Novel crane crown block wheel structure with automatic deviation rectifying function

A technology of automatic deviation correction and sky wheel, which is applied in the direction of traveling mechanism, load hanging components, transportation and packaging, etc., can solve the problems of increasing crane maintenance costs and downtime, failure to solve well, and track straightness exceeding the standard. , to achieve the effect of being conducive to large-scale promotion and use, low manufacturing cost, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

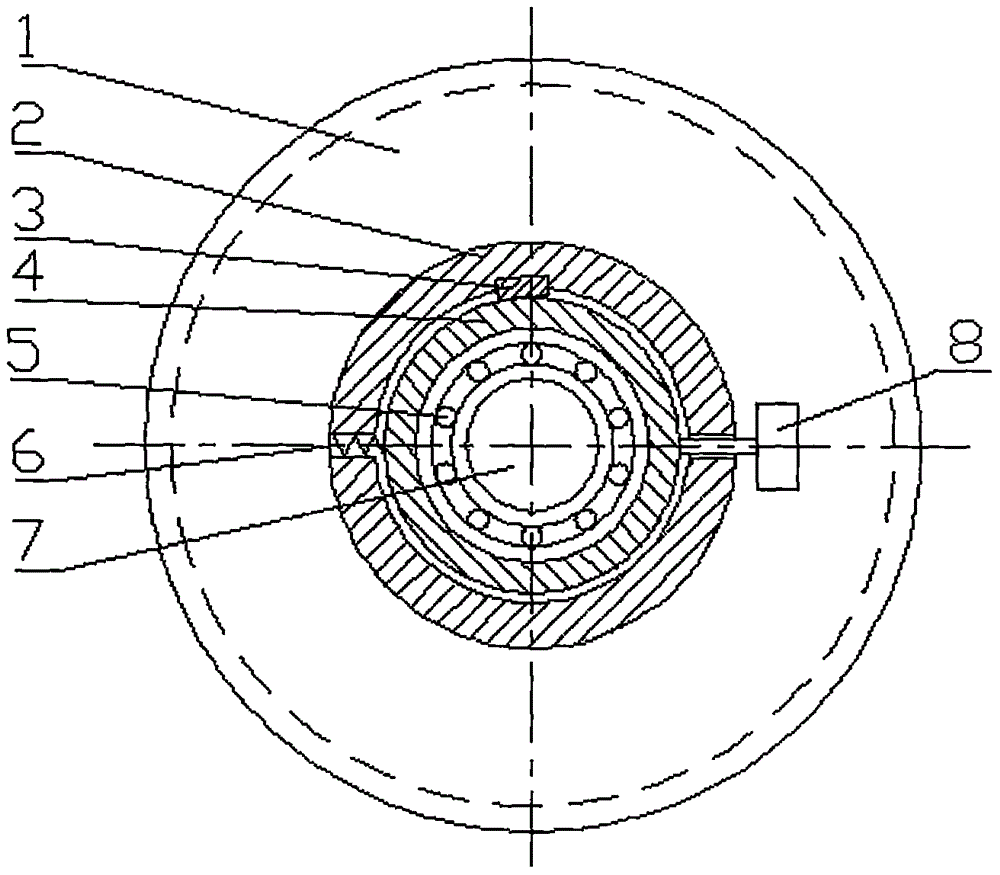

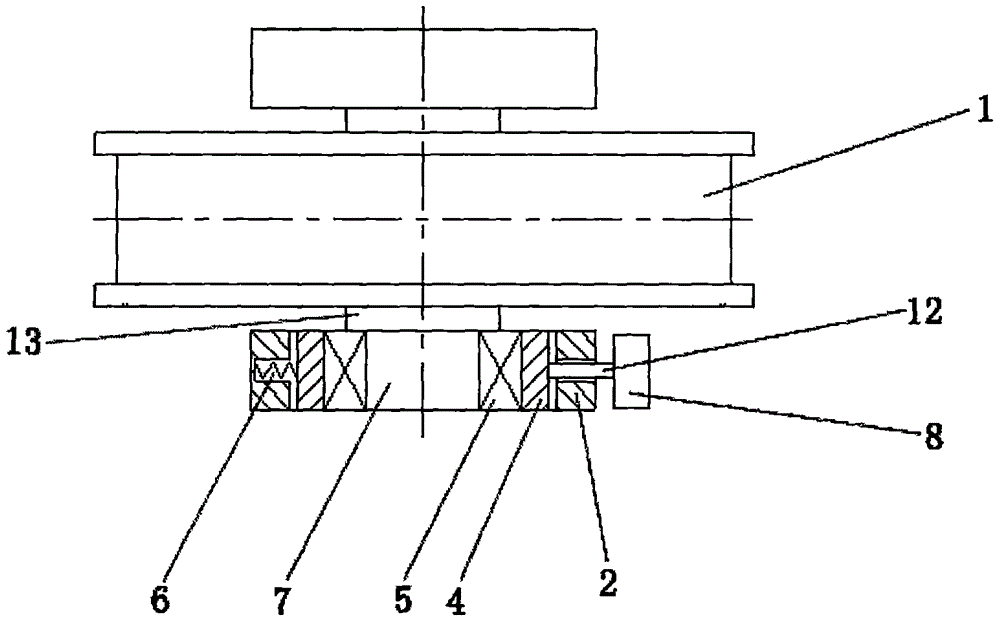

[0014] Such as Figure 1 to Figure 3 As shown, the new crown wheel structure of the crane that can automatically correct the deviation includes the crown wheel 1 installed on the crown wheel fixed shaft 13, and the crown wheel fixed shaft 13 on the side of the crown wheel 1 is sleeved with the wheel shaft 7.

