Winch with angle-adjustable winding drum axis

A technology for adjusting the angle and hoisting machine, applied in the field of hoisting machine, can solve the problems of increasing the quality cost of the manufacturer, aggravating the user's cost of use, short service life, etc., and achieves the effects of reasonable structure, prolonged service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

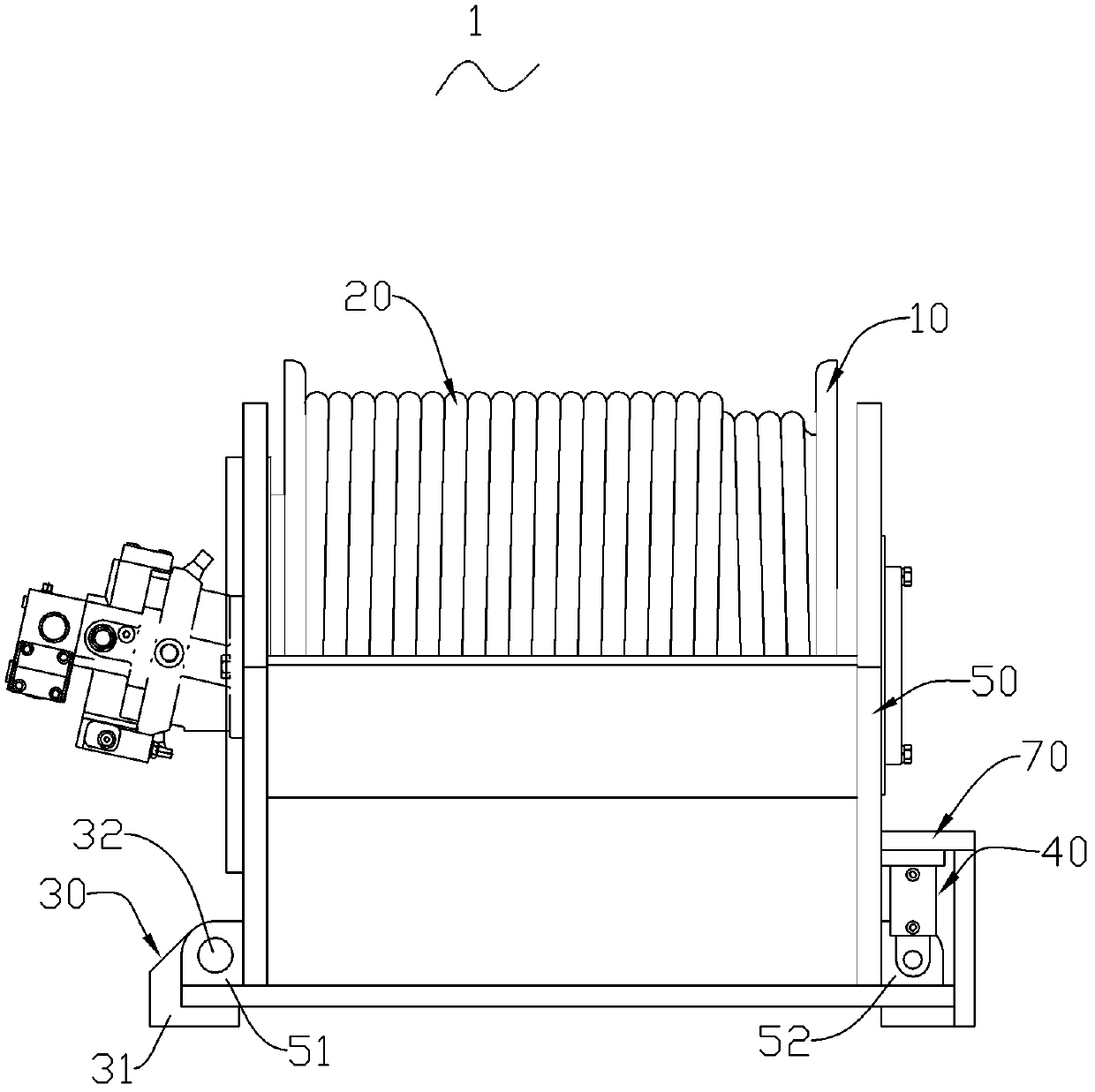

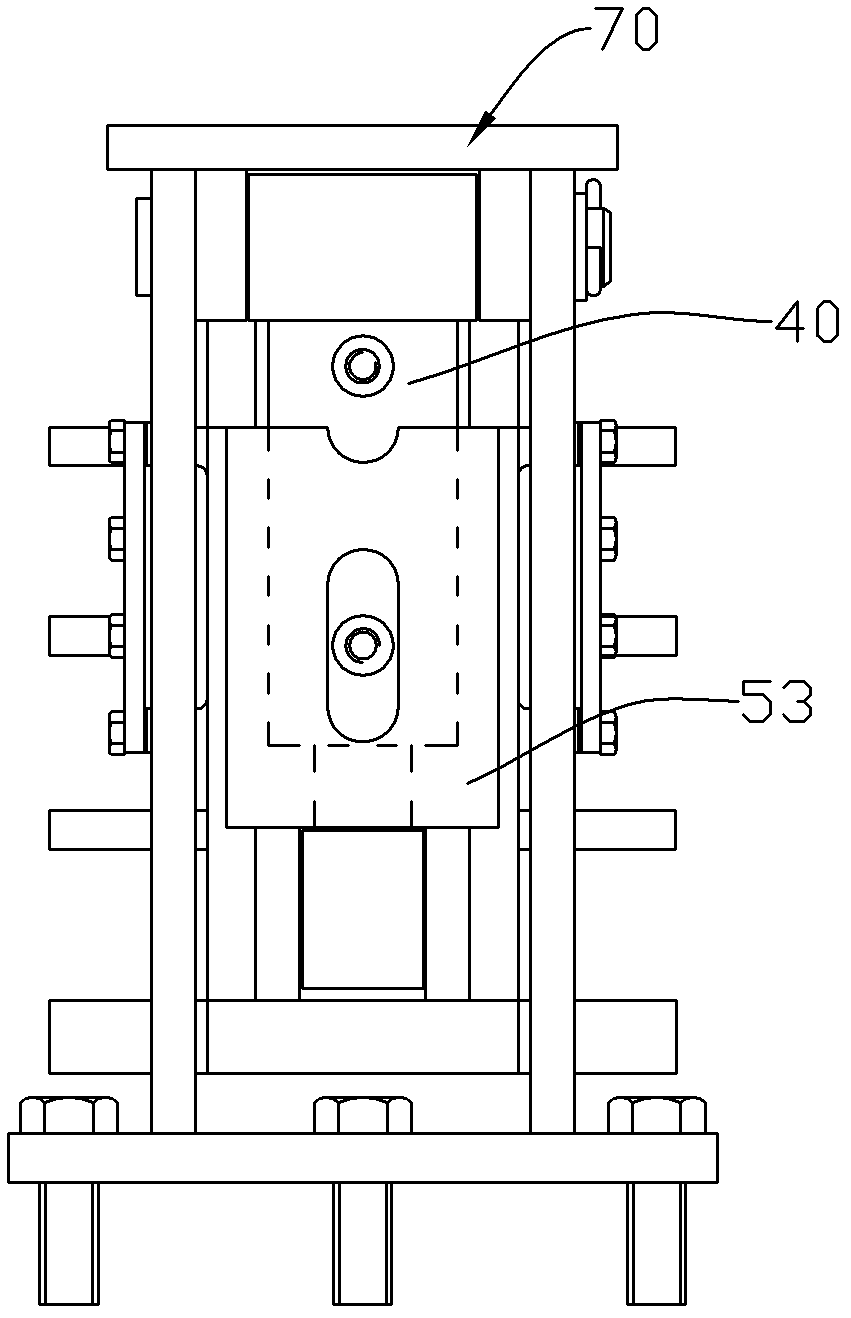

