Patents

Literature

30results about How to "Solve serious wear and tear problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

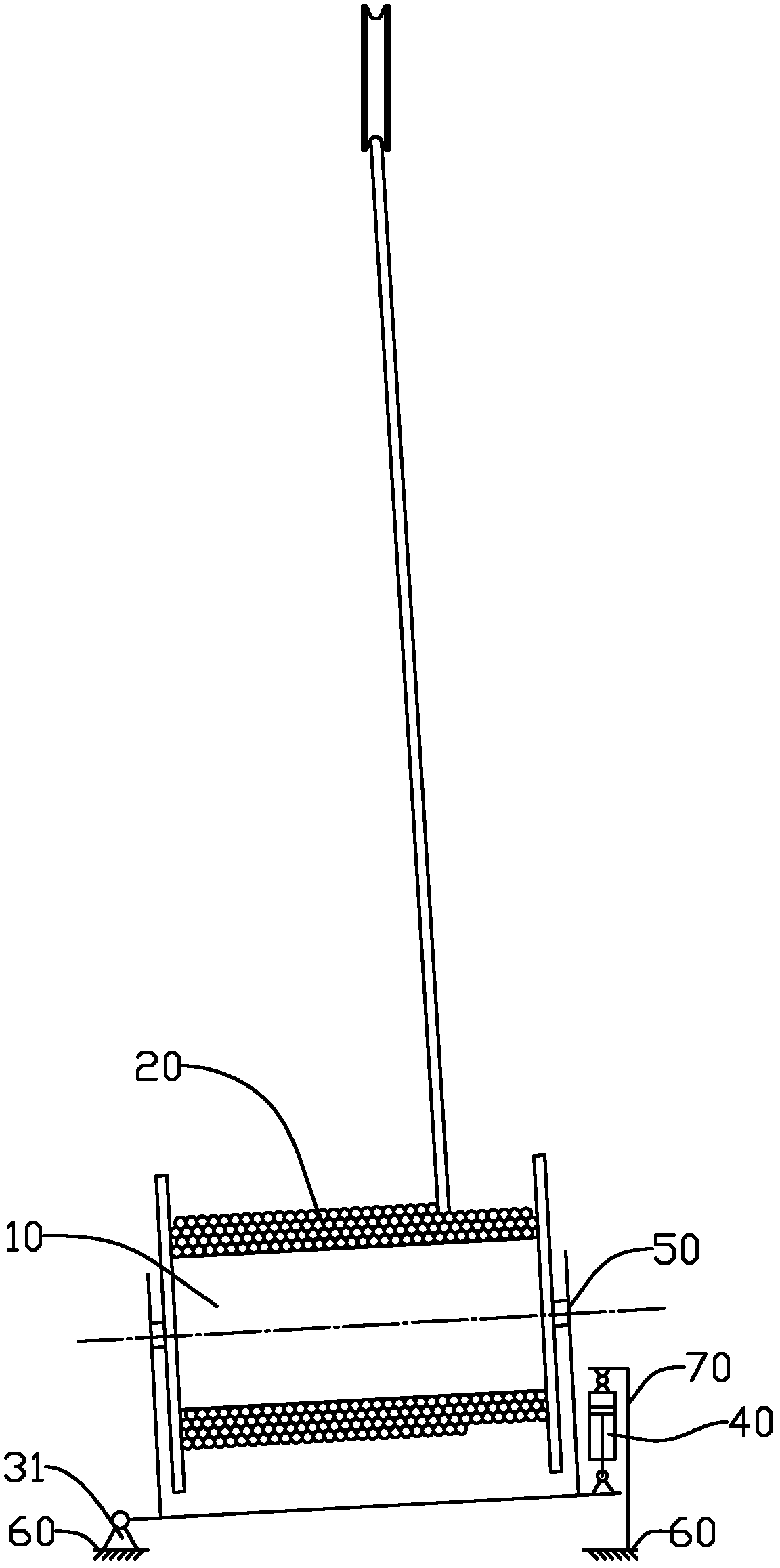

Multifunctional wave energy profile buoyage system

ActiveCN109572936AAnti-mis-trigger designSolve the problem of not being able to switch normallyWaterborne vesselsBuoysWear resistantEngineering

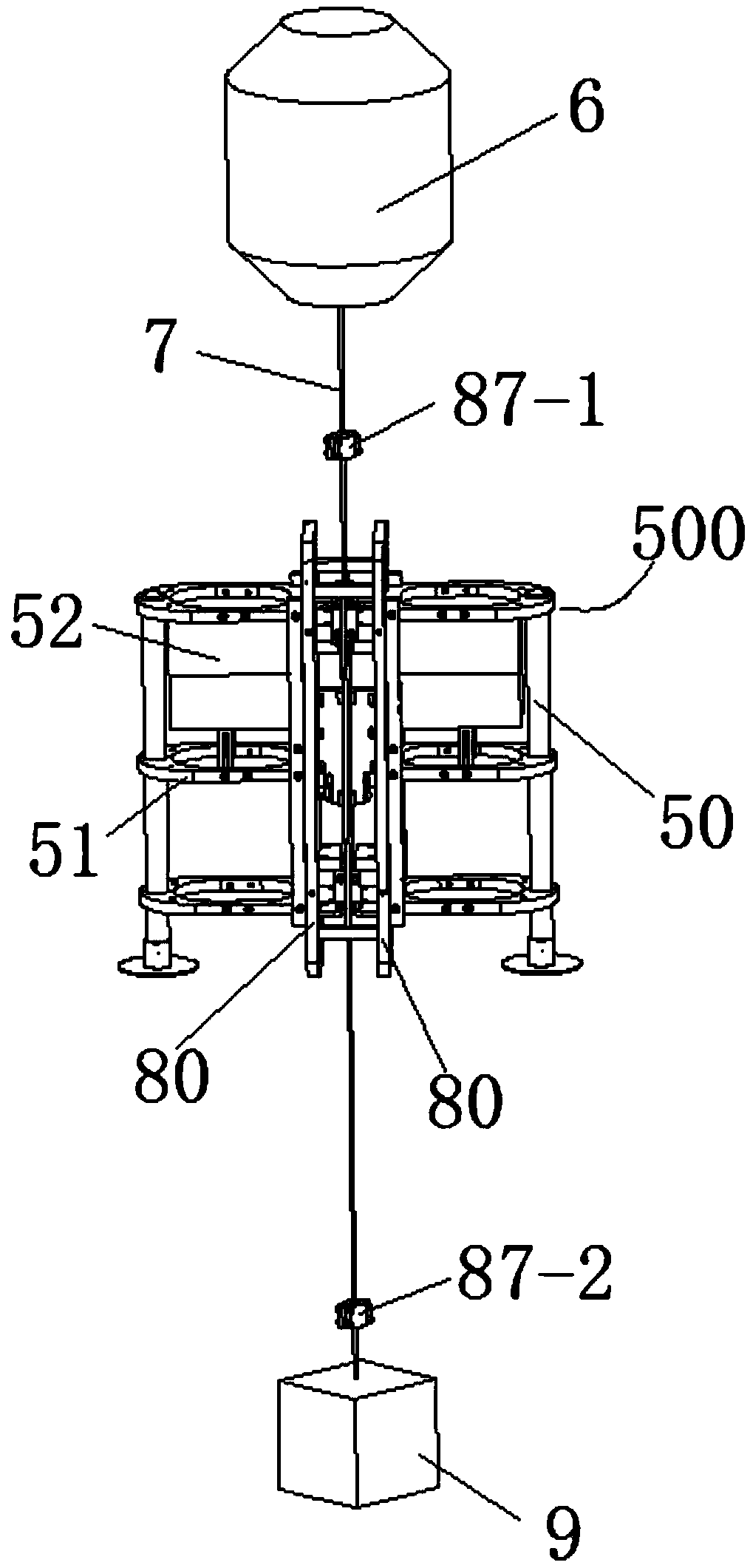

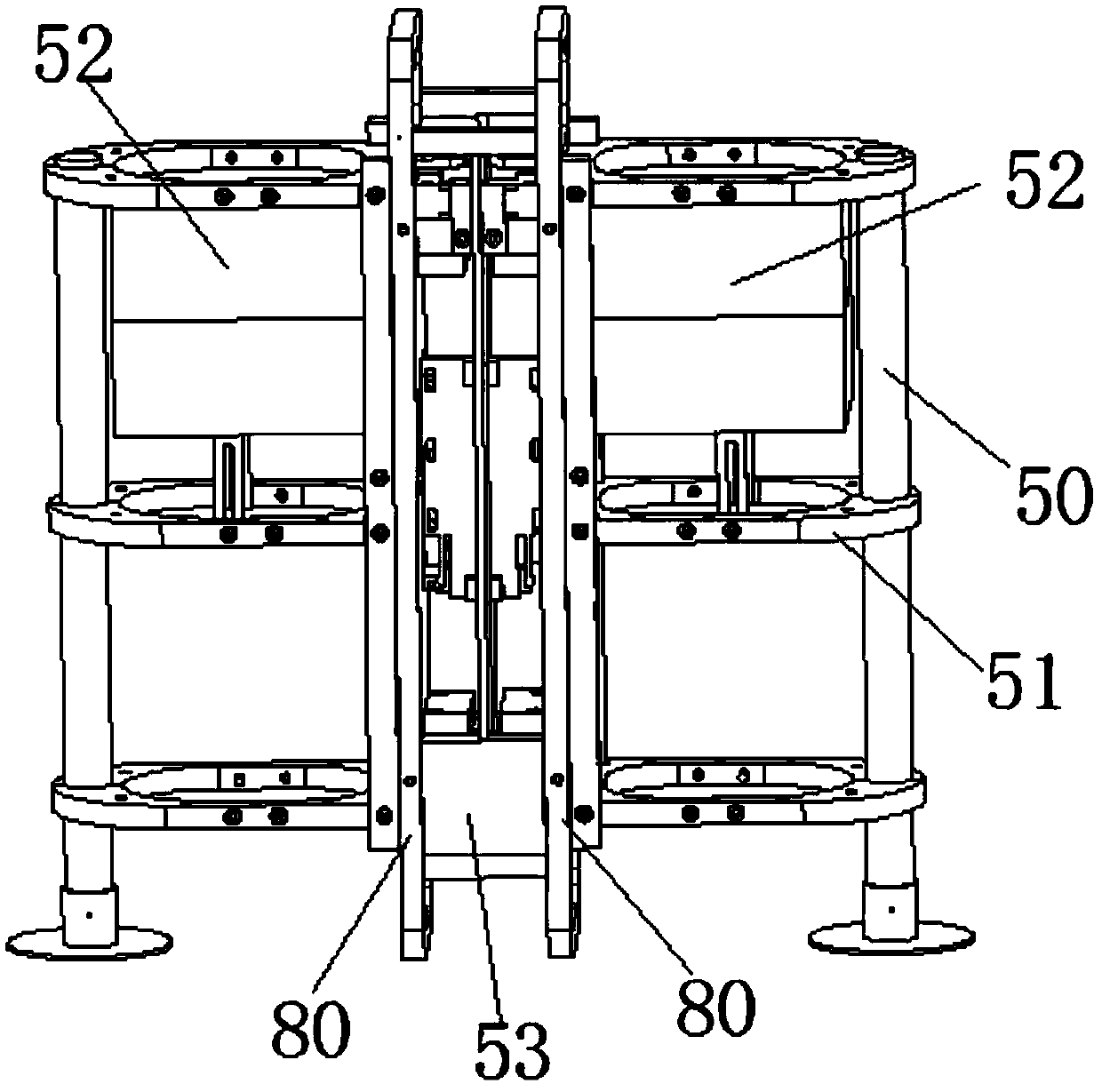

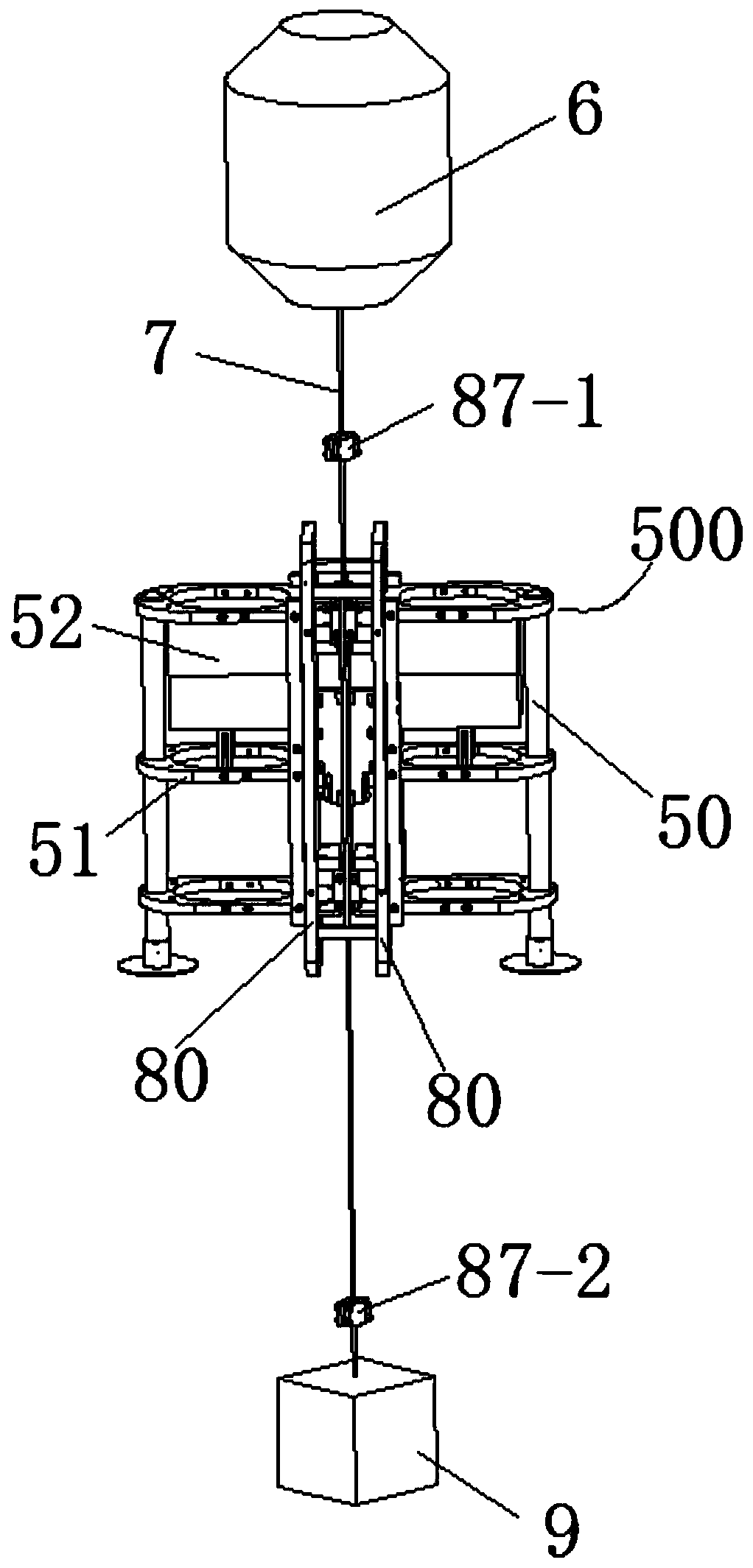

The invention relates to the field of ocean detection equipment, in particular to a multifunctional wave energy profile buoyage system. The multifunctional wave energy profile buoyage system comprisesa floating ball, a buoyage platform, a steel cable, an upper triggering block, a lower triggering block and an anchorage block; the buoyage platform comprises a supporting column, an isolation frame,a big floating block, a main supporting plate, a steel cable single-double way control unit, a lever unit and a concentric limiting unit. The multifunctional wave energy profile buoyage system has the advantages that the sensitivity is high; a false triggering prevention design and a wear resistant design are adopted; a switching plate can be pushed downwards / upwards under the driving of outsidepower so that the steel cable is in single / double-way working modes so as to realize a purpose that the whole profile buoyage platform can move on upper and lower profiles along the steel cable underthe action of the wave energy; under the action of waves, the multifunctional wave energy profile buoyage system can move up and down along the steel cable in a reciprocating manner and can carry different types of sensors to finish ocean three-dimensional profile parameter measurement; and the multifunctional wave energy profile buoyage system has the advantages that the launching / recovery is convenient, the carrying(loading) capacity is high, power supply is not consumed, and the multifunctional wave energy profile buoyage system can anchor and can also float.

Owner:OCEAN UNIV OF CHINA

Buoy system applied to field observation of three-dimensional cross-sectional structure of ocean vortex

InactiveCN109878638AAnti-mis-trigger designMulti-parameter synchronizationWaterborne vesselsBuoysSurface oceanEngineering

The invention relates to the field of ocean monitoring equipment, in particular to a buoy system applied to the field observation of a three-dimensional cross-sectional structure of an ocean vortex. The system comprises a water sail, a wave energy buoy platform, a floating ball, a steel cable and an anchor block, the water sail is composed of four sail boards, the four sail boards are fixedly connected to the outer frame of the wave energy buoy platform in a cross shape, the floating ball is connected to the top end of the steel cable, the anchor block is connected to the bottom end of the steel cable, and the steel cable passes through the wave energy buoy platform which is crawled along the steel cable. The system can flow with the ocean vortex to achieve long-term continuous, adaptive-tracking, multi-parameter-synchronization and ultra-high space-time recognizing observation of the ocean vortex, especially a sub-middle-scale vortex three-dimensional section structure.

