Sludge drying machine and drying method

A sludge drying and sludge technology, applied in the field of solid waste recycling, can solve problems such as device wear and blockage, and achieve the effects of solving severe wear, ensuring moisture content, and increasing drying capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 A kind of sludge drying machine

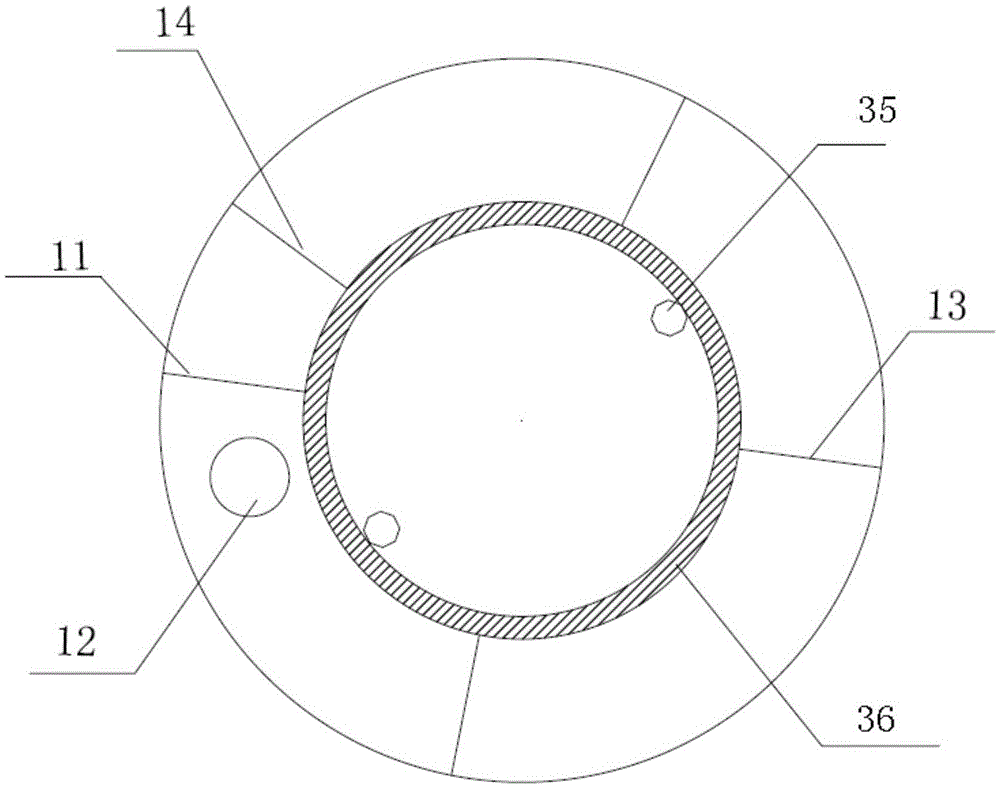

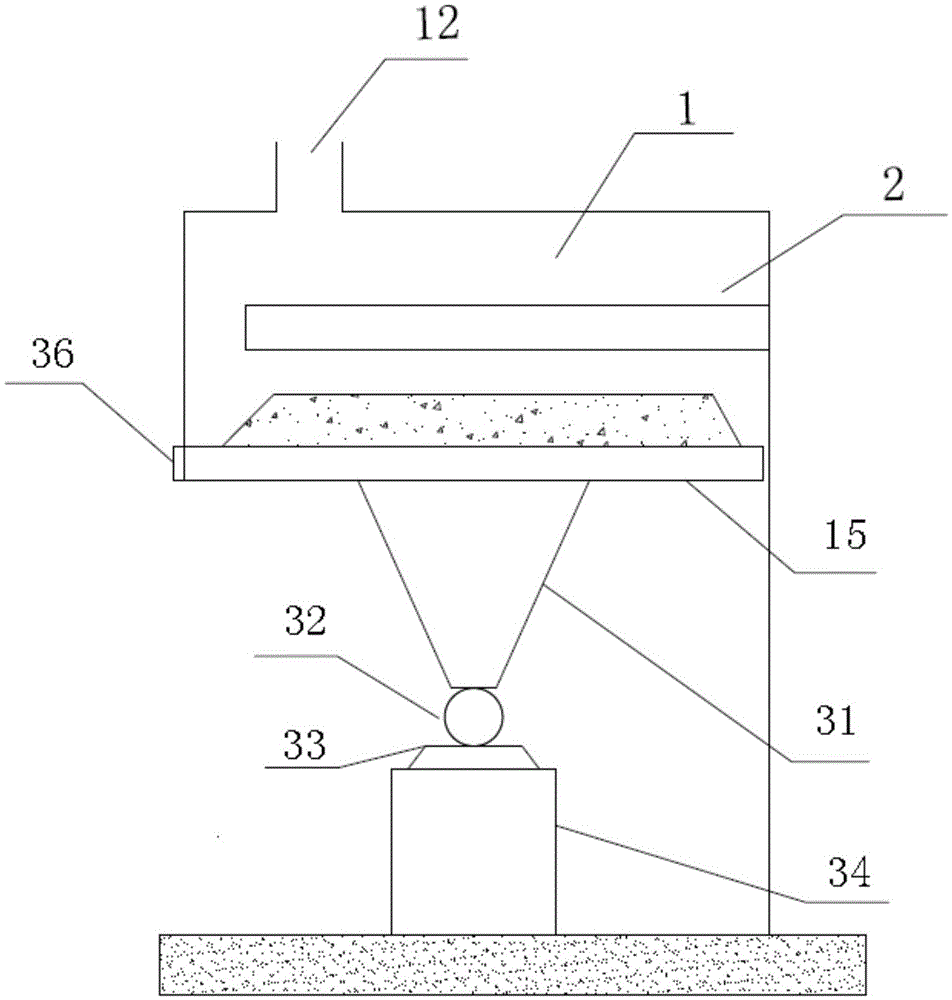

[0038] A sludge dryer, such as figure 2 , image 3 As shown, it includes: an annular hollow cavity 1, the bottom surface of the cavity is used as a distribution pan 15, and it is set to rotate horizontally relative to the side wall and top of the cavity, and on the side wall of the cavity A sludge outlet (including an intermediate sludge outlet 13 and a final sludge outlet 14) is provided, and the cavity is also provided with a drying flue gas outlet 12 and a sludge inlet 11. Wherein, the dried flue gas outlet is arranged on the top of the cavity and is located near the sludge feed port;

[0039] A driving device 3, the driving device is arranged under the distribution pan 15, and is used to drive the distribution pan to rotate;

[0040] The radiation heating device 2 is arranged inside the cavity 1, fixed on the side wall of the cavity and arranged parallel to the distribution pan.

[0041] Wherein, the distributing p...

Embodiment 2

[0048] Embodiment 2 A kind of sludge drying method

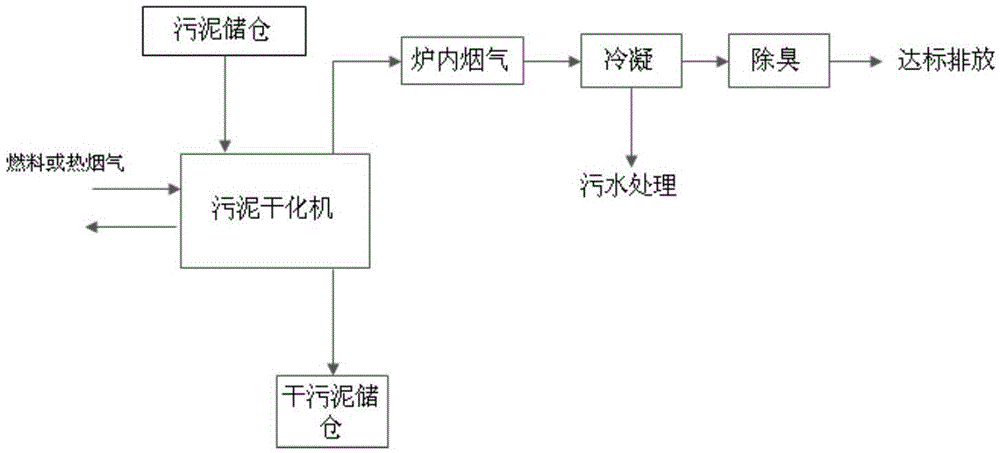

[0049] A kind of drying method that utilizes the sludge drying machine described in embodiment 1 to process sludge, such as figure 1 shown, including the following steps:

