Sludge drier and drying method

A sludge drying and sludge technology, which is applied in the field of solid waste resource treatment, can solve the problems of sludge wear and blockage on drying devices, and achieve the effect of reducing the amount of flue gas treatment and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A kind of sludge drying machine

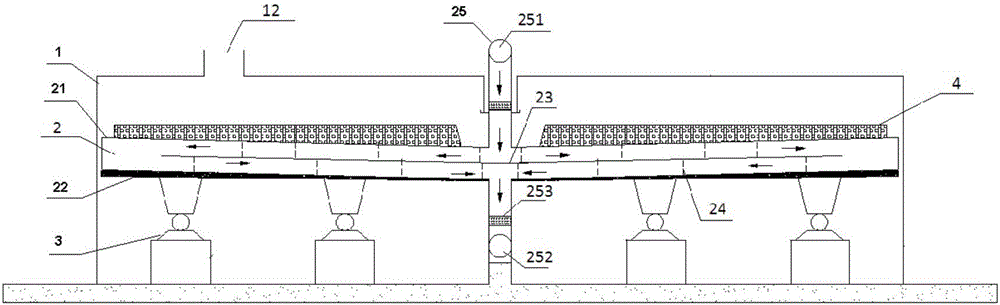

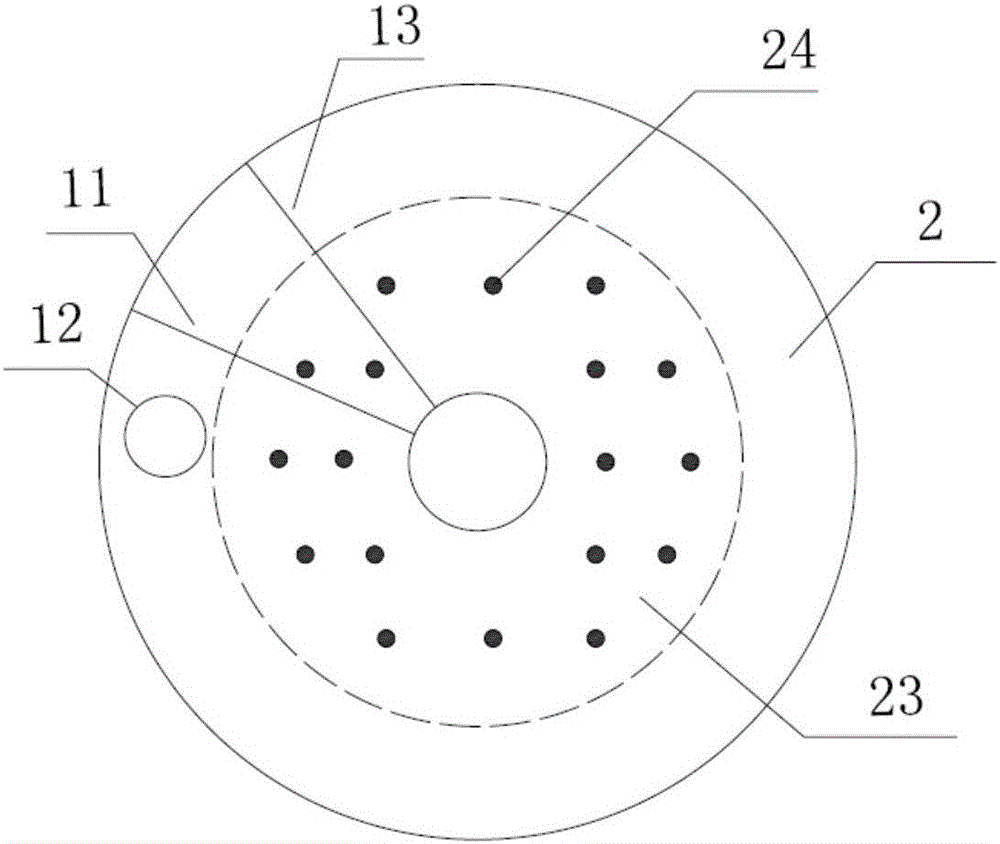

[0037] A sludge dryer, such as figure 1 , figure 2 As shown, it includes a cylindrical cavity 1, a material bed 2 arranged horizontally in the cavity, and a driving device 3 for driving the material bed to rotate horizontally;

[0038] The material bed 2 is a rotating hollow cylinder structure, and a circular baffle 23 coaxial with the material bed is horizontally arranged between the upper and lower bottom plates 21, 22 of the material bed, and the inner space of the material bed is divided into upper and lower parts. Two layers; the diameter of the circular baffle is smaller than the diameter of the material bed;

[0039] A heat medium pipeline 25 perpendicular to the material bed and communicating with the material bed is also arranged at the center of the material bed;

[0040] The surface of the cavity is provided with a sludge feed port 11, a drying flue gas outlet 12, and a sludge discharge port 13; wherein, the ...

Embodiment 2

[0044] Embodiment 2 A kind of sludge drying machine

[0045] A sludge dryer, similar in structure to Embodiment 1, the only difference is that the diameter of the baffle plate 23 is 75% of the diameter of the material bed 2 .

Embodiment 3

[0046] Embodiment 3 A kind of sludge drying method

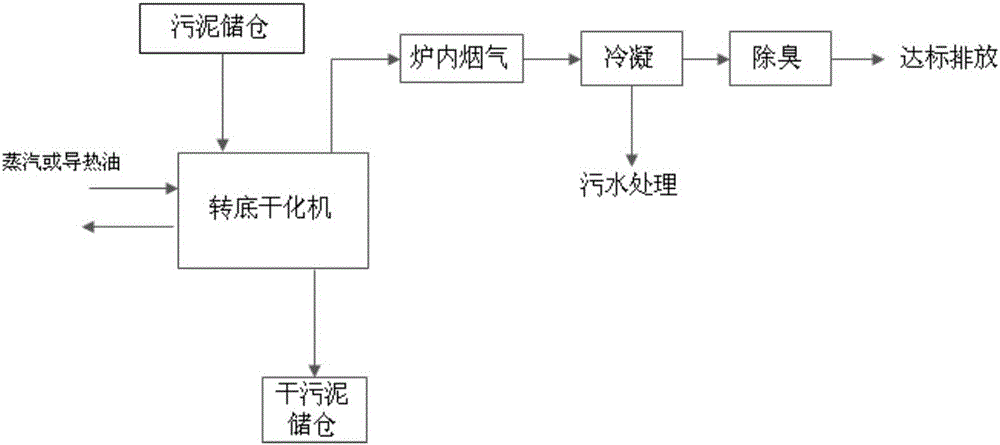

[0047] A method for drying sludge using the sludge dryer described in Example 1, as shown in 3, includes the following steps:

[0048] (1) Send the sludge (moisture content 80%) from the sewage treatment plant into the sludge storage bin, transport it to the sludge dryer through the sludge pump, and feed it from the feeding device located on one side of the dryer;

[0049]The sludge is evenly arranged on the surface of the upper bottom plate of the material bed of the sludge dryer through the material distribution mechanism, and the thickness of the sludge is 10mm; the material bed is in contact with the outer wall of the cavity, and does not need to be sealed, and the atmosphere in the dryer is generated by drying. Flue gas and part of the air containing water vapor;

[0050] (2) The heat medium enters the material bed through the heat medium pipeline, and circulates between the upper and lower layers of the material bed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com