Owner:OCEAN UNIV OF CHINA

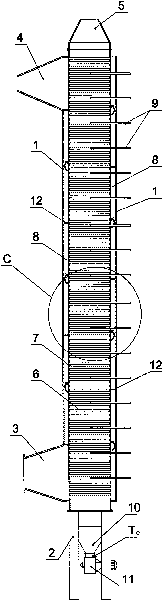

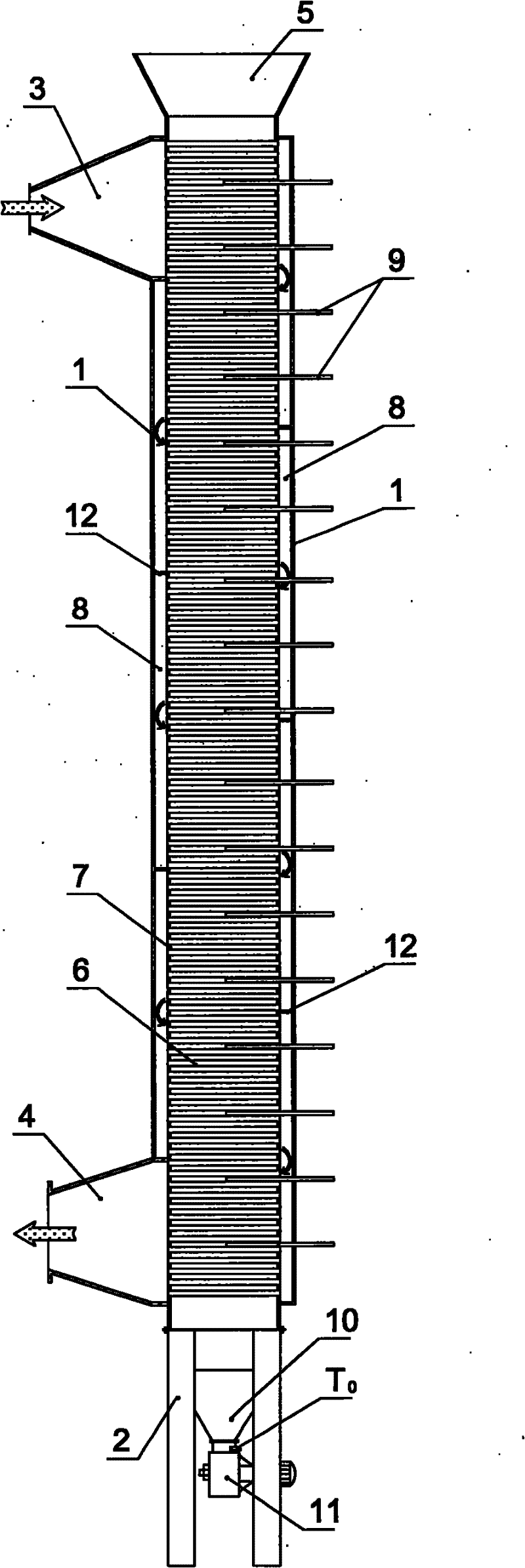

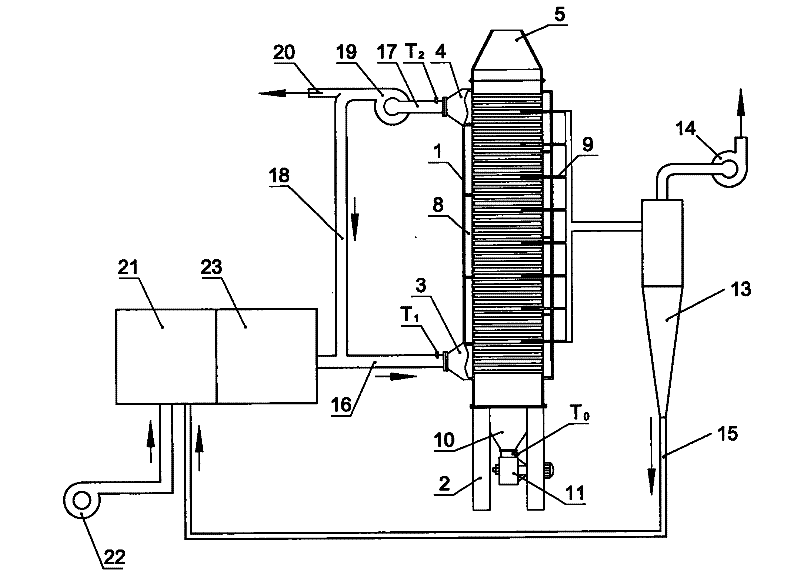

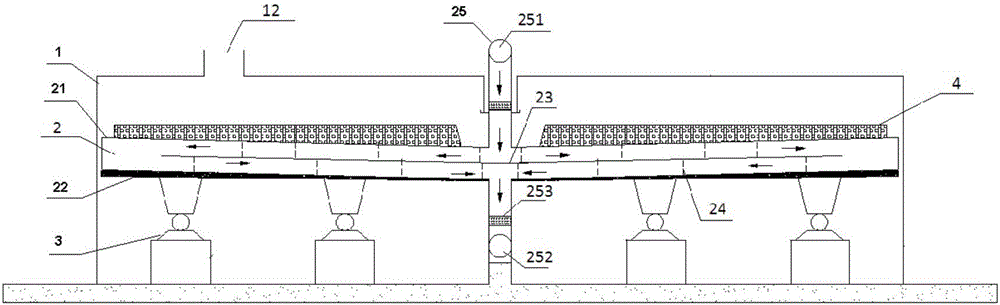

Coal anaerobic drying device and drying system

InactiveCN101762145ALong-distance transportSolve fire problemsDrying solid materials with heatSolid fuelsSurface moistureTemperature control

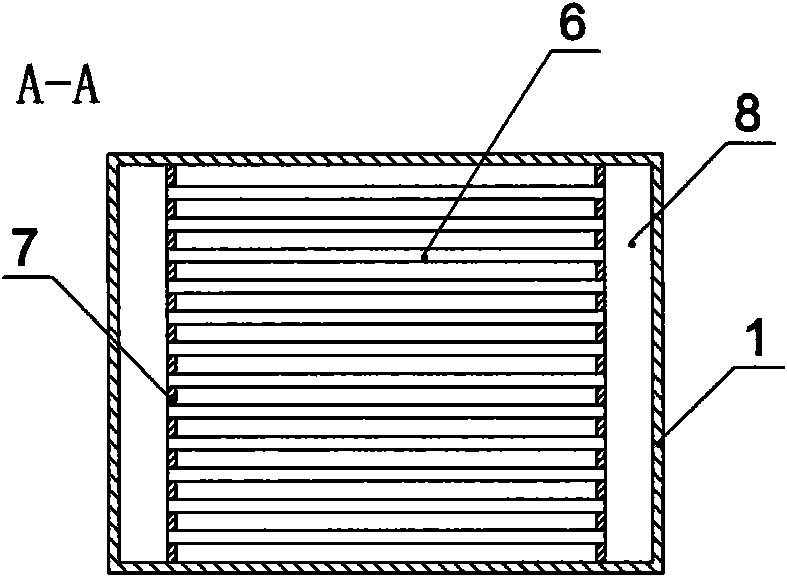

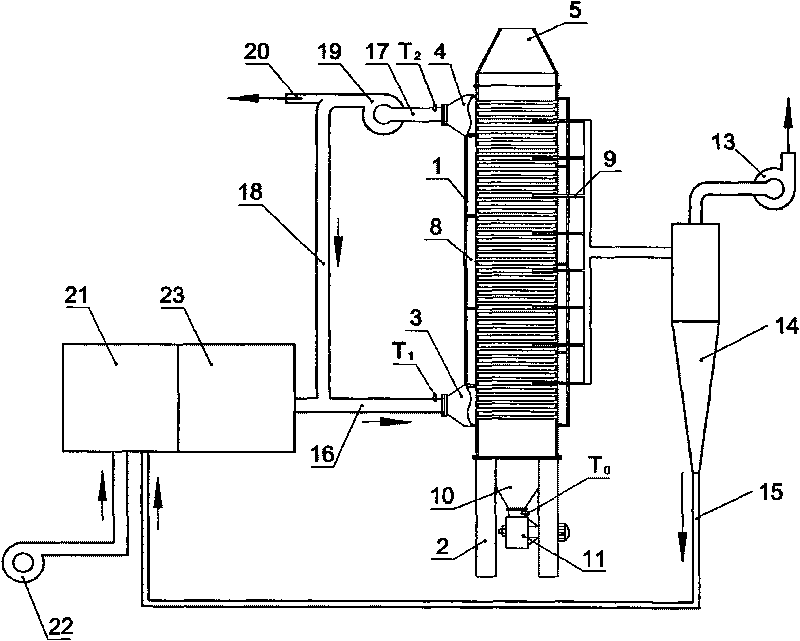

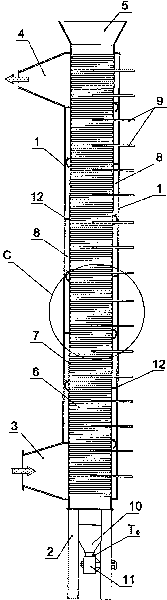

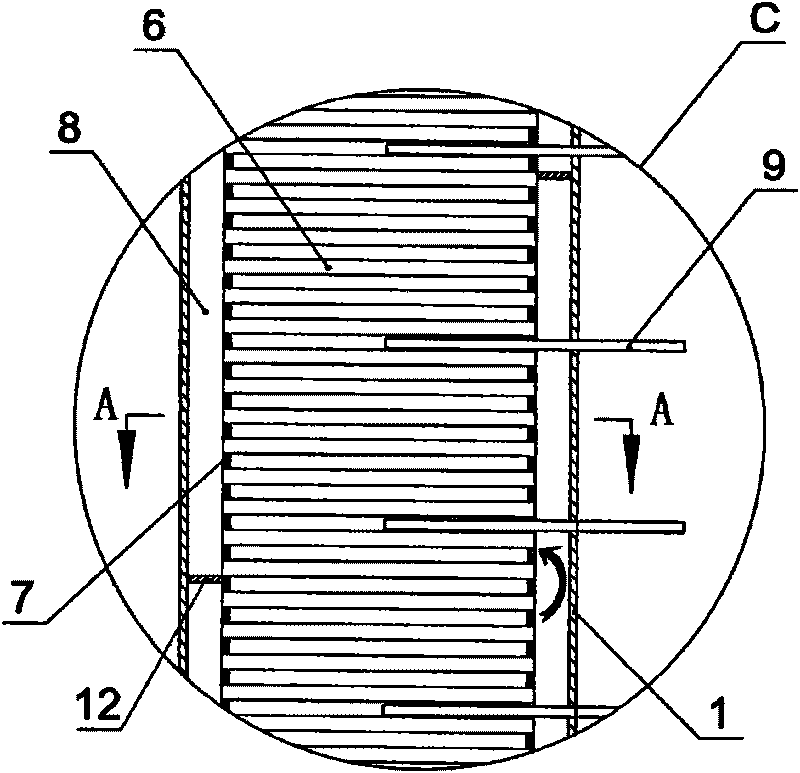

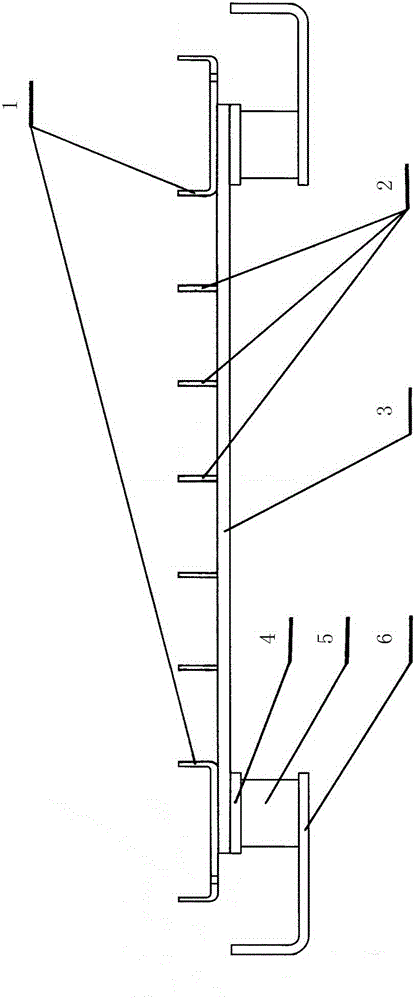

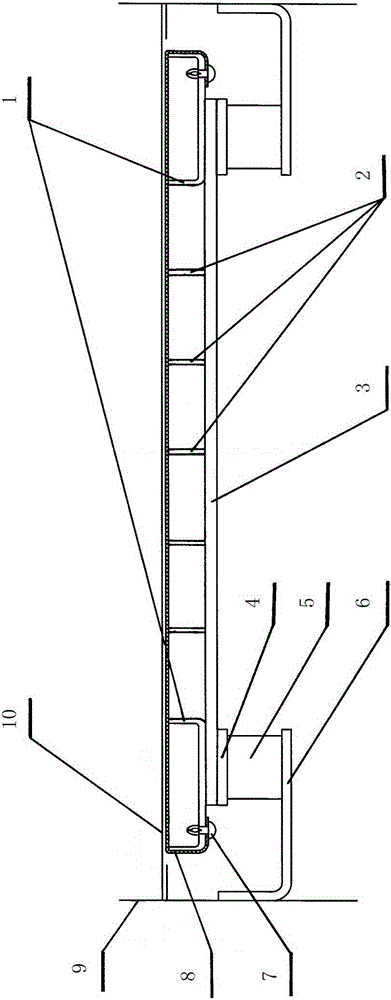

The invention relates to a coal anaerobic drying device and a drying system. The device comprises a vertical drying cylinder, a coal inlet, a coal outlet, an air inlet pipe and an air outlet pipe, wherein hot air cavities are respectively arranged outside two lateral walls of the drying cylinder; a certain number of array pipes or array plates are communicated between the two hot air cavities so as to ensure that coal in the drying cylinder and hot air in the hot air cavities and hot air in the array pipes or array plates are completely isolated; a steam pipe arranged inside the drying cylinder is extracted outside the drying device; the coal anaerobic drying system comprises the coal anaerobic drying device and a heating system, wherein a thermometer T1 and a thermometer T2 are arranged at the air inlet pipe port and the air outlet pipe port respectively; a discharge valve and a thermometer T0 are arranged at the discharge port. By controlling the temperature, the device and the system are applicable to both the drying of common coal and coal slime and the drying and upgrading of brown coal, not only can extract surface moisture of the brown coal, but also can remove partial bound water, transforms the brown coal from soft coal to hard coal, transforms the brown coal from hydrophily to hydrophobicity, are convenient for transportation, storage and use, and are favorable to popularization and implementation.

Owner:郑州拉姆顿清洁能源工程技术有限公司

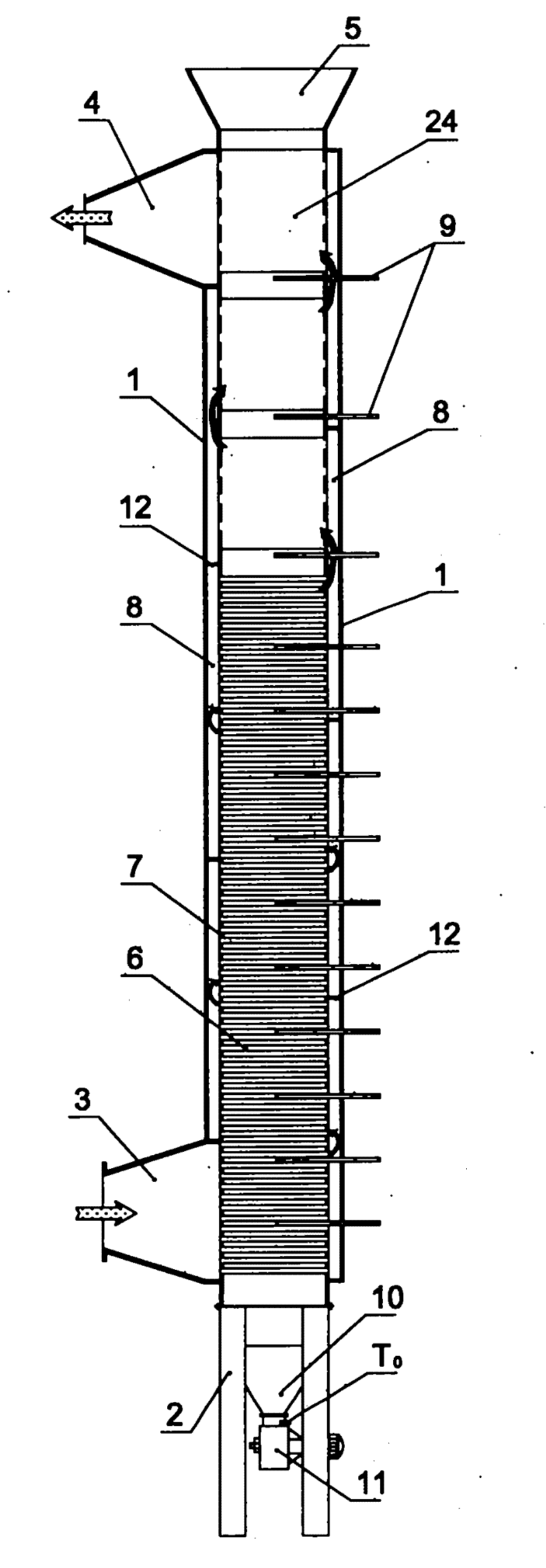

Oxygen-free surface water drying system and surface water drying technology for material

InactiveCN101706197ASolve fire problemsSolve the explosionDrying solid materials with heatHearth type furnacesSludgeEngineering

The invention relates to an oxygen-free surface water drying system and a surface water drying technology for material, wherein the oxygen-free surface water drying system comprises a drying device and a heating system; the drying device comprises a vertical drying cylinder and a coal inlet, a coal outlet, an air inlet pipe and an air outlet pipe which are arranged at the upper end and the lower end of the vertical drying cylinder; the outer sides of two side walls of the drying cylinder are respectively provided with a hot-gas cavity; a certain number of rack pipes or rack plates are communicated between the two hot-gas cavities to lead the coal in the drying cylinder to be completely separated from the hot gas in the hot-gas cavities and the rack pipes or the rack plates; the orifices of the air inlet pipe and the air outlet pipe are respectively provided with a thermograph T1 and a thermograph T2, a discharge hole is provided with a thermograph T0, a steam tube is arranged in the drying cylinder and led out of a drying device, drying is conducted at normal atmosphere, and the temperature of T1, T2 and T0 is controlled to remove the surface water of the material. The invention completely solves the problem of firing and explosion caused by combustible gas precipitation, is not only applicable to oxygen-free surface water drying of coal, but also applicable to the drying of chemical products, industrial and municipal sludge, metallic and nonmetallic minerals, coal slime and the like.