[0050] (1) Send the sludge (moisture content 80%) from the sewage treatment plant into the sludge storage bin, transport it to the sludge dryer through the sludge pump, and feed it from the feeding device located on one side of the dryer;

[0051] The sludge is evenly arranged on the distribution plate of the drying machine through the material distribution mechanism. The total thickness of the sludge is 60mm; the distance between the radiation heating device and the highest point of the sludge is 15mm; the entire cavity does not need to be sealed;

[0052] (2) The sludge on the distributing pan is heated and dried by radiation through the radiation heating device. During the drying process, the sludge moves through the rotation of the distributing pan; ...

Embodiment 3

[0056] Embodiment 3 A kind of sludge drying method

[0057] A method for drying sludge by using the sludge dryer described in Example 1, comprising the steps of:

[0058] (1) Sludge (moisture content 85%) from the sewage treatment plant is sent to the sludge storage bin, transported to the sludge dryer by the sludge pump, and fed by the feeding device located on one side of the dryer.

[0059] The sludge is evenly arranged on the distribution plate of the drying machine through the material distribution mechanism. The total thickness of the sludge is 20mm; the distance between the radiation heating device and the highest point of the sludge is 25mm; the entire cavity does not need to be sealed;

[0060] (2) The sludge on the distributing pan is heated and dried by radiation through the radiation heating device. During the drying process, the sludge moves through the rotation of the distributing pan;

[0061] Wherein, the drying temperature is 180°C, the total sludge drying ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com