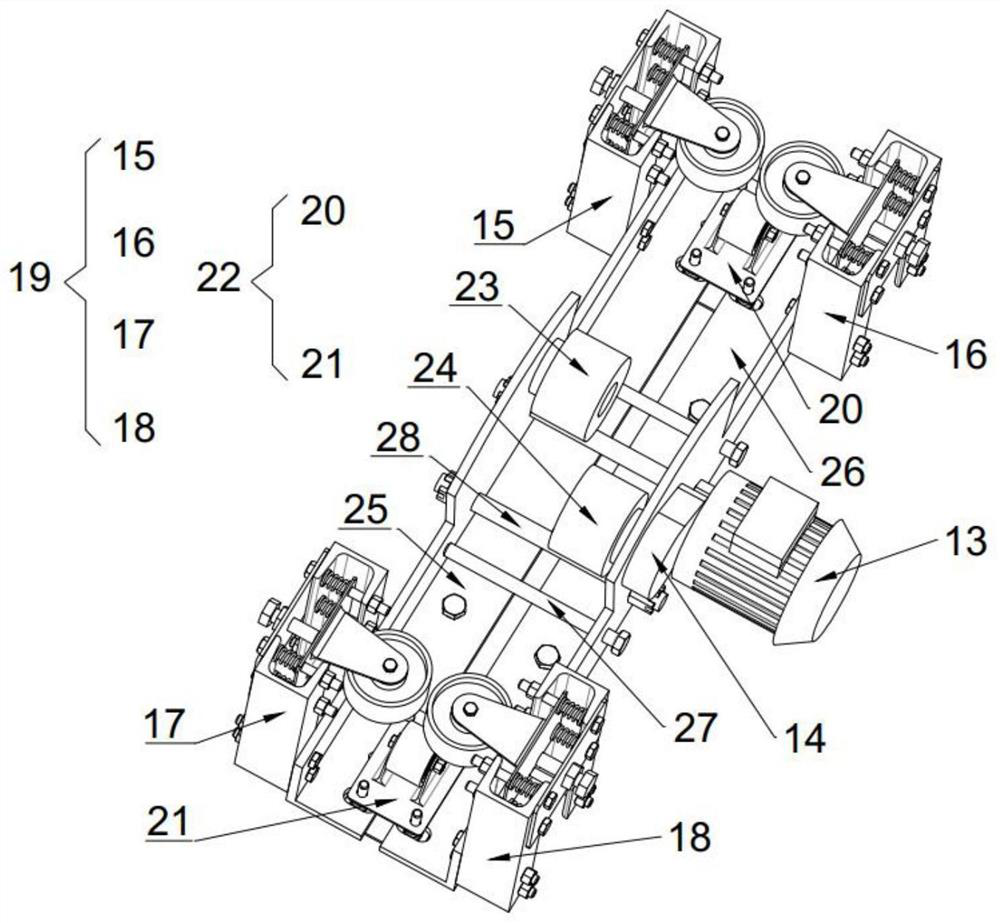

[0058] An anti-rail rail walking device, reference Figure 1 to 11 First orbit 1 and the second track 2, including each other, and the active trails disposed on the first track 1 and the drive train 4 disposed on the second track 2; the active trolley 3 There is also two sliced cross beams from the vehicle 4, respectively, the first belt sliding cross member 5 and the second tide beam 6, the first belt slot beam 5 and the second band slot beam. 6 is also equipped with electric gap 7;

[0059] The active trail 3 is suspended on the first track 1 by the first carrier, and the driven trolley 4 is suspended on the second rail 2 by the second bearing wheel; the active trolley 3 passes through the first bolt group 11 and the belt The hole groove on the chute beam is fixed, the driven trolley 4 is attached to a sliding groove 64 with a sliding groove group 12 by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com