Owner:郑州拉姆顿清洁能源工程技术有限公司

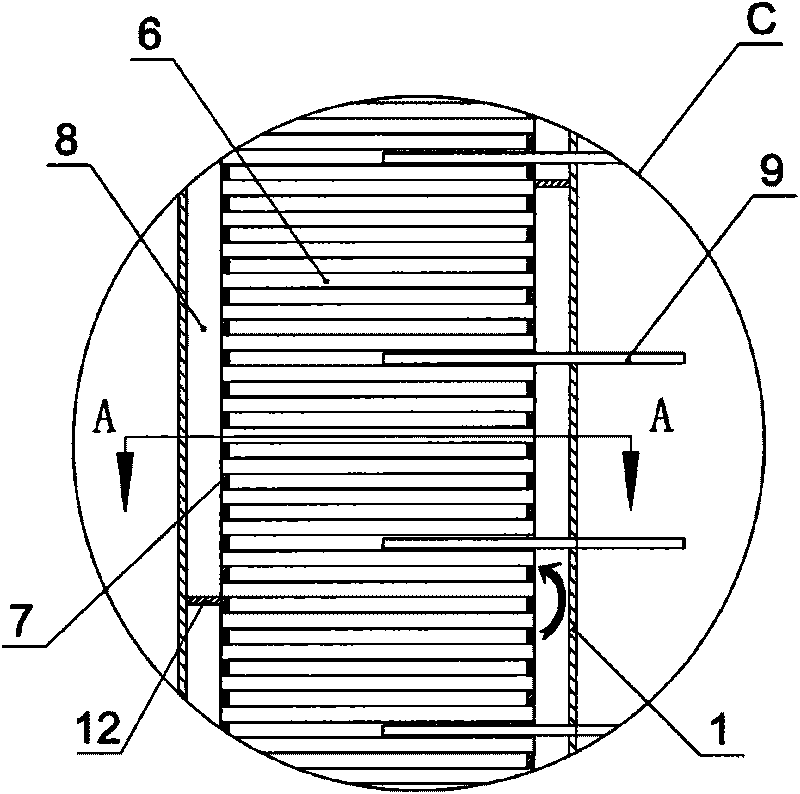

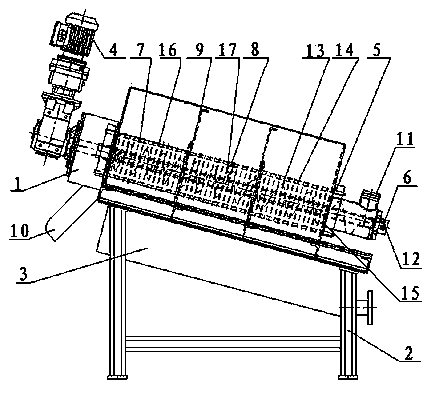

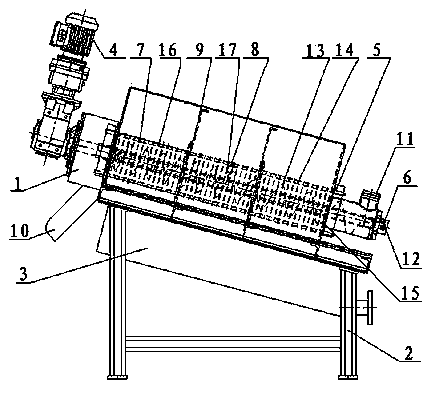

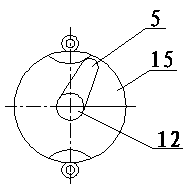

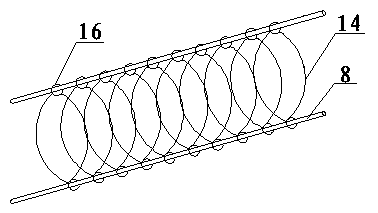

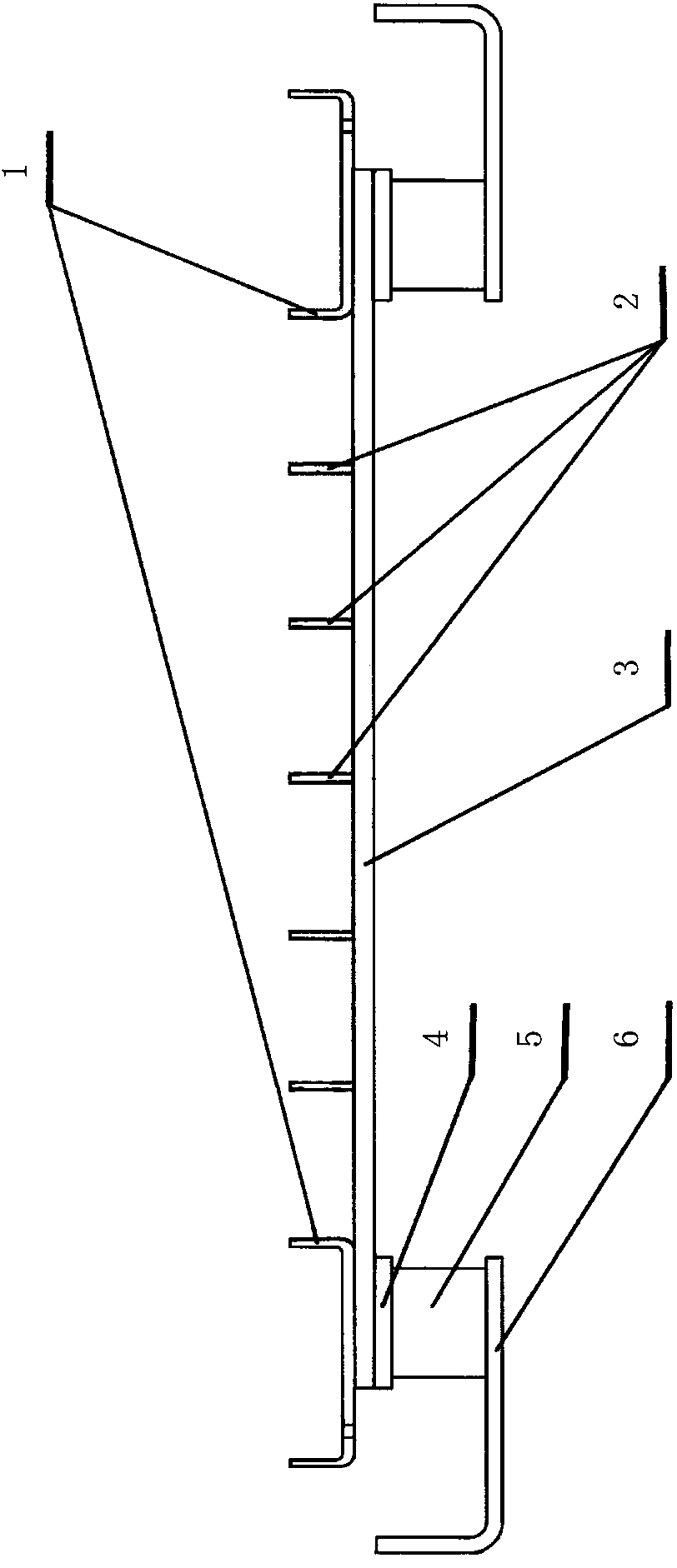

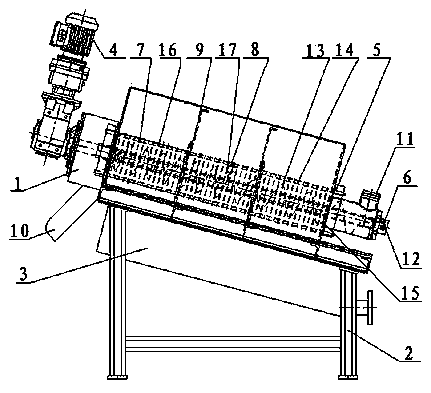

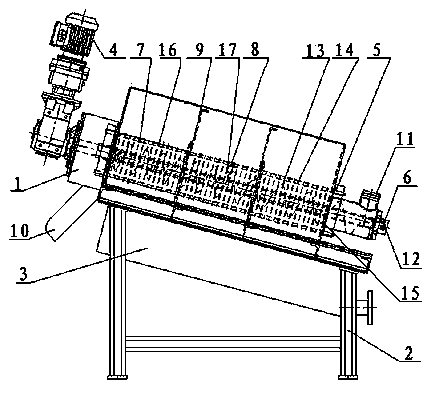

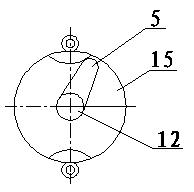

Sludge dewatering machine capable of lowering sludge water content

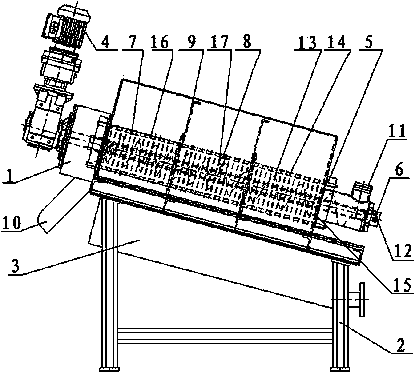

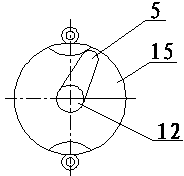

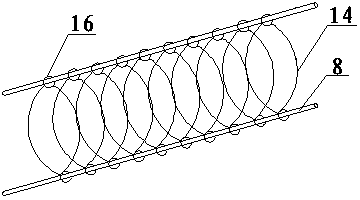

InactiveCN103663902AReduce moisture contentSimple and efficient operationSludge treatment by de-watering/drying/thickeningPropellerWater content

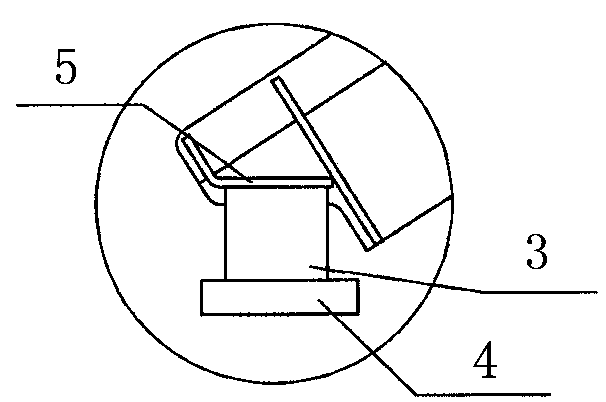

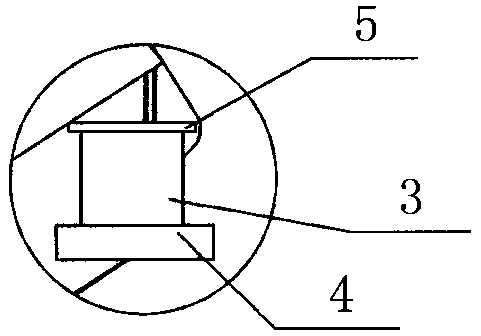

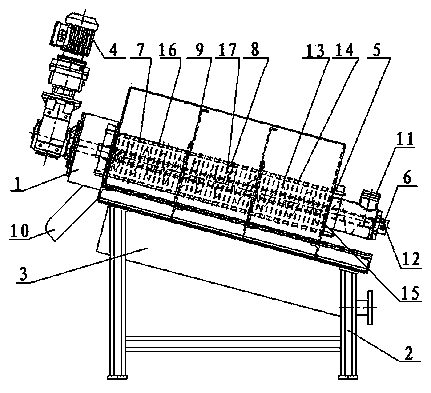

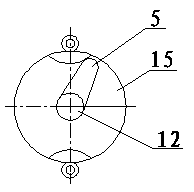

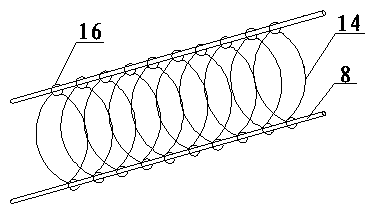

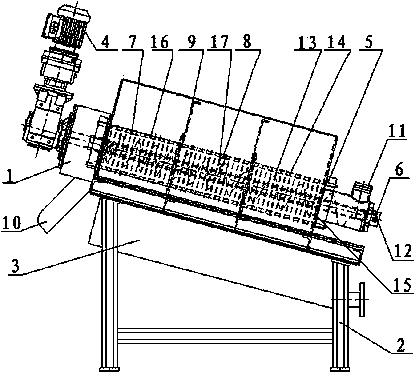

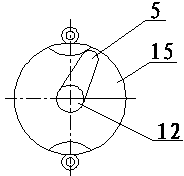

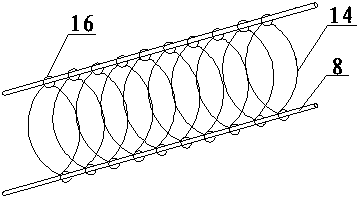

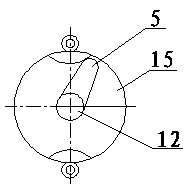

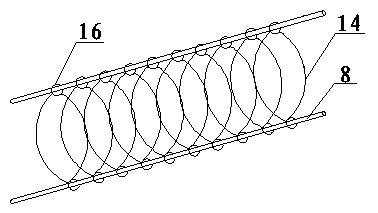

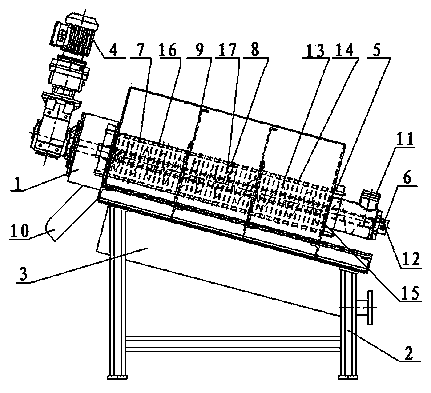

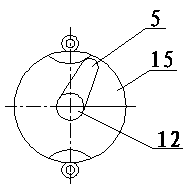

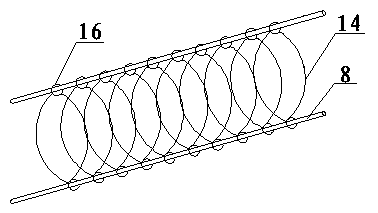

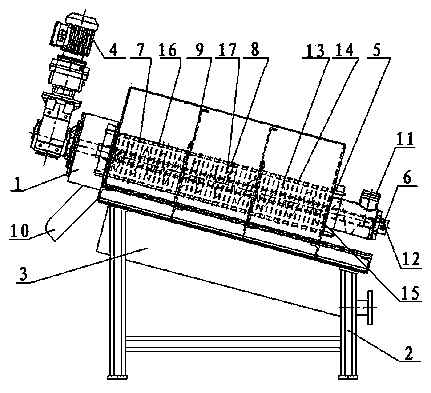

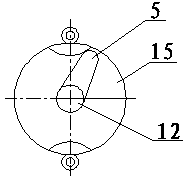

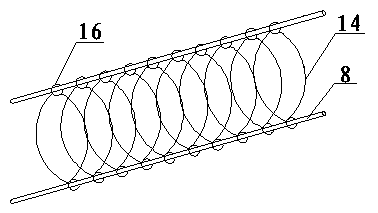

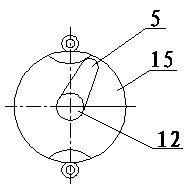

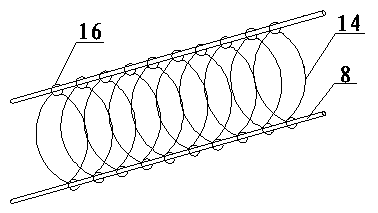

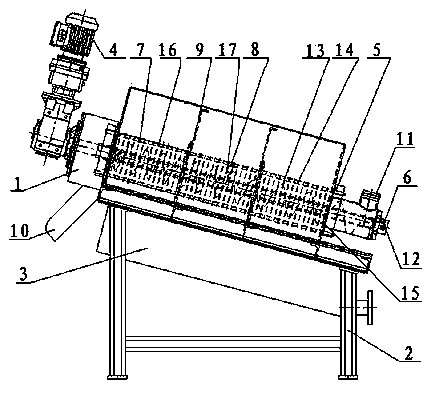

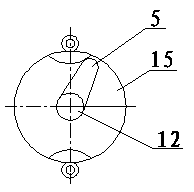

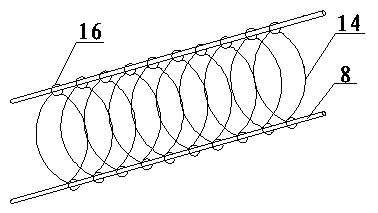

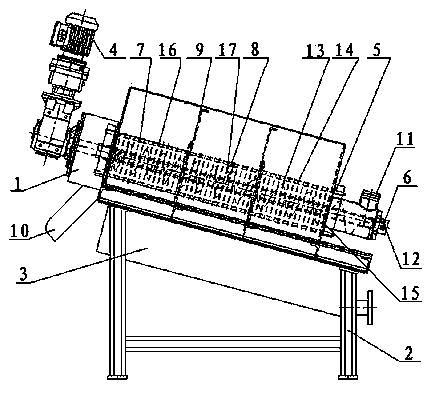

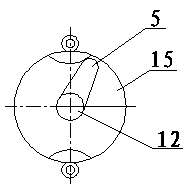

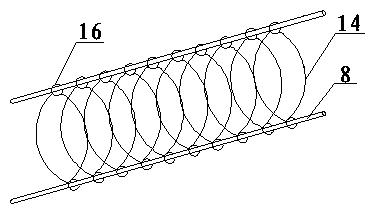

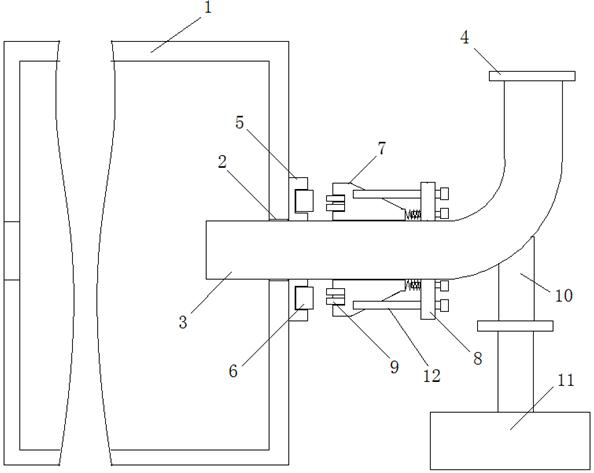

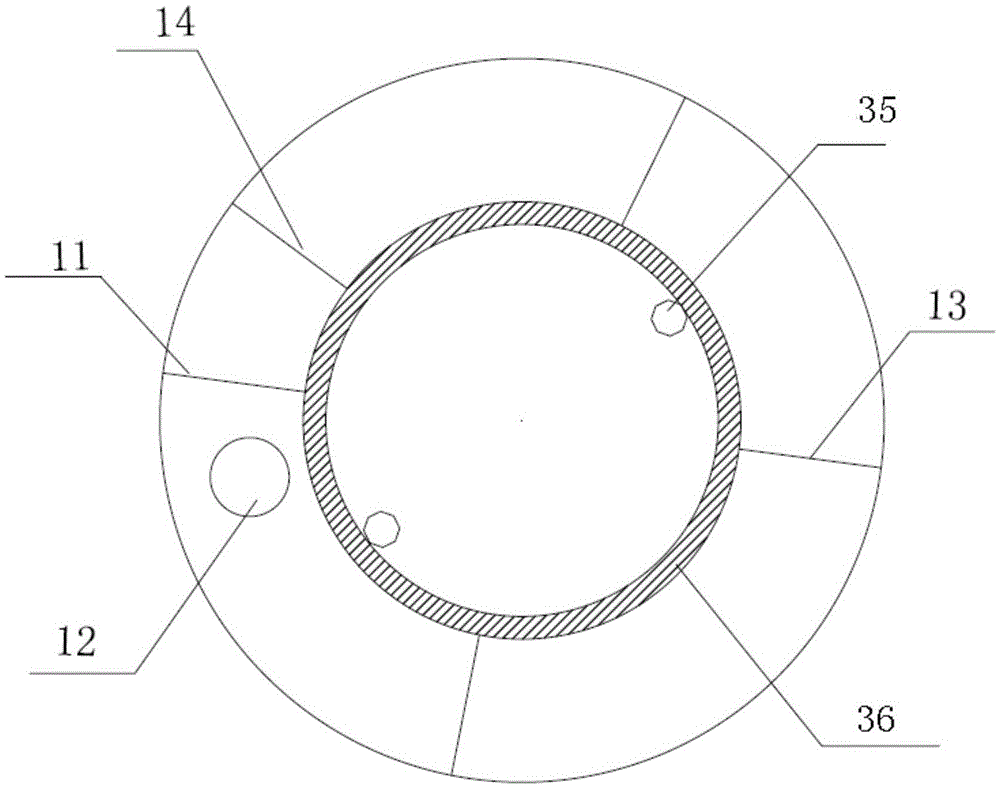

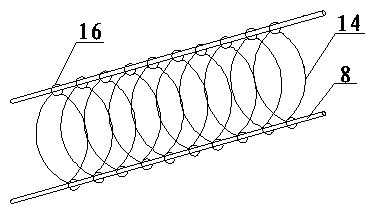

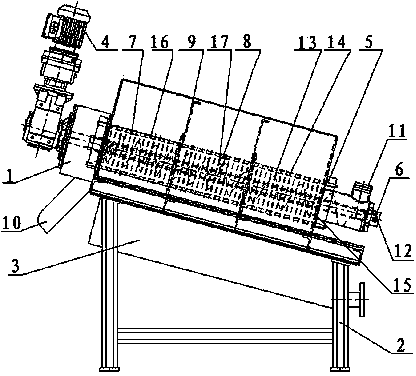

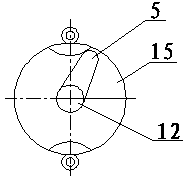

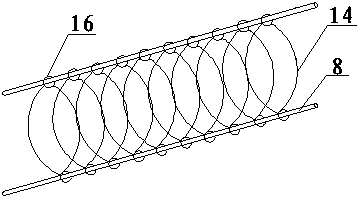

The invention relates to a sludge dewatering machine, particularly a sludge dewatering machine capable of lowering sludge water content, which comprises a machine body (1), a bracket (2) and a liquid collection reflux unit (3). The sludge dewatering machine is characterized in that the machine body (1) is arranged above the bracket (2) in parallel, and the liquid collection reflux unit (3) is arranged below the bracket (2); the machine body (1) comprises a cam driving gear (5), a connecting shaft (14), a screw propeller (6), fixed rings (7), floating rings (8) and support vertical plates (9); both ends of the machine body (1) are respectively provided with a sludge outlet (10) and a sludge inlet (11); the machine body (1) is uniformly provided with the plurality of support vertical plates (9); a plurality of fixed shafts are arranged between every two support vertical plates (9); each fixed shaft is connected with the corresponding fixed ring (7); the upper and lower ends of each support vertical plate (9) are provided with the connecting shaft (14) which is used for connecting and fixing the floating rings (8) with circular slipknots (16) to the cam driving gear (5) and a cam driving baffle (15) on both ends; the distance between every two floating rings (8) is the thickness of one fixed ring (7); and one end of a screw shaft (12) is arranged in the screw propeller (6), and the other end is connected with a motor (4) through the cavities of the fixed rings (7) and floating rings (8). Compared with the prior art, the sludge dewatering machine has the advantage of no wear, reduces the water content, is simple to operate and easy to replace, and lowers the cost.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Improved resonant type vibrating screen

