Coal anaerobic drying device and drying system

A drying device and drying system technology, used in heating devices, drying solid materials, heating to dry solid materials, etc., can solve the problems of large power consumption and high drying costs, reduce emissions, overcome severe wear of heat exchangers, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

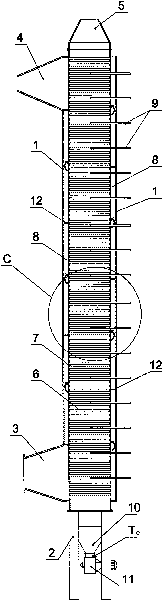

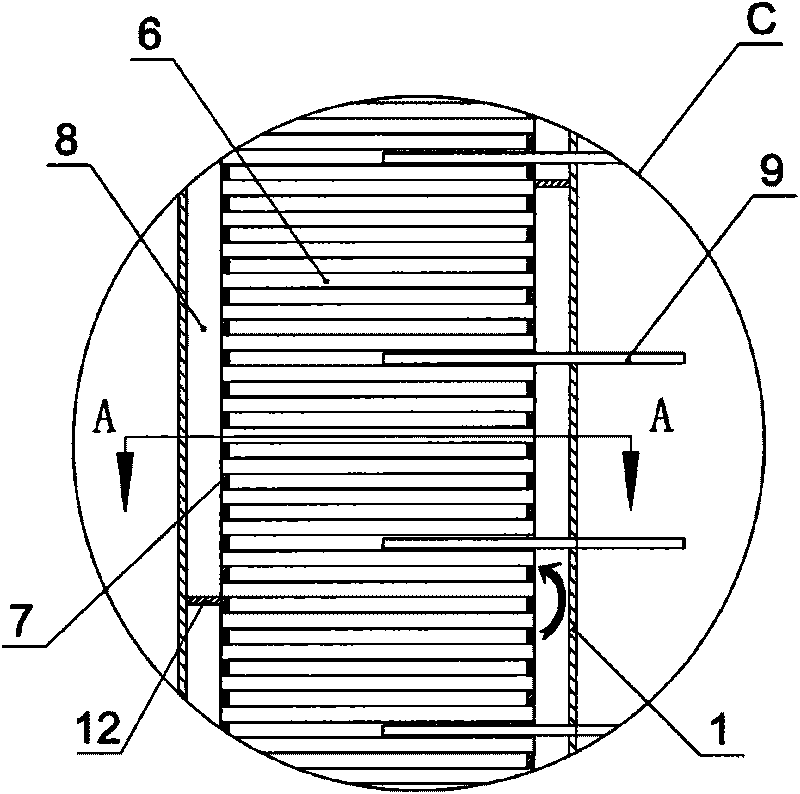

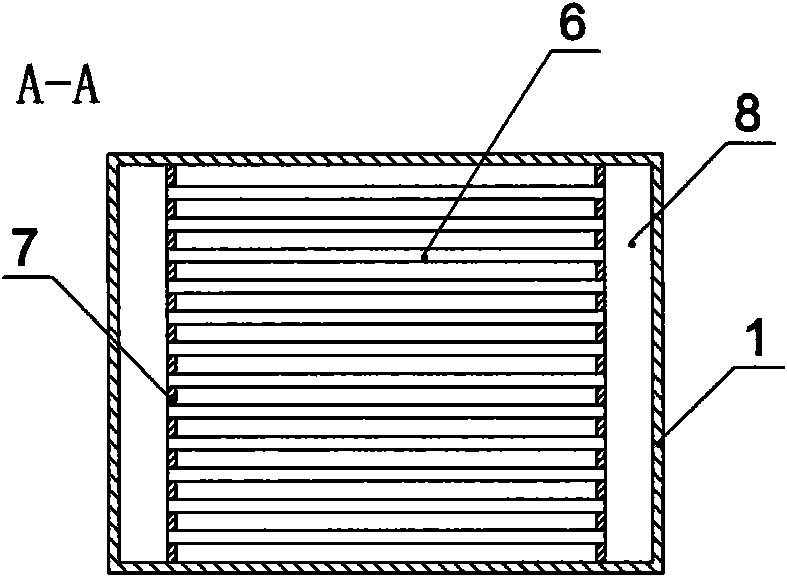

[0052] Embodiment one: see figure 1 , Picture 1-1 , Figure 1-2 , Figure 1-3 , a coal anaerobic drying device, comprising a vertical drying cylinder 7, the upper and lower ends of the drying cylinder 7 are respectively provided with a coal inlet 5 and a coal outlet 10, and the upper part of the drying cylinder 7 is fixedly equipped with an air outlet pipe 17, The lower part or the middle part is fixedly equipped with an intake pipe 16 .

[0053] On the outside (in the vertical direction) of the opposite side walls of the vertical drying cylinder 7 (left and right), there are hot air chambers 8 that are isolated from the drying cylinder 7 and independent from each other, and between the two independent hot air chambers 8 A certain number of row pipes 6 are connected.

[0054] A certain number of transverse partitions 12 are arranged in the two adjacent hot gas chambers 8 up and down, so that the hot gas chamber is divided into multiple independent hot gas chambers from to...

Embodiment 2

[0058] Embodiment two: see figure 2 , diagram 2-1 , Figure 2-2 , Figure 2-3 , Figure 2-4 , the numbering is the same as that of Embodiment 1, the meaning is the same, the same parts will not be repeated, and the difference is: change the row of pipes as follows Figure 2-3 The row plate 24.

Embodiment 3

[0059] Embodiment three: see image 3 , Figure 3-1 , the numbering is the same as in Embodiment 1, the meaning is the same, the same parts will not be repeated, the difference is: the air inlet pipe 16 is located in the middle of the drying cylinder 7, and the hot gas flow sequence is deflected downward from the hot air chamber in the middle of the drying cylinder and discharged, and then passes through The hot air chamber at the bottom of the drying cylinder leads upwards to the return pipe 25 for the flue gas to communicate with the hot air chamber above the inlet pipe 16 , and then deflects upwards in sequence, and finally flows to the air outlet pipe 17 . This embodiment is suitable for drying the surface water of ordinary coal or lignite, and of course it is also suitable for drying chemical industry, metal and non-metallic minerals, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com