[0015] A bearing 5, a bearing sleeve 4 and a support seat 2 are sheathed on the wheel shaft 7 sequentially from the inside to the outside.

[0016] A reset pad 3 is arranged between the support base 2 and the bearing sleeve 4, holes are drilled on both sides of the support base 2, a return spring 6 is installed in one side hole, and one end of a drive shaft 12 is fixed in the other side hole, The other end of the drive shaft 12 is connected to the drive device 8 .

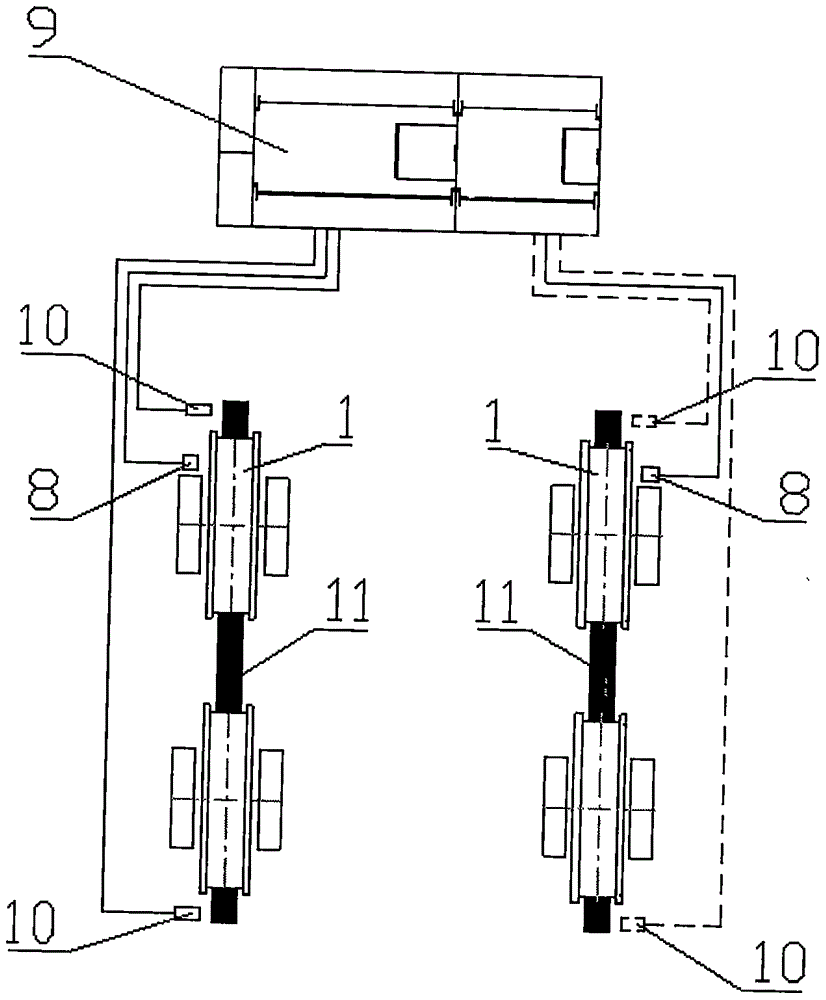

[0017] Both sides of the sky wheel 1 are provided with a plurality of position sensors 10, and each of the position sensors 10 is connected to a PLC controller 9 at the same time; the controller 9 controls t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com