Disclosed is an improved resonant type vibrating screen. Auxiliary springs are added below a screen box combination articulated beam and supports a screen box combination together with an original shear spring, so that work load of the shear spring is greatly reduced, and the problem of overwork fracture during usage of the shear spring is solved; a complex excitation system consisting of excitation ranks, an excitation rank connection frame and four resonant springs arranged at four corners of the lower portion of the excitation rank connection frame is used, and a spring transmission excitation force which is parallel to a screen machine vibration direction is used, so that the problem of serious abrasion of the resonant type spring is solved; the excitation ranks and the excitation rank connection frame of the complex excitation system are combined to arrange and tension a support net, so that the structure is simplified, vibration mass of the screen box combination is reduced, workload of the spring bearing the screen box combination is reduced, and meanwhile, fault hidden danger brought by fixed bolt looseness caused by vibration during usage is fundamentally eliminated; the improved resonant type vibrating screen is skillful in design, low in failure rate and maintenance charge, and reliable in work.

Owner:TANGSHAN LANDSKY TECH

Novel stacked sludge dewatering machine

InactiveCN103663901AReduce moisture contentSimple and efficient operationSludge treatment by de-watering/drying/thickeningWater contentPropeller

The invention relates to a sludge dewatering machine, particularly a novel stacked sludge dewatering machine which comprises a machine body (1), a bracket (2) and a liquid collection reflux unit (3). The sludge dewatering machine is characterized in that the machine body (1) is arranged above the bracket (2) in parallel, and the liquid collection reflux unit (3) is arranged below the bracket (2); the machine body (1) comprises a cam driving gear (5), a connecting shaft (14), a screw propeller (6), fixed rings (7), floating rings (8) and support vertical plates (9); both ends of the machine body (1) are respectively provided with a sludge outlet (10) and a sludge inlet (11); the machine body (1) is uniformly provided with the plurality of support vertical plates (9); a plurality of fixed shafts are arranged between every two support vertical plates (9); each fixed shaft is connected with the corresponding fixed ring (7); the upper and lower ends of each support vertical plate (9) are provided with the connecting shaft (14) which is used for connecting and fixing the floating rings (8) with circular slipknots (16) to the cam driving gear (5) and a cam driving baffle (15) on both ends; the distance between every two floating rings (8) is the thickness of one fixed ring (7); and one end of a screw shaft (12) is arranged in the screw propeller (6), and the other end is connected with a motor (4) through the cavities of the fixed rings (7) and floating rings (8). Compared with the prior art, the sludge dewatering machine has the advantage of no wear, reduces the water content, is simple to operate and easy to replace, and lowers the cost.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Sludge dewatering machine

InactiveCN103663903AAvoid direct contactSolve serious wear and tear problemsSludge treatment by de-watering/drying/thickeningRefluxPropeller

The invention relates to a sludge dewatering machine which comprises a machine body (1), a bracket (2) and a liquid collection reflux unit (3). The sludge dewatering machine is characterized in that the machine body (1) is arranged above the bracket (2) in parallel, and the liquid collection reflux unit (3) is arranged below the bracket (2); the machine body (1) comprises a cam driving gear (5), a connecting shaft (14), a screw propeller (6), fixed rings (7), floating rings (8) and support vertical plates (9); both ends of the machine body (1) are respectively provided with a sludge outlet (10) and a sludge inlet (11); and the machine body (1) is uniformly provided with the plurality of support vertical plates (9). Compared with the prior art, the sludge dewatering machine has the advantage of no wear, reduces the water content, is simple to operate and easy to replace, and lowers the cost.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

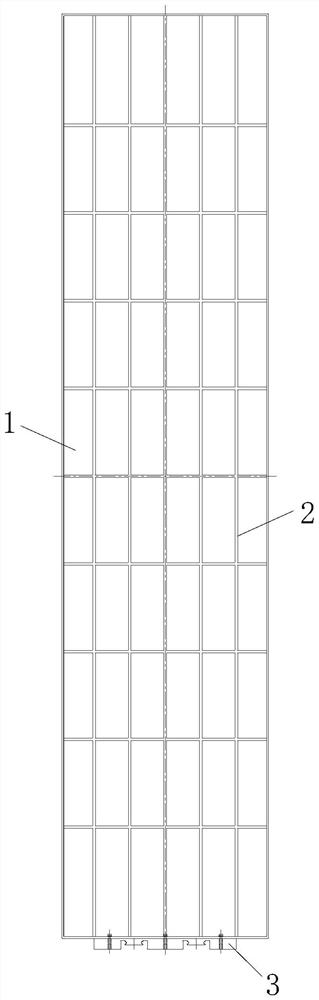

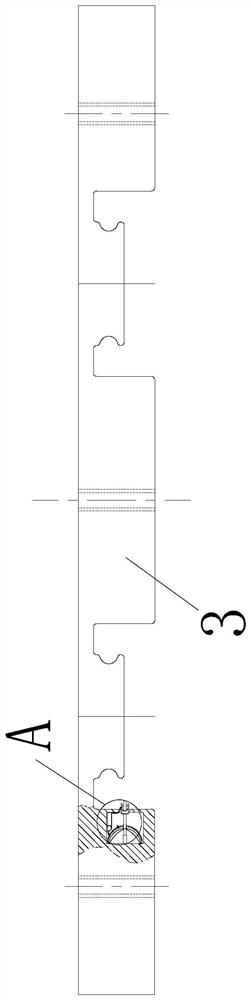

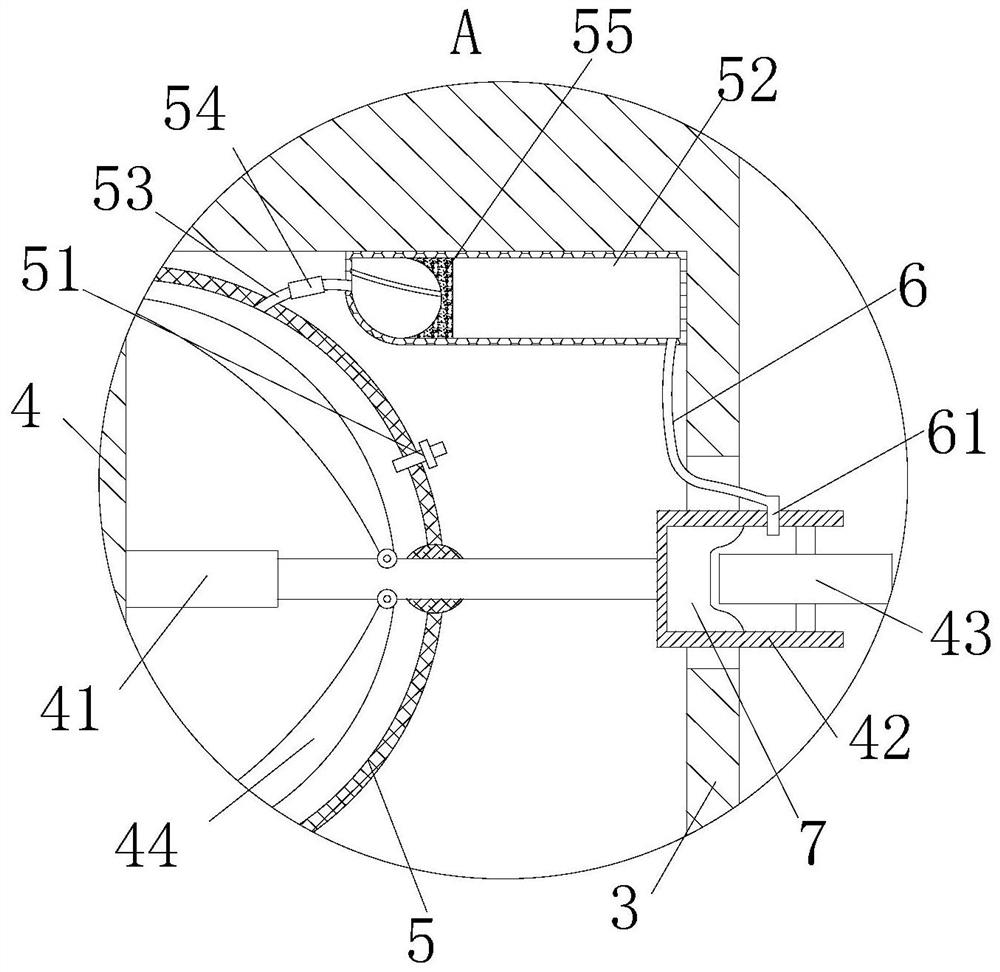

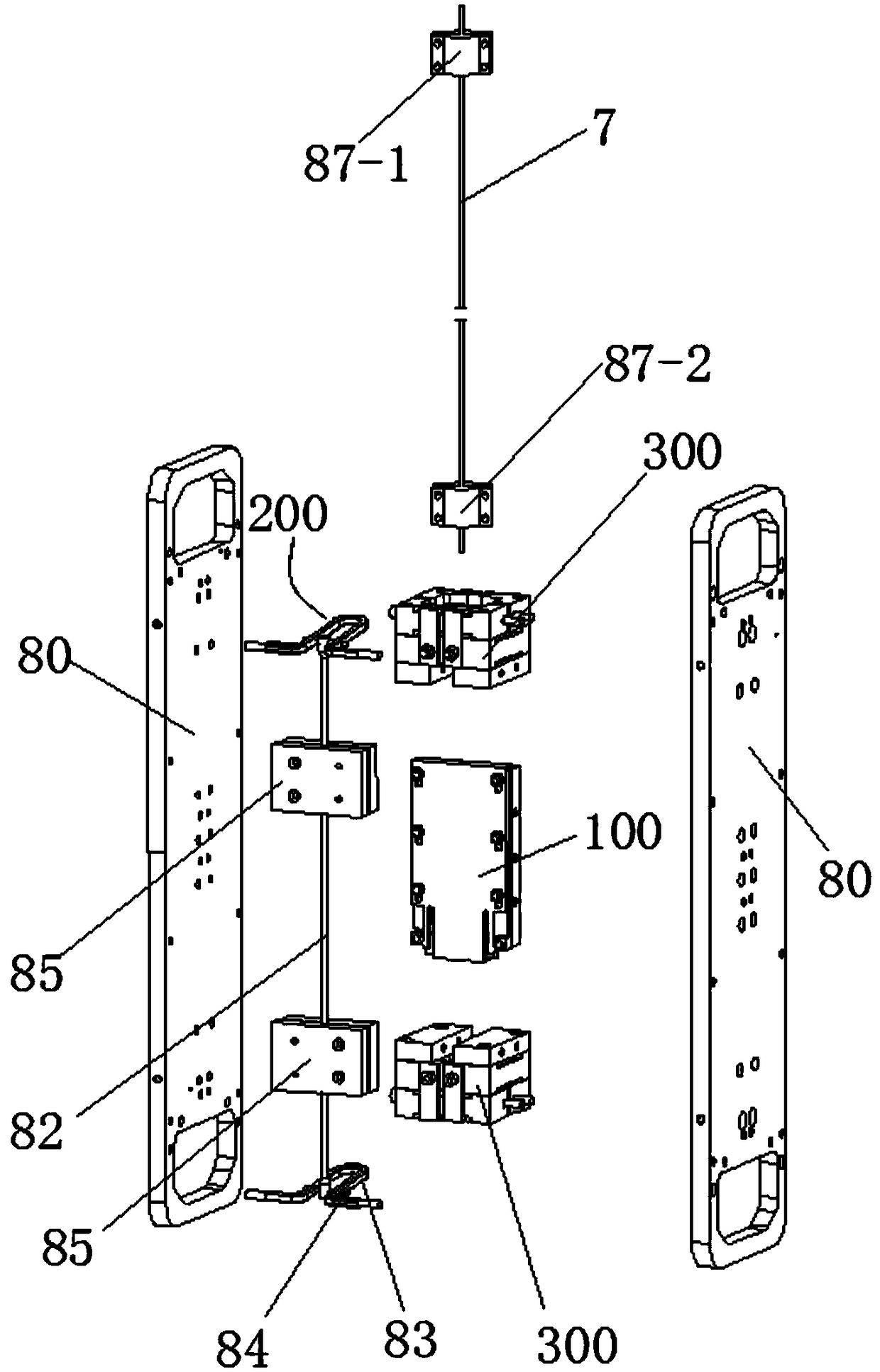

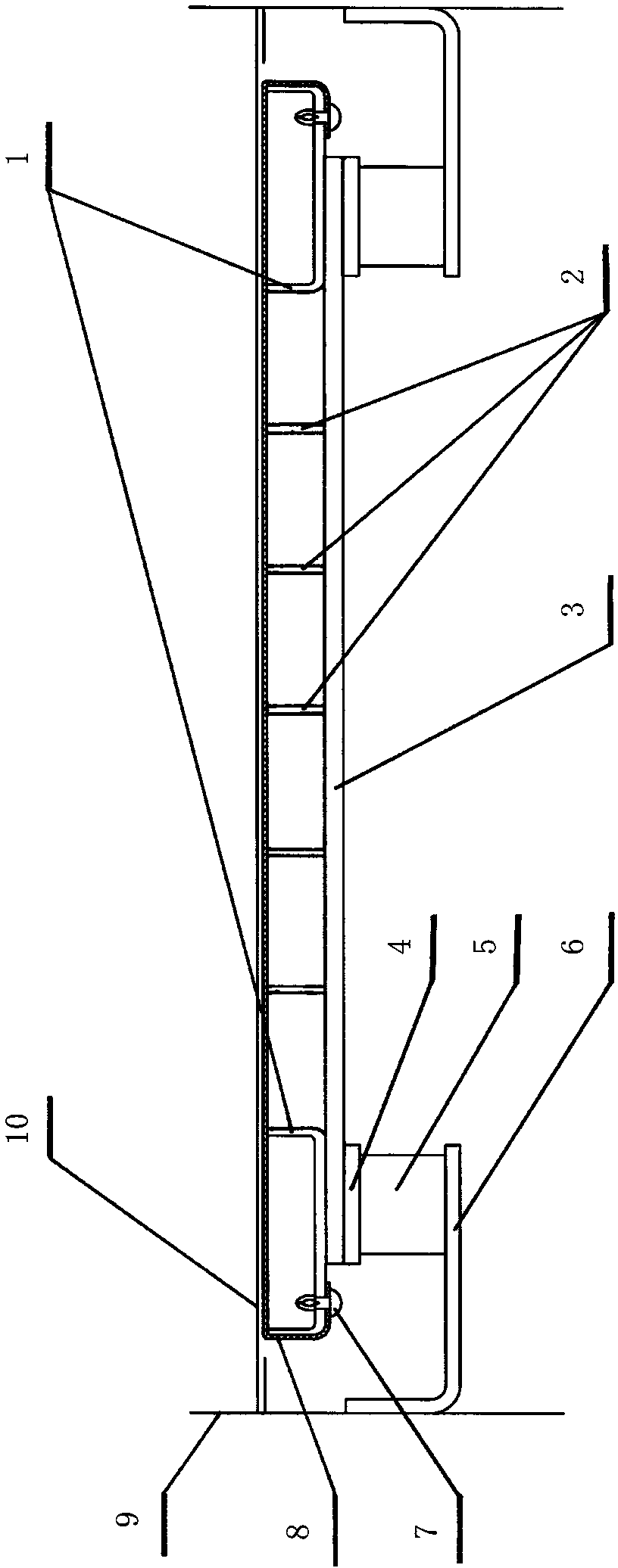

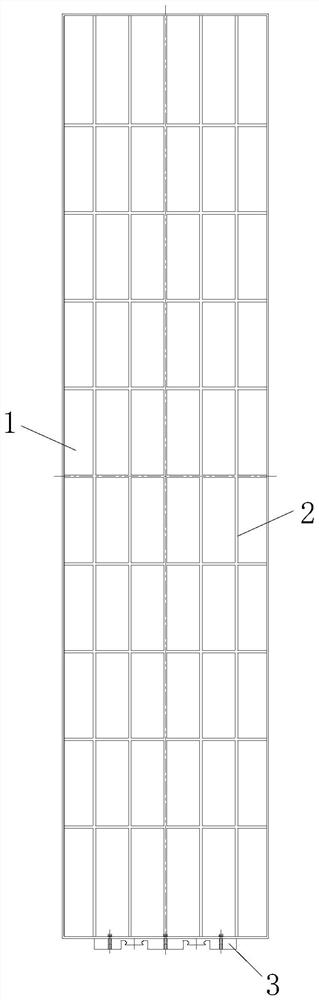

Novel elevator landing door plate assembly

PendingCN112850440AGood corrosion resistance such as acid, alkali and saltGood environmental aging resistanceElevatorsBuilding liftsCorrosive substanceAerospace engineering

The invention belongs to the technical field of elevator equipment, and particularly relates to a novel elevator landing door plate assembly which comprises a landing door plate assembly body. The landing door plate assembly body comprises a landing door plate, reinforcing ribs and guide shoe plates. The multiple sets of reinforcing ribs are fixedly connected to the landing door plate. The reinforcing ribs are arranged on the landing door plate in a latticed manner. The multiple sets of guide shoe plates are fixedly connected to the bottom of the landing door plate. By using a non-metal high polymer material, an anti-rust coating does not need to be additionally sprayed after the landing door plate assembly body is formed, and the material has very good corrosion resistance such as acid, alkali and salt resistance and meanwhile has very good environmental aging resistance; the surface color of the landing door plate assembly body can be changed by mixing colors of the material; and various colors can be mixed according to the requirements of customers, and selectable diversity is achieved.