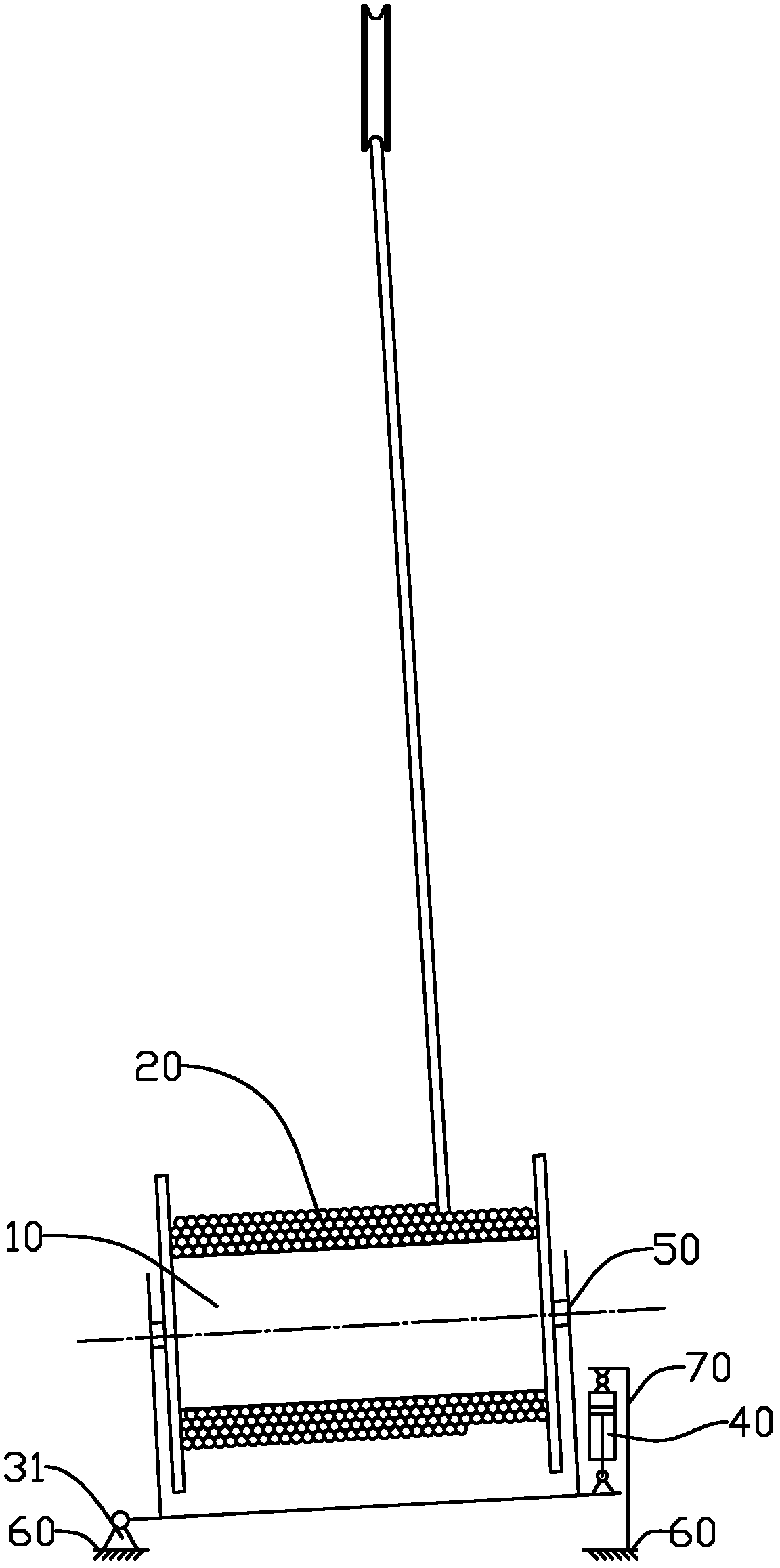

[0022] figure 1 The hoist 1 in some embodiments of the present invention is shown, and the hoist 1 is especially suitable for a hoist that works for a long time with heavy loads, such as a rotary drilling rig, and is also generally applicable to any other machine that uses a hoist. This hoist 1 comprises reel 10, frame 50 and steel wire rope 20, and the left end 51 of frame 50 is hinged on the carrier 60 of supporting hoist, and right end 52 is connected with the carrier 60 of supporting hoist by adjusting oil cylinder 40; When hoist 1 work, The frame 50 can be driven by the adjustment oil cylinder 40, and when the wire rope 20 winds in or out of the drum 10, it can be adjusted correspondingly with the deflection angle (that is, the angle of entry) of the vertical plane of the shaft of the drum 10, so that the entry angle of the wire rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com