A vibrating screen vibration system

A resonant sieve and vibration excitation technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems affecting the normal operation of the sieve machine, the wear of the resonance spring, the spring falling off, etc., to solve the problem of serious wear, reduce the failure rate, Guaranteed normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention is not limited.

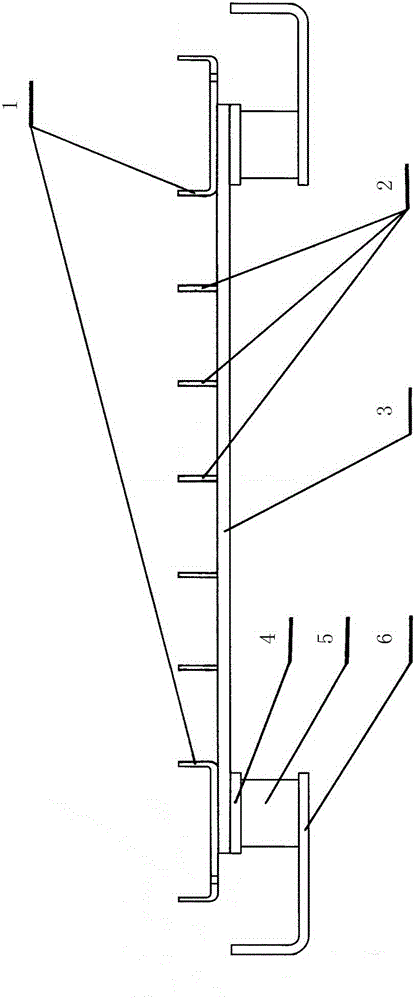

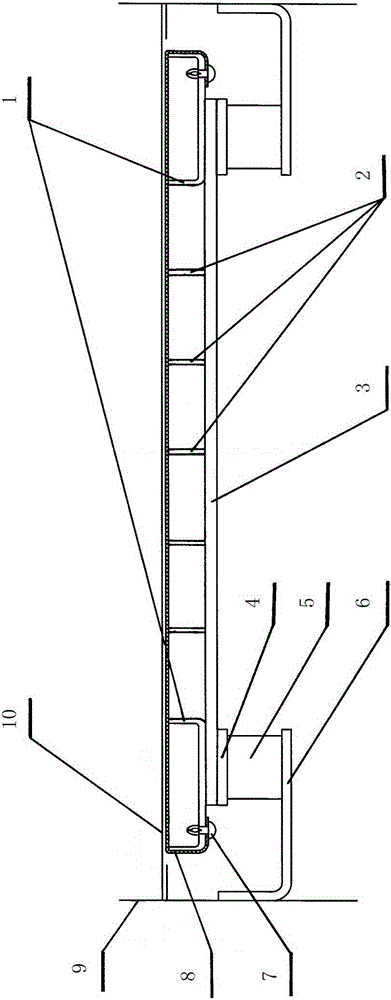

[0012] Referring to the accompanying drawings, the embodiment of the present invention provides an improved compound excitation system for a resonant vibrating screen, that is, a vibrating screen excitation system, which consists of an exciting row, an exciting row connecting frame 3 and an A resonant spring 5 is arranged at each of the four corners below the connecting frame 3. The resonant spring 5 is a columnar spring and is installed upright. 3 connection, the lower end is fixed on the lower spring support seat 6 fixed on the inner side of the screen frame 9; the excitation row includes the fixed support net excitation row 1 installed on the two ends of the excitation row connection frame 3 respectively and the two fixed The support net excitation row 2 between the support net excitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com