Owner:陈觉

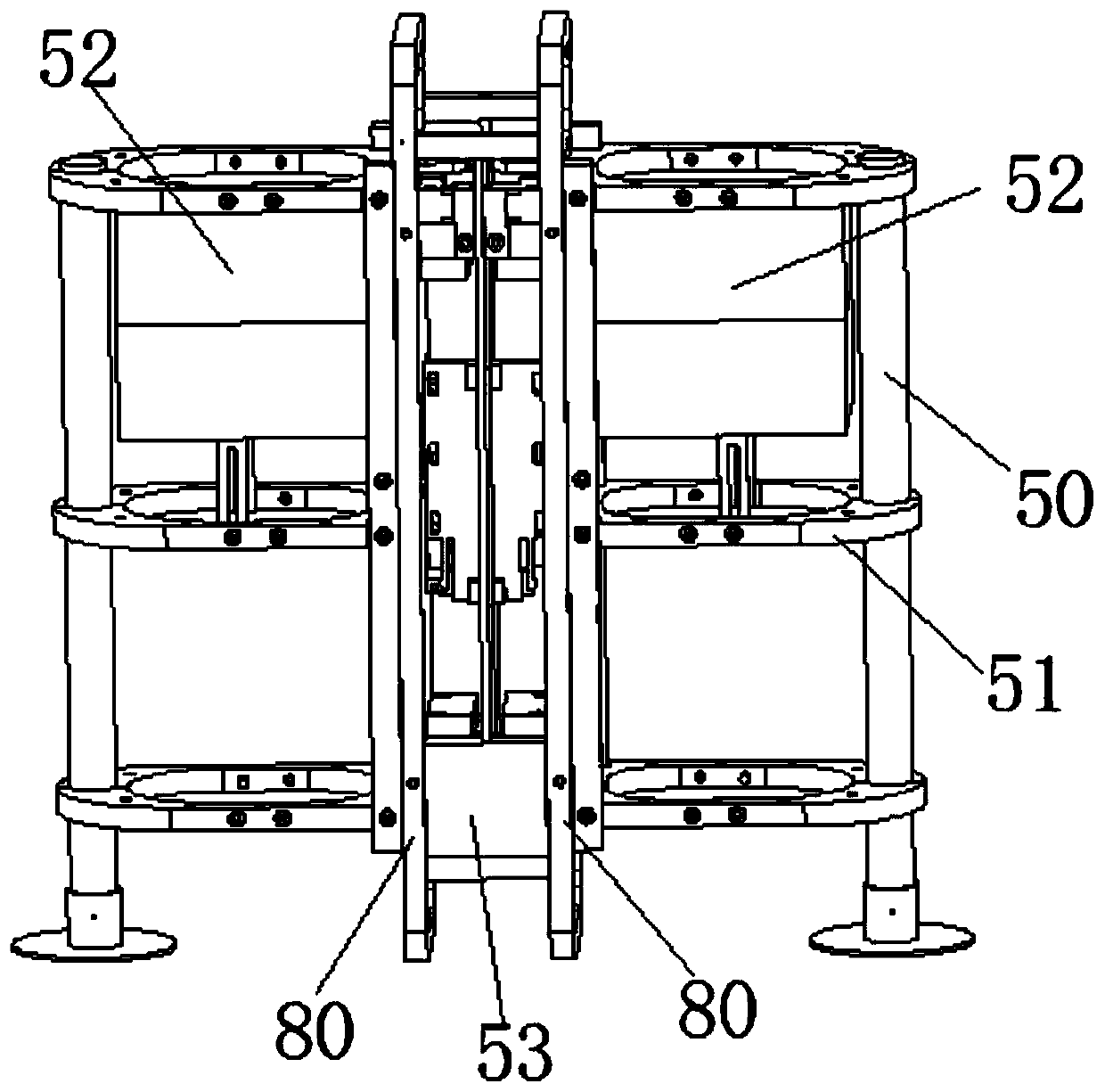

Novel sludge dewatering machine

InactiveCN103663900AAvoid direct contactSolve serious wear and tear problemsSludge treatment by de-watering/drying/thickeningPropellerPulp and paper industry

The invention relates to a sludge dewatering machine, particularly a novel sludge dewatering machine which comprises a machine body (1), a bracket (2) and a liquid collection reflux unit (3). The sludge dewatering machine is characterized in that the machine body (1) is arranged above the bracket (2) in parallel, and the liquid collection reflux unit (3) is arranged below the bracket (2); the machine body (1) comprises a cam driving gear (5), a connecting shaft (14), a screw propeller (6), fixed rings (7), floating rings (8) and support vertical plates (9); both ends of the machine body (1) are respectively provided with a sludge outlet (10) and a sludge inlet (11); the machine body (1) is uniformly provided with the plurality of support vertical plates (9); a plurality of fixed shafts are arranged between every two support vertical plates (9); each fixed shaft is connected with the corresponding fixed ring (7); the upper and lower ends of each support vertical plate (9) are provided with the connecting shaft (14) which is used for connecting and fixing the floating rings (8) with circular slipknots (16) to the cam driving gear (5) and a cam driving baffle (15) on both ends; the distance between every two floating rings (8) is the thickness of one fixed ring (7); and one end of a screw shaft (12) is arranged in the screw propeller (6), and the other end is connected with a motor (4) through the cavities of the fixed rings (7) and floating rings (8). Compared with the prior art, the sludge dewatering machine has the advantage of no wear, reduces the water content, is simple to operate and easy to replace, and lowers the cost.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Energy-saving consumption-reduction sludge dewatering machine

InactiveCN103663914AReduce moisture contentSimple and efficient operationSludge treatment by de-watering/drying/thickeningPropellerWater content

The invention relates to a sludge dewatering machine, particularly an energy-saving consumption-reduction sludge dewatering machine which comprises a machine body (1), a bracket (2) and a liquid collection reflux unit (3). The sludge dewatering machine is characterized in that the machine body (1) is arranged above the bracket (2) in parallel, and the liquid collection reflux unit (3) is arranged below the bracket (2); the machine body (1) comprises a cam driving gear (5), a connecting shaft (14), a screw propeller (6), fixed rings (7), floating rings (8) and support vertical plates (9); both ends of the machine body (1) are respectively provided with a sludge outlet (10) and a sludge inlet (11); and the machine body (1) is uniformly provided with the plurality of support vertical plates (9). Compared with the prior art, the sludge dewatering machine has the advantage of no wear, reduces the water content, is simple to operate and easy to replace, and lowers the cost.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

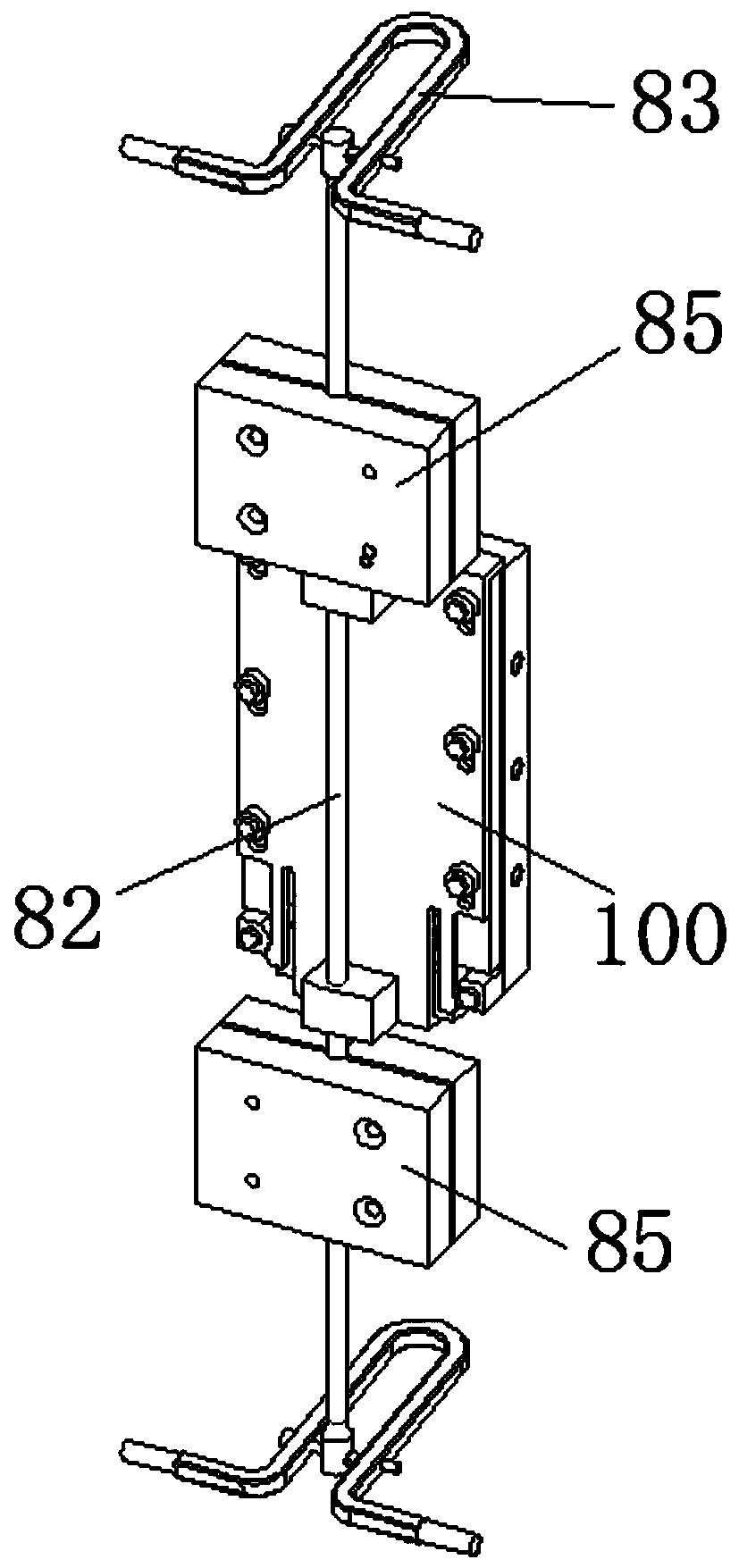

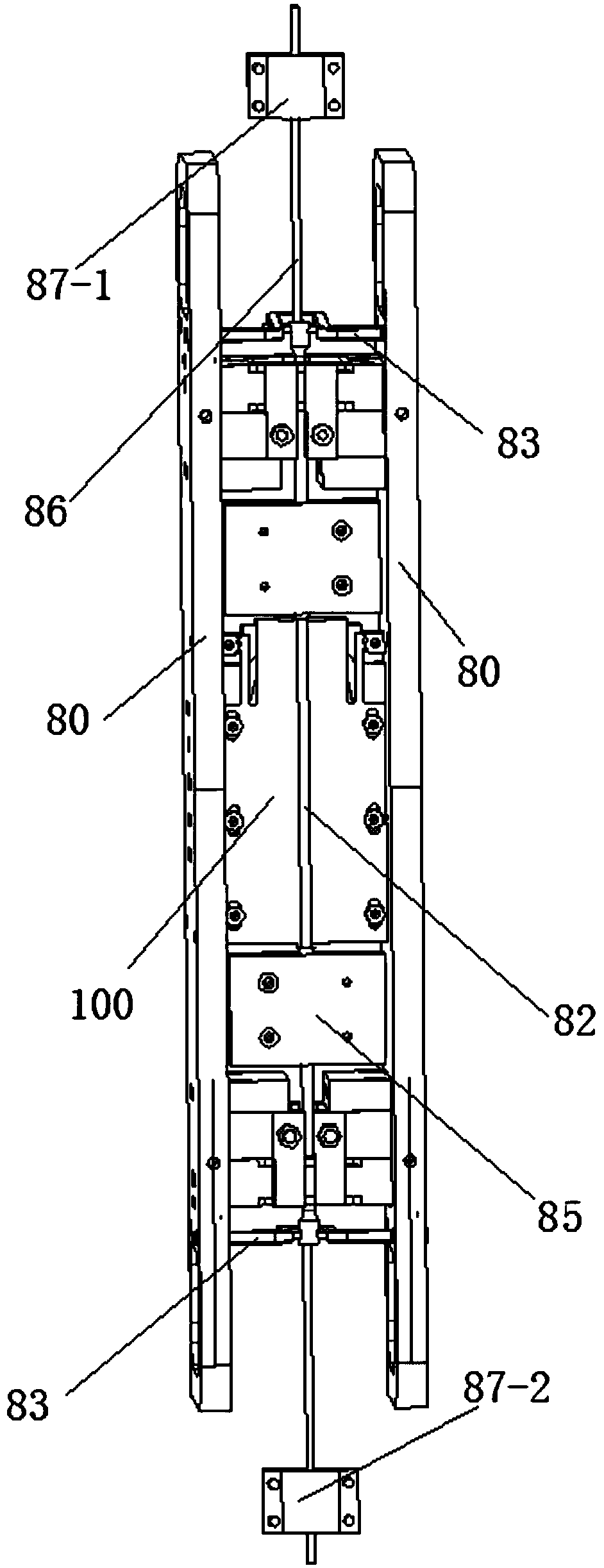

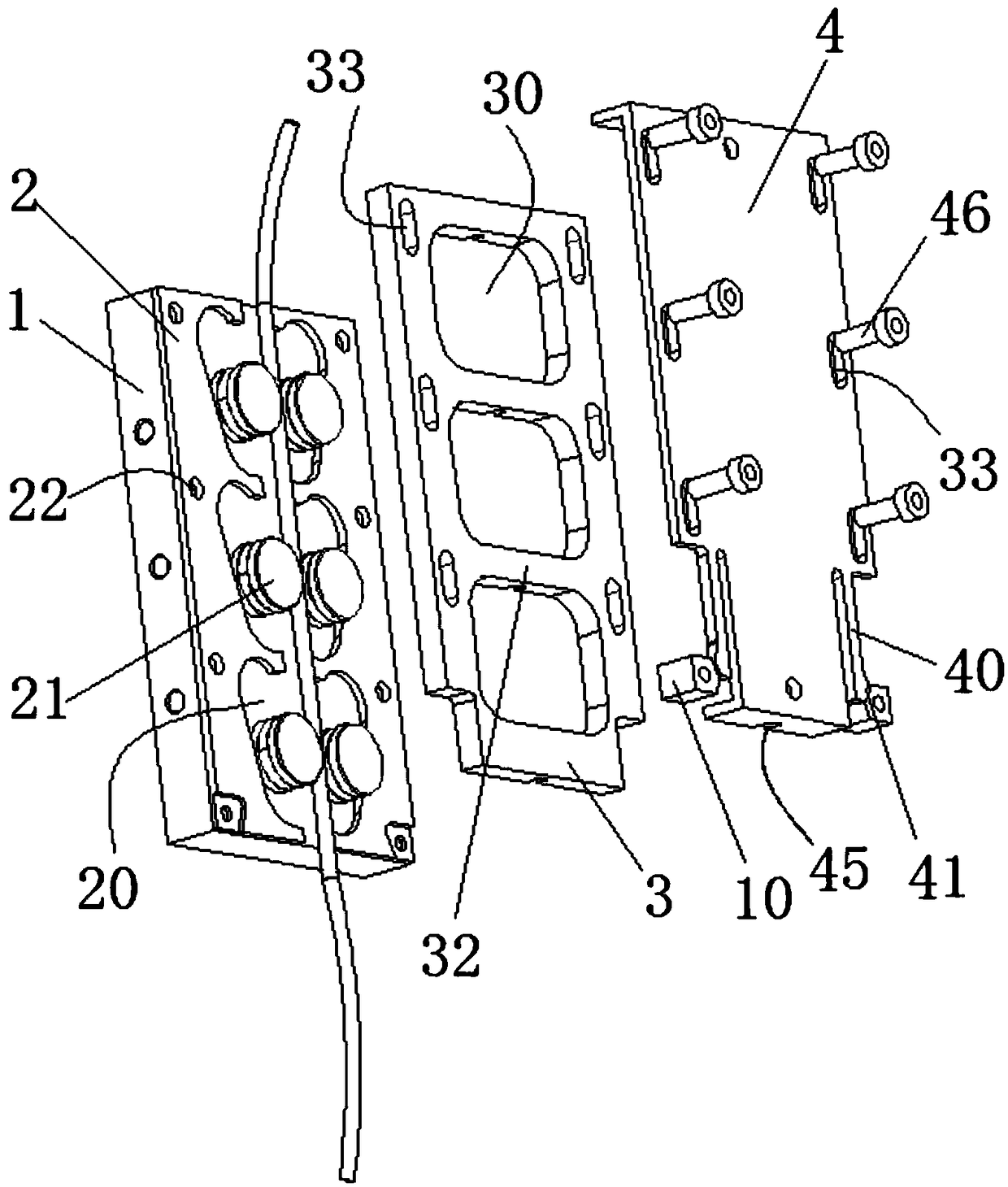

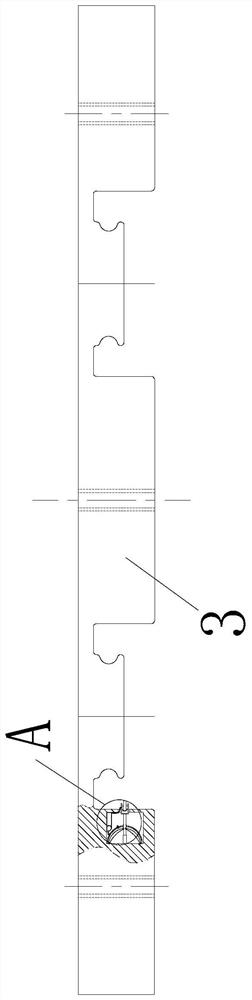

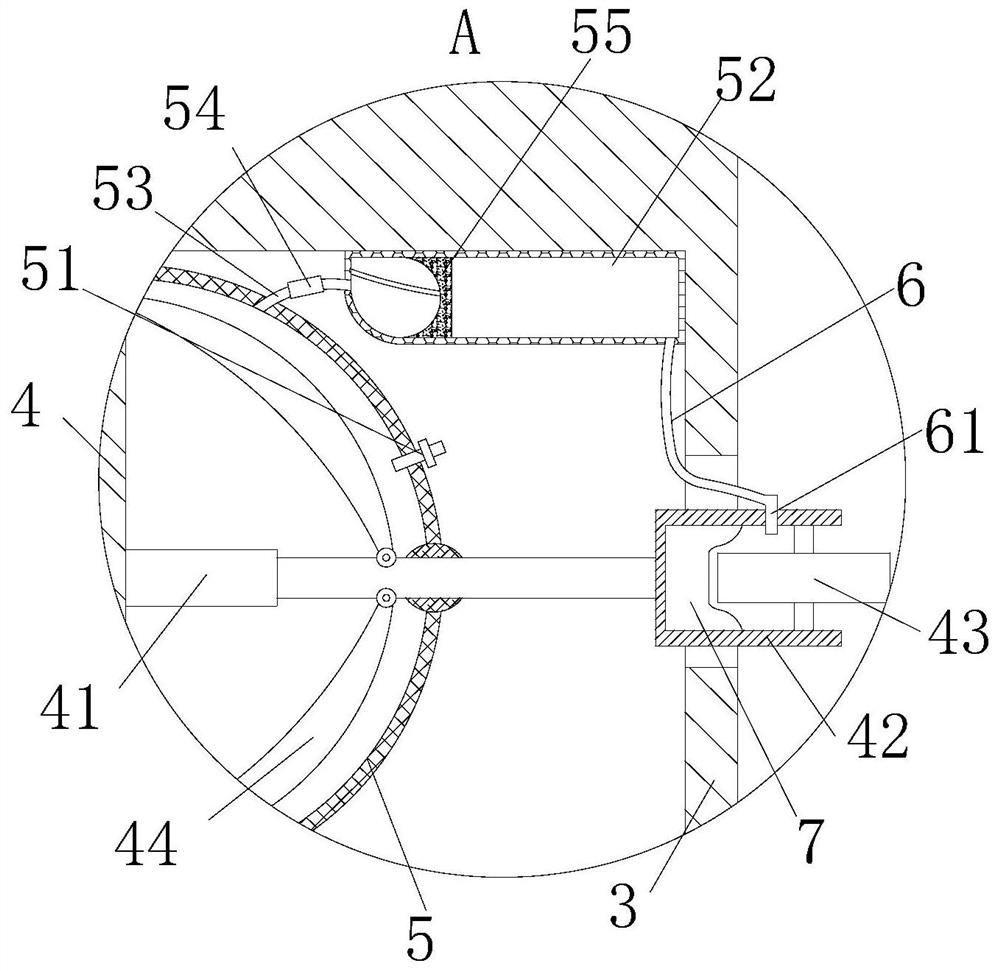

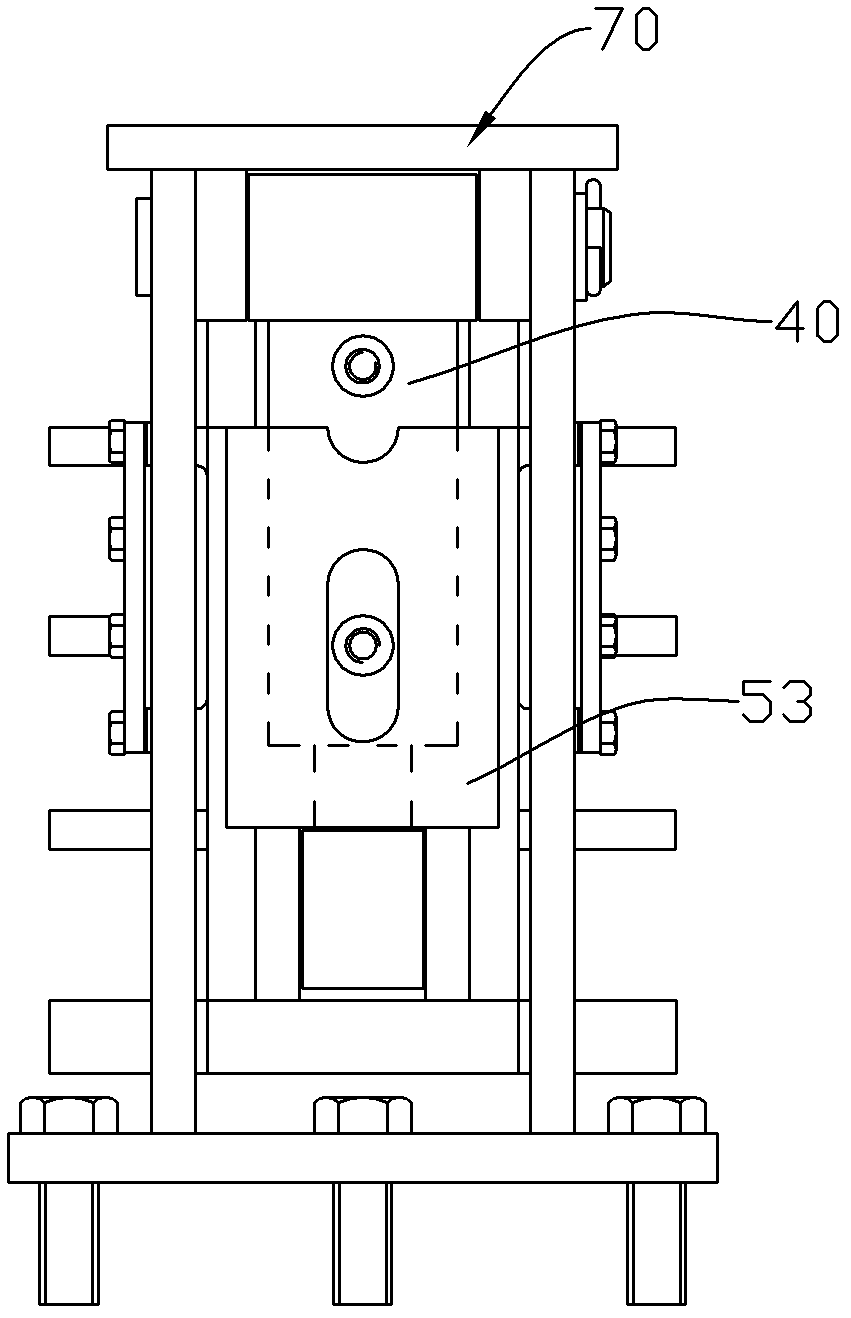

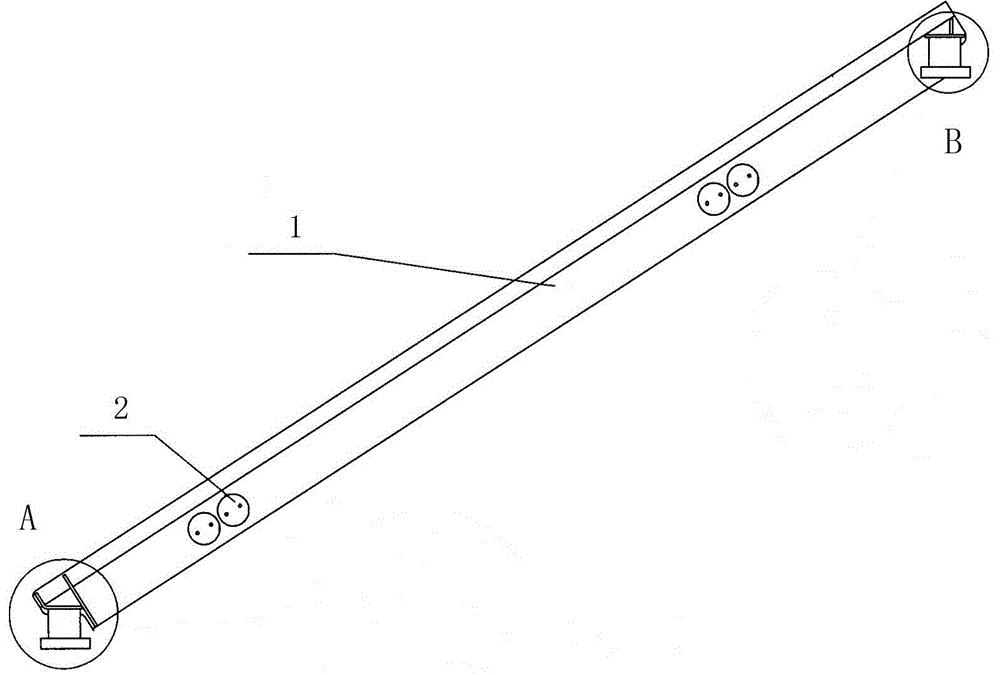

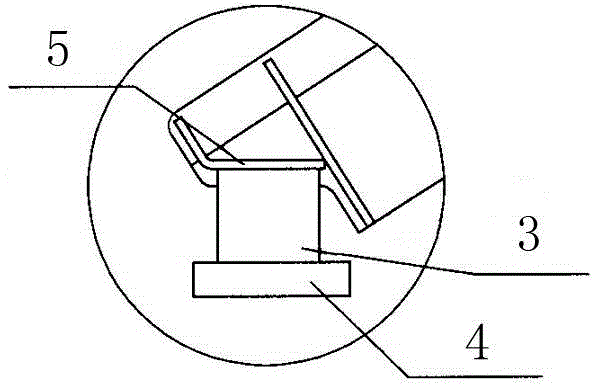

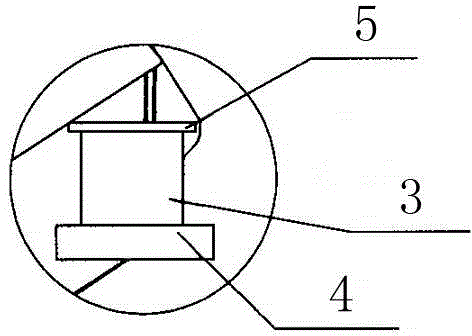

Underwater lever type steel cable single-double directional control assembly of wave energy profile buoy

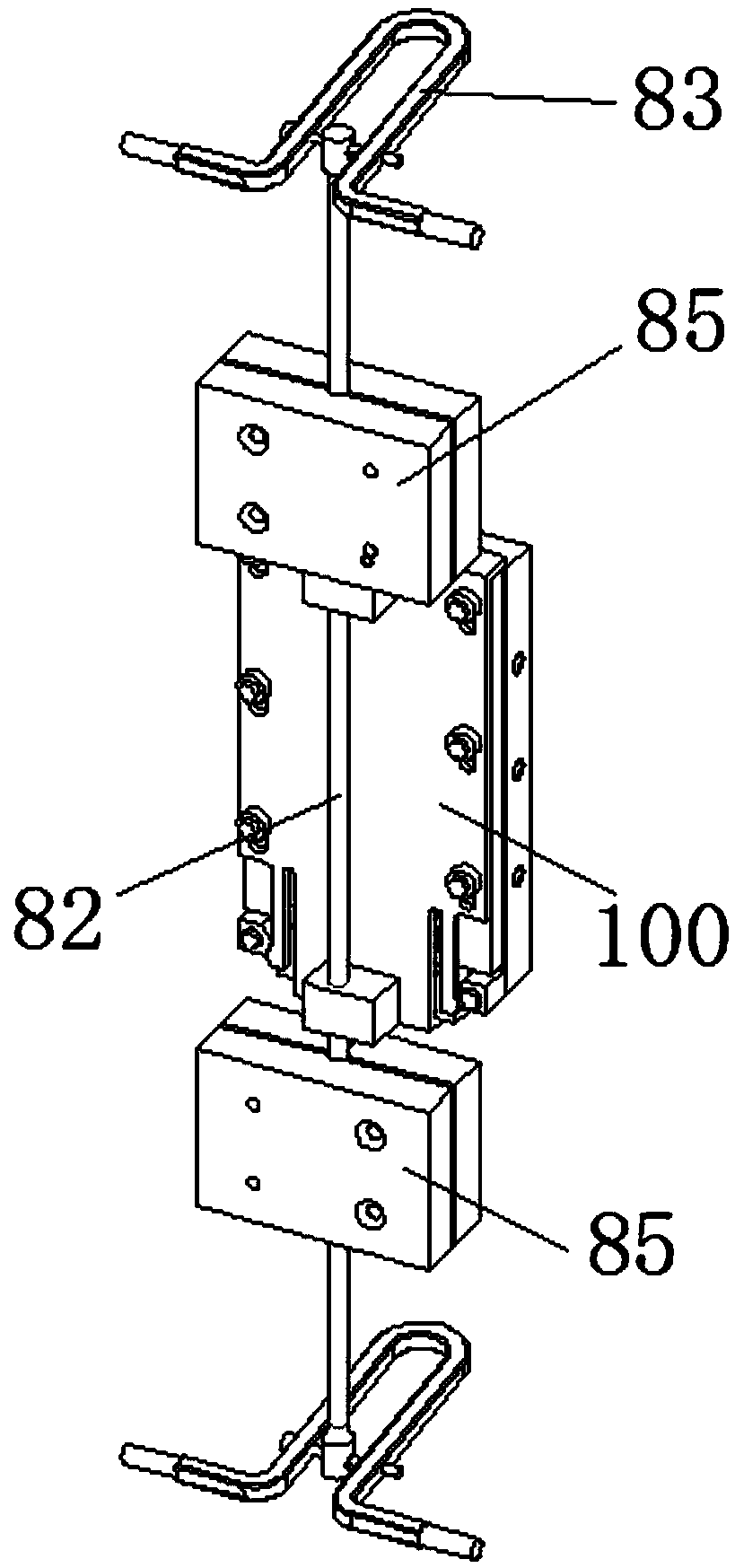

ActiveCN109398620ARealize the purpose of up and down profile movementAnti-mis-trigger designWaterborne vesselsBuoysEngineeringBuoy

The invention relates to the field of marine detection equipment, in particular to an underwater lever type steel cable single-double directional control assembly of a wave energy profile buoy. The underwater lever type steel cable single-double directional control assembly of the wave energy profile buoy comprises main supporting plates, a steel cable single / double directional control unit, a lever unit and a concentric limit unit, the steel cable single / double directional control unit, the lever unit and the concentric limit unit are arranged between the two main supporting plates, an uppertrigger block is fixed to the top end of a steel cable, a lower trigger block is fixed to the bottom end of the steel cable, and the steel cable penetrates through the concentric limit unit and the steel cable single / double directional control unit to move in the two directions or only in one direction under control of the steel cable single / double directional control unit. According to the underwater lever type steel cable single-double directional control assembly of the wave energy profile buoy, high sensitivity, anti-trigger design, and anti-wear design are achieved, under driving of external power, the steel cable can be in two working modes of the single / double directions by pushing a switching plate downwards / upwards, and thus the purpose that a whole profile buoy platform conductsup-down profile movement along the steel cable under the action of wave energy is achieved.

Owner:OCEAN UNIV OF CHINA

Stacked sludge dewatering machine

InactiveCN103663909AAvoid direct contactSolve serious wear and tear problemsSludge treatment by de-watering/drying/thickeningShaping pressSludgePulp and paper industry

The invention relates to a sludge dewatering machine, particularly a stacked sludge dewatering machine which comprises a machine body (1), a bracket (2) and a liquid collection reflux unit (3). The sludge dewatering machine is characterized in that the machine body (1) is arranged above the bracket (2) in parallel, and the liquid collection reflux unit (3) is arranged below the bracket (2); the machine body (1) comprises a cam driving gear (5), a connecting shaft (14), a screw propeller (6), fixed rings (7), floating rings (8) and support vertical plates (9); both ends of the machine body (1) are respectively provided with a sludge outlet (10) and a sludge inlet (11); and the machine body (1) is uniformly provided with the plurality of support vertical plates (9). Compared with the prior art, the sludge dewatering machine has the advantage of no wear, reduces the water content, is simple to operate and easy to replace, and lowers the cost.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Resonance screen excitation system

ActiveCN103769367ASimple structureSolve serious wear and tear problemsSievingScreeningPhysicsMachining vibrations

The invention relates to a complex excitation system for a resonant type vibrating screen and discloses a resonance screen excitation system. The resonance screen excitation system consists of excitation ranks, an excitation connection frame and four resonance springs arranged at four corners of the lower portion of the excitation connection frame; by means of the resonance screen excitation system, the problem that existing complex excitation systems for resonant type vibrating screens are poor in reliability is solved; the structure is simple, and a spring transmission excitation force which is parallel to a screen machine vibration direction is used, so that the problem of serious abrasion of the resonant type spring is solved, the fault rate of the complex excitation system is greatly reduced, and normal operation of the resonant screen is guaranteed; if the resonant screen is used as a device for arranging and tensioning a support net, hook plates and fixing bolts used for connecting a screen frame and the resonant screen to arrange and tension the support net are reduced, vibration mass of the screen box combination is reduced, workload of the spring bearing the screen box combination is reduced, service life of the spring is prolonged, meanwhile, fault hidden danger brought by fixed bolt looseness caused by vibration during usage is fundamentally eliminated, and the fault rate of the vibration screen is further reduced.

Owner:TANGSHAN LANDSKY TECH

Novel elevator landing door plate assembly

InactiveCN113562579AGood corrosion resistance such as acid, alkali and saltImprove environmental aging resistanceElevatorsBuilding liftsElevatorMechanical engineering

The invention belongs to the technical field of elevator equipment, and particularly relates to a novel elevator landing door plate assembly. The novel elevator landing door plate assembly comprises a landing door plate assembly. The landing door plate assembly comprises a landing door plate, a plurality of reinforcing ribs and a plurality of guide shoe plates; the multiple groups of reinforcing ribs are fixedly connected to the landing door plate; the reinforcing ribs are arranged on the landing door plate in a latticed mode; the multiple groups of guide shoe plates are fixedly connected to the bottom of the landing door plate; by using a non-metal high polymer material, an anti-rust coating does not need to be additionally sprayed after the landing door plate assembly is formed, and the material has very good corrosion resistance such as acid, alkali and salt resistance and further has very good environmental aging resistance at the same time; the surface color of the landing door plate assembly can be changed by adjusting the color of the material; and various colors can be blended according to the requirements of customers, and selectable diversity is achieved.

Owner:广州市景让信息科技有限公司

Sludge dewatering machine with floating rings

InactiveCN103663908AAvoid direct contactSolve serious wear and tear problemsSludge treatment by de-watering/drying/thickeningRefluxPropeller

The invention relates to a sludge dewatering machine, particularly a sludge dewatering machine with floating rings, which comprises a machine body (1), a bracket (2) and a liquid collection reflux unit (3). The sludge dewatering machine is characterized in that the machine body (1) is arranged above the bracket (2) in parallel, and the liquid collection reflux unit (3) is arranged below the bracket (2); the machine body (1) comprises a cam driving gear (5), a connecting shaft (14), a screw propeller (6), fixed rings (7), floating rings (8) and support vertical plates (9); both ends of the machine body (1) are respectively provided with a sludge outlet (10) and a sludge inlet (11); and the machine body (1) is uniformly provided with the plurality of support vertical plates (9). Compared with the prior art, the sludge dewatering machine has the advantage of no wear, reduces the water content, is simple to operate and easy to replace, and lowers the cost.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

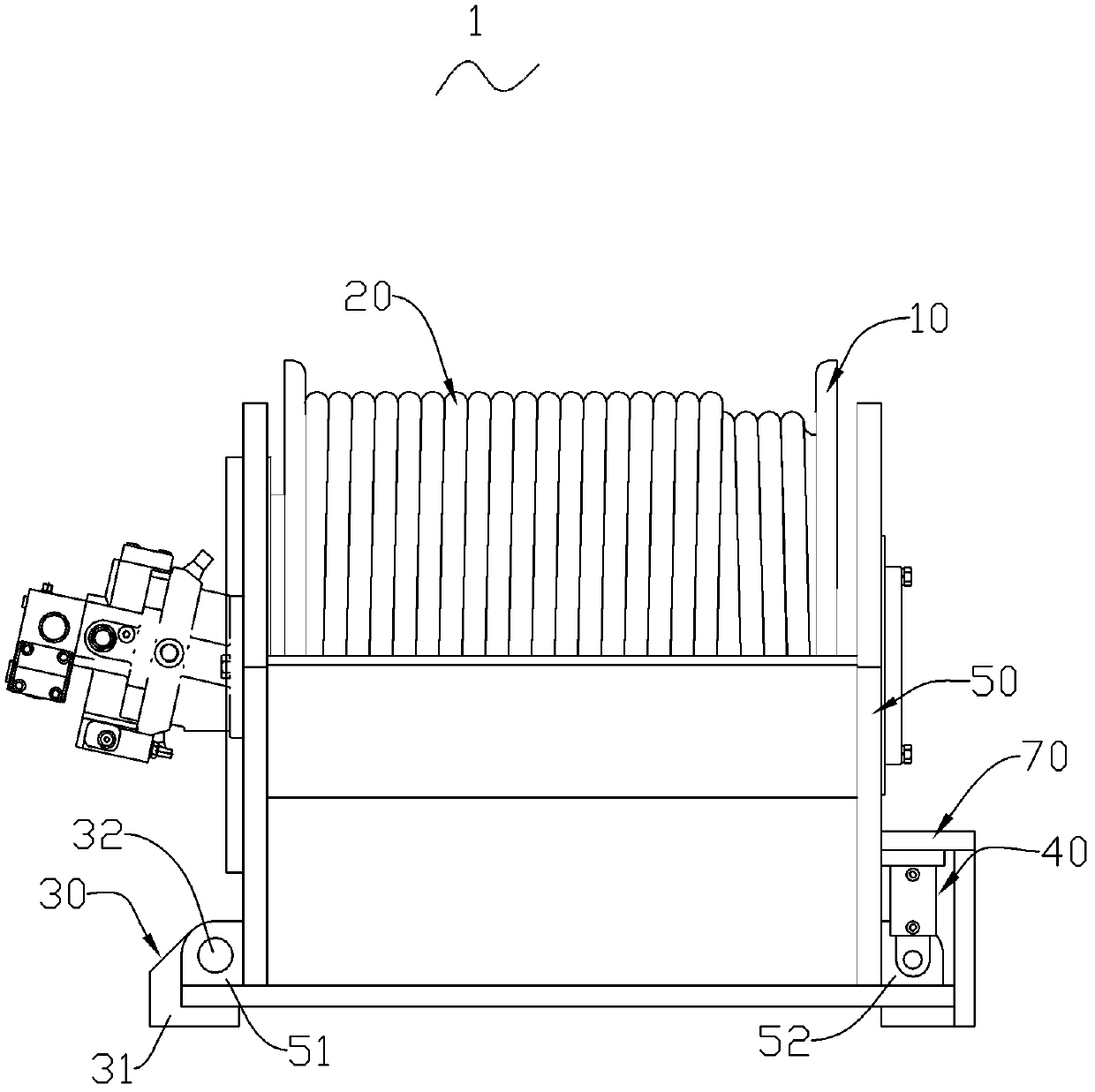

Winch with angle-adjustable winding drum axis

ActiveCN102515048BExtended service lifeSolve serious wear and tear problemsWinding mechanismsVertical planeMachine

The invention provides a hoist with an adjustable angle of the drum axis, which includes a drum, a frame and a steel wire rope. One end of the frame is hinged on a carrier supporting the hoist, and the other end is connected to the carrier supporting the hoist through an adjustment oil cylinder; when the hoist When working, the frame can be driven by the adjustment cylinder, and the deflection angle between the steel wire rope and the vertical plane of the drum shaft can be adjusted correspondingly as the wire rope winds in or out of the drum, so that the deflection angle between the steel wire rope and the vertical plane of the drum shaft can be reduced . The invention greatly reduces the wear and tear of the steel wire rope and the adjacent rope ring, prolongs the service life of the steel wire rope, and has simple structure, reasonable structure, strong load bearing and easy installation, and solves the problem that the related technology cannot fundamentally eliminate the serious problem of the hoist wire rope. The problem of wear and tear has filled the gap in this technical field. The present invention is especially suitable for hoisting machines with long-term heavy-duty operations, such as rotary drilling rigs, and is also generally applicable to any other machines using hoisting machines.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

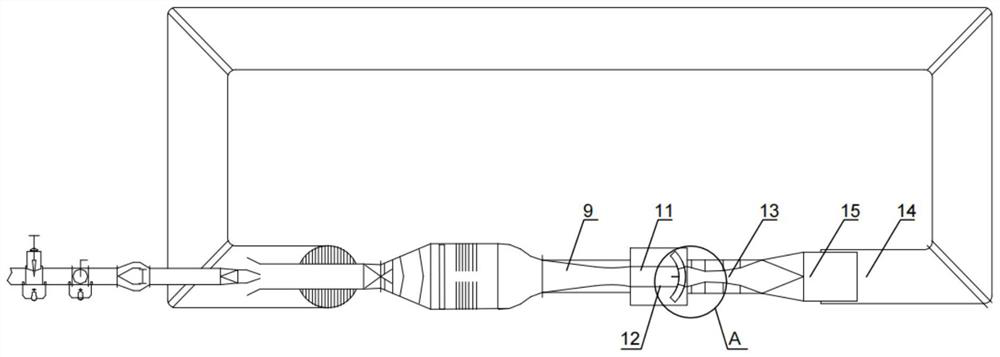

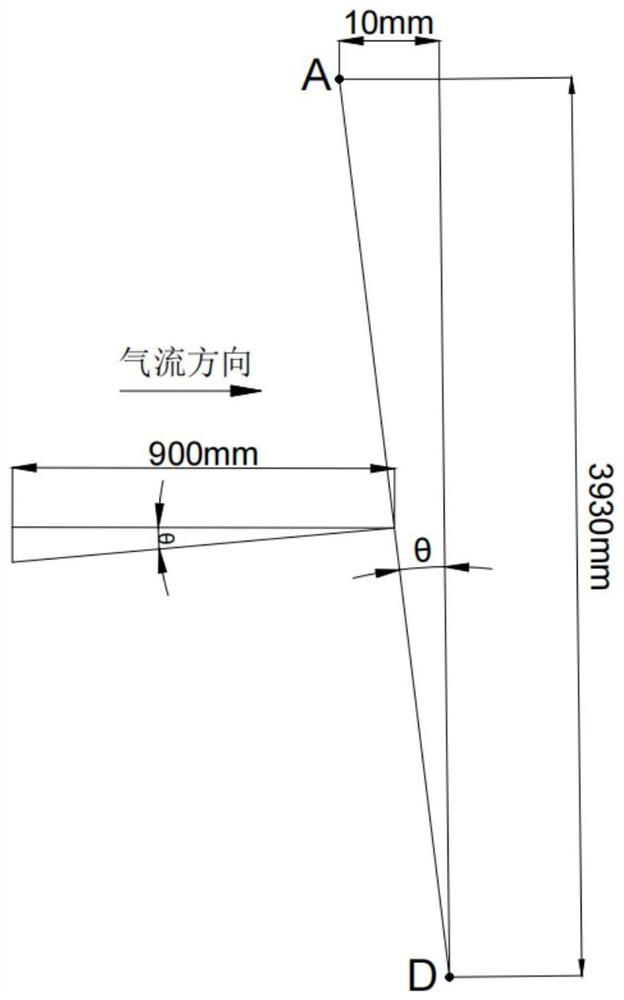

Method for detecting and recovering axis sinking of large section of wind tunnel

ActiveCN114216438AEnsure consistencyZoom out markerMechanical clearance measurementsMechanical thickness measurementsMarine engineeringStructural engineering

The invention discloses a method for detecting and recovering axis sinking of a large section of a wind tunnel. The method comprises the following steps: measuring and establishing a tunnel body state reference; the super-expansion section is retreated in place, and the telescopic section is supported and fixed; the super-expansion section and the telescopic section are disconnected; the whole super-expansion section is lifted; cleaning the guide rail slide block; detecting the planar guide rail and the V-shaped guide rail, and repairing the planar guide rail and the V-shaped guide rail; local high points of the guide rail sliding block are repaired; gaskets are arranged at the joints of the guide rail sliding blocks and the super-expansion section body, and all the connecting parts of the super-expansion section are reset and fastened in place; respectively moving the super-expansion section to a transonic speed test station and a supersonic speed test station, moving the attack angle of the model to a zero position, measuring the axis of the super-expansion section, and analyzing data until the height direction and the transverse direction meet the requirements; and iterating for multiple times until the comprehensive effect meets the maintenance requirement. The problem of detection and repair of sinking of the super-expansion section is solved, the problems that hooks are clamped, auxiliary supporting rollers are frequently damaged and the like are effectively solved, and meanwhile the basic consistency of the state of a hole body before and after is guaranteed.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

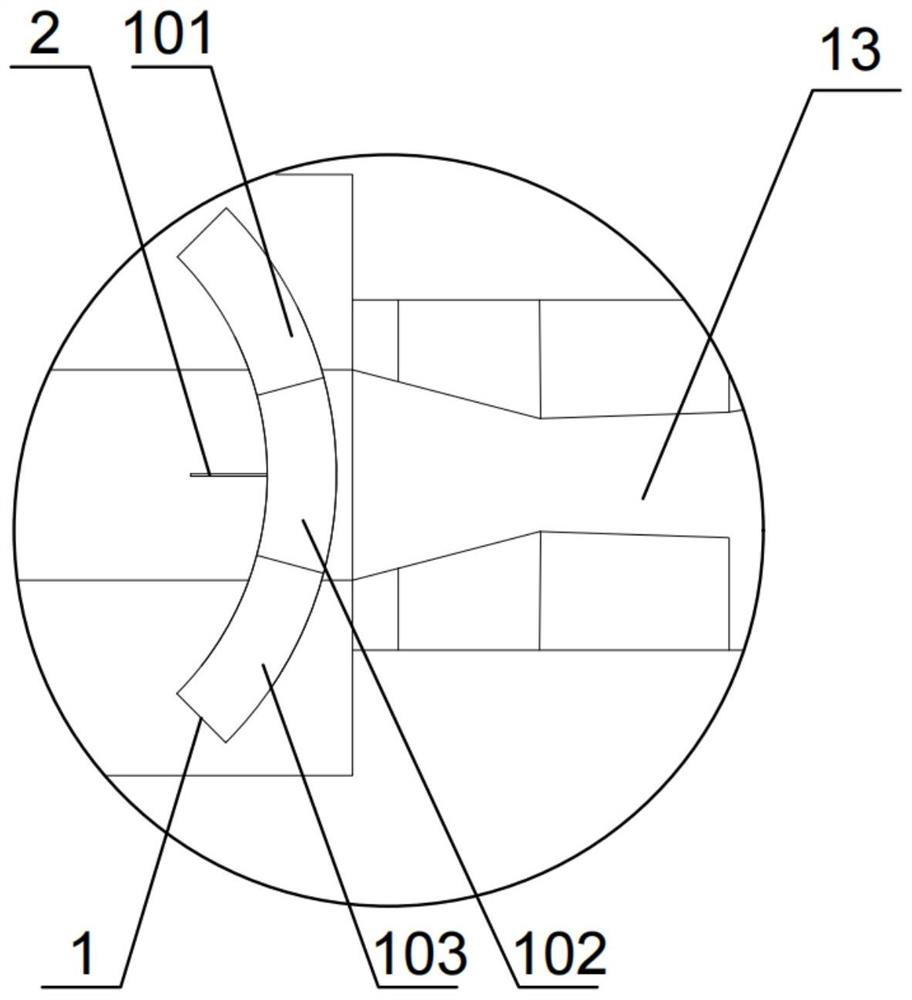

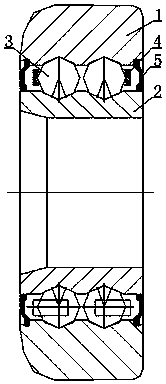

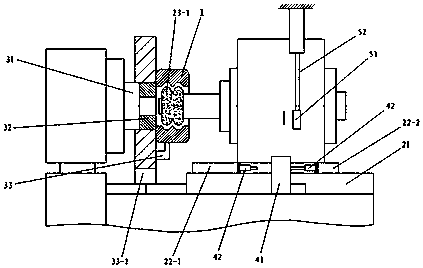

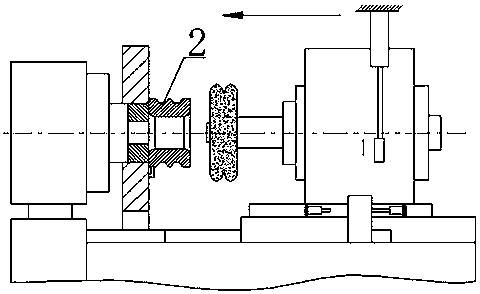

A six-point contact double-row ball roller bearing and its groove processing method and device

ActiveCN105221565BSolve serious wear and tear problemsExtended service lifeBall bearingsBearing componentsHyperboloidBall bearing

The invention relates to the field of double-row ball roller processing, in particular to a six-point-contact double-row ball roller and a groove processing method and device thereof. It includes an outer ring, an inner ring, steel balls, and a cage. The inner ring is installed in the outer ring. It is characterized in that the outer side of the inner ring and the inner side of the outer ring are respectively designed with double-row grooves at the same distance, and the double-row grooves on the inner side of the outer ring It is a spherical curved surface ring groove. The double-row groove designed on the outside of the inner ring is a peach-shaped groove ring groove composed of two non-concentric hyperboloids. The steel balls are installed between the outer ring and the inner ring through the cage. The advantage is that the design structure is simple and ingenious. Through the design of the peach-shaped groove and ring groove on the inner ring channel, the previous one-point contact becomes two-point contact, the force on the inner ring changes from one point to two points, and the bearing force of the inner ring becomes Two points mean that the amount of wear is greatly reduced, and the processing method is perfect and reasonable, which solves the serious problem of bearing wear and greatly improves the service life of the double row ball roller.

Owner:JIANGSU WANDA SPECIAL BEARING CO LTD

Coal anaerobic drying device and drying system

InactiveCN101762145BLong-distance transportSolve fire problemsDrying solid materials with heatSolid fuelsSurface moistureBound water

The invention relates to a coal anaerobic drying device and a drying system. The device comprises a vertical drying cylinder, a coal inlet, a coal outlet, an air inlet pipe and an air outlet pipe, wherein hot air cavities are respectively arranged outside two lateral walls of the drying cylinder; a certain number of array pipes or array plates are communicated between the two hot air cavities so as to ensure that coal in the drying cylinder and hot air in the hot air cavities and hot air in the array pipes or array plates are completely isolated; a steam pipe arranged inside the drying cylinder is extracted outside the drying device; the coal anaerobic drying system comprises the coal anaerobic drying device and a heating system, wherein a thermometer T1 and a thermometer T2 are arranged at the air inlet pipe port and the air outlet pipe port respectively; a discharge valve and a thermometer T0 are arranged at the discharge port. By controlling the temperature, the device and the system are applicable to both the drying of common coal and coal slime and the drying and upgrading of brown coal, not only can extract surface moisture of the brown coal, but also can remove partial bound water, transforms the brown coal from soft coal to hard coal, transforms the brown coal from hydrophily to hydrophobicity, are convenient for transportation, storage and use, and are favorable to popularization and implementation.

Owner:郑州拉姆顿清洁能源工程技术有限公司

Novel no-wear sludge dewatering machine

InactiveCN103663905AReduce moisture contentSimple and efficient operationSludge treatment by de-watering/drying/thickeningShaping pressWater contentPropeller

The invention relates to a sludge dewatering machine, particularly a novel no-wear sludge dewatering machine which comprises a machine body (1), a bracket (2) and a liquid collection reflux unit (3). The sludge dewatering machine is characterized in that the machine body (1) is arranged above the bracket (2) in parallel, and the liquid collection reflux unit (3) is arranged below the bracket (2); the machine body (1) comprises a cam driving gear (5), a connecting shaft (14), a screw propeller (6), fixed rings (7), floating rings (8) and support vertical plates (9); both ends of the machine body (1) are respectively provided with a sludge outlet (10) and a sludge inlet (11); and the machine body (1) is uniformly provided with the plurality of support vertical plates (9). Compared with the prior art, the sludge dewatering machine has the advantage of no wear, reduces the water content, is simple to operate and easy to replace, and lowers the cost.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Sludge dewatering machine with circular slipknots

InactiveCN103663907AReduce moisture contentSimple and efficient operationSludge treatment by de-watering/drying/thickeningPropellerWater content

The invention relates to a sludge dewatering machine, particularly a sludge dewatering machine with circular slipknots, which comprises a machine body (1), a bracket (2) and a liquid collection reflux unit (3). The sludge dewatering machine is characterized in that the machine body (1) is arranged above the bracket (2) in parallel, and the liquid collection reflux unit (3) is arranged below the bracket (2); the machine body (1) comprises a cam driving gear (5), a connecting shaft (14), a screw propeller (6), fixed rings (7), floating rings (8) and support vertical plates (9); both ends of the machine body (1) are respectively provided with a sludge outlet (10) and a sludge inlet (11); and the machine body (1) is uniformly provided with the plurality of support vertical plates (9). Compared with the prior art, the sludge dewatering machine has the advantage of no wear, reduces the water content, is simple to operate and easy to replace, and lowers the cost.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

High-efficiency sludge dewatering machine

InactiveCN103663911AAvoid direct contactSolve serious wear and tear problemsSludge treatment by de-watering/drying/thickeningPropellerPulp and paper industry

The invention relates to a sludge dewatering machine, particularly a high-efficiency sludge dewatering machine which comprises a machine body (1), a bracket (2) and a liquid collection reflux unit (3). The sludge dewatering machine is characterized in that the machine body (1) is arranged above the bracket (2) in parallel, and the liquid collection reflux unit (3) is arranged below the bracket (2); the machine body (1) comprises a cam driving gear (5), a connecting shaft (14), a screw propeller (6), fixed rings (7), floating rings (8) and support vertical plates (9); both ends of the machine body (1) are respectively provided with a sludge outlet (10) and a sludge inlet (11); and the machine body (1) is uniformly provided with the plurality of support vertical plates (9). Compared with the prior art, the sludge dewatering machine has the advantage of no wear, reduces the water content, is simple to operate and easy to replace, and lowers the cost.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Sealing structure of grinding head of wet ball mill

PendingCN112705322ASolve serious wear and tear problemsSimple connection structureEngine sealsGrain treatmentsStructural engineeringSlurry

The invention discloses a sealing mechanism of a grinding head of a wet ball mill. The sealing mechanism is characterized in that a connecting port is arranged at one side of a grinding head cylinder, one end of an elbow is inserted into the connecting port, and the other end of the elbow is connected to a mixer through a flange; a cylinder side moving base is arranged outside the connecting port of the grinding head cylinder and the elbow, a groove surrounding the elbow by a circle is arranged in the cylinder side moving base, and a rotating seal ring is arranged in the groove of the cylinder side moving base; and an elbow side static base and a static base pressing frame are arranged outside the elbow at the feeding end in a sleeving mode, a groove is arranged in the face, facing the cylinder side moving base, of the elbow side static base, a stationary seal ring is arranged in the groove of the elbow side static base, and the static base pressing frame presses the elbow side static base to the cylinder side moving base, so that the end face of the stationary seal ring makes contact with the end face of the rotating seal ring. The sealing mechanism completely solves the problems of slurry leakage and severe abrasion of the feeding elbow and the cylinder, the service life is at least two years, only the rotating seal ring and the stationary seal ring need to be replaced after abrasion, the connecting structure is simple, and replacement is extremely convenient.

Owner:ANHUI HUADIAN SUZHOU POWER GENERATION

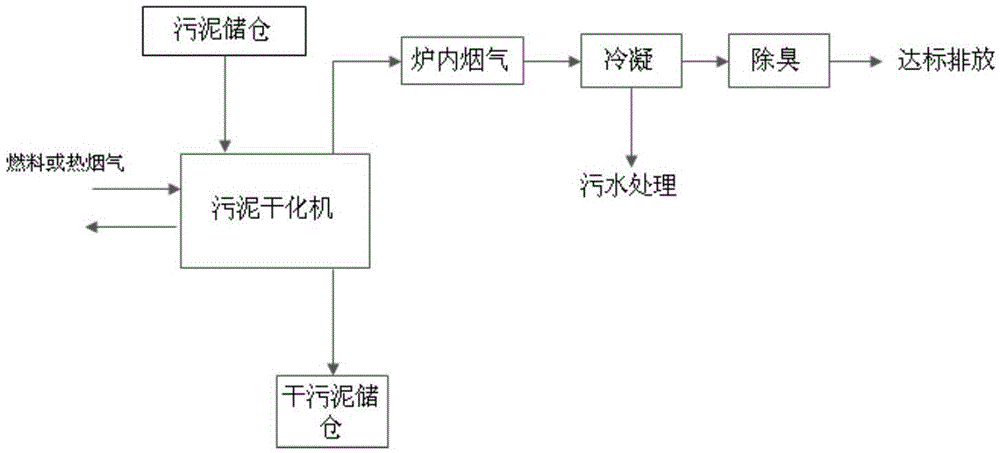

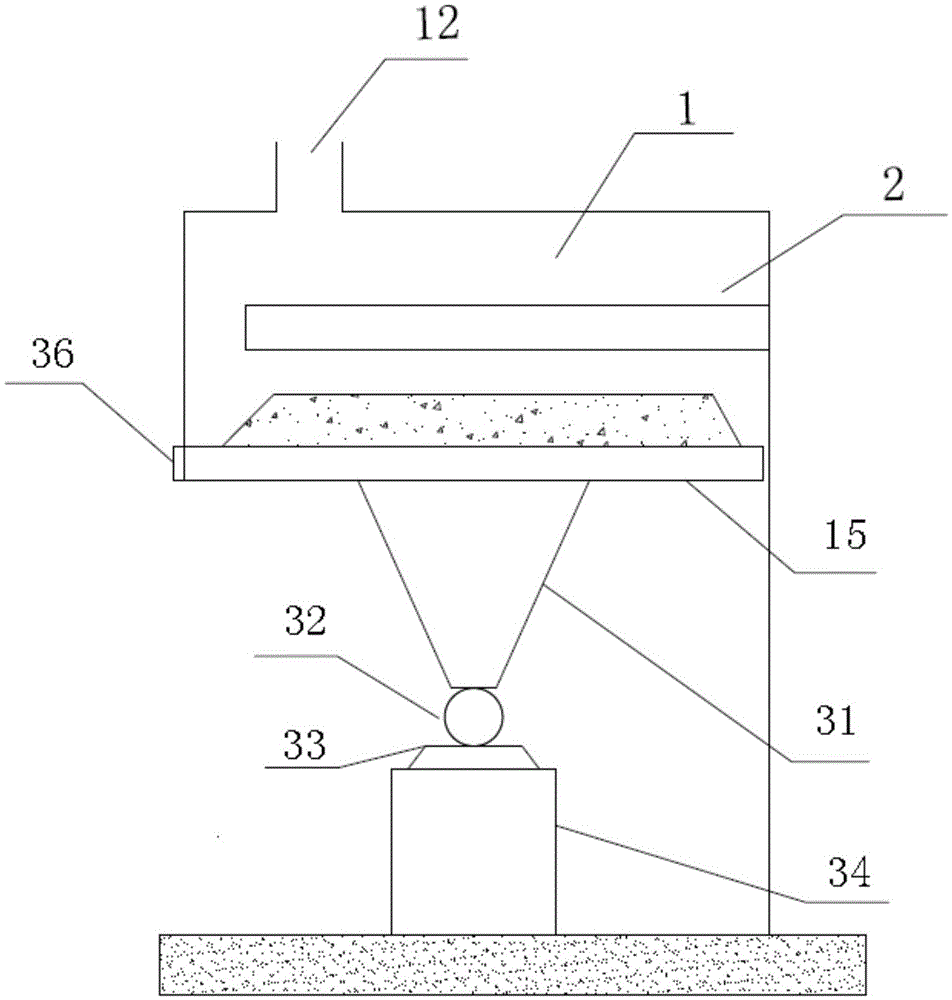

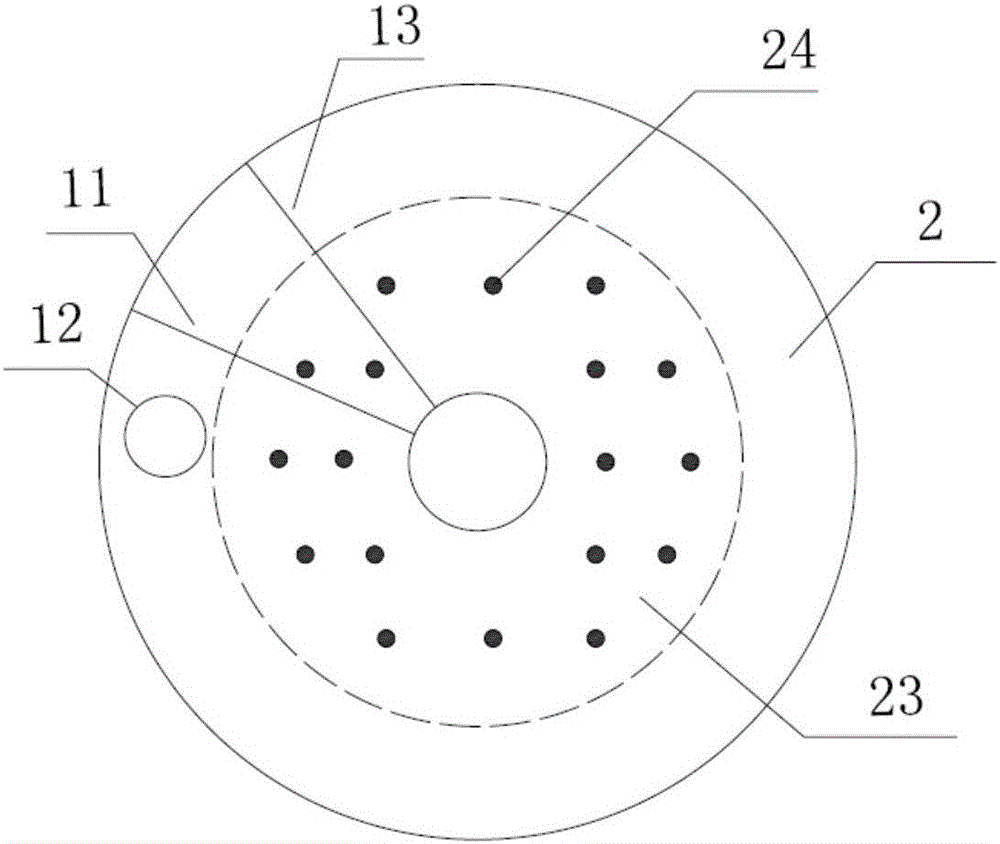

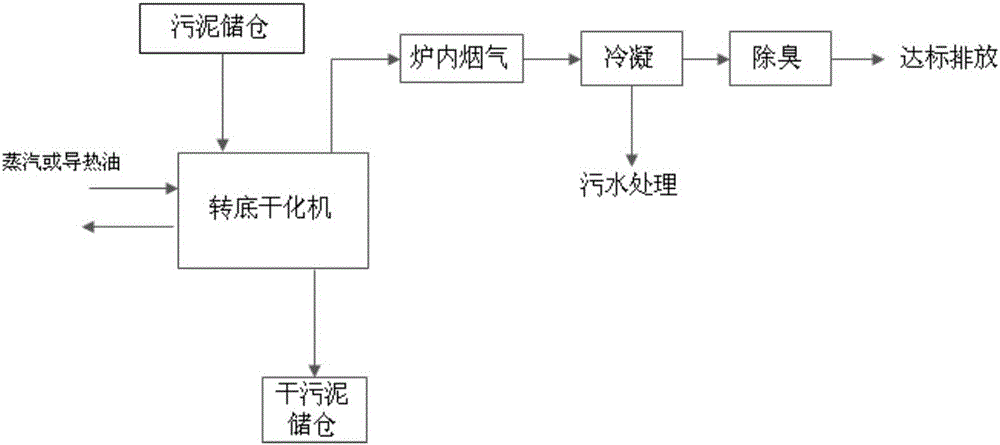

Sludge drying machine and drying method

PendingCN105541080ASolve the problems in the drying methodAvoid it happening againSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeEngineering

The invention relates to a sludge drying machine and drying method. The sludge drying machine comprises an annular hollow cavity, a driving device and a radiation heating device, wherein the bottom surface of the cavity serves as a distribution tray and is arranged to horizontally rotate relative to the side wall and top of the cavity; a sludge discharge hole is formed in the side wall of the cavity; the cavity is also provided with a dried smoke outlet and a sludge feeding hole; the dried smoke outlet is formed in the top of the cavity and is near the sludge feeding hole; the driving device is arranged below the distribution tray and is used for driving the distribution tray to rotate; the radiation heating device is arranged inside the cavity, is fixed on the side wall of the cavity and is arranged to be parallel to the distribution tray. By adopting the sludge drying machine and drying method, the problem that devices are seriously worn by sludge with high sand content is solved; plenty of dust is not generated, explosion dangers do not exist and the oxygen content of furnaces is unnecessary to be controlled in the drying process; the problem of blocking does not exist.

Owner:SHENWU TECH GRP CO LTD

An Improved Resonant Vibrating Screen

Owner:TANGSHAN LANDSKY TECH

Sludge drier and drying method

PendingCN105668979ASolve serious wear and tear problemsReduce processingSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFlue gasSludge

The invention relates to a sludge drying machine and a drying method. The sludge drying machine includes a cavity, a horizontally arranged material bed located in the cavity, and a driving device for driving the horizontal rotation of the material bed; the material bed is a rotating hollow cylinder structure, and the upper and lower bottom plates of the material bed A circular baffle plate coaxial with the material bed is arranged horizontally between them, and the internal space of the material bed is divided into upper and lower layers; the diameter of the circular baffle plate is smaller than the diameter of the material bed; a The heat medium pipeline is perpendicular to the material bed; the surface of the cavity is provided with a sludge inlet, a drying flue gas outlet, and a sludge outlet; wherein the flue gas outlet is close to the sludge inlet. The invention solves the problem of severe wear and tear on the device by the sludge with large sand content; and does not generate a large amount of dust in the drying process, does not have the danger of explosion, does not need to control the oxygen content in the furnace; and does not have the problem of blockage and jamming.

Owner:SHENWU TECH GRP CO LTD

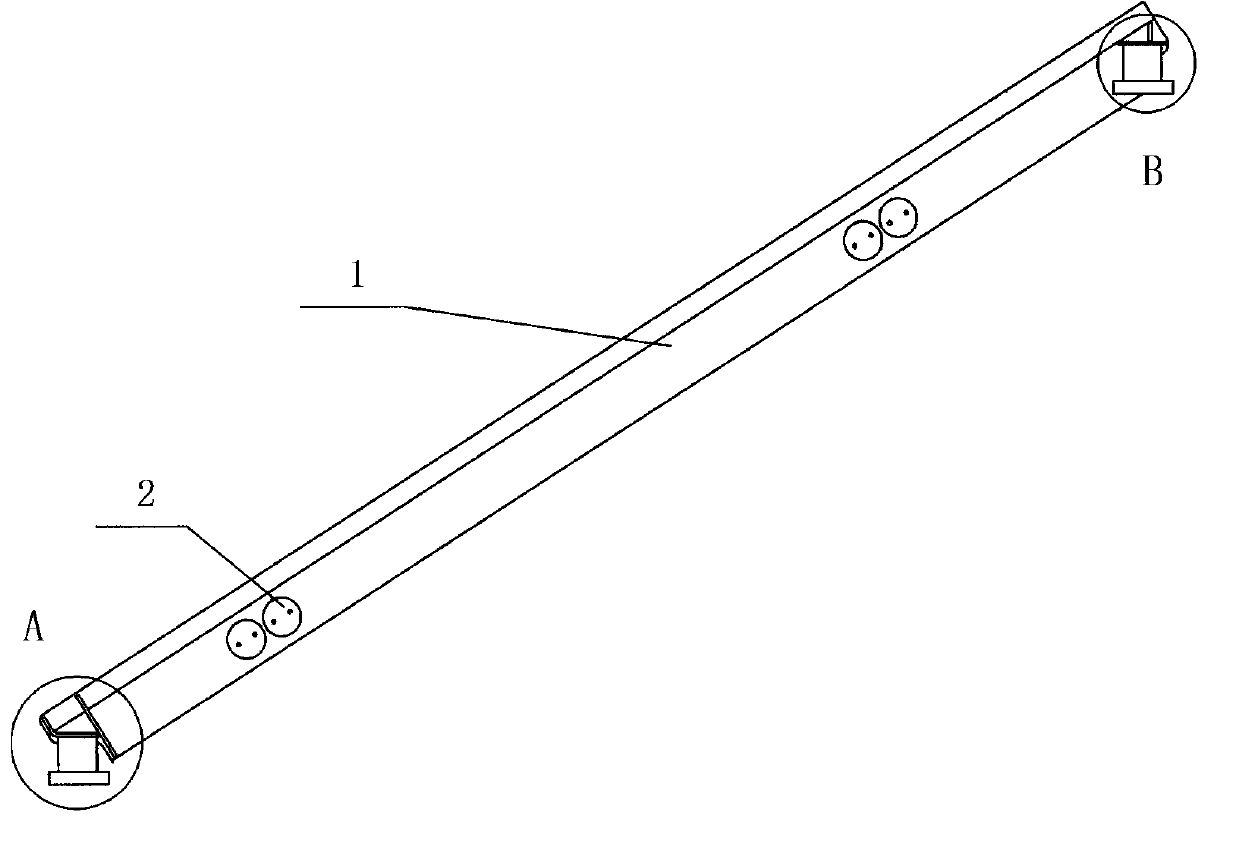

Wear-free screw-lapping sludge dewatering machine

ActiveCN102887618BAvoid direct contactSolve serious wear and tear problemsSludge treatment by de-watering/drying/thickeningPulp and paper industryCam

The invention refers to a sludge dewatering machine. More definitely, the invention relates to a wear-free screw-lapping sludge dewatering machine which comprises a machine body (1), a bracket (2), and a liquid collecting backflow device (3). The wear-free screw-lapping sludge dewatering machine is characterized in that the machine body (1) is arranged at the upper part of the bracket (2) in parallel, the liquid collecting backflow device (3) is arranged at the lower part of the bracket (2); the machine body (1) comprises a cam driving device (5), a connecting shaft (14), a spiral pusher (6), a fixing ring (7), a movable ring (8), and vertical supporting plates (9); and a mud outlet (10) and a mud inlet (11) are respectively arranged at both ends of the machine body (1); a plurality of vertical supporting plates (9) are uniformly arranged on the machine body (1). Compared with the prior art, the wear-free screw-lapping sludge dewatering machine has the outstanding advantages as follows: 1, wear-free; 2, moisture content is reduced; 3, operation is simple and replacement can be easily achieved; and 4, cost is reduced.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Sludge dewatering machine with stepped shaft

InactiveCN103663898AAvoid direct contactSolve serious wear and tear problemsSludge treatment by de-watering/drying/thickeningPropellerPulp and paper industry

The invention relates to a sludge dewatering machine, particularly a sludge dewatering machine with a stepped shaft, which comprises a machine body (1), a bracket (2) and a liquid collection reflux unit (3). The sludge dewatering machine is characterized in that the machine body (1) is arranged above the bracket (2) in parallel, and the liquid collection reflux unit (3) is arranged below the bracket (2); the machine body (1) comprises a cam driving gear (5), a connecting shaft (14), a screw propeller (6), fixed rings (7), floating rings (8) and support vertical plates (9); both ends of the machine body (1) are respectively provided with a sludge outlet (10) and a sludge inlet (11); and the machine body (1) is uniformly provided with the plurality of support vertical plates (9). Compared with the prior art, the sludge dewatering machine has the advantage of no wear, reduces the water content, is simple to operate and easy to replace, and lowers the cost.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

A vibrating screen vibration system

ActiveCN103769367BSimple structureLow failure rateSievingScreeningMachining vibrationsResonance excitation

The invention relates to a complex excitation system for a resonant type vibrating screen and discloses a resonance screen excitation system. The resonance screen excitation system consists of excitation ranks, an excitation connection frame and four resonance springs arranged at four corners of the lower portion of the excitation connection frame; by means of the resonance screen excitation system, the problem that existing complex excitation systems for resonant type vibrating screens are poor in reliability is solved; the structure is simple, and a spring transmission excitation force which is parallel to a screen machine vibration direction is used, so that the problem of serious abrasion of the resonant type spring is solved, the fault rate of the complex excitation system is greatly reduced, and normal operation of the resonant screen is guaranteed; if the resonant screen is used as a device for arranging and tensioning a support net, hook plates and fixing bolts used for connecting a screen frame and the resonant screen to arrange and tension the support net are reduced, vibration mass of the screen box combination is reduced, workload of the spring bearing the screen box combination is reduced, service life of the spring is prolonged, meanwhile, fault hidden danger brought by fixed bolt looseness caused by vibration during usage is fundamentally eliminated, and the fault rate of the vibration screen is further reduced.

Owner:TANGSHAN LANDSKY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com