Deformation control method in laser cladding of bimetal guide rail

A laser cladding and deformation control technology, applied in metal material coating process, coating and other directions, can solve problems such as warping deformation, achieve the effect of small deformation, reduce residual stress, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

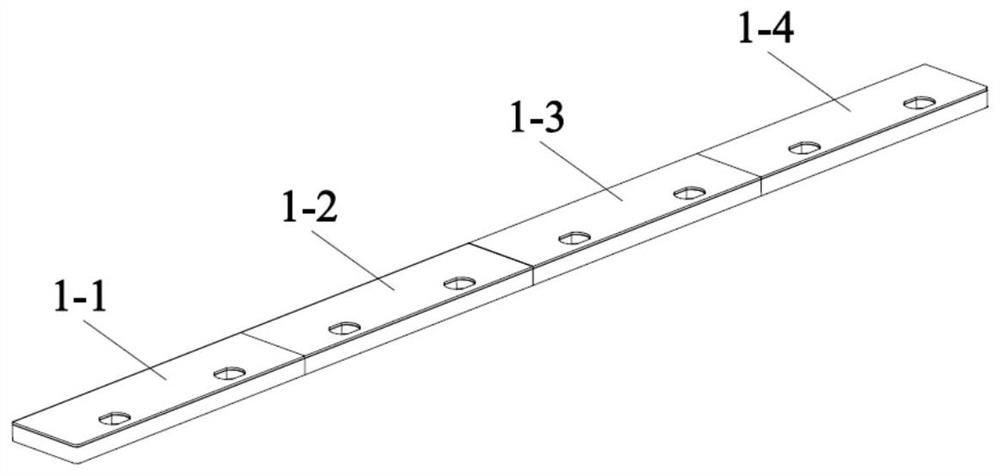

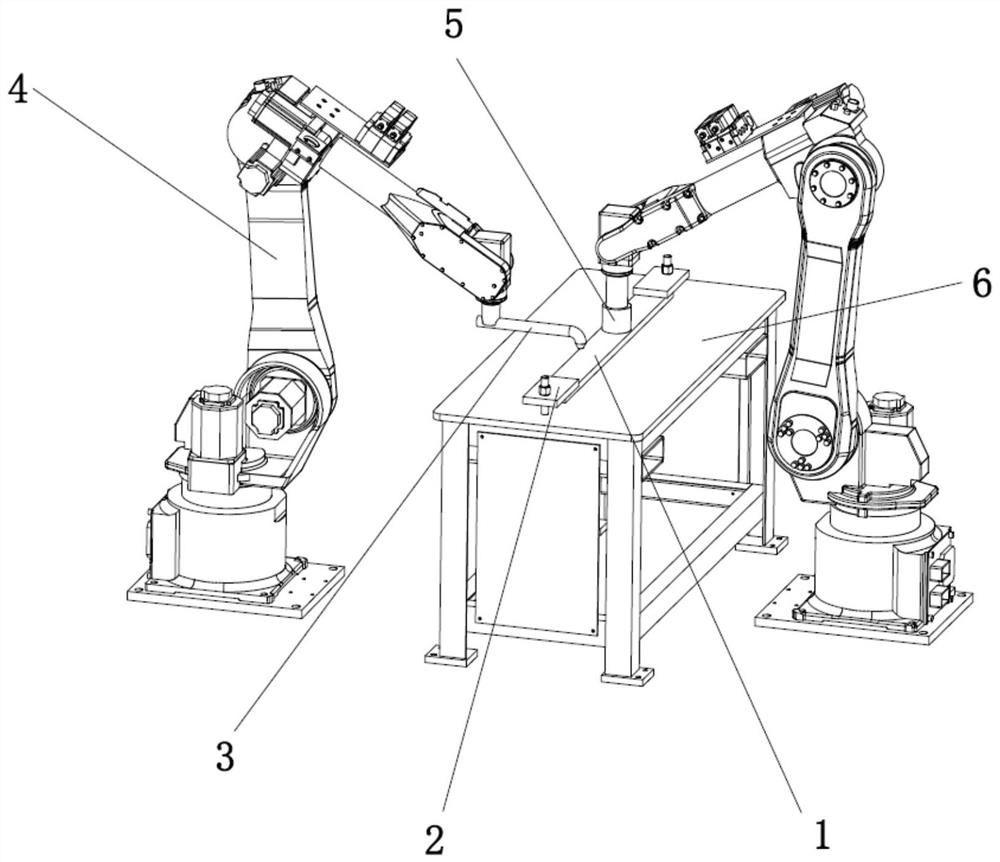

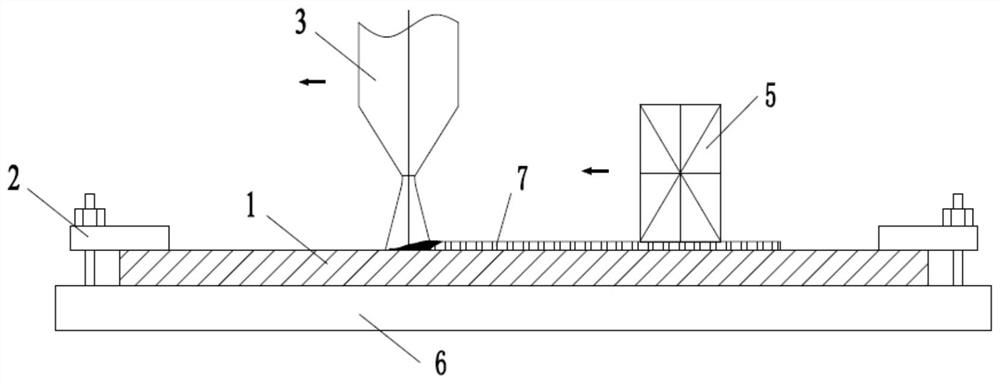

[0026] see Figure 1 to Figure 4 , shows the method for controlling deformation in laser cladding of bimetallic rails of the present invention.

[0027] The deformation control method in the laser cladding of the bimetal guide rail includes the following steps:

[0028] Step 1: Divide the long guide rail into multiple guide rail segments (the figure shows four guide rail segments of equal length, including the first guide rail segment 1-1, the second guide rail segment 1-2, the third guide rail segment 1-3 and The fourth guide rail section 1-4), in the specific setting, the shorter the length, the smaller the stress deformation during the cladding process, but the too short guide rail section will lead to complicated follow-up procedures and difficult to control during cladding, therefore, the appropriate The length limit is the guarantee for the smooth progress of the cladding process. In the present invention, the preferred length is 200mm-300mm;

[0029] Step 2: Fix the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com