Sludge dewatering machine with stepped shaft

A sludge dewatering machine, step-shaped technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems that the equipment cannot achieve the expected treatment effect, the spiral blade and the ring are easy to wear, and the disassembly is inconvenient, etc., to reduce The effect of material cost, high yield and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

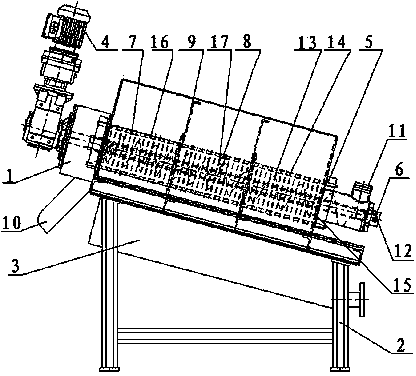

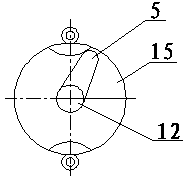

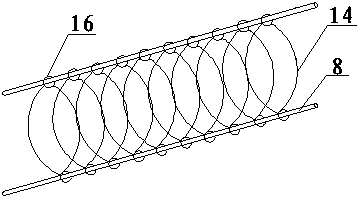

[0017] Such as figure 1 A sludge dewatering machine with a stepped shaft is shown, including a body 1, a bracket 2, and a liquid collection and return device 3. The body 1 is arranged parallel to the top of the support 2, and the liquid collection and return device 3 is provided below; The body 1 includes a cam driving device 5, a connecting shaft 14, a screw propeller 6, a fixed ring 7, a moving ring 8 and a support vertical plate 9, and mud outlets 10 and mud inlets 11 are respectively arranged at both ends, and the body 1 A number of support vertical plates 9 are evenly arranged on the top, and several fixed shafts are arranged between the support vertical plates 9. The fixed shafts are connected with the fixed ring 7, and the upper and lower ends of the support vertical plates 9 are provided with connecting shafts 14, which are connected to several The swimming ring 16 of the circular loose buckle and the cam driving device 5 and the cam driving baffle plate 15